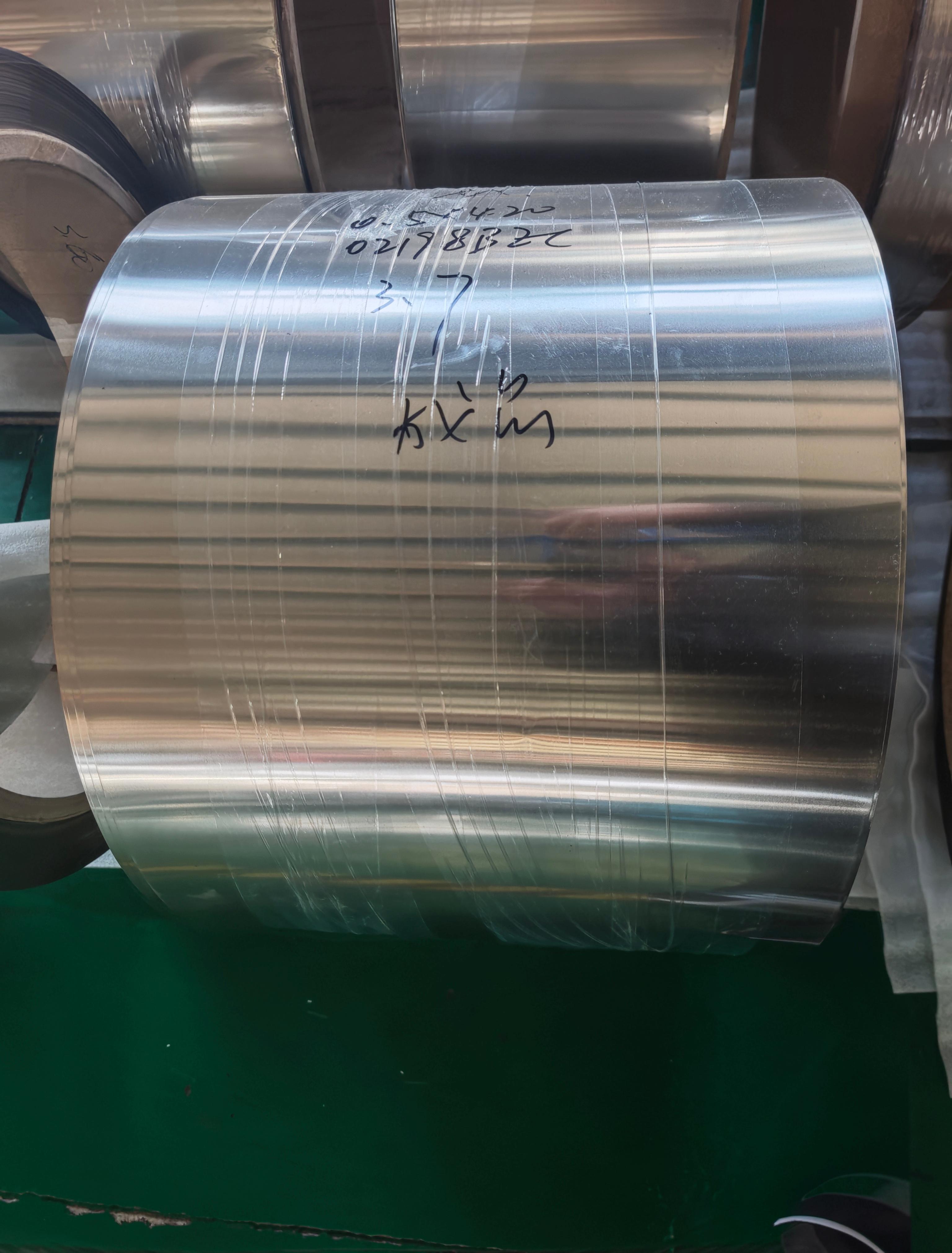

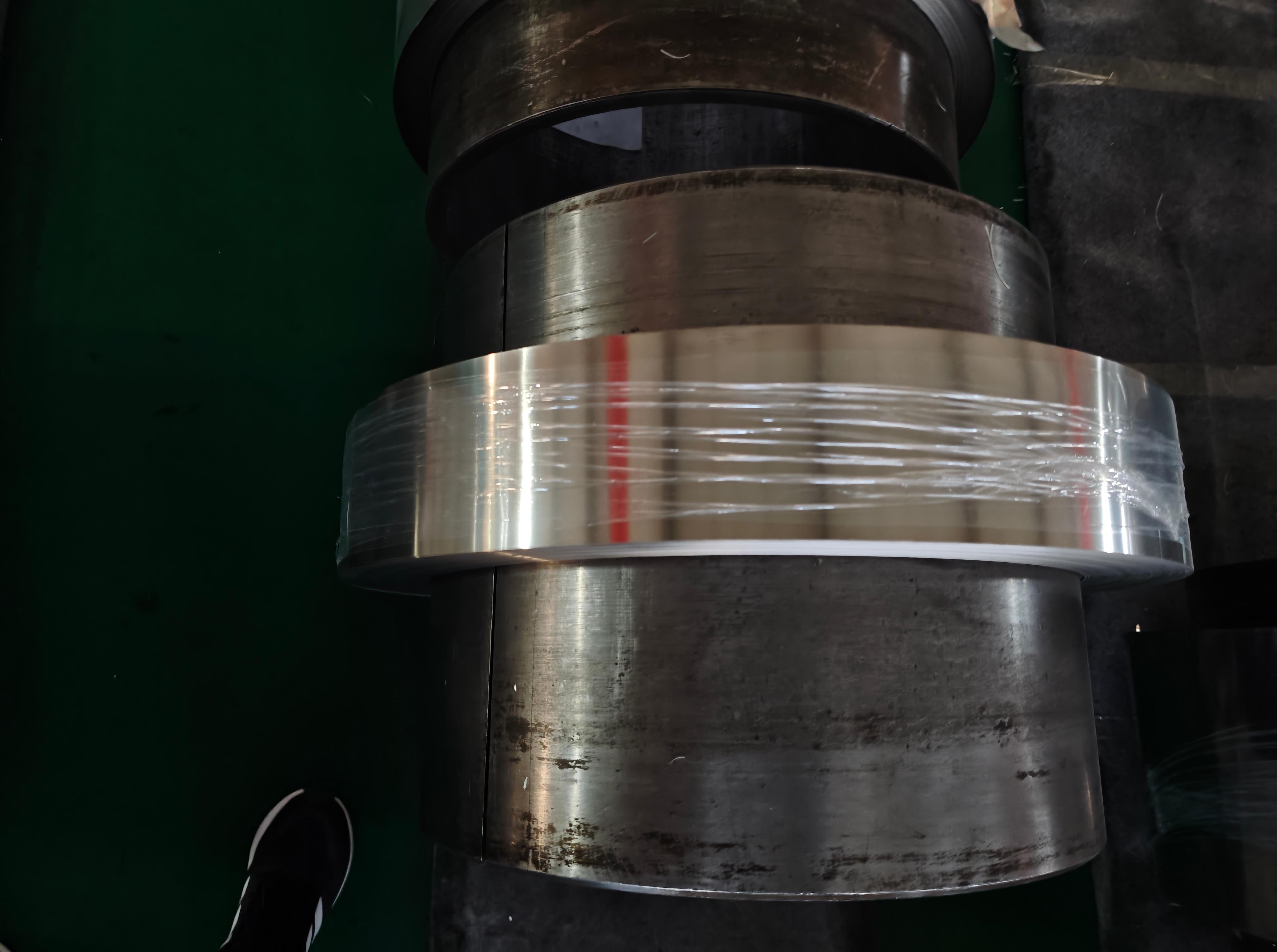

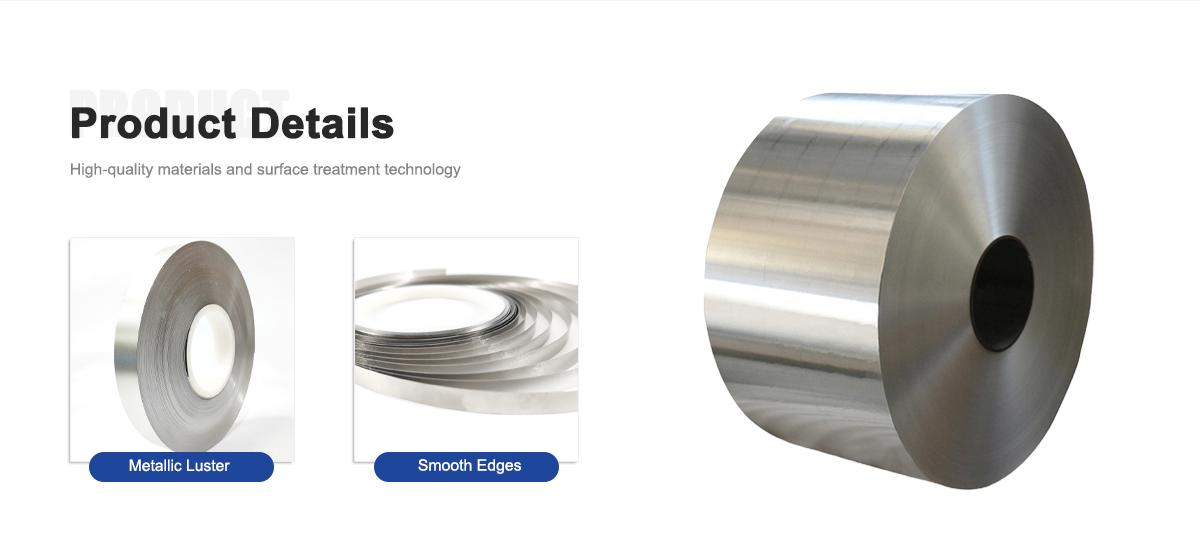

We're proud to offer our 3J01 high-strength elastic alloy strip, a game-changer for precision spring manufacturing. This alloy is engineered for applications where reliability, elasticity, and durability are non-negotiable. With a unique composition featuring nickel, chromium, and titanium, our 3J01 strip delivers exceptional mechanical properties, including a yield strength of up to 2,800 MPa and a stable elastic modulus across a wide temperature range. Whether you're designing intricate components for automotive systems, aerospace equipment, or precision instruments, this alloy strip ensures your springs perform consistently under stress.

