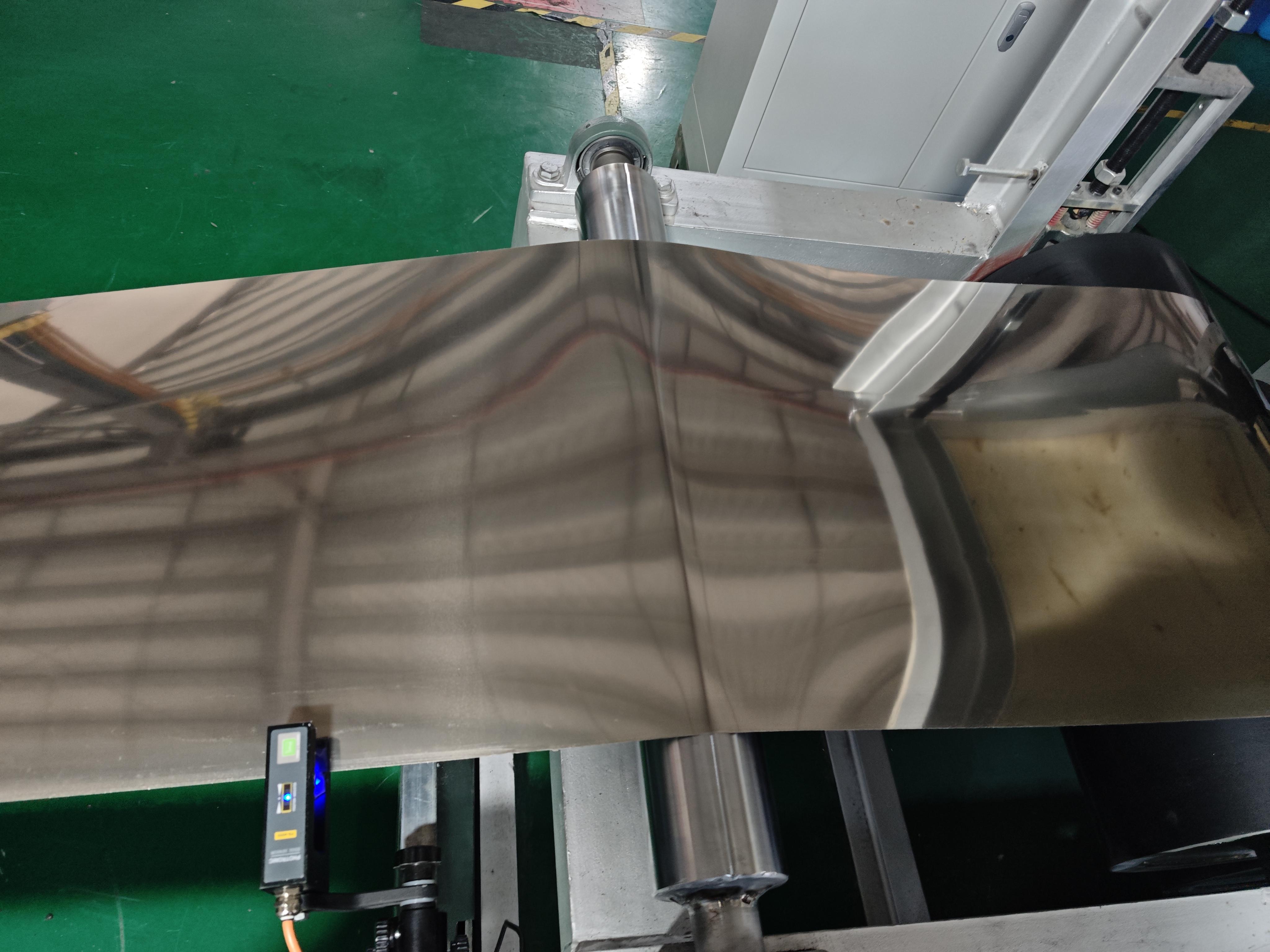

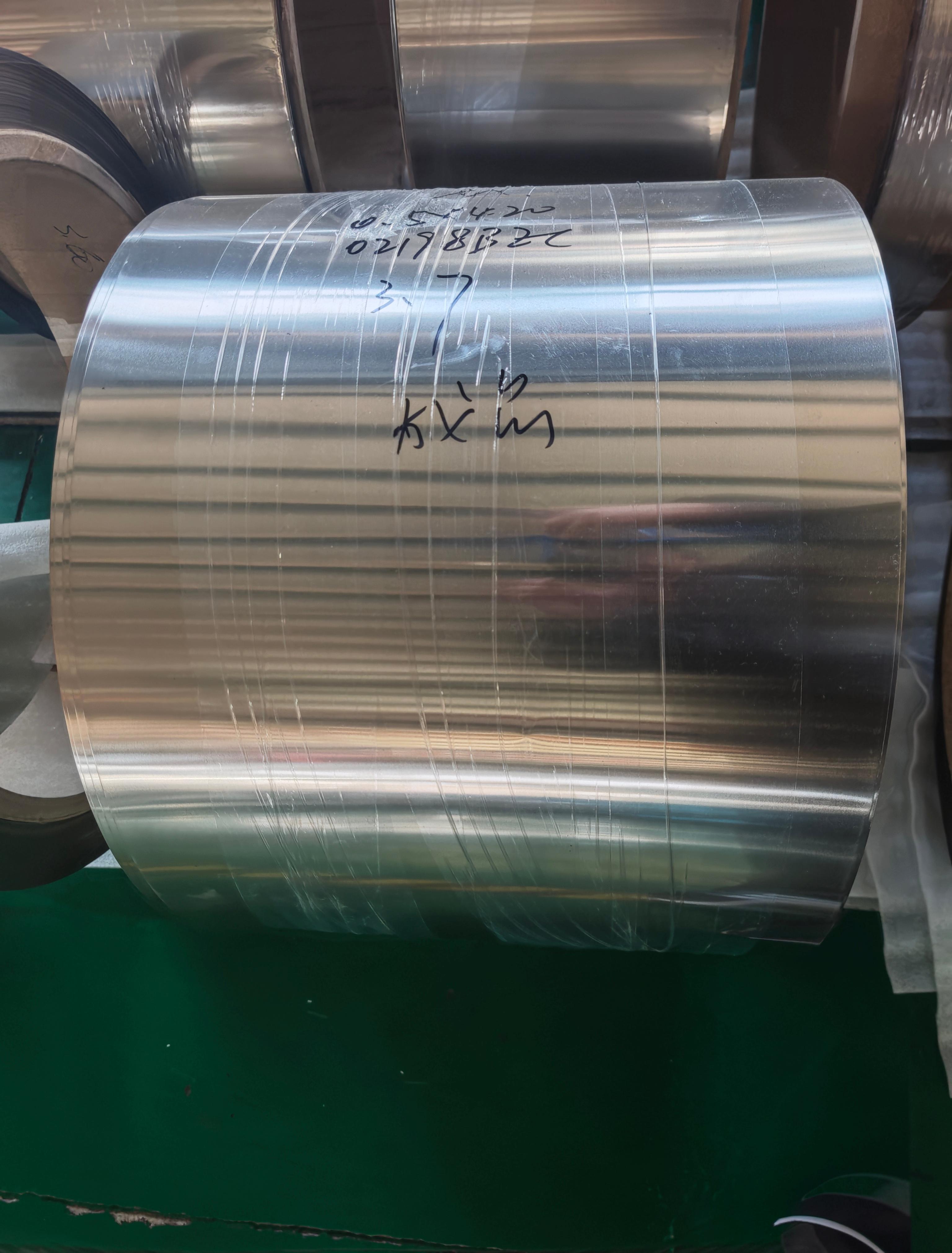

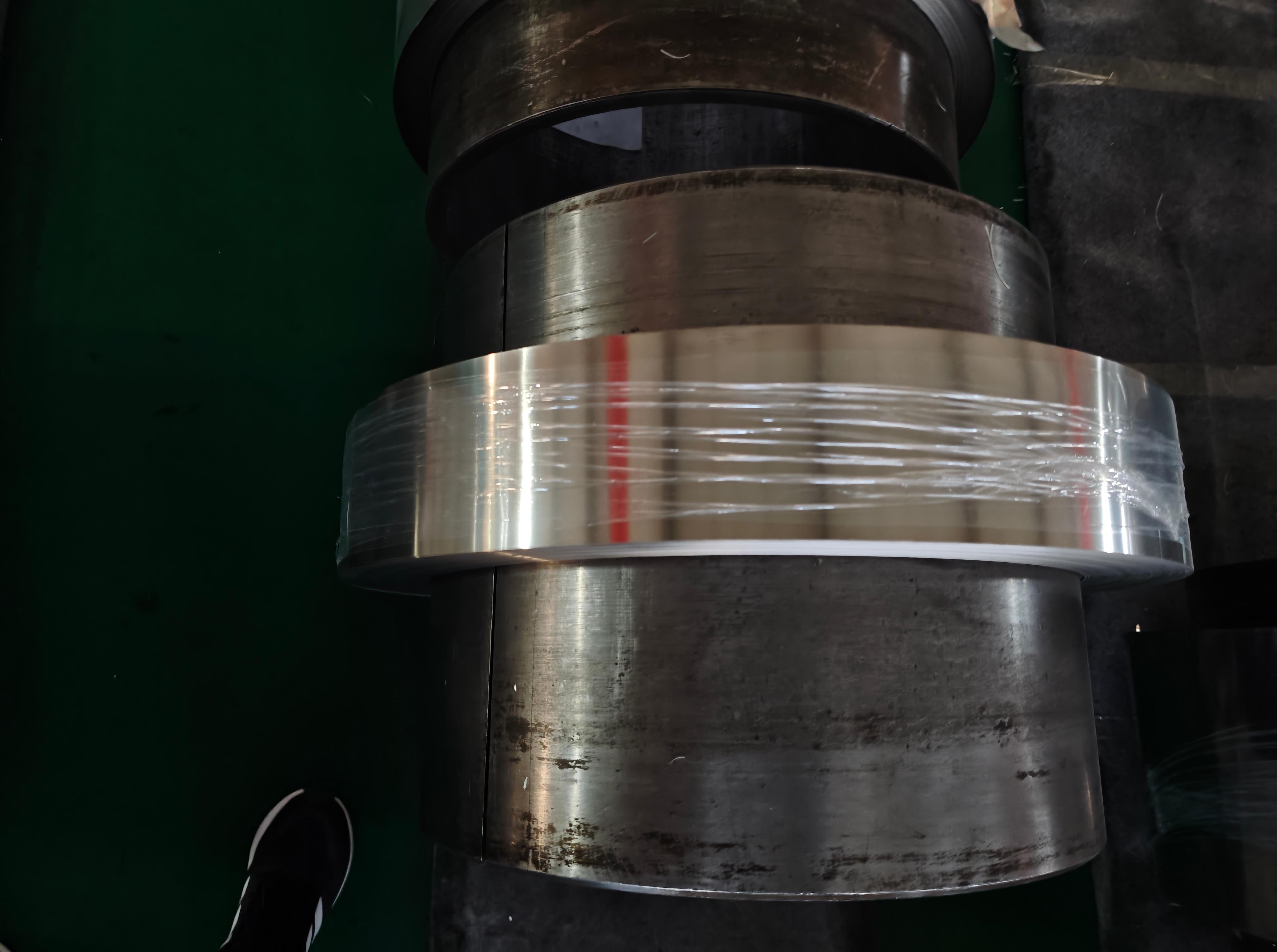

Our S3J47 nickel-based elastic alloy strip is a cutting-edge material for advanced sensor technology. With a yield strength of up to 2,700 MPa and exceptional elasticity, this strip is designed for precision sensors in electronics, aerospace, and industrial applications. Its nickel-based composition ensures stable performance, even in high-vibration environments, while its low hysteresis guarantees minimal energy loss.

This strip’s corrosion resistance and thermal stability up to 120°C make it ideal for demanding conditions. We craft it with precision cold rolling and heat treatment, ensuring tight tolerances and consistent quality. If you’re building next-gen sensors that need to perform flawlessly, our S3J47 strip is the material you can rely on.

