Our flexible Aluminum Foam sheets are a game-changer for sports equipment protection, delivering lightweight, impact-resistant solutions for athletes and gear. Designed for sports equipment manufacturing, they’re transforming how protection is integrated into sports. Let’s explore what makes our aluminum foam sheets special, their applications, industry trends, and why we’re leading the way in protective solutions.

For more details, pls directly contact us.

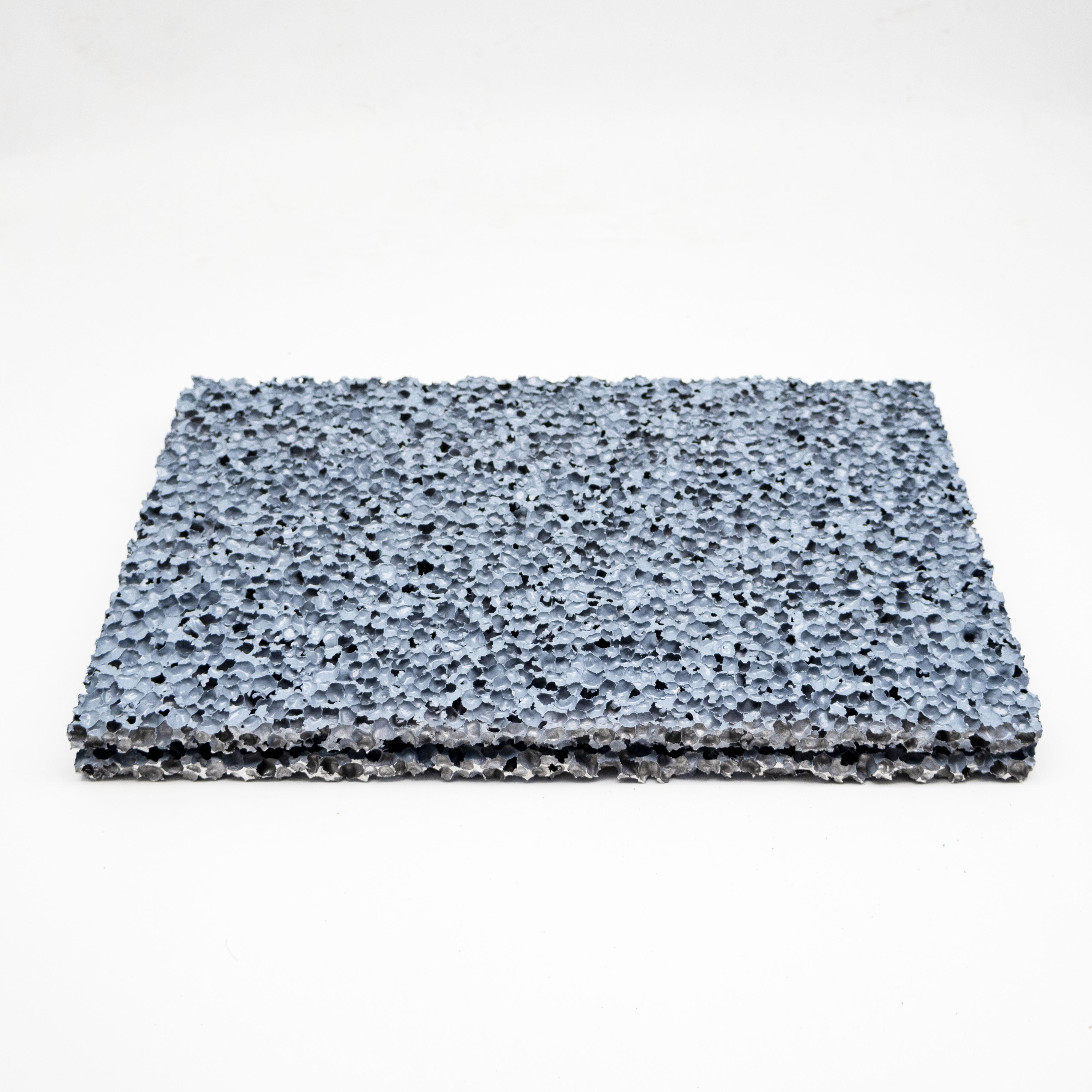

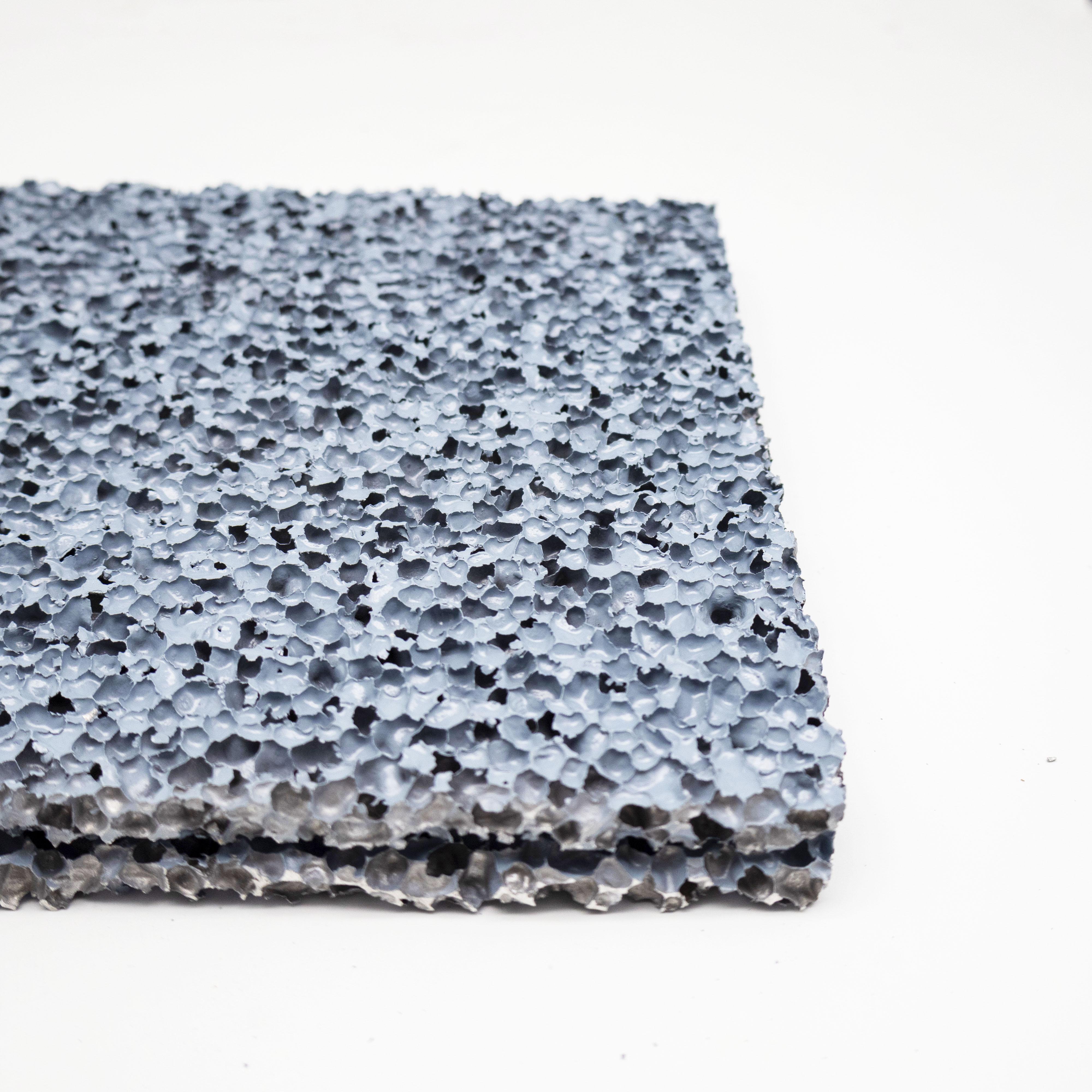

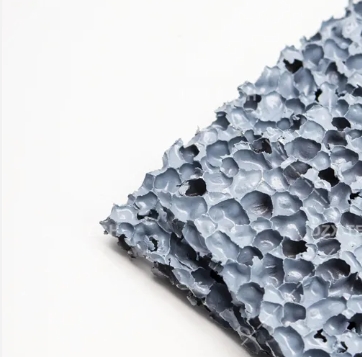

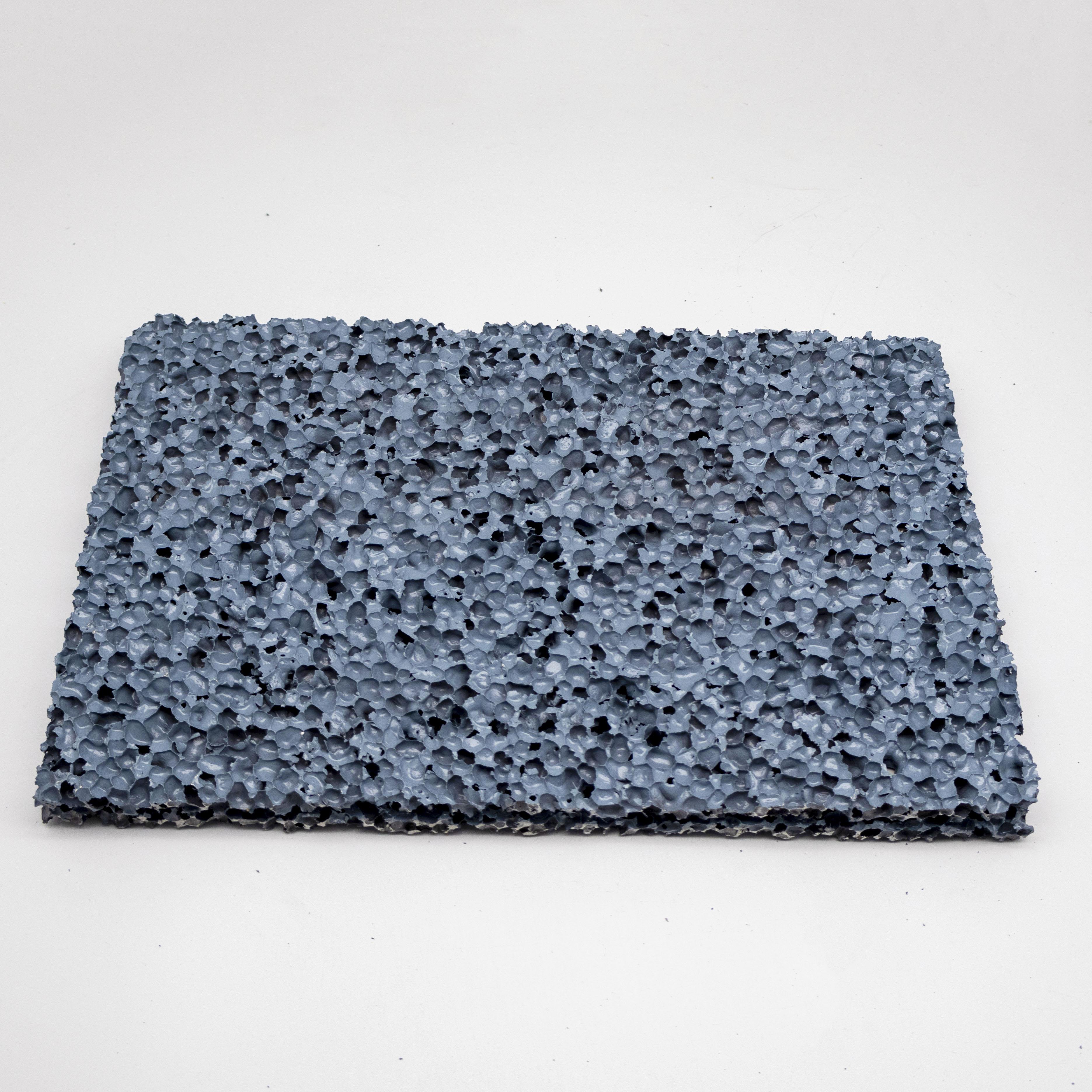

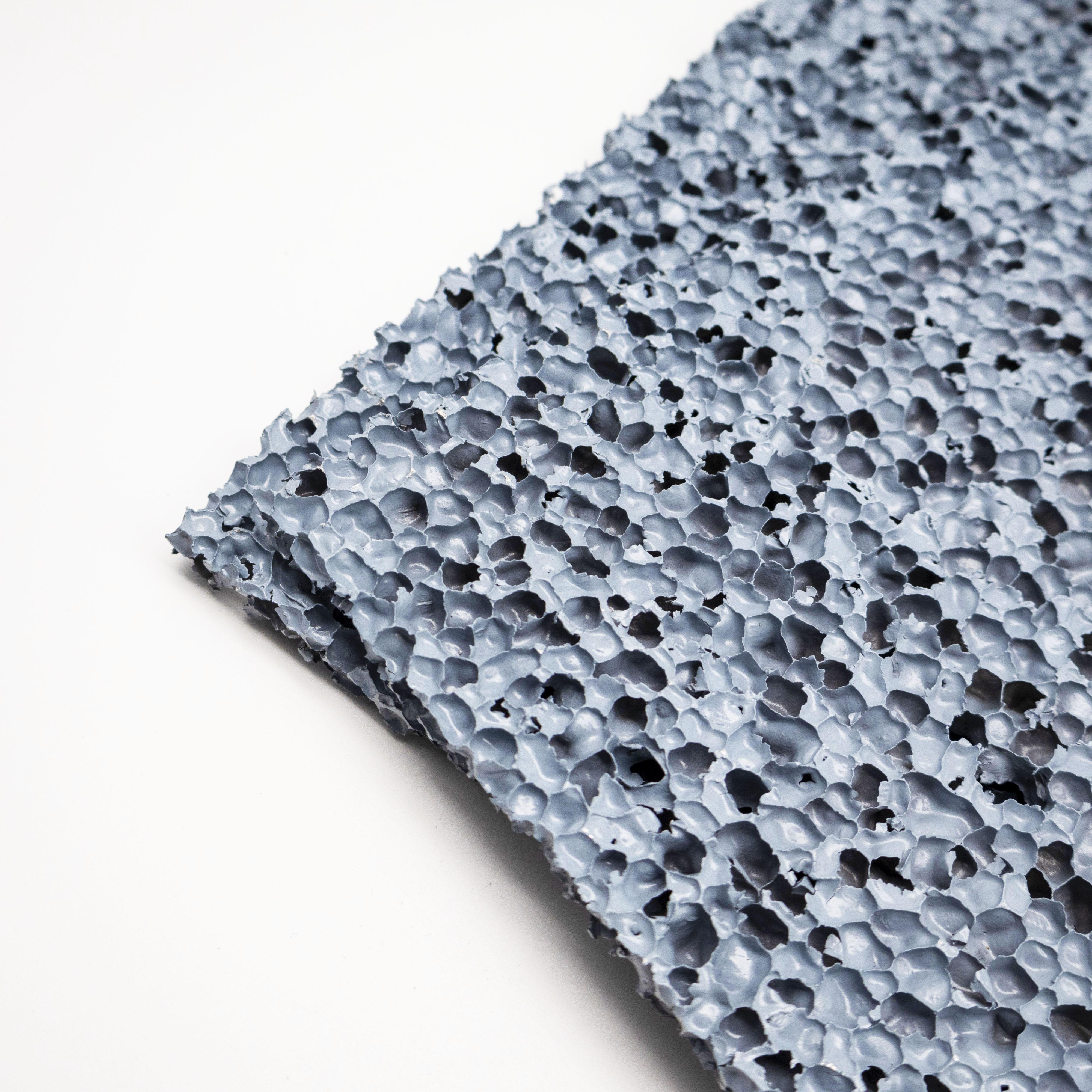

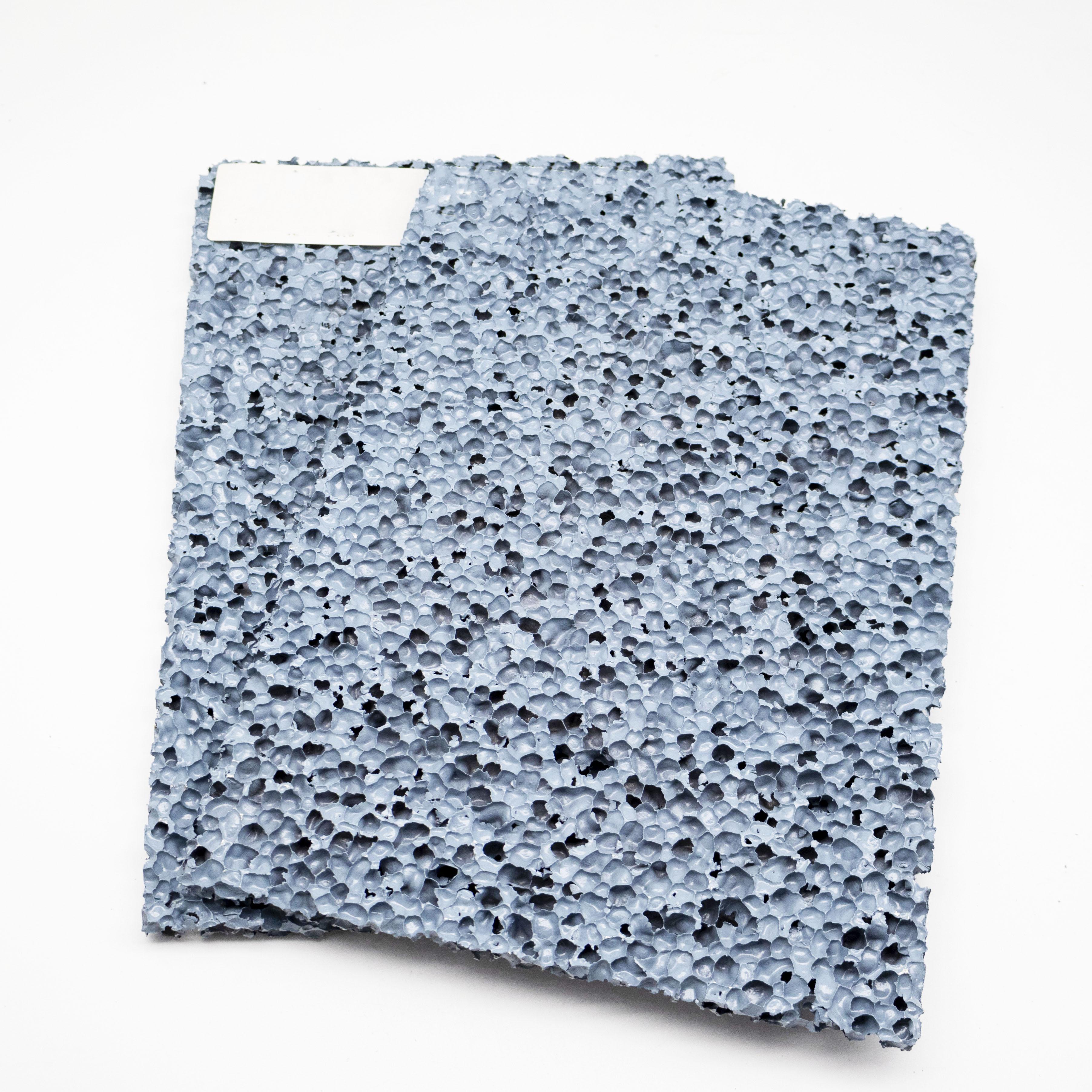

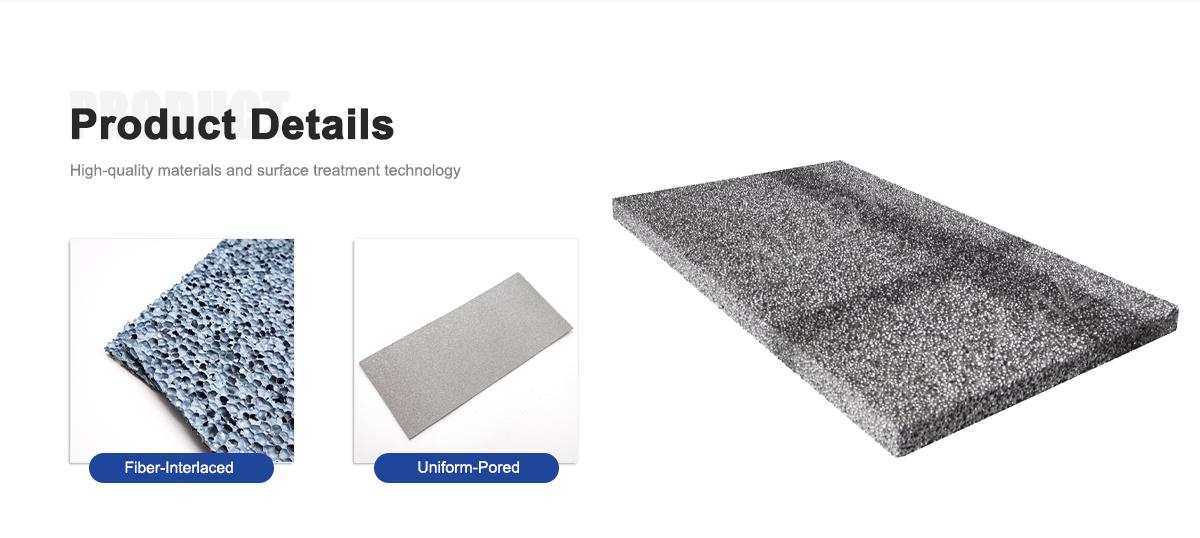

