Our 3J21 High-Elasticity Alloy Tube is a powerhouse for robust spring and diaphragm systems, delivering the flexibility and durability needed for high-performance applications. Whether you’re crafting springs for aerospace actuators or diaphragms for industrial machinery, this alloy tube is engineered to handle the toughest challenges. Let’s dive into what makes 3J21 special, explore its applications, check out industry trends, and show why our company is your go-to supplier for this high-performance material.

For more details, pls directly contact us.

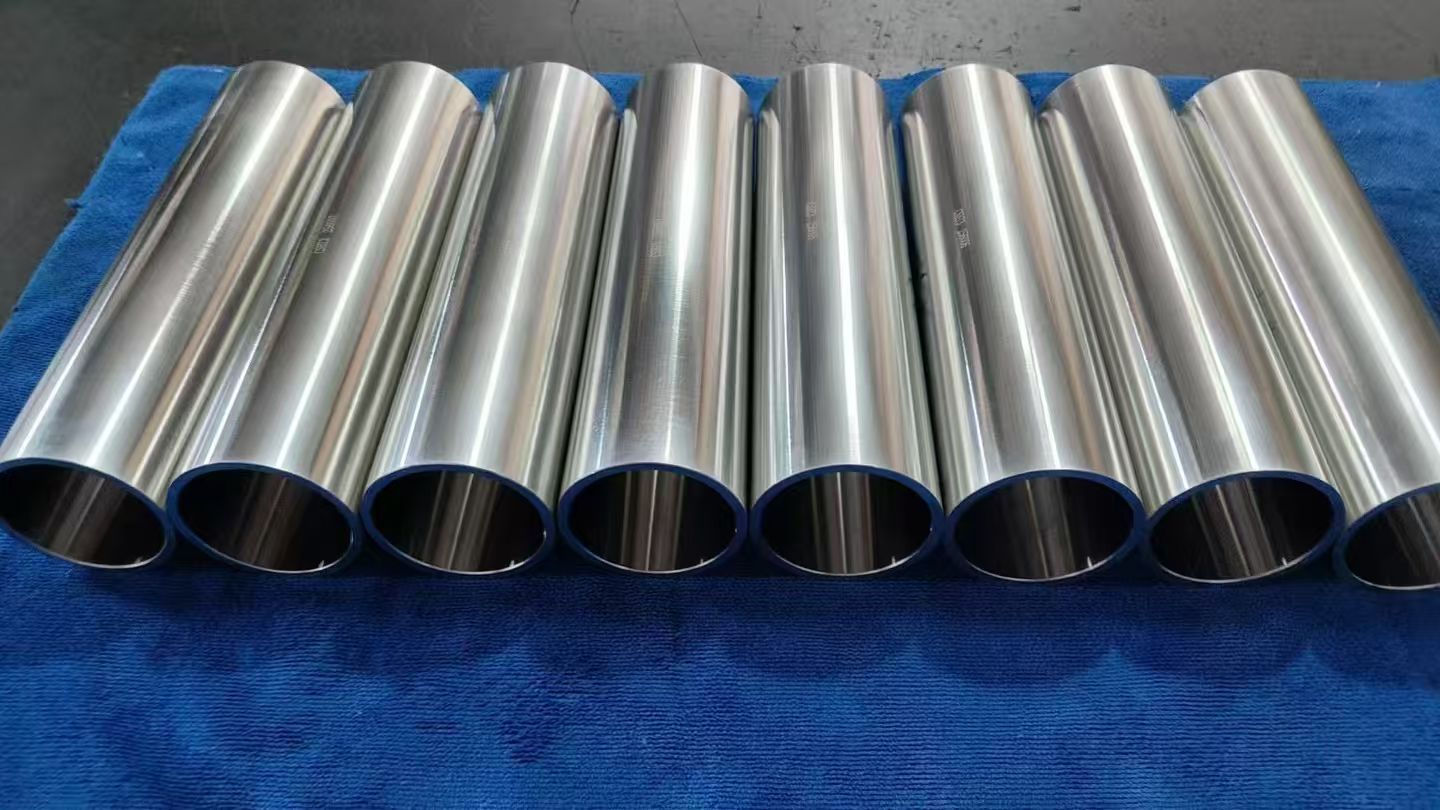

The 3J21 High-Elasticity Alloy Tube, also known as Elgiloy, is a cobalt-chromium-nickel alloy designed for robust spring and diaphragm systems. Its composition—cobalt, chromium, nickel, and molybdenum—provides superelasticity, high strength, and excellent corrosion resistance, performing reliably from -60°C to +200°C. Processed through cold-drawing and heat treatment, this tube offers a high strength-to-weight ratio and exceptional fatigue resistance. With a low thermal expansion coefficient (10–12 × 10⁻⁶/°C), density of ~8.3 g/cm³, and electrical resistivity of ~1.0 μΩ·m, it’s ideal for demanding elastic applications.

