Our flexible Copper Foam sheets are a game-changer for wearable electronics cooling, delivering high-efficiency heat dissipation in a lightweight, bendable package. Designed for industries like consumer electronics and healthcare, they’re transforming how wearables manage heat. Let’s dive into what makes our copper foam sheets special, explore their applications, unpack industry trends, and show why we’re leading the way in wearable cooling solutions.

For more details, pls directly contact us.

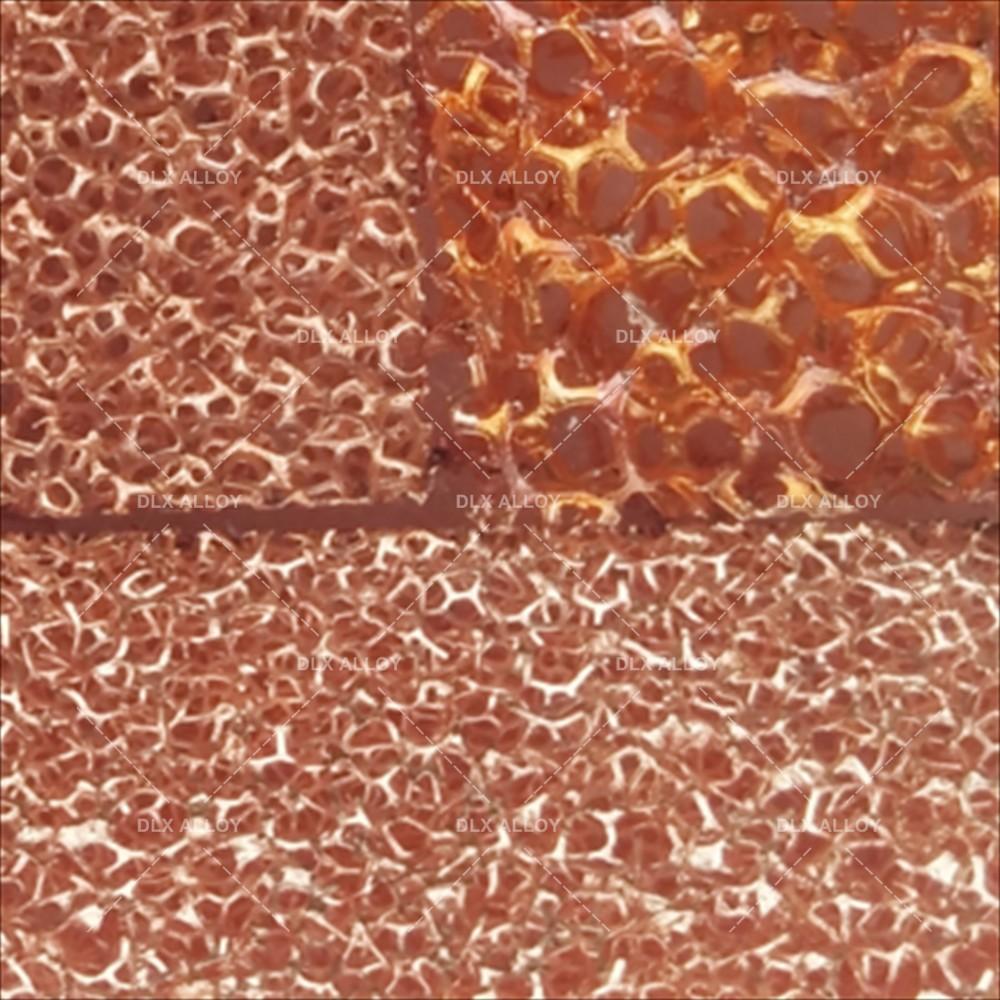

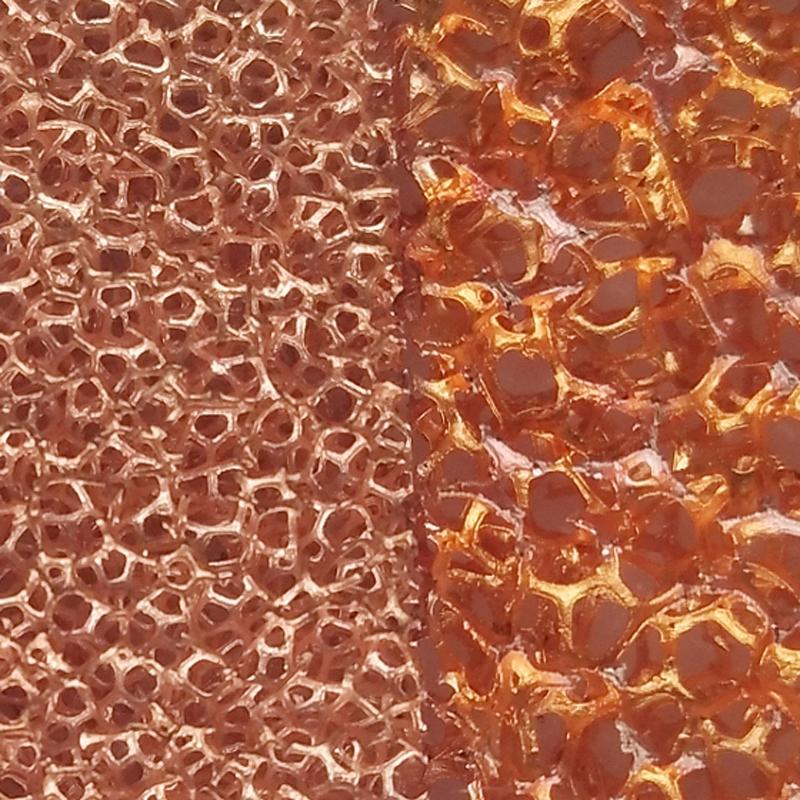

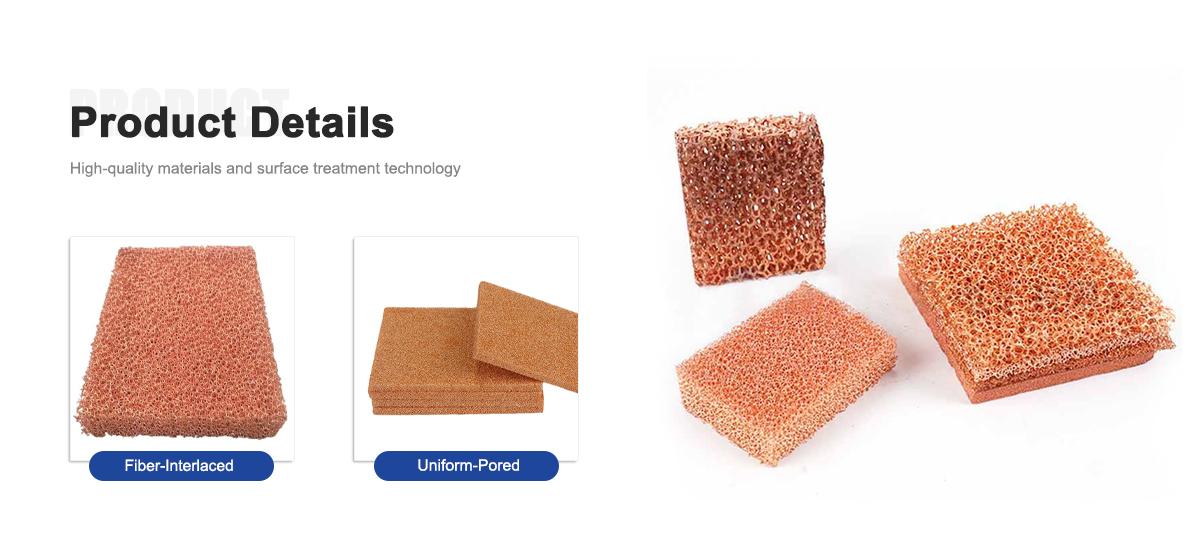

Our copper foam sheets are high-purity, porous materials with a three-dimensional, open-cell structure, boasting up to 95% porosity. Weighing just 0.5-1.5 g/cm³, they’re ultra-lightweight and highly flexible, perfect for conforming to the curved, compact designs of wearable electronics. Their high thermal conductivity ensures rapid heat dissipation, while the porous structure promotes airflow for efficient cooling. The foam’s good corrosion resistance ensures reliability in humid or sweaty environments. We craft them using advanced electrodeposition and 3D printing, allowing us to customize pore size and density to fit your specific cooling needs. Whether you’re cooling a smartwatch or a medical wearable, our foam sheets deliver top-tier performance.

