Our low-density Copper Foam is a game-changer for lightweight structural components, delivering high strength in an ultra-light package. Designed for industries like automotive and aerospace, it’s transforming how structures are built for efficiency and performance. Let’s dive into what makes our copper foam special, explore its applications, unpack industry trends, and show why we’re leading the way in lightweight structural solutions.

For more details, pls directly contact us.

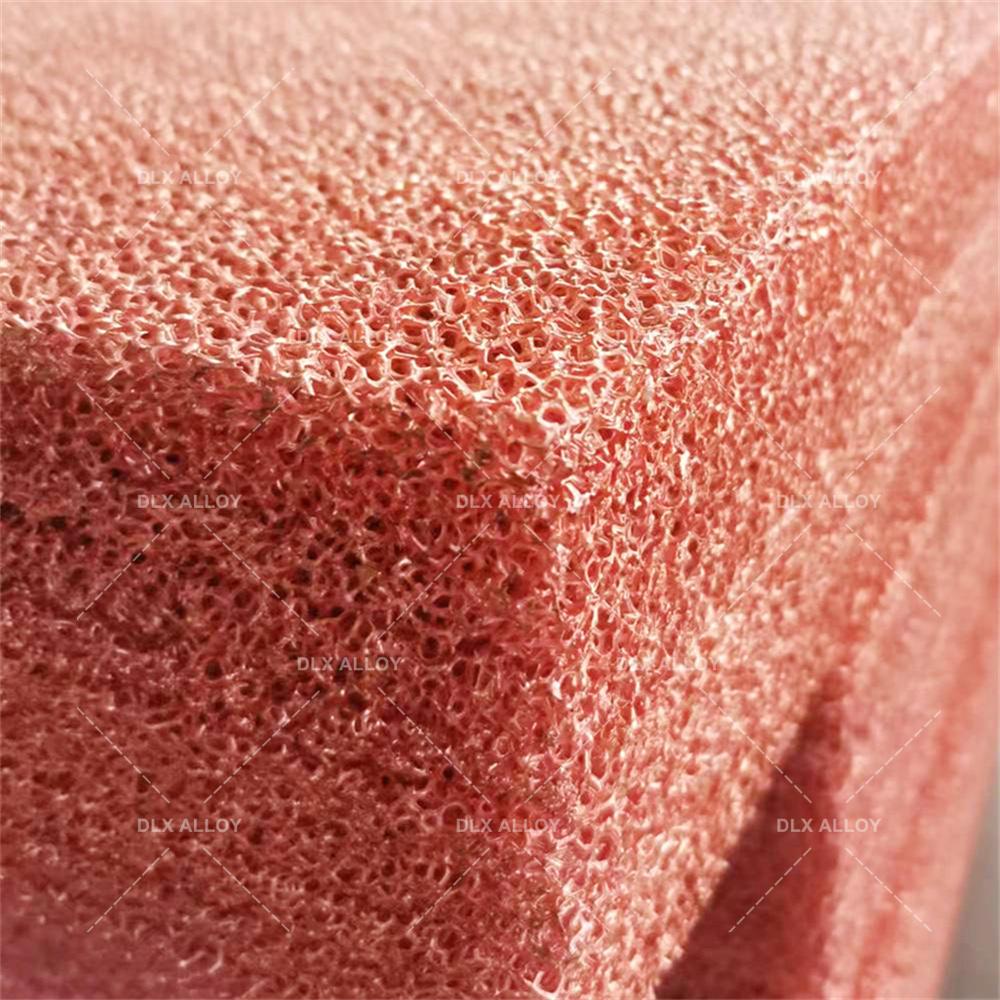

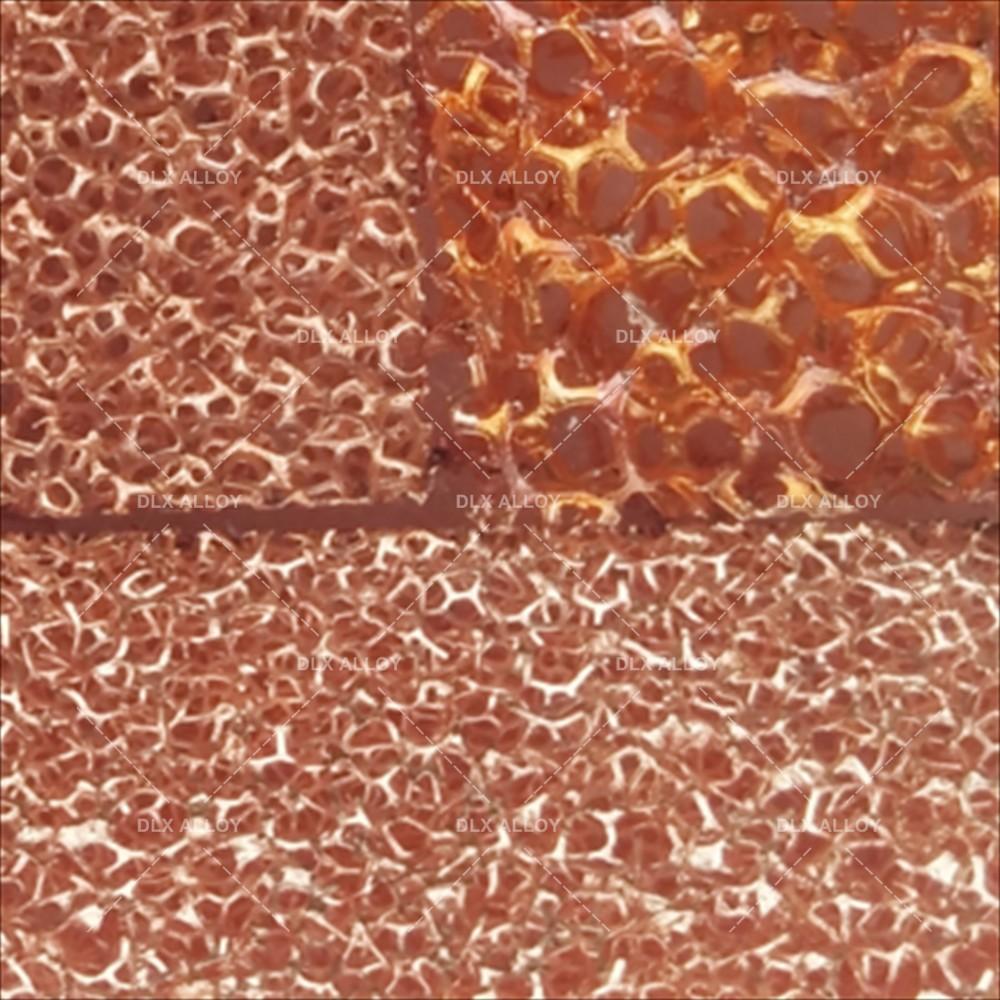

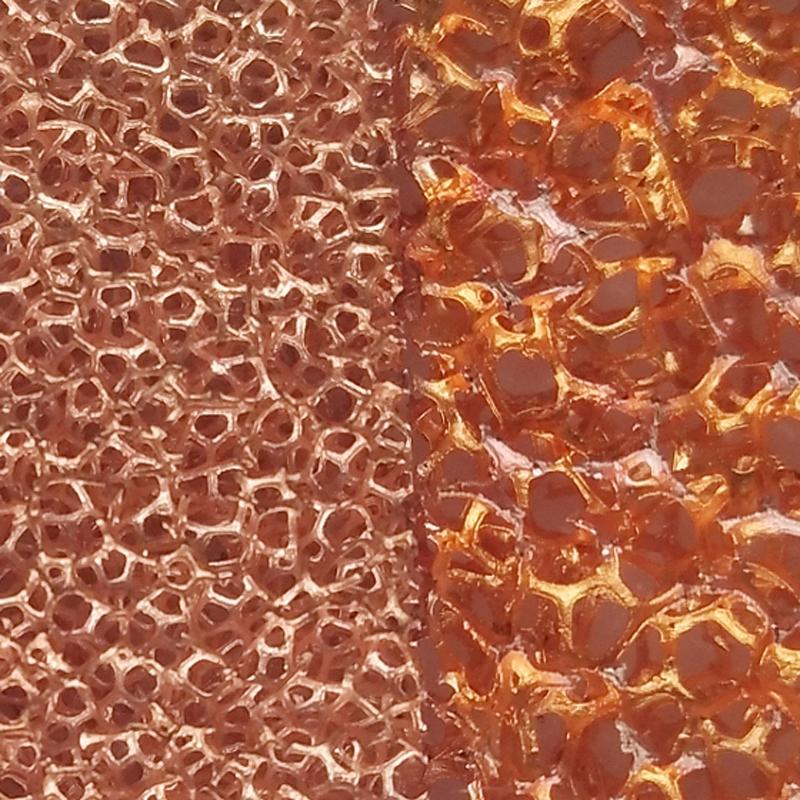

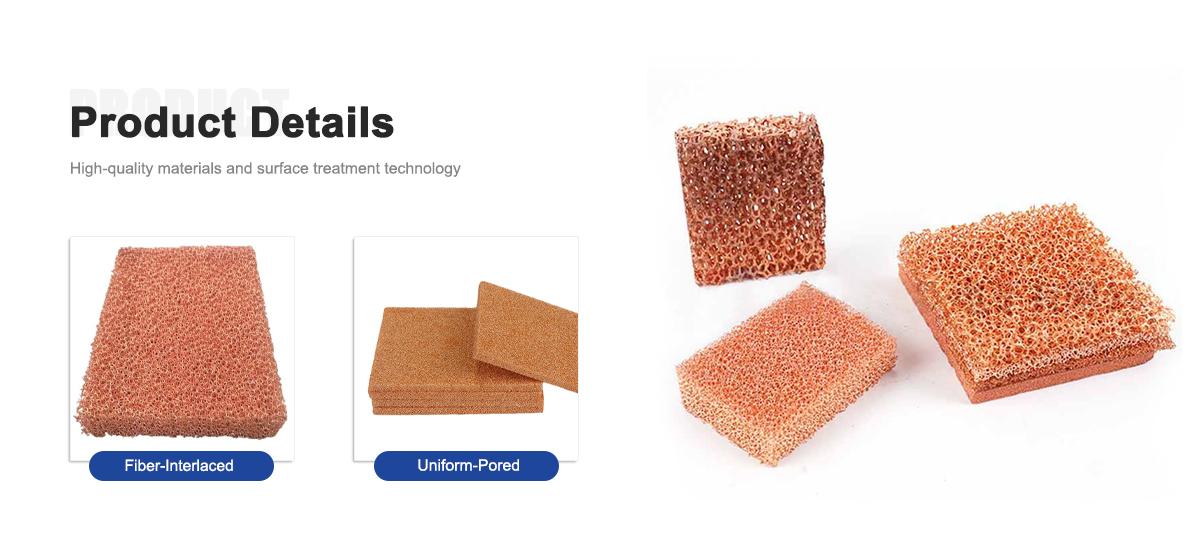

Our copper foam is a high-purity, porous material with a three-dimensional, open-cell structure, boasting up to 95% porosity and a density of just 0.5-1.5 g/cm³. It’s ultra-lightweight yet strong, making it ideal for structural components where weight reduction is critical. Its high strength-to-weight ratio ensures structural integrity, while the good corrosion resistance protects against environmental wear. The foam’s thermal conductivity also supports heat dissipation, a bonus for applications requiring thermal management. We craft it using advanced electrodeposition and 3D printing, allowing us to customize pore size and density to fit your specific structural needs. Whether you’re building vehicle frames or aerospace panels, our foam delivers unmatched results.