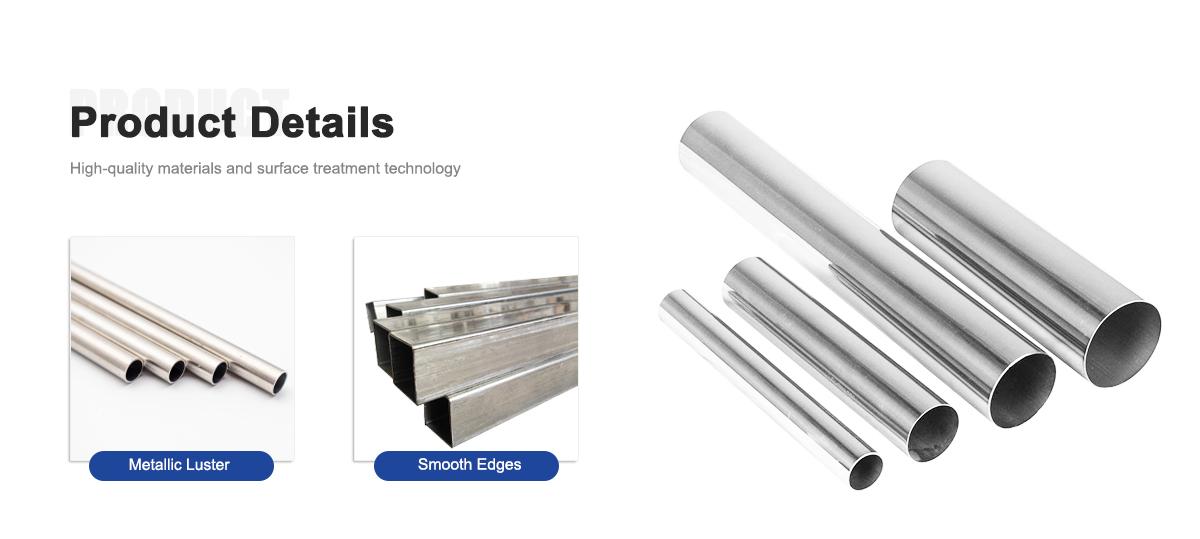

We provide 3J21 alloy tubes in various sizes and wall thicknesses, with customizable compositions to meet your specific requirements, ensuring they’re ready for your spring and diaphragm projects.

| Grades | Density (g/cm³) | Electrical Resistivity (10⁻⁶ Ω·cm) | Thermal Conductivity (W/m·K) | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Limit (MPa) | Fatigue Life (cycles) | Working Temperature Range (°C) | Temperature Coefficient |

| 8.1 | 80 | 11 | 144 | 800 | 1000 | 10 | 800 | >10⁷ | -60 to 200 | Extremely low temperature coefficient of elasticity | |

| 8.3 | 120 | 40 | 125 | 300 | 600 | 20 | 300 | >10⁷ | -40 to 150 | Elasticity remains constant with minimal temperature sensitivity | |

| 8.2 | 100 | 15 | 180 | 1100 | 1400 | 5 | 1100 | >10⁶ | -200 to 500 | Maintains high strength even at elevated temperatures |

For more details, pls directly contact us.