For more details, pls directly contact us.

Wearable electronics are all about staying compact and comfortable, and our copper foam sheets are built to keep them cool without adding bulk. Their high porosity maximizes heat transfer, ensuring devices like fitness trackers or AR headsets don’t overheat during use. The flexible design allows the foam to bend and fit into tight, curved spaces, making it ideal for sleek wearable designs. The lightweight nature keeps devices comfortable for users, while the thermal conductivity prevents performance drops in high-power applications. Its durability ensures long-lasting cooling, even in sweaty or humid conditions. This mix of flexibility, efficiency, and lightweight design makes our foam a must-have for wearable tech.

Industry Analysis: The Copper Foam Market Surge

The copper foam market is booming, driven by the global rise of wearable electronics and IoT devices. Valued at $180.5 million in 2023, it’s projected to hit $246.7 million by 2030, growing at a CAGR of 5.42%. Consumer electronics and healthcare are leading the charge, as smartwatches, fitness trackers, and medical wearables demand compact, efficient cooling solutions. The growth of AR/VR and smart textiles is also fueling demand for flexible, high-performance materials. Industries are prioritizing lightweight, durable cooling to enhance user comfort and device reliability.

Sustainability is a major force in this market. Regulations and consumer demand are pushing industries toward recyclable materials and eco-friendly production. Our copper foam fits perfectly—it’s fully recyclable and made with energy-efficient processes. Innovations like nanostructured foams and 3D printing are opening new possibilities, allowing us to create tailored cooling structures for specific wearable designs. As industries prioritize efficiency, flexibility, and sustainability, our copper foam sheets are poised to lead the wearable cooling market.

Applications: Where Our Copper Foam Sheets Shine

Our flexible copper foam sheets are a versatile solution, delivering results across a range of wearable electronics cooling applications:

Smartwatches: They keep processors cool, ensuring performance and comfort during extended use.

Fitness Trackers: The foam dissipates heat from sensors and batteries, maintaining accuracy and wearability.

Medical Wearables: It supports cooling in devices like glucose monitors, ensuring reliability in critical applications.

AR/VR Headsets: Our foam prevents overheating in high-power headsets, enhancing user experience.

Smart Textiles: It integrates into wearable fabrics for efficient heat management in smart clothing.

IoT Devices: The foam cools compact sensors and modules, supporting reliable performance in connected systems.

Industry Trends: What’s Driving Copper Foam Forward

The copper foam market is moving fast, and we’re staying ahead of the curve. Here are the trends shaping the industry:

Wearable Tech Boom: The rise of smartwatches, fitness trackers, and AR/VR devices is driving demand for compact cooling solutions.

Sustainability Push: Eco-friendly production and recyclable materials are must-haves, and our foam aligns with sustainable manufacturing.

Miniaturization Demand: Industries prioritize smaller, lighter cooling systems, and our flexible foam delivers.

Nanostructured Foams: Advances in nanotechnology are enabling ultra-high-porosity foams, boosting cooling efficiency.

Customization Surge: 3D printing and electroforming let us tailor foam structures for specific wearable designs.

IoT Growth: The expansion of connected devices is fueling demand for efficient, lightweight cooling materials.

Why Choose Our Copper Foam Sheets?

We’re not just making copper foam sheets—we’re crafting solutions that keep wearables cool and comfortable. Here’s why our flexible copper foam sheets stand out:

High Porosity: With up to 95% porosity, our foam maximizes heat dissipation and airflow, outperforming traditional materials.

Unmatched Flexibility: The sheets bend to fit curved designs, ensuring effective cooling in compact wearables.

