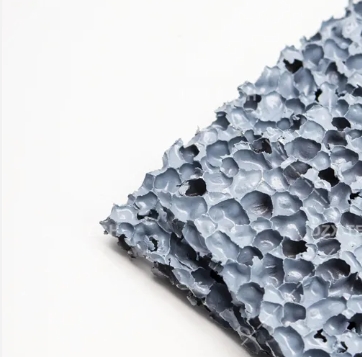

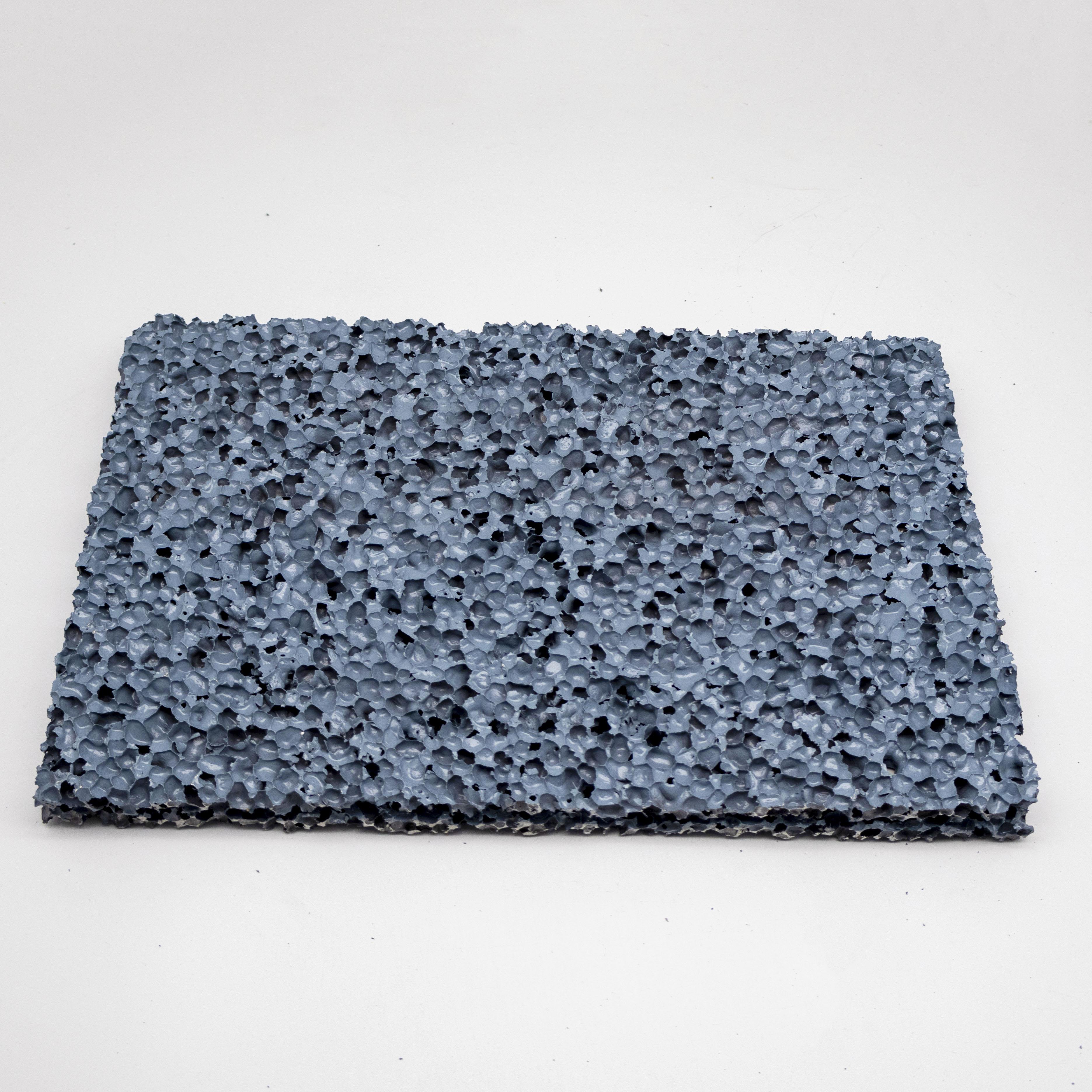

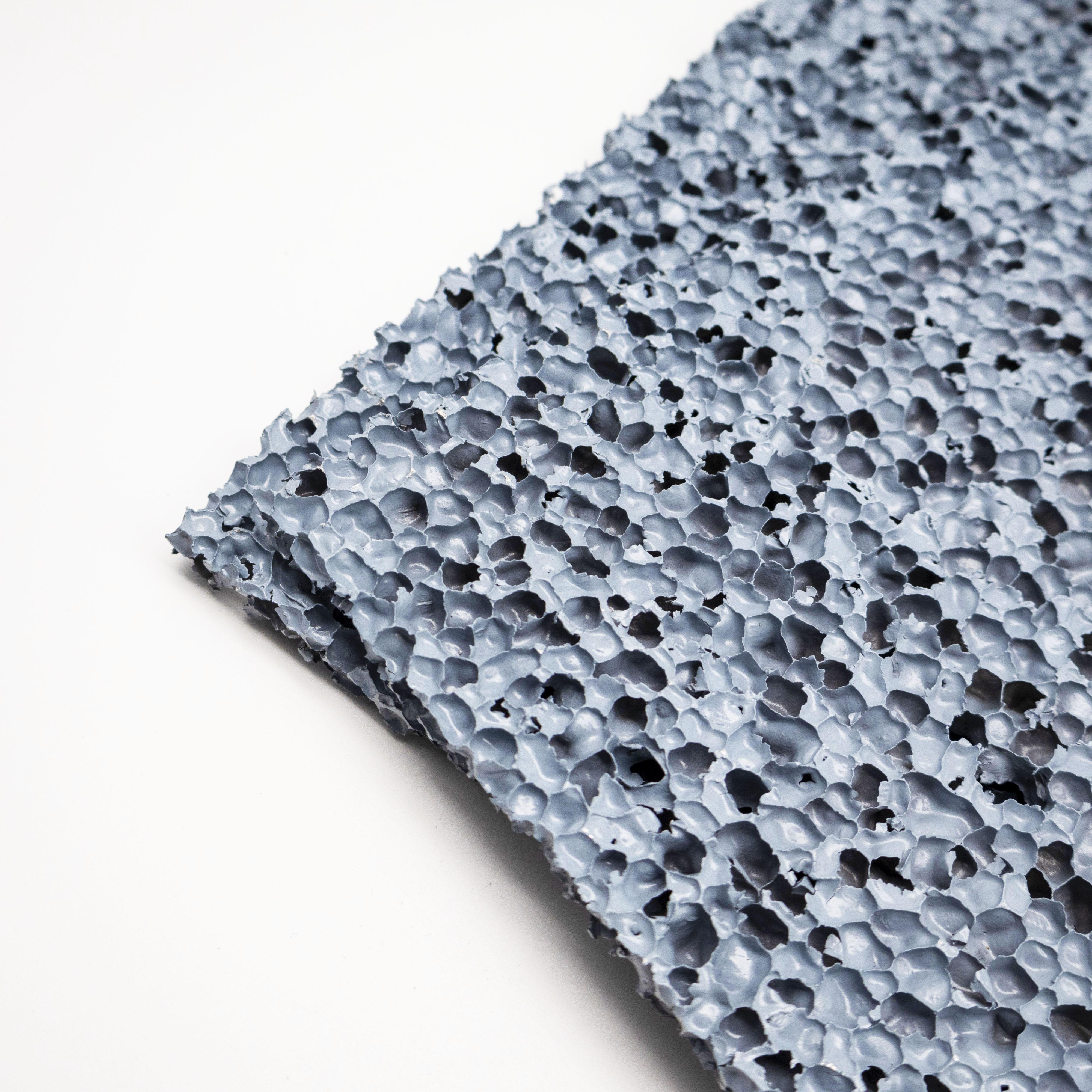

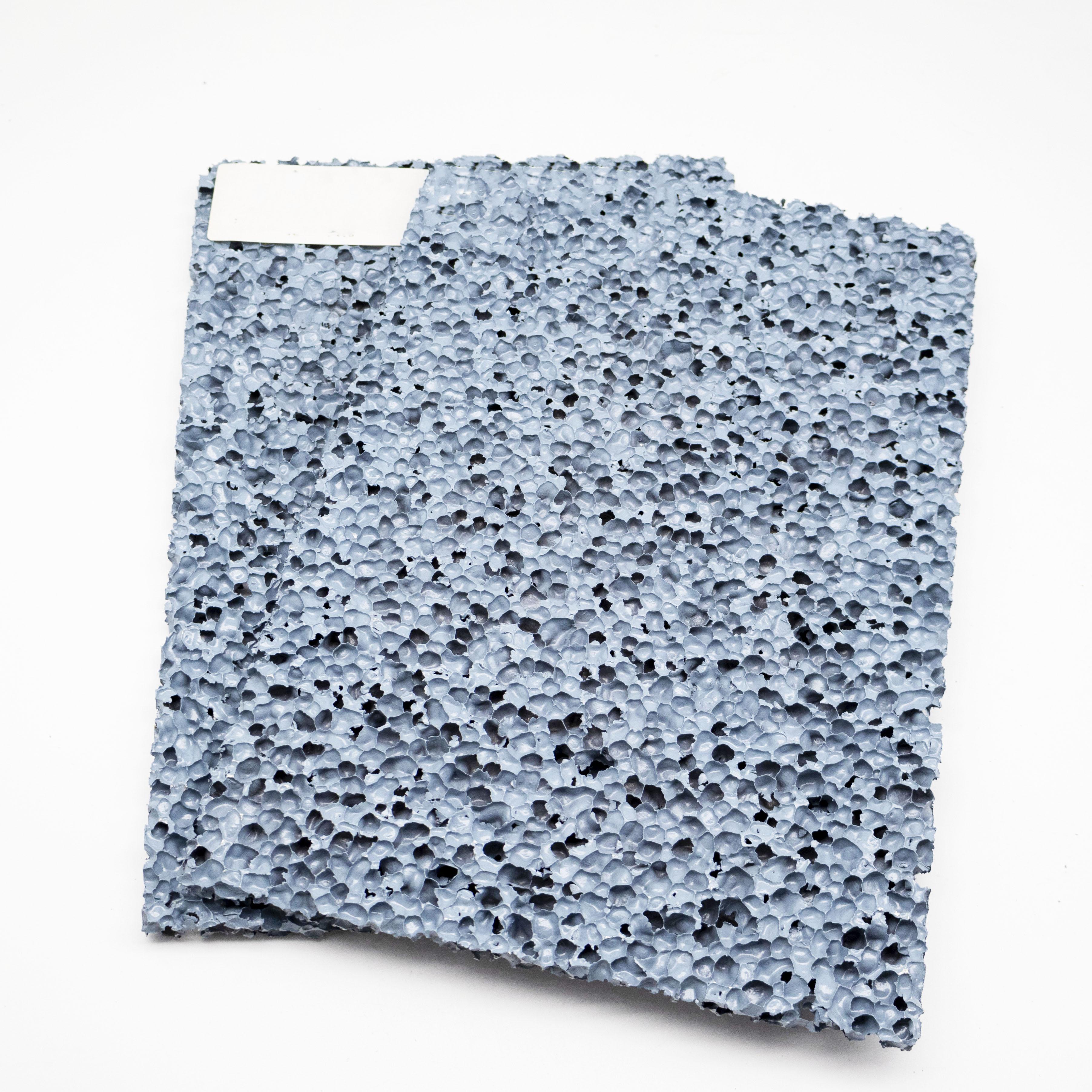

Our open-cell Aluminum Foam with 90% porosity is a game-changer for heat exchangers, delivering lightweight, high-performance solutions for efficient heat transfer. Designed for HVAC, automotive, and aerospace industries, it’s transforming how heat is managed. Let’s explore what makes our aluminum foam special, its applications, industry trends, and why we’re leading the way in heat exchanger solutions.

For more details, pls directly contact us.

|

Material |

Nickel foam, Sold in sheet |

|

Dimension |

500*1000, or customized as request |

|

Thickness |

0.5mm, 1.0mm, 1.5mm, 2.0mm,3.00mm etc |

|

The aperture |

80 PPI (5-80 PPI available) |

|

Porosity |

90-98% |

|

Through Hole Rate |

≥98% |

|

Bulk density |

0.25-1.00g/cm3 |

For more details, pls directly contact us.