The market for high-performance alloys like 3J21 is booming, driven by demand in aerospace, medical, and industrial sectors. The global specialty alloy market is projected to grow through 2030, fueled by advancements in manufacturing and the need for materials that can handle high-stress conditions. Springs and diaphragms are critical components in these industries, requiring alloys with exceptional elasticity and durability.

Customization is a key trend—engineers want materials tailored to specific performance or environmental needs. Sustainability is also a focus, with industries seeking durable alloys to reduce maintenance costs and waste. The rise of advanced aerospace systems, medical implants, and industrial automation is increasing demand for reliable elastic components, where 3J21 excels. While production costs can be a challenge, our optimized processes keep costs competitive without sacrificing quality.

Applications of 3J21 Alloy Tube

Our 3J21 alloy tube excels in:

Aerospace: Powers springs in actuators and sensors for extreme environments.

Medical Devices: Supports diaphragms in biocompatible implants like stents.

Industrial Machinery: Ensures reliable performance in high-stress diaphragms.

Automotive: Powers springs in airbag and fuel systems.

Precision Engineering: Supports elastic components in gauges and balances.

Electronics: Resists arc erosion in relays and switches.

Marine Applications: Performs in corrosive saline environments.

Energy: Supports elastic components in renewable energy systems.

These applications highlight why 3J21 is a trusted choice for robust spring and diaphragm systems.

Company Comparison and Our Advantages

We’re committed to delivering 3J21 alloy tubes that outperform in demanding applications. Here’s why we stand out:

Tailored Solutions: We customize tube size, wall thickness, and composition to fit your needs.

Rigorous Quality Control: ISO and ROHS certified, with COA-backed samples.

Advanced Processing: Our cold-drawing and heat-treatment maximize elasticity.

Low MOQ, Great Pricing: Start with small quantities at factory-direct prices.

Fast Delivery: Ample stock and efficient production ensure quick turnaround.

Expert Support: Our alloy specialists guide you through material selection.

Eco-Friendly Focus: Our durable tubes support sustainable designs.

Compared to standard suppliers, our focus on customization, quality, and speed makes us the ideal partner for your spring and diaphragm projects.

Comparison Parameters Table

Parameter | 3J21 Alloy Tube | Generic Co-Based Alloy Tube |

|---|---|---|

Elastic Modulus | Superelastic, stable to +200°C | Moderate, less stable |

Corrosion Resistance | Excellent (acids, saline) | Good, less resistant to acids |

Thermal Expansion Coefficient | Low (10–12 × 10⁻⁶/°C) | Higher, less consistent |

Tensile Strength | Very high (post-treatment) | Moderate, varies by grade |

Processing | Cold-drawn + heat-treated | Basic processing, less refined |

Fatigue Resistance | High | Moderate |

Applications | Spring and diaphragm systems | General tubing, limited strength |

Customization Options | Extensive (size, composition) | Limited |

Our 3J21 High-Elasticity Alloy Tube is built for robust spring and diaphragm systems that demand reliability. Its superelasticity, corrosion resistance, and customizability make it a top choice for industries where performance is critical. With our commitment to quality and support, you’re getting a product that’s ready to power your success. Let’s make your next project a win with 3J21!

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is 3J21 High-Elasticity Alloy Tube used for?

Ideal for robust spring and diaphragm systems in aerospace, medical, and industrial applications.What are the key properties of 3J21 Alloy Tube?

Superelasticity, high strength, excellent corrosion resistance, and stability up to +200°C.Which industries benefit from 3J21 Alloy Tube?

Aerospace, medical devices, industrial machinery, and automotive.How does 3J21 perform in high-stress environments?

It resists corrosion and maintains elasticity in demanding conditions.Can 3J21 Alloy Tube be customized?

Yes, we offer custom sizes, wall thicknesses, and compositions to meet your project needs.Why is 3J21 ideal for spring and diaphragm systems?

Its superelasticity and high fatigue resistance ensure reliable performance in dynamic systems.How is 3J21 Alloy Tube processed?

Cold-drawn and heat-treated for maximum strength and elasticity.What benefits does 3J21 offer for elastic systems?

High strength-to-weight ratio and low modulus drift ensure consistent performance.