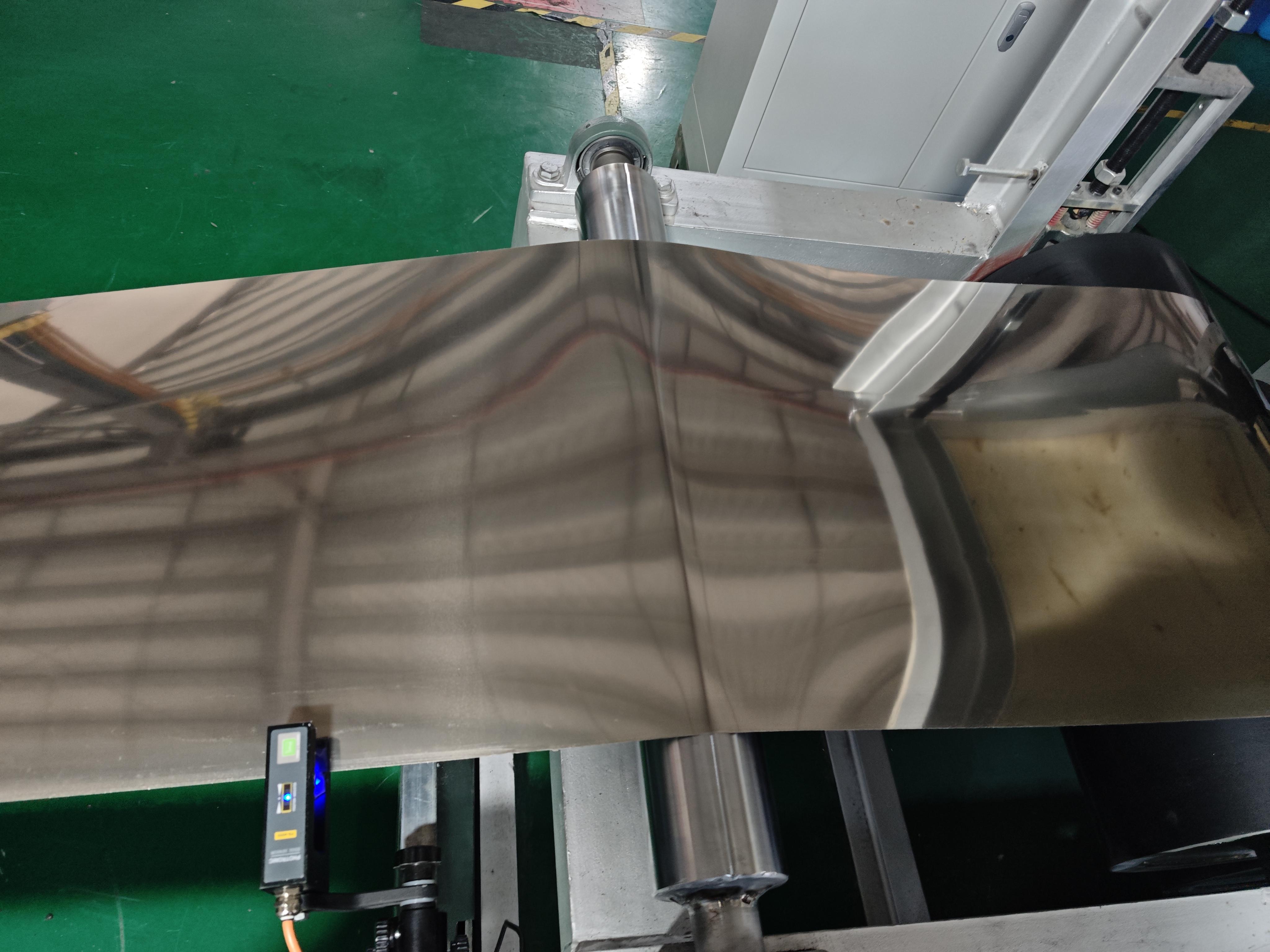

Our 3J01 alloy strip stands out for its high elasticity, low hysteresis, and excellent fatigue resistance. These qualities make it perfect for dynamic applications like mechanical vibrators, precision sensors, and frequency components. It’s not just about strength—it’s about maintaining performance over millions of loading cycles without deformation. Plus, its corrosion resistance means it thrives in challenging environments, reducing maintenance costs and extending component lifespans. We manufacture this strip with precision cold rolling and heat treatment, ensuring tight tolerances and consistent quality for every batch.

For more details, pls directly contact us.

The precision spring manufacturing industry is evolving fast, driven by demand for lightweight, durable, and high-performance materials. Automotive and aerospace sectors are pushing for components that can handle extreme conditions while meeting strict safety and efficiency standards. Meanwhile, the rise of smart electronics and medical devices has spiked the need for compact, reliable springs that operate flawlessly in high-frequency applications. According to industry trends, the global spring market is expected to grow steadily, with a focus on advanced alloys like our 3J01 strip that combine strength, elasticity, and corrosion resistance.