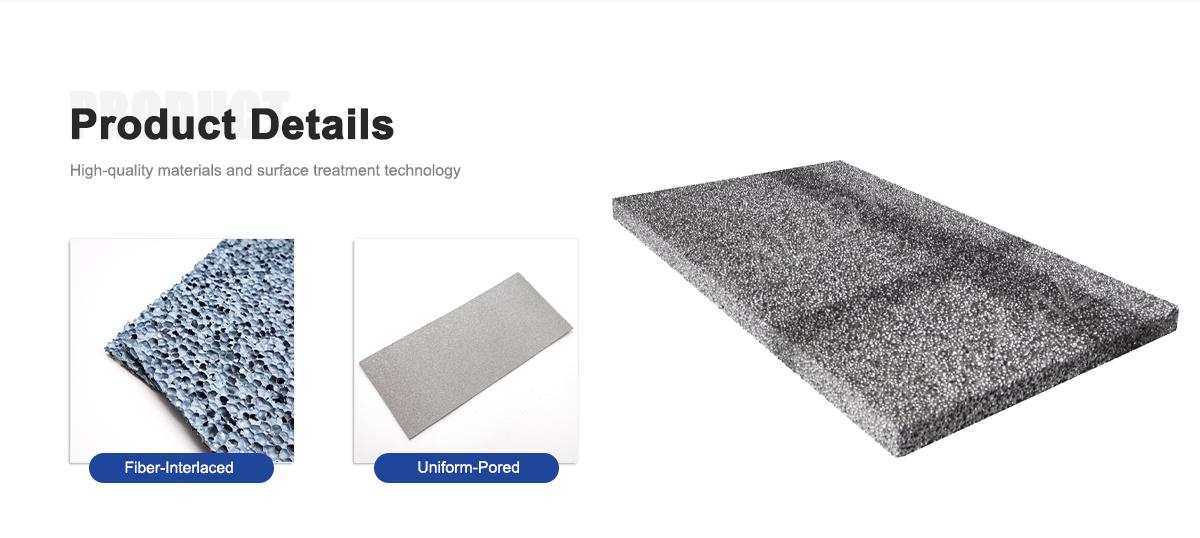

Our aluminum foam is a high-purity, porous material with a three-dimensional, open-cell structure, boasting 90% porosity. Weighing just 0.3-0.9 g/cm³, it’s ultra-lightweight yet robust, ideal for heat exchangers. Its high porosity maximizes surface area and fluid flow, enhancing heat transfer efficiency. The foam’s high thermal conductivity ensures rapid heat dissipation, while its corrosion resistance ensures durability in harsh environments. We craft it using advanced casting and foaming techniques, allowing customization of pore size and density to meet specific cooling needs. Whether for radiators or industrial exchangers, our foam delivers unmatched performance.

Comparison Parameters Table

|

Parameter |

Aluminum Foam (90% Porosity) |

Copper Fins |

Steel Fins |

Ceramic Exchangers |

|---|---|---|---|---|

|

Thermal Conductivity |

High (excellent heat transfer) |

Very High (but heavy) |

Low (poor heat transfer) |

Low (poor heat transfer) |

|

Porosity |

High (90%, maximizes fluid flow) |

Low (limited surface area) |

Low (limited surface area) |

Low (fixed structure) |

|

Weight |

Lightweight (0.3-0.9 g/cm³) |

Heavy (denser than aluminum) |

Heavy (denser than aluminum) |

Heavy (denser than aluminum) |

|

Corrosion Resistance |

High (resists environmental wear) |

Moderate (prone to oxidation) |

Low (prone to rust) |

High (but brittle) |

|

Durability |

High (resists wear and thermal cycling) |

Moderate (prone to corrosion) |

Moderate (prone to rust) |

Low (prone to cracking) |

|

Recyclability |

Fully recyclable |

Recyclable (energy-intensive) |

Recyclable (energy-intensive) |

Limited (complex recycling) |

|

Cost-Effectiveness |

Moderate (long lifespan, high performance) |

High (expensive material) |

Low (shorter lifespan) |

High (expensive production) |

Heat exchangers require materials that balance thermal efficiency, weight, and durability, and our aluminum foam excels at all three. Its 90% porosity maximizes heat transfer and fluid flow, enabling compact, high-performance designs. The lightweight design reduces system weight, easing installation and improving efficiency. Its corrosion resistance ensures reliability in humid or chemical environments, minimizing maintenance costs. The foam’s high thermal conductivity supports rapid cooling, critical for high-performance systems.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is open-cell aluminum foam with 90% porosity?

It’s a lightweight, highly porous aluminum material with 90% open-cell structure, designed for heat exchangers. -

How does aluminum foam improve heat exchangers?

