We're thrilled to showcase our corrosion-resistant Nickel Foam , a standout solution for industrial filtration. This advanced material is built to handle the toughest filtration challenges, from chemical processing to environmental cleanup. With its durability, efficiency, and versatility, it’s transforming how industries manage fluids and gases. Let’s dive into what makes our nickel foam special, explore its applications, analyze industry trends, and highlight why our product leads the way.

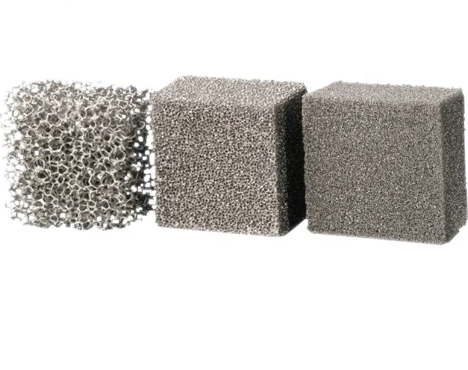

Our corrosion-resistant nickel foam is a high-performance, open-cell metallic material designed for industrial filtration. Picture a lightweight, sponge-like structure made of pure nickel, with interconnected pores that trap contaminants while allowing fluids or gases to flow through. Its porosity—up to 98%—delivers exceptional filtration efficiency, while its nickel composition ensures it stands up to corrosive environments like acids, alkalis, or saltwater.

This foam isn’t just about filtering. It’s engineered for longevity, with a lifespan of 5–10 years even in harsh conditions. It’s also customizable, letting us adjust pore sizes (0.1–3 mm), thickness, or density to match your specific filtration needs. Whether you’re purifying wastewater or separating gases in a refinery, our nickel foam gets the job done.

Key features include:

-

High filtration efficiency: Captures 99% of particles larger than 5 microns.

-

Corrosion resistance: Thrives in aggressive chemical or marine environments.

-

Heat tolerance: Performs reliably up to 1000°C.

-

Lightweight design: Densities as low as 7 mg/cm³ for easy integration.

-

Sustainable: Long-lasting and recyclable, reducing waste and costs.

|

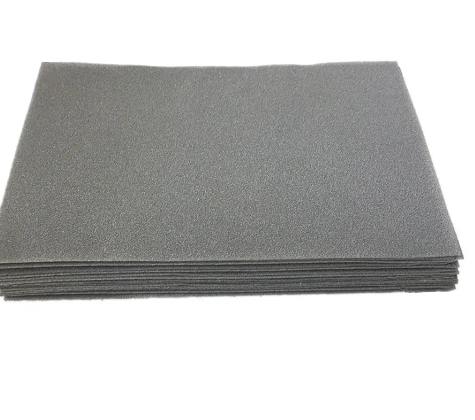

Material |

Nickel foam, Sold in sheet |

|

Dimension |

500*1000, or customized as request |

|

Thickness |

0.5mm, 1.0mm, 1.5mm, 2.0mm, etc |

|

The aperture |

80 PPI (5-80 PPI available) |

|

Porosity |

90-98% |

|

Through Hole Rate |

≥98% |

|

Bulk density |

0.15-0.45g/cm3 |

For more details, pls directly contact us.

The industrial filtration market is booming, driven by stricter environmental regulations, growing industrial output, and the need for cleaner processes. From reducing emissions in oil refineries to ensuring safe drinking water, filtration is critical. The global filtration market is expected to grow steadily, with a focus on materials that combine efficiency, durability, and sustainability.

Key industry trends include:

-

Environmental compliance: Tighter regulations on emissions and wastewater are pushing industries toward high-performance filtration.

-

Energy efficiency: Lightweight, low-pressure-drop materials like our nickel foam reduce energy costs in filtration systems.

-

Sustainability focus: Companies are seeking recyclable, long-lasting filters to minimize environmental impact.

-

Custom solutions: Industries demand tailored filtration media to handle specific contaminants or operating conditions.

-

Pharma and food safety: High-purity filtration is critical for ensuring product quality in these sectors.

Challenges remain, though. Traditional materials like stainless steel mesh or polymer filters often struggle with corrosion, heat, or clogging. They’re also less durable, requiring frequent replacements that drive up costs. Metallic foams, like our corrosion-resistant nickel foam, are stepping up as a superior alternative, offering unmatched resilience and performance.

Applications: Where Our Nickel Foam Excels

Our corrosion-resistant nickel foam is a versatile workhorse, delivering filtration solutions across a range of industries. Here’s where it’s making a difference:

-

Chemical Processing: Filters corrosive liquids like acids or solvents, protecting equipment and ensuring product purity.

-

Oil and Gas: Removes contaminants from crude oil, natural gas, or wastewater, improving efficiency and meeting environmental standards.

-

Wastewater Treatment: Captures fine particles and pollutants, enabling cleaner discharge or water reuse.

-

Pharmaceuticals: Provides sterile filtration for drug manufacturing, ensuring compliance with strict purity requirements.

-

Food and Beverage: Filters liquids or gases in processing, maintaining hygiene and quality.

-

Air Purification: Traps dust or harmful particles in industrial exhaust systems, improving air quality.

-

Marine Applications: Resists saltwater corrosion, ideal for desalination or shipboard filtration.

