We specialize in delivering top-tier materials that power the future of healthcare, and our 316L stainless steel round rod for long-term medical implants stands out as a cornerstone of that mission. This versatile product isn't just another alloy—it's engineered to meet the rigorous demands of the human body, ensuring reliability where it matters most. With its low-carbon composition, our 316L stainless steel round rod offers exceptional corrosion resistance, making it ideal for implants that need to last years or even decades without failing. We've honed our production processes to guarantee purity and precision, so every rod we supply contributes to better patient outcomes in orthopedic and cardiovascular procedures.

For more details, pls directly contact us.

Diving into what makes our 316L stainless steel round rod so effective starts with its core properties. Composed mainly of iron, chromium, nickel, and molybdenum, this alloy achieves a balance of strength and flexibility that's hard to beat. The "L" designation means ultra-low carbon content—under 0.03%—which minimizes the risk of carbide precipitation during welding or heat treatment, enhancing its durability in sterile environments. Our rods boast a tensile strength ranging from 485 to 620 MPa, allowing them to withstand the stresses of daily movement in implants like hip stems or spinal fixation devices. Plus, with an elastic modulus of about 193 GPa, it mimics bone's natural stiffness better than some alternatives, reducing stress shielding that can lead to bone loss over time.

In the medical field, biocompatibility is non-negotiable, and our 316L stainless steel round rod excels here. It forms a stable passive oxide layer on its surface, shielding it from aggressive body fluids that could cause pitting or crevice corrosion. This layer regenerates quickly if scratched, ensuring long-term stability. We've seen it perform flawlessly in clinical settings, with minimal ion release that could trigger inflammation. For long-term medical implants, this means fewer revisions and happier patients. Our commitment to electropolishing and passivation treatments further boosts this biocompatibility, creating a smoother surface that discourages bacterial adhesion and promotes tissue integration.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us.

Shifting gears to industry analysis, the medical implants sector is booming, driven by an aging population and advances in minimally invasive surgeries. Global market projections show the orthopedic implants market hitting over $60 billion by 2030, with stainless steel holding a significant share due to its affordability and proven track record. Trends like personalized medicine are reshaping how we approach materials—think 3D-printed implants tailored to individual anatomies. Our 316L stainless steel round rod fits perfectly into this, as it's easily machinable for custom designs. Sustainability is another hot topic; healthcare providers are pushing for recyclable materials to cut down on medical waste. Our rods are fully recyclable, aligning with eco-friendly initiatives without compromising performance.

On the flip side, challenges persist. Corrosion remains a top concern, with studies showing that up to 90% of stainless steel implant failures stem from localized attacks in the body's saline-like environment. That's why we're investing in research for enhanced coatings, like hydroxyapatite or nanostructured surfaces, to improve osseointegration—the process where bone fuses with the implant. Industry trends also highlight a shift toward nickel-free alloys to address allergies affecting about 10-15% of patients. While our 316L contains nickel, we've optimized it to minimize release, and we're exploring hybrid solutions. Regulatory bodies like the FDA are tightening standards, emphasizing fatigue testing and long-term biocompatibility data, which our products exceed through rigorous in-house validation.

Applications of our 316L stainless steel round rod span a wide array of medical scenarios, proving its versatility. In orthopedics, it's the go-to for fracture fixation—bone plates and screws made from our rods provide the stability needed for healing without restricting mobility. For instance, in hip replacements, the rod forms the stem that anchors into the femur, distributing weight evenly and lasting 15-20 years on average. Cardiovascular uses include stents and guidewires, where the rod's corrosion resistance prevents narrowing or blockage over time. Dental implants benefit too; our round rods are shaped into abutments that support crowns, offering a cost-effective alternative to pricier options while maintaining aesthetics and function.

Beyond these, emerging applications in neurology and trauma care are exciting. Spinal fusion rods from our 316L material correct deformities with minimal MRI interference, thanks to its low magnetic permeability. In trauma scenarios, like emergency surgeries for broken limbs, the rod's quick availability and ease of sterilization make it a lifesaver. We're also seeing growth in veterinary medicine, where similar implants aid animal recovery. Overall, the adaptability of our 316L stainless steel round rod ensures it's not just a product but a solution for diverse clinical needs.

