As a leading innovator in advanced materials, we’re proud to spotlight our 3D porous Nickel Foam , a game-changer for sound absorption and vibration damping. This cutting-edge product is designed to tackle noise and vibration challenges across multiple industries, delivering unmatched performance, durability, and versatility. Let’s dive into what makes this material special, explore its applications, analyze industry trends, and showcase why our solution stands out.

Product Introduction: What’s 3D Porous Nickel Foam?

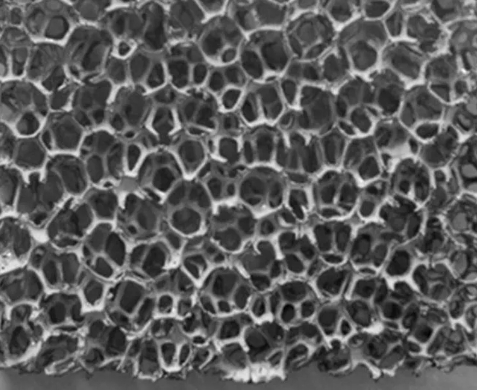

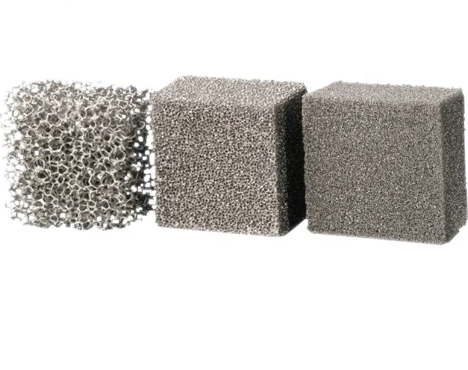

Our 3D porous nickel foam is a lightweight, open-cell metallic material with a unique three-dimensional structure. Think of it as a sponge, but made of nickel, with interconnected pores that trap sound waves and dampen vibrations. Its high porosity—up to 98%—gives it exceptional acoustic and mechanical properties, while its nickel composition ensures corrosion resistance and heat tolerance.

This foam isn’t just about soaking up noise. It’s engineered to dissipate vibrational energy, making it a dual-purpose solution for environments where both sound and movement need control. Whether it’s reducing engine hum in a car or stabilizing machinery in a factory, our product delivers. Plus, it’s fully customizable—porosity, thickness, and dimensions can be tailored to fit your specific needs.

Key features include:

Superior sound absorption: Achieves coefficients of 0.8–0.9 at 2000–4000 Hz, perfect for human-sensitive frequencies.

Excellent vibration damping: High damping ratio reduces structural fatigue.

Lightweight yet strong: Densities as low as 7.4 mg/cm³ without sacrificing durability.

Heat and corrosion resistance: Thrives in temperatures up to 1000°C and resists moisture or chemical degradation.

Eco-friendly potential: Recyclable and long-lasting, reducing waste.

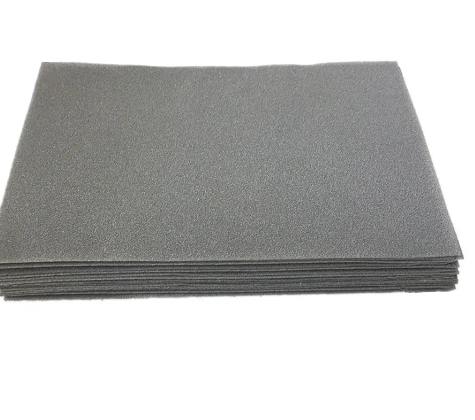

Material | Nickel foam, Sold in sheet |

Dimension | 500*1000, or customized as request |

Thickness | 0.5mm, 1.0mm, 1.5mm, 2.0mm, etc |

The aperture | 80 PPI (5-80 PPI available) |

Porosity | 90-98% |

Through Hole Rate | ≥98% |

Bulk density | 0.15-0.45g/cm3 |

For more details, pls directly contact us.

Noise pollution and structural vibrations are more than just annoyances—they’re health and performance hazards. With urbanization and industrial growth, the demand for effective sound and vibration control is skyrocketing. The global acoustic materials market is projected to grow steadily, driven by stricter regulations on noise emissions and rising consumer expectations for quieter, smoother experiences.

Key industry trends include:

Automotive push for quieter cabins: Electric vehicles (EVs) are quieter, but road and wind noise are now more noticeable, driving demand for advanced sound absorbers.

Aerospace and rail innovations: Lightweight materials like our nickel foam are critical for reducing weight while meeting stringent noise and vibration standards.