For more details, pls directly contact us.

The advanced sensor technology market is booming, fueled by the rise of IoT, smart devices, and automation. Industries like electronics, aerospace, and automotive are demanding materials that deliver precision and reliability in dynamic environments. Our S3J47 strip meets these needs, offering unmatched elasticity and stability. The global market for sensor components is growing steadily, with a focus on high-performance alloys that support efficiency and sustainability.

Sustainability is a major driver, and our alloy’s durability reduces waste and replacement costs. Innovations like AI-driven material optimization and advanced manufacturing are shaping the industry, and we’re leveraging these to enhance our products. While competition is fierce, many alternatives lack the elasticity and vibration resistance of our S3J47 strip, making it a top choice for advanced sensor applications.

| Grades | Density (g/cm³) | Electrical Resistivity (10⁻⁶ Ω·cm) | Thermal Conductivity (W/m·K) | Modulus of Elasticity (GPa) | Yield Strength (MPa) | Tensile Strength (MPa) | Elongation at Break (%) | Elastic Limit (MPa) | Fatigue Life (cycles) | Working Temperature Range (°C) | Temperature Coefficient |

| 8.1 | 80 | 11 | 144 | 800 | 1000 | 10 | 800 | >10⁷ | -60 to 200 | Extremely low temperature coefficient of elasticity | |

| 8.3 | 120 | 40 | 125 | 300 | 600 | 20 | 300 | >10⁷ | -40 to 150 | Elasticity remains constant with minimal temperature sensitivity | |

| 8.2 | 100 | 15 | 180 | 1100 | 1400 | 5 | 1100 | >10⁶ | -200 to 500 | Maintains high strength even at elevated temperatures |

For more details, pls directly contact us.