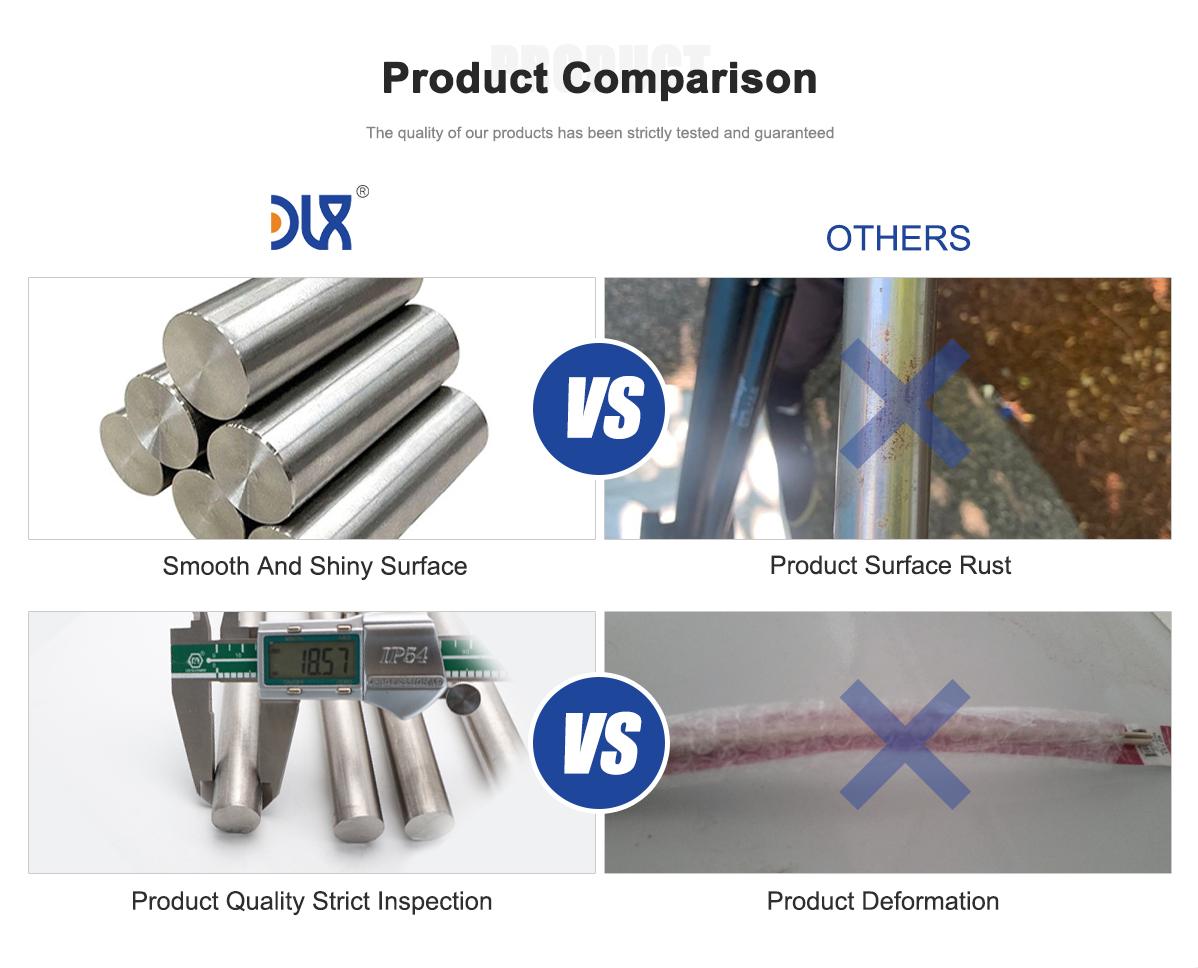

When it comes to comparing our offerings, we stand head and shoulders above the rest in the market. Our company prioritizes innovation, starting with sourcing the purest raw materials to avoid impurities that could compromise implant integrity. Unlike generic suppliers, we implement advanced forging and annealing techniques that enhance grain structure, resulting in superior fatigue resistance—critical for implants enduring millions of cycles in the body. Our quality control is unmatched; every batch undergoes ultrasonic testing and chemical analysis to meet ASTM F138 standards, ensuring zero defects.