Sustainable materials: Industries are shifting toward recyclable, durable solutions to meet environmental goals.

Smart manufacturing: Customizable materials that integrate with 3D printing or advanced fabrication are gaining traction.

Challenges persist, though. Traditional materials like polyurethane foam or fibrous composites often fall short in extreme conditions, degrading under heat or moisture. Plus, they’re less effective at low frequencies or for vibration damping. Metallic foams, like our 3D porous nickel foam, address these gaps, offering a robust alternative that’s both high-performing and adaptable.

Applications: Where Our Nickel Foam Shines

Our 3D porous nickel foam is a versatile solution with applications across diverse sectors. Here’s where it’s making waves:

Automotive: Used in engine compartments, exhaust systems, and cabin interiors to reduce noise and vibrations. It’s a go-to for EVs, where minimizing road noise is critical.

Aerospace: Applied in aircraft engine liners and fuselage panels, where its lightweight design and heat resistance are game-changers.

Rail Transit: Enhances passenger comfort by dampening track vibrations and reducing cabin noise in trains.

Construction: Integrated into sound insulation panels for buildings, highways, and tunnels, offering both acoustic and structural benefits.

Electronics: Shields sensitive components from vibrations and reduces noise in devices like generators or compressors.

Industrial Machinery: Protects equipment from wear by absorbing vibrations, extending lifespan and improving efficiency.

Its ability to perform in high-temperature, corrosive, or high-vibration environments makes it a standout choice for demanding applications. Plus, its open-cell structure allows for additional functionality, like filtration or electromagnetic shielding, expanding its utility.

Company Comparison: Why Our Nickel Foam Leads the Pack

When it comes to 3D porous nickel foam, we’re not just another supplier—we’re innovators setting the standard. Here’s how we stack up against a typical competitor in the metallic foam space:

Material Quality: Our nickel foam is crafted with precision, achieving consistent porosity (92–98%) and uniform pore sizes (0.65–0.9 mm). Others often struggle with uneven structures, reducing performance.

Customization: We offer bespoke solutions, tweaking thickness, density, or pore size to match your project. Competitors typically stick to off-the-shelf options, limiting flexibility.

Performance: Our foam hits sound absorption coefficients of 0.8–0.9 at key frequencies and boasts superior vibration damping. Alternative products often lag, especially at low frequencies.

Durability: With nickel’s natural corrosion resistance, our foam thrives in harsh conditions—think salty air or chemical exposure—where others degrade.

Sustainability: We prioritize eco-friendly production and recyclability, aligning with green building and manufacturing trends. Many competitors rely on less sustainable processes.

Support: Our team provides end-to-end guidance, from design to integration. Others may leave you to figure out application details alone.

Our edge comes from years of R&D, advanced manufacturing, and a customer-first approach. We don’t just sell a product—we partner with you to solve noise and vibration challenges.

Why Choose Our 3D Porous Nickel Foam?

Our 3D porous nickel foam isn’t just a material—it’s a solution. It tackles noise and vibration head-on, delivering performance where traditional options fall short. Its lightweight design, durability, and versatility make it a must-have for industries facing tough acoustic and mechanical demands. Whether you’re building quieter cars, safer aircraft, or more comfortable buildings, our product has you covered.

We’re committed to pushing the boundaries of what metallic foams can do. By investing in innovation and sustainability, we ensure our nickel foam meets today’s needs while preparing for tomorrow’s challenges. Ready to quiet the noise and steady the shake? Our 3D porous nickel foam is the answer.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is 3D porous nickel foam used for?

It’s primarily used for sound absorption and vibration damping in industries like automotive, aerospace, construction, and electronics.How does it absorb sound?

Its open-cell structure traps sound waves, converting acoustic energy into heat through friction within the pores.Can it handle high temperatures?

Yes, it’s highly heat-resistant, making it ideal for extreme environments like engine compartments or industrial machinery.Is it lightweight?

Absolutely, its porous design keeps it lightweight while maintaining strength and durability.What industries benefit most from this product?

Automotive, aerospace, rail transit, construction, and electronics see the biggest advantages.How does it compare to traditional sound-absorbing materials?

It offers better sound absorption across a wider frequency range, plus superior vibration damping and corrosion resistance.Is it customizable?

Yes, we can tailor porosity, thickness, and size to meet specific application needs.What’s the lifespan of 3D porous nickel foam?

With its corrosion resistance and durability, it lasts years even in harsh conditions.