For more details, pls directly contact us.

Lightweight structural components are all about balancing strength and weight, and our copper foam is built to excel at both. Its low density slashes weight, improving fuel efficiency in vehicles or payload capacity in aerospace systems. The high strength ensures it can handle structural loads, from vibrations in cars to aerodynamic stresses in aircraft. The foam’s corrosion resistance makes it reliable in harsh environments, like marine or outdoor applications, reducing maintenance costs. Its thermal conductivity adds value by dissipating heat in structures exposed to high temperatures. This mix of low density, high strength, and durability makes our foam a must-have for modern structural designs.

Industry Analysis: The Copper Foam Market Surge

The copper foam market is booming, driven by the global demand for lightweight, high-performance materials. Valued at $180.5 million in 2023, it’s projected to hit $246.7 million by 2030, growing at a CAGR of 5.42%. Automotive and aerospace industries are major drivers, as they seek lightweight materials to boost fuel efficiency and performance. Construction and marine sectors are also adopting copper foam for its durability and corrosion resistance. The rise of renewable energy, like wind turbines, is fueling demand for lightweight structural components that can withstand environmental stress.

Sustainability is a key force in this market. Regulations and consumer demand are pushing industries toward recyclable materials and eco-friendly production. Our copper foam fits perfectly—it’s fully recyclable and made with energy-efficient processes. Innovations like nanostructured foams and 3D printing are opening new possibilities, allowing us to create tailored structures for specific applications. As industries prioritize efficiency, durability, and sustainability, our copper foam is poised to lead the lightweight structural market.

Applications: Where Our Copper Foam Shines

Our low-density copper foam is a versatile material, delivering results across a range of lightweight structural applications:

-

Vehicle Frames: It reduces weight in EV and hybrid vehicle chassis, boosting range and efficiency.

-

Aerospace Panels: The foam supports lightweight, strong panels for aircraft and satellites, enhancing payload capacity.

-

Building Facades: It provides durable, lightweight cladding for modern architectural designs.

-

Marine Structures: The foam’s corrosion resistance makes it ideal for lightweight components in boats and offshore platforms.

-

Wind Turbine Components: It supports lightweight, durable parts in turbine towers and blades, improving efficiency.

-

Portable Equipment: The foam creates strong, lightweight frames for mobile infrastructure like telecom towers.

Industry Trends: What’s Driving Copper Foam Forward

The copper foam market is moving fast, and we’re staying ahead of the curve. Here are the trends shaping the industry:

-

Lightweight Design Surge: Automotive and aerospace industries prioritize weight reduction, and our foam delivers.

-

Sustainability Push: Eco-friendly production and recyclable materials are must-haves, and our foam aligns with sustainable manufacturing.

-

Renewable Energy Growth: The rise of wind and solar systems is driving demand for lightweight, durable components.

-

Nanostructured Foams: Advances in nanotechnology are enabling ultra-high-strength foams, boosting structural performance.

-

Customization Boom: 3D printing and electroforming let us tailor foam structures for specific structural needs.

-

Construction Innovation: The rise of modern architecture is fueling demand for lightweight, durable materials.

Why Choose Our Copper Foam?

We’re not just making copper foam—we’re crafting solutions that redefine lightweight strength. Here’s why our low-density copper foam stands out:

-

Ultra-Low Density: At 0.5-1.5 g/cm³, our foam slashes weight while maintaining structural integrity.

-

High Strength-to-Weight Ratio: It delivers robust performance for lightweight applications, outperforming heavier materials.

-

Corrosion Resistance: It thrives in harsh environments, reducing maintenance and extending lifespan.

-

Thermal Conductivity: The foam supports heat dissipation, adding value in high-temperature applications.

-

Eco-Friendly Edge: Fully recyclable and produced with sustainable methods, our foam aligns with green initiatives.