We also excel in customization. Need a specific diameter or length for a unique surgical application? Our team delivers precision-cut 316L stainless steel round rods with tolerances as tight as ±0.005 inches, tailored to your specs. This flexibility reduces waste and speeds up production for device manufacturers. On the service side, our rapid turnaround times—often under two weeks for orders—keep your supply chain humming, while competitors lag. Plus, we offer value-added services like surface texturing for better bone adhesion, which studies show can cut integration time by 20-30%.

Cost-wise, our 316L stainless steel round rod provides unbeatable value without skimping on quality. By optimizing our manufacturing in state-of-the-art facilities, we pass savings to you, making high-performance implants accessible for hospitals worldwide. Our rods have a proven lower failure rate in real-world use, translating to fewer costly revisions and better ROI for medical practices. We're not just selling metal; we're partnering for success, with dedicated support from material scientists who help integrate our products into your designs.

Comparison Parameters Table

| Parameter | 316L Stainless Steel | Titanium (Ti-6Al-4V) | Cobalt-Chrome (Co-Cr) |

|---|---|---|---|

| Density (g/cm³) | 7.9-8.0 | 4.4-4.5 | 8.3-9.2 |

| Elastic Modulus (GPa) | 193 | 110-114 | 210-240 |

| Yield Strength (MPa) | 170-290 | 800-900 | 450-1000 |

| Tensile Strength (MPa) | 485-620 | 900-1000 | 900-1200 |

| Corrosion Resistance | Excellent (passive oxide layer) | Superior in body fluids | Very good, but potential ion release |

| Biocompatibility | High, but possible Ni sensitivity | Excellent, low reactivity | Good, but Co ion concerns |

| Cost | Low | Medium | High |

| Common Applications | Bone plates, screws, stents | Joint replacements, trauma plates | Hip/knee bearings, dental |

| Fatigue Strength | Good for cyclic loads | Excellent | Superior |

| Machinability | High | Medium | Low |

Looking ahead, we're bullish on the future of 316L stainless steel round rod in long-term medical implants. With telemedicine and AI-driven diagnostics accelerating implant innovations, materials like ours will play a pivotal role. We're already prototyping bioresorbable coatings that could make implants even smarter, degrading harmlessly after healing. Industry forecasts predict a surge in demand for affordable, durable options amid rising healthcare costs, and our product is positioned to lead.

In essence, choosing our 316L stainless steel round rod means investing in reliability, innovation, and patient care. It's the backbone of countless successful procedures, from routine orthopedic fixes to life-changing reconstructions. We continue to push boundaries, ensuring our materials evolve with the industry. Whether you're developing the next generation of hip implants or spinal hardware, our rods deliver the performance you need. As the medical world advances, we're right there, forging the path forward with quality that endures.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of 316L stainless steel?

316L stainless steel is an austenitic alloy primarily composed of iron (about 60-70%), chromium (16-18%), nickel (10-14%), molybdenum (2-3%), and small amounts of manganese, silicon, phosphorus, sulfur, and carbon (less than 0.03% for the low-carbon "L" grade).

What are the key mechanical properties of 316L stainless steel for medical implants?

It offers a tensile strength of 485-620 MPa, yield strength of 170-290 MPa, elongation of 40-50%, hardness of 95 HRB, and an elastic modulus of around 193 GPa, making it durable for load-bearing applications.

How is 316L stainless steel used in long-term medical implants?

It's commonly used for orthopedic devices like bone plates, screws, pins, hip stems, and spinal rods, as well as cardiovascular stents and dental implants due to its strength and biocompatibility.

What makes 316L stainless steel corrosion-resistant in the human body?

The high chromium and molybdenum content forms a passive oxide layer that protects against pitting, crevice corrosion, and degradation from body fluids like saline or acidic environments.

What are current industry trends for 316L stainless steel in medical implants?

Trends include surface modifications like anodization or nanostructuring for better osseointegration, integration with 3D printing for patient-specific designs, and development of nickel-free variants to reduce allergy risks.

Is 316L stainless steel biocompatible for long-term use?

Yes, it's highly biocompatible, with low toxicity and minimal inflammatory response, though rare nickel sensitivity can occur, making it suitable for permanent implants.

What advantages does 316L stainless steel have over titanium or cobalt-chrome in implants?

It's more cost-effective, easier to machine, and has higher fatigue strength in some scenarios, while offering comparable corrosion resistance at a lower price point.

How does 316L stainless steel support sustainability in the medical industry?

Its recyclability, long lifespan reducing replacement needs, and efficient manufacturing processes align with green trends, minimizing waste in healthcare supply chains