Our aluminum foam sheets are high-purity, porous materials with a three-dimensional, open-cell structure, boasting up to 95% porosity. Weighing just 0.3-0.9 g/cm³, they’re ultra-lightweight yet robust, ideal for sports equipment protection. Their flexible design allows them to conform to complex shapes, while their porous structure absorbs impact energy. The foam’s high corrosion resistance ensures durability in sweaty or outdoor conditions. We craft them using advanced casting and foaming techniques, allowing customization of thickness and flexibility to meet specific protective needs. Whether for helmets or padding, our foam sheets deliver unmatched performance.

|

Material |

Nickel foam, Sold in sheet |

|

Dimension |

500*1000, or customized as request |

|

Thickness |

0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

|

The aperture |

80 PPI (5-80 PPI available) |

|

Porosity |

90-98% |

|

Through Hole Rate |

≥98% |

|

Bulk density |

0.25-1.00g/cm3 |

For more details, pls directly contact us.

Sports equipment requires materials that balance protection, weight, and comfort, and our aluminum foam sheets excel at all three. Their porous structure absorbs impact energy, protecting athletes and equipment from injury or damage. The lightweight design enhances mobility, critical for performance in sports. Their flexibility allows seamless integration into curved or complex designs, ensuring comfort and fit. The foam’s corrosion resistance ensures durability in harsh conditions, reducing replacement costs. This combination of impact absorption, lightweight design, and flexibility makes our foam sheets a must-have for modern sports equipment.