Its high porosity and thermal conductivity maximize heat transfer and fluid flow efficiency. -

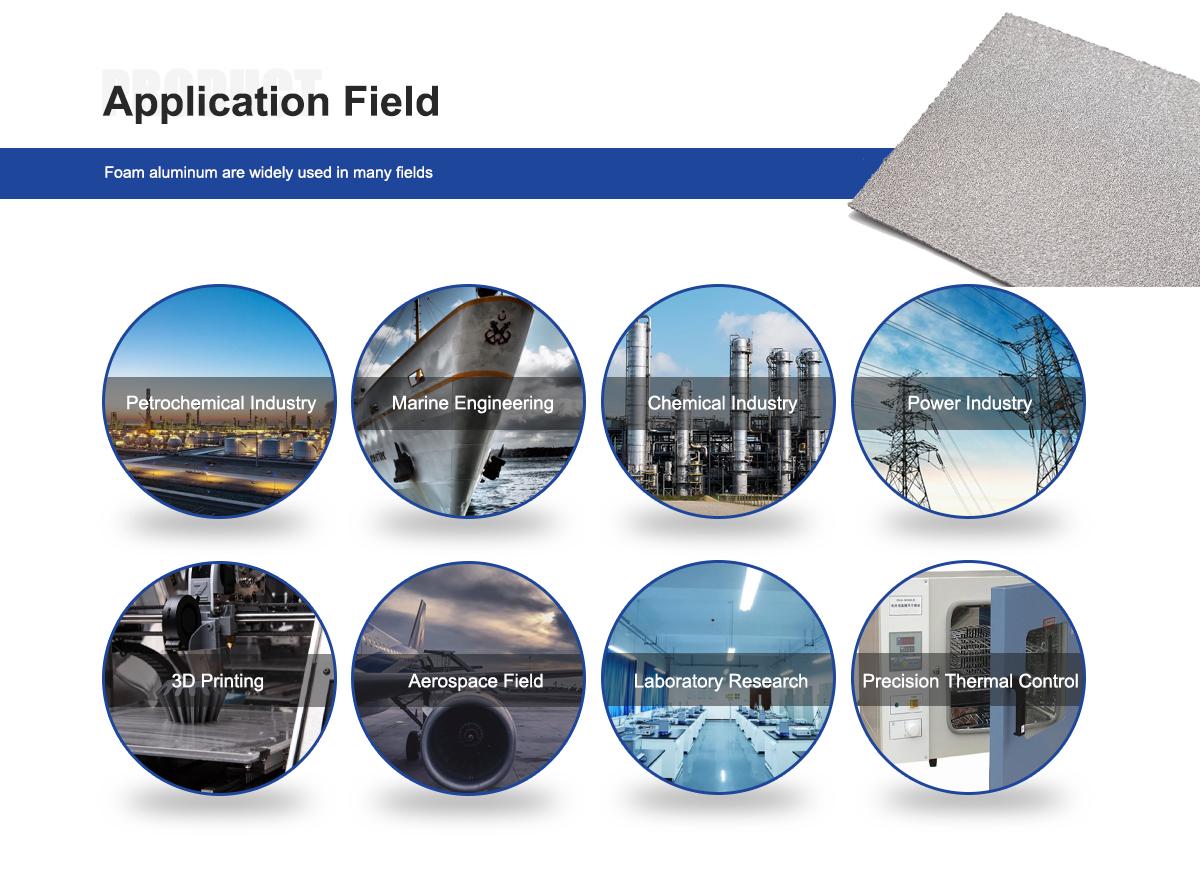

Which industries use this aluminum foam?

HVAC, automotive, aerospace, power generation, and chemical industries rely on it for heat exchange. -

Why is 90% porosity important for heat exchangers?

It enhances surface area and fluid flow, improving heat transfer in compact designs. -

What are the key applications of this aluminum foam?

It’s used in HVAC systems, automotive radiators, aerospace cooling, and industrial heat exchangers. -

How does aluminum foam compare to other heat exchanger materials?

It offers better thermal efficiency, lighter weight, and higher corrosion resistance than copper or steel. -

What are the latest trends in aluminum foam for heat exchangers?

Growing demand for compact, efficient, and sustainable cooling solutions is driving growth. -

Is this aluminum foam eco-friendly?

Yes, it’s fully recyclable, supports energy-efficient cooling, and is produced with sustainable methods.