Its ability to handle extreme temperatures, aggressive chemicals, and fine particles makes it a go-to choice for demanding filtration tasks. Plus, its cleanability means it can be reused, cutting down on maintenance costs.

|

Parameter |

Corrosion-Resistant Nickel Foam |

Stainless Steel Mesh |

Polymer Filters |

|---|---|---|---|

|

Filtration Efficiency |

High (99% for particles >5 microns) |

Moderate (90–95% for similar sizes) |

High (varies by polymer type) |

|

Pore Size Range |

0.1–3 mm (customizable) |

0.5–5 mm (less flexible) |

0.01–1 mm (fixed) |

|

Corrosion Resistance |

Excellent (resists acids, alkalis, saltwater) |

Good (prone to pitting in chlorides) |

Poor (degrades in chemicals) |

|

Heat Resistance |

Up to 1000°C |

Up to 800°C |

Low (100–200°C max) |

|

Lifespan |

Long (5–10 years in harsh conditions) |

Moderate (2–5 years) |

Short (1–3 years) |

|

Weight |

Lightweight (7–10 mg/cm³) |

Heavier (50–100 mg/cm³) |

Lightweight (varies) |

|

Cleanability |

Excellent (reusable after cleaning) |

Good (clogs over time) |

Poor (often disposable) |

|

Recyclability |

High (fully recyclable) |

High |

Low (depends on polymer) |

When it comes to corrosion-resistant nickel foam, we’re not just in the game—we’re leading it. Here’s how we compare to a typical competitor in the industrial filtration space:

-

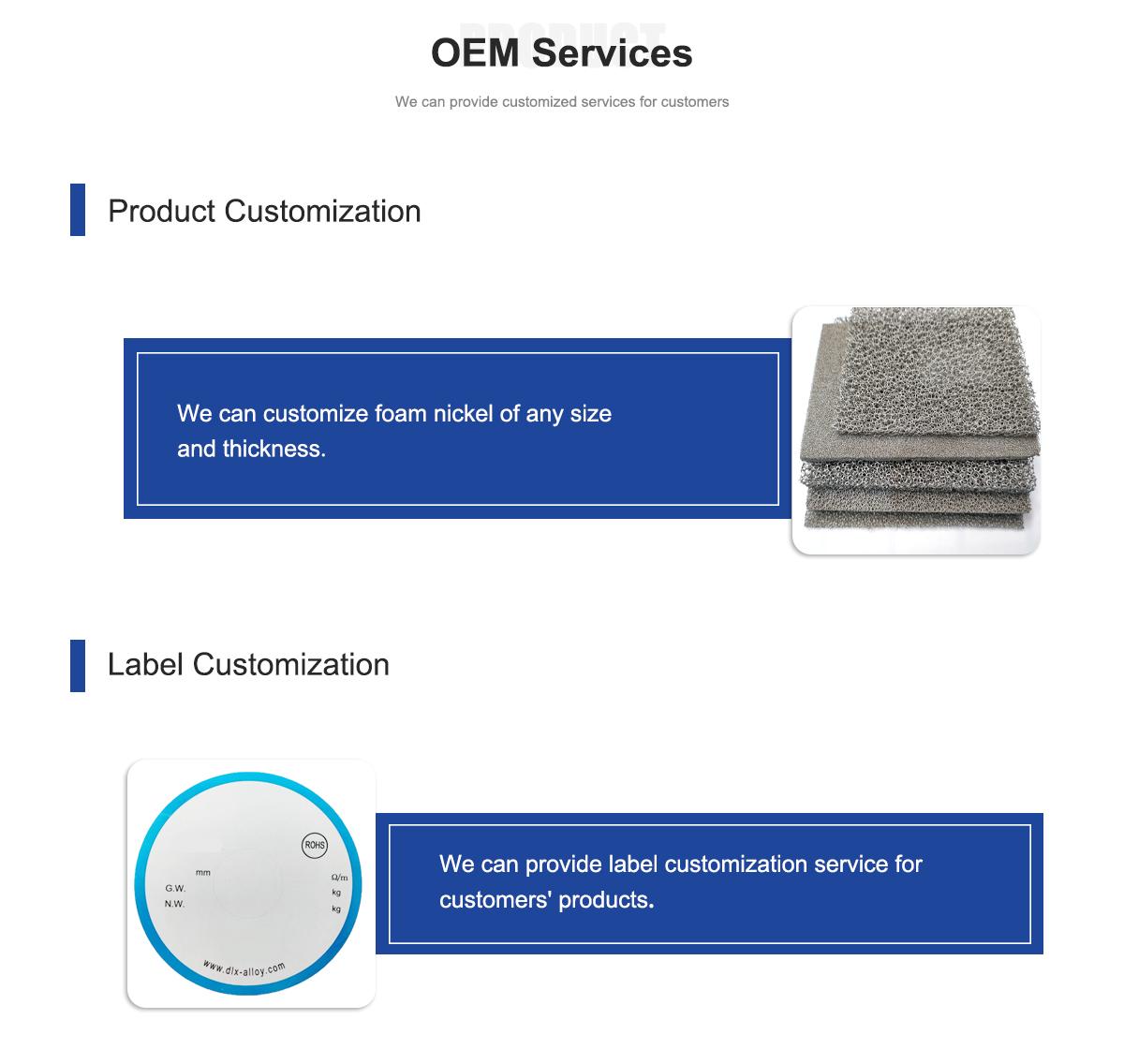

Material Quality: Our nickel foam boasts consistent porosity (92–98%) and precise pore sizes (0.1–3 mm), ensuring reliable filtration. Others often deliver uneven structures, compromising efficiency.

-

Customization: We tailor pore size, thickness, and density to your exact needs. Competitors tend to offer standard products, limiting flexibility.

-

Performance: Our foam achieves 99% filtration efficiency for particles over 5 microns and excels in corrosive or high-temperature settings. Alternative materials often fall short in extreme conditions.

-

Durability: With superior corrosion and heat resistance, our foam lasts 5–10 years, even in harsh environments. Others degrade faster, requiring frequent replacements.

-

Sustainability: Our recyclable foam and eco-friendly production align with green initiatives. Many competitors rely on less sustainable methods.

-

Support