Our S3J47 strip is a powerhouse for advanced sensor applications. In electronics, it’s used for precision sensors and resonators, ensuring stable performance in high-frequency systems. Aerospace relies on it for sensors in control systems and navigation equipment, where its vibration resistance shines. Automotive applications include sensors for engine management and safety systems, benefiting from its fatigue resistance.

Industrial automation uses the strip for sensors in robotics and control systems, thriving in moderate to harsh environments due to its corrosion resistance. Its thermal stability makes it ideal for demanding conditions. From smart devices to aerospace sensors, our S3J47 strip delivers the precision and reliability engineers need.

Comparison Parameters Table

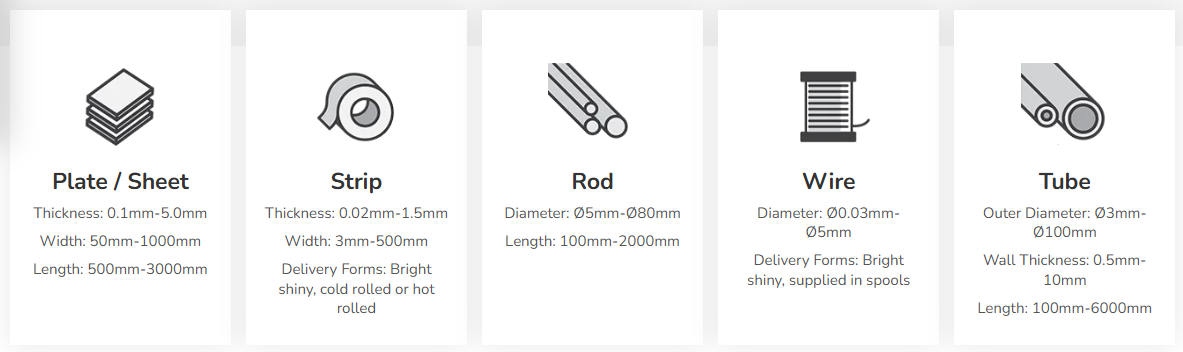

Parameter | S3J47 Nickel-Based Strip | Standard Spring Steel | Stainless Steel (e.g., SUS301) |

|---|---|---|---|

Yield Strength (MPa) | Up to 2,700 | 1,500–2,000 | 1,000–1,800 |

Elastic Modulus (GPa) | ~190 | ~200 | ~193 |

Corrosion Resistance | Good, suitable for moderate conditions | Moderate, needs coatings | Excellent, chromium-based |

Temperature Range (°C) | -40 to +120 | -20 to +150 | -50 to +300 |

Fatigue Resistance | Excellent, millions of cycles | Good, but lower than S3J47 | Good, varies by alloy |

Hysteresis | Very low, minimal energy loss | Moderate | Moderate to high |

Applications | Sensors, resonators, elastic components | General springs | Springs, electronics |

Cost-Effectiveness | High, due to advanced performance | Moderate, lower initial cost | Higher, material-driven |

Our S3J47 nickel-based alloy strip sets the bar high. Unlike typical competitors, we use advanced manufacturing to achieve superior elasticity and vibration resistance, ensuring our strip performs in advanced sensor applications. While others may struggle with dynamic conditions, our alloy delivers consistent stability, saving costs. Its corrosion resistance also outpaces many alternatives, reducing the need for coatings.

Customization is where we excel. We tailor the strip’s properties to your exact specifications, unlike competitors who stick to standard offerings. Our rigorous quality control ensures every batch meets stringent standards, minimizing defects and boosting efficiency. Cost-wise, our alloy’s durability means fewer replacements, offering better value than cheaper materials that wear out faster. We’re committed to sustainable production, minimizing waste and aligning with industry trends toward greener solutions. With fast lead times and a global supply chain, our S3J47 strip keeps your projects moving forward.

For more details, pls directly contact us.