Superior Thermal Conductivity: It ensures rapid heat transfer, critical for high-performance devices.

Lightweight Design: At 0.5-1.5 g/cm³, our foam keeps wearables comfortable without adding bulk.

Eco-Friendly Edge: Fully recyclable and produced with sustainable methods, our foam aligns with green initiatives.

Expert Support: Our team partners with you from design to deployment, offering expertise to tackle your toughest cooling challenges.

Comparison Parameters Table

Parameter | Copper Foam Sheets | Aluminum Films | Polymer Films | Graphite Sheets |

|---|---|---|---|---|

Thermal Conductivity | High (excellent heat dissipation) | Moderate (lower than copper) | Low (poor heat transfer) | High (but less flexible) |

Flexibility | High (conforms to curved designs) | Low (rigid structure) | High (but less durable) | Low (brittle under bending) |

Porosity | High (up to 95%, customizable) | None (solid structure) | Low (limited surface area) | Low (non-porous) |

Weight | Lightweight (0.5-1.5 g/cm³) | Lightweight (but less porous) | Lightweight (but less durable) | Moderate (heavier than copper) |

Corrosion Resistance | Good (resists moderate environments) | Moderate (prone to oxidation) | Poor (degrades in moisture) | Good (but less durable) |

Mechanical Durability | High (withstands flexing) | Moderate (prone to deformation) | Low (degrades under stress) | Low (brittle under stress) |

Recyclability | Fully recyclable | Recyclable (energy-intensive) | Limited (degrades over time) | Limited (complex recycling process) |

Cost-Effectiveness | Moderate (long lifespan, high performance) | Low (cheaper but less effective) | Low (frequent replacements needed) | High (expensive production) |

Our copper foam sheets outperform other cooling materials for wearables. Aluminum films are lightweight but rigid, limiting their use in curved designs. Polymer films are flexible but lack thermal conductivity and durability. Graphite sheets offer good conductivity but are brittle and less versatile. Our copper foam hits the sweet spot: ultra-high porosity, lightweight design, superior flexibility, and excellent thermal performance, all backed by sustainable production.

We go beyond the product itself. Our end-to-end support—from custom design consultations to integration—ensures you get the most out of our foam. Our advanced manufacturing techniques, like electrodeposition and 3D printing, deliver consistent quality and tailored solutions that competitors can’t match.

Looking to the Future

The future of flexible copper foam sheets for wearable electronics is bright, and we’re excited to lead the way. As wearables and IoT devices continue to grow, the demand for compact, sustainable cooling solutions will skyrocket. We’re investing heavily in R&D to push the boundaries of what our foam can do, from nanostructured designs for ultra-efficient cooling to high-density options for advanced wearables. Our commitment to sustainability means we’re constantly refining our processes to reduce waste and energy use, aligning with global environmental goals.

Our flexible copper foam sheets aren’t just a material—they’re a solution for the cooling challenges of tomorrow’s wearables. They’re lightweight, bendable, and built to keep devices comfortable and efficient. Ready to see how they can transform your project? Let’s talk about making it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What are flexible copper foam sheets?

They’re lightweight, porous copper sheets with high flexibility, designed for cooling wearable electronics.How do copper foam sheets improve wearable cooling?

Their high porosity and thermal conductivity enhance heat dissipation, keeping wearables comfortable and efficient.Which industries use these copper foam sheets?

Consumer electronics, healthcare, fitness tech, IoT, and smart textiles rely on them for thermal management.Why is flexibility important for wearables?

It allows the foam to conform to curved or compact designs, ensuring effective cooling in small, flexible devices.What are the key applications of these sheets?

They’re used in smartwatches, fitness trackers, medical wearables, AR/VR headsets, and smart clothing.How do copper foam sheets compare to other materials?

They offer higher porosity, better thermal conductivity, and greater flexibility than alternatives like aluminum or polymers.What are the latest trends in copper foam for wearables?

Growing demand for compact wearables, nanostructured foam advancements, and sustainable production are driving growth.Are these copper foam sheets eco-friendly?

Yes, they’re fully recyclable, support energy-efficient cooling, and are produced with sustainable methods.