Sustainability is another key driver. Manufacturers are under pressure to reduce material waste and improve energy efficiency. Our 3J01 alloy strip aligns with these goals, offering longevity that minimizes replacements and a composition that supports efficient production processes. The shift toward electric vehicles (EVs) and renewable energy systems also boosts demand for precision springs in battery systems and energy storage, where our alloy’s stable performance shines. Additionally, advancements in additive manufacturing and AI-driven material design are opening new possibilities for customizing alloys, and we’re at the forefront, leveraging these technologies to enhance our offerings.

Competition in the market is fierce, with players focusing on material innovation and cost-effectiveness. While traditional spring steels and stainless steels remain popular, advanced elastic alloys like 3J01 are gaining traction for their superior performance in niche applications. The challenge for manufacturers is balancing cost with quality, and our alloy strip strikes that balance by delivering premium performance without prohibitive costs. As industries prioritize miniaturization and precision, our 3J01 strip is well-positioned to meet these demands, offering unmatched reliability for next-generation applications.

| Grades | Density (g/cm³) | Electrical Resistivity (10⁻⁶ Ω·cm) | Thermal Conductivity (W/m·K) | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Limit (MPa) | Fatigue Life (cycles) | Working Temperature Range (°C) | Temperature Coefficient |

| 8.1 | 80 | 11 | 144 | 800 | 1000 | 10 | 800 | >10⁷ | -60 to 200 | Extremely low temperature coefficient of elasticity | |

| 8.3 | 120 | 40 | 125 | 300 | 600 | 20 | 300 | >10⁷ | -40 to 150 | Elasticity remains constant with minimal temperature sensitivity | |

| 8.2 | 100 | 15 | 180 | 1100 | 1400 | 5 | 1100 | >10⁶ | -200 to 500 | Maintains high strength even at elevated temperatures |

For more details, pls directly contact us.

Our 3J01 high-strength elastic alloy strip is a versatile material with applications across multiple industries. In the automotive sector, it’s a go-to choice for suspension systems, seat belt retractor springs, and clutch components. Its ability to withstand cyclic loading without losing elasticity ensures safety and performance in critical systems. For aerospace, the alloy’s lightweight yet robust nature makes it ideal for control mechanisms, actuators, and vibration dampers, where precision and durability are paramount.

In electronics, our 3J01 strip powers precision springs in tactile switches, connectors, and membrane switches. Its stable elastic modulus and low frequency-temperature coefficient make it perfect for high-frequency components like mechanical vibrators and resonance relays. The medical industry also benefits, with the alloy used in surgical tools, dental devices, and implantable components, thanks to its corrosion resistance and biocompatibility. Industrial machinery relies on 3J01 for heavy-duty springs and cutting tools, where its fatigue resistance extends equipment life even under intense operational stress.

Beyond these, the alloy’s non-magnetic properties and thermal stability make it suitable for specialized applications like aerospace sensors and precision instruments operating in extreme environments. Whether it’s a tiny spring in a smartwatch or a robust component in a jet engine, our 3J01 strip delivers consistent performance, making it a trusted choice for engineers worldwide.

Company Comparison and Our Advantages

When it comes to high-strength elastic alloys, we know you have options. But here’s why our 3J01 alloy strip stands out. Compared to a typical competitor in the precision alloy market, our product offers distinct advantages that make it the smarter choice for your manufacturing needs.

First, our 3J01 strip is manufactured with state-of-the-art cold rolling and heat treatment processes, achieving tighter tolerances and higher consistency than many alternatives. While other companies might offer similar alloys, their products often fall short in terms of fatigue resistance and long-term reliability. Our alloy’s ability to endure millions of loading cycles without deformation gives you peace of mind for safety-critical applications. We also prioritize corrosion resistance, meaning our strip performs reliably in harsh environments without the need for costly coatings or treatments, unlike some competitors’ offerings.

Customization is another area where we shine. We work closely with clients to tailor the 3J01 strip’s thickness, width, and mechanical properties to specific project requirements. Many competitors stick to standard specifications, but we go the extra mile to ensure our alloy fits your exact needs, whether it’s for a high-frequency sensor or a heavy-duty automotive spring. Our advanced testing facilities and quality control systems guarantee every batch meets stringent standards, reducing defects and ensuring performance consistency.

Cost-effectiveness is a big deal, and we get it. While some competitors cut corners to lower prices, we focus on delivering value through durability and performance. Our 3J01 strip’s longevity means fewer replacements and lower maintenance costs, saving you money in the long run. Plus, our global supply chain and efficient production processes keep lead times short without compromising quality, giving you a competitive edge in fast-paced markets.

Sustainability is part of our DNA. We’ve optimized our manufacturing to reduce waste and energy consumption, aligning with the industry’s push for greener solutions. Some competitors lag in this area, relying on outdated processes that harm the environment. By choosing our 3J01 alloy strip, you’re not just getting a high-performance material—you’re partnering with a company committed to responsible production and innovation.

Comparison Parameters Table

Parameter | 3J01 Alloy Strip | Standard Spring Steel | Stainless Steel (e.g., SUS301) |

|---|---|---|---|

Yield Strength (MPa) | Up to 2,800 | 1,500–2,000 | 1,000–1,800 |

Elastic Modulus (GPa) | ~190 | ~200 | ~193 |

Corrosion Resistance | Good, suitable for harsh environments | Moderate, often requires coating | Excellent, inherent due to chromium |

Temperature Range (°C) | -40 to +80 | -20 to +150 | -50 to +300 |

Fatigue Resistance | Excellent, withstands millions of cycles | Good, but lower than 3J01 | Good, varies by alloy |

Hysteresis | Low, minimal energy loss | Moderate | Moderate to high |

Applications | Precision springs, sensors, vibrators | General springs, automotive parts | Springs, medical tools, electronics |

Cost-Effectiveness | High, due to performance and longevity | Moderate, lower initial cost | Higher, due to material composition |

Our 3J01 high-strength elastic alloy strip isn’t just another material—it’s a solution engineered for the toughest challenges in precision spring manufacturing. Its high yield strength, excellent fatigue resistance, and stable performance across a wide temperature range make it a standout choice for industries from automotive to medical devices. We’ve poured years of expertise into perfecting this alloy, ensuring it meets the demands of modern engineering while offering cost-effective, sustainable benefits.

Whether you’re designing springs for a next-gen electric vehicle, a cutting-edge medical implant, or a high-frequency electronic component, our 3J01 strip delivers the reliability and performance you need. With our commitment to customization, quality, and innovation, we’re not just a supplier—we’re a partner in your success. Choose our 3J01 alloy strip and experience the difference of working with a company that puts your needs first.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is 3J01 alloy strip used for?

It's used for precision springs in industries like automotive, aerospace, and electronics, where high elasticity and durability are critical.What makes 3J01 alloy strip special?

Its high yield strength, excellent fatigue resistance, and stable elastic modulus make it ideal for demanding applications.Can 3J01 alloy strip withstand extreme temperatures?

Yes, it performs reliably in temperatures from -40°C to +80°C, maintaining consistent mechanical properties.Is 3J01 alloy strip corrosion-resistant?

It offers good corrosion resistance, especially in harsh environments, reducing the need for additional coatings.What industries benefit most from 3J01 alloy strip?

Automotive, aerospace, medical devices, and precision instruments rely on it for high-performance components.How is 3J01 alloy strip manufactured?

It undergoes precise cold rolling and heat treatment to achieve high strength and elasticity with tight tolerances.What are the key mechanical properties of 3J01 alloy strip?

It boasts a yield strength up to 2,800 MPa, high elastic modulus, and low frequency-temperature coefficient.How does 3J01 alloy strip support precision spring design?

Its stable elastic modulus and minimal hysteresis ensure consistent performance in high-frequency and cyclic loading applications.