About Us:

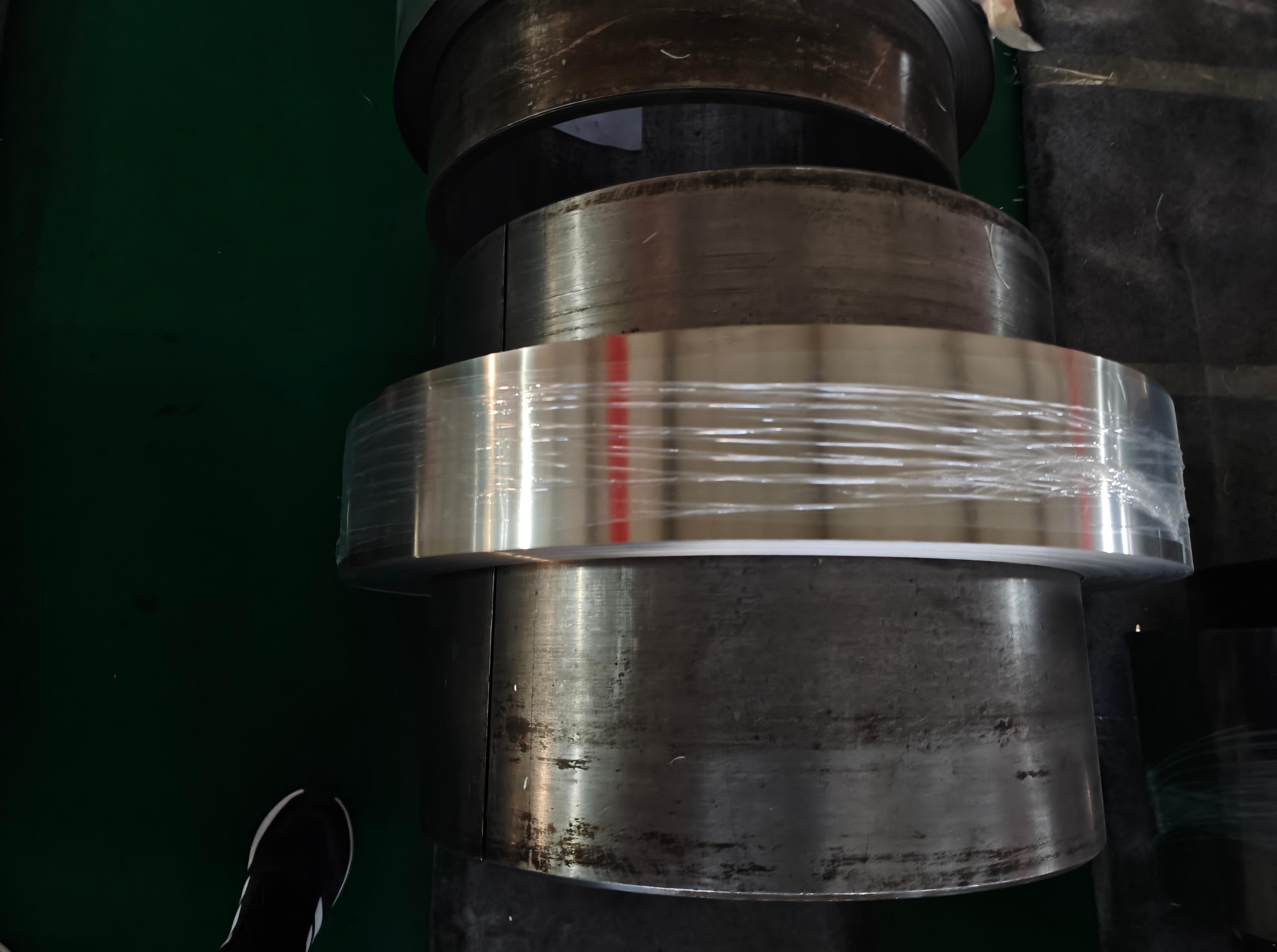

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the S3J47 alloy strip used for?

It’s used for advanced sensor technology in electronics, aerospace, and industrial applications.What makes this alloy unique?

Its nickel-based composition offers high elasticity and stable performance for sensors.Can it handle dynamic conditions?

Yes, it’s stable in high-vibration environments and up to 120°C.Which industries use this strip?

Electronics, aerospace, automotive, and industrial automation for precision sensors.How is it manufactured?

Precision cold rolling and heat treatment ensure consistent elastic properties.What’s its fatigue resistance?

Excellent, enduring millions of cycles without failure.Is it corrosion-resistant?

Yes, it performs well in moderate to harsh environments.Why choose S3J47 for sensor technology?

Its elasticity and stability outperform standard alloys in advanced applications.