-

Expert Support: Our team partners with you from design to deployment, offering expertise to tackle your toughest structural challenges.

Comparison Parameters Table

|

Parameter |

Copper Foam |

Aluminum Panels |

Steel Frames |

Polymer Composites |

|---|---|---|---|---|

|

Density |

Low (0.5-1.5 g/cm³) |

Moderate (higher than copper foam) |

High (much denser than copper) |

Low (but less durable) |

|

Strength-to-Weight Ratio |

High (excellent for lightweight structures) |

Moderate (less efficient than copper) |

Low (heavy for strength) |

Moderate (weaker under stress) |

|

Corrosion Resistance |

Good (resists moderate environments) |

Moderate (prone to oxidation) |

Poor (prone to rust) |

Poor (degrades in moisture) |

|

Thermal Conductivity |

High (supports heat dissipation) |

Moderate (lower than copper) |

Low (poor heat transfer) |

Low (not thermally conductive) |

|

Mechanical Durability |

High (withstands vibrations/stress) |

Moderate (prone to deformation) |

High (but heavy) |

Low (deforms under stress) |

|

Recyclability |

Fully recyclable |

Recyclable (energy-intensive) |

Recyclable (energy-intensive) |

Limited (complex recycling process) |

|

Ease of Fabrication |

High (customizable via 3D printing) |

Moderate (less versatile) |

Low (requires heavy machining) |

Moderate (inconsistent quality) |

|

Cost-Effectiveness |

Moderate (long lifespan, high performance) |

Low (cheaper but less efficient) |

Low (shorter lifespan in corrosion) |

Low (frequent replacements needed) |

Our copper foam outperforms other structural materials. Aluminum panels are lightweight but less corrosion-resistant and thermally conductive. Steel frames are strong but heavy, reducing efficiency. Polymer composites are lightweight but lack durability and strength. Our copper foam hits the sweet spot: ultra-low density, high strength, excellent corrosion resistance, and thermal conductivity, all backed by sustainable production.

We go beyond the product itself. Our end-to-end support—from custom design consultations to system integration—ensures you get the most out of our foam. Our advanced manufacturing techniques, like electrodeposition and 3D printing, deliver consistent quality and tailored solutions that competitors can’t match.

Looking to the Future

The future of low-density copper foam is bright, and we’re excited to lead the way. As industries like automotive, aerospace, and renewable energy push for lighter, more efficient designs, the demand for high-performance materials will skyrocket. We’re investing heavily in R&D to push the boundaries of what our foam can do, from nanostructured designs for ultra-strong components to high-density options for large-scale structures. Our commitment to sustainability means we’re constantly refining our processes to reduce waste and energy use, aligning with global environmental goals.

Our low-density copper foam isn’t just a material—it’s a solution for lighter, stronger structures. It’s ultra-light, durable, and built to power the next generation of structural designs. Ready to see how it can transform your project? Let’s talk about making it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is low-density copper foam?

It’s an ultra-lightweight, porous copper material designed for structural components requiring minimal weight and high strength. -

How does copper foam benefit structural components?

Its low density reduces weight while maintaining structural integrity, ideal for lightweight applications. -

Which industries use this copper foam?

Automotive, aerospace, construction, marine, and renewable energy rely on it for lightweight structural solutions. -

Why is low density important for structural components?

It reduces overall weight, improving fuel efficiency, payload capacity, and ease of installation. -

What are the key applications of this copper foam?

It’s used in vehicle frames, aerospace panels, building facades, marine structures, and wind turbine components. -

How does copper foam compare to other structural materials?

It offers lower density, better corrosion resistance, and higher thermal conductivity than alternatives like aluminum or steel. -

What are the latest trends in copper foam for structural components?

Growing demand for lightweight materials, nanostructured foam advancements, and sustainable production are driving growth. -

Is this copper foam eco-friendly?

Yes, it’s fully recyclable, supports energy-efficient designs, and is produced with sustainable methods.