Industry Analysis: The Aluminum Foam Market Surge

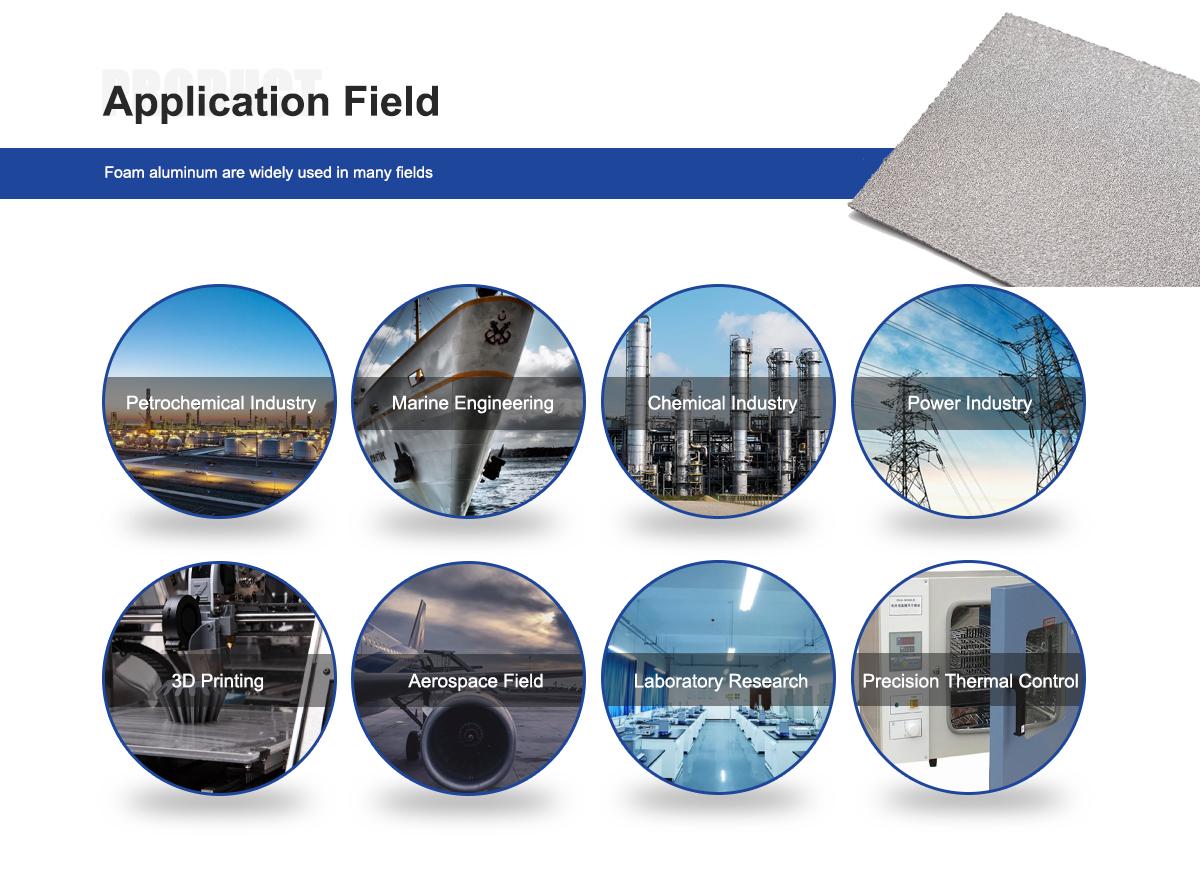

The aluminum foam market is booming, driven by demand for lightweight, high-performance materials. Valued at $180.5 million in 2023, it’s projected to reach $246.7 million by 2030, growing at a CAGR of 5.42%. The sports equipment industry is a key driver, seeking lightweight, durable materials for protective gear. Fitness and outdoor recreation sectors are also adopting aluminum foam for its impact resistance. Sustainability is shaping the market, with regulations pushing for recyclable materials and eco-friendly production. Our aluminum foam aligns perfectly—it’s fully recyclable and produced with energy-efficient methods. Innovations like nanostructured foams and customizable designs are opening new possibilities for tailored protective solutions.

Applications: Where Our Aluminum Foam Shines

Our flexible aluminum foam sheets deliver results across a range of sports equipment protection applications:

-

Helmets: They absorb impact energy, enhancing safety in sports like cycling and football.

-

Padding: The foam provides lightweight, durable protection for knees, elbows, and shoulders.

-

Shin Guards: Flexible and robust, it protects athletes in soccer and hockey.

-

Protective Vests: The foam ensures impact resistance for motorsports and extreme sports.

-

Equipment Casings: It safeguards gear like rackets and boards during transport.

-

Fitness Gear: The foam enhances durability in gym equipment padding.

Industry Trends: What’s Driving Aluminum Foam Forward

The aluminum foam market is evolving rapidly, and we’re staying ahead of the curve. Key trends include:

-

Athlete Safety Demand: Growing focus on injury prevention drives demand for advanced protective materials.

-

Sustainability Push: Eco-friendly production and recyclable materials are essential, and our foam meets these standards.

-

Lightweight Design Focus: Sports prioritize mobility, and our foam delivers.

-

Nanostructured Foams: Advances in nanotechnology enhance impact absorption efficiency.

-

Customization Boom: Advanced manufacturing allows tailored foam structures for specific gear designs.

-

Sports Industry Growth: Expanding fitness and outdoor markets fuel demand for protective materials.

Why Choose Our Aluminum Foam Sheets?

We’re not just making aluminum foam—we’re crafting solutions for safer, more agile sports equipment. Here’s why our flexible aluminum foam sheets stand out:

-

High Impact Absorption: Their porous structure protects athletes and equipment from injury.

-

Lightweight Design: At 0.3-0.9 g/cm³, they enhance mobility without sacrificing strength.

-

Flexibility: They conform to complex shapes for optimal comfort and fit.

-

Corrosion Resistance: They thrive in sweaty or outdoor conditions, ensuring durability.

-

Eco-Friendly Edge: Fully recyclable and produced sustainably, they align with green initiatives.

-

Expert Support: Our team collaborates from design to integration, ensuring optimal performance.

Comparison Parameters Table

|

Parameter |

Aluminum Foam Sheets |

Foam Padding |

Rubber Padding |

Plastic Shells |

|---|---|---|---|---|

|

Impact Absorption |

High (excellent energy dissipation) |

Moderate (less durable) |

Moderate (limited capacity) |

Moderate (less effective) |

|

Weight |

Lightweight (0.3-0.9 g/cm³) |

Lightweight (but less durable) |

Moderate (heavier than foam) |

Moderate (heavier than foam) |

|

Flexibility |

High (conforms to complex shapes) |

High (but degrades) |

Moderate (less adaptable) |

Low (rigid structure) |

|

Durability |

High (resists wear and moisture) |

Low (degrades over time) |

Moderate (degrades in moisture) |

Moderate (prone to cracking) |

|

Fire Resistance |

High (non-combustible) |

Low (flammable) |

Low (flammable) |

Low (flammable) |

|

Recyclability |

Fully recyclable |

Limited (complex recycling) |

Limited (complex recycling) |

Limited (complex recycling) |

|

Cost-Effectiveness |

Moderate (long lifespan, high performance) |

Low (frequent replacements) |

Low (frequent replacements) |

Moderate (maintenance costs) |

Our aluminum foam sheets outperform other protective materials. Foam padding is lightweight but flammable and less durable. Rubber padding is heavier and degrades over time. Plastic shells are rigid and offer limited impact absorption. Our aluminum foam offers the perfect balance: high impact absorption, lightweight design, flexibility, and durability, all backed by sustainable production.

We provide end-to-end support, from custom design to integration, ensuring you get the most out of our foam. Our advanced manufacturing techniques deliver consistent quality and tailored solutions that competitors can’t match.

Looking to the Future

The future of flexible aluminum foam sheets for sports equipment protection is bright, and we’re leading the charge. As athlete safety and sustainability become critical, demand for high-performance, eco-friendly materials will soar. We’re investing in R&D to develop nanostructured foams and custom designs for even better protection. Our commitment to sustainability ensures our processes minimize waste and energy use, aligning with global environmental goals.

Our flexible aluminum foam sheets aren’t just a material—they’re a solution for safer, more agile sports equipment. They’re lightweight, protective, and built for the next generation of sports gear. Ready to transform your project? Let’s make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What are flexible aluminum foam sheets?

They’re lightweight, porous aluminum sheets designed for flexible, impact-resistant sports equipment protection. -

How do aluminum foam sheets protect sports equipment?

Their porous structure absorbs impact energy, safeguarding equipment and athletes from damage. -

Which industries use these aluminum foam sheets?

Sports equipment manufacturing, fitness, and outdoor recreation industries rely on them for protective gear. -

Why is flexibility important for sports equipment?

It allows the foam to conform to complex shapes, ensuring comfort and effective protection. -

What are the key applications of these aluminum foam sheets?

They’re used in helmets, padding, shin guards, protective vests, and equipment casings. -

How do aluminum foam sheets compare to other protective materials?

They offer better impact absorption, lighter weight, and higher durability than foam, rubber, or plastic. -

What are the latest trends in aluminum foam for sports protection?

Growing demand for lightweight, durable, and sustainable protective gear is driving growth. -

Are these aluminum foam sheets eco-friendly?

Yes, they’re fully recyclable, support sustainable designs, and are produced with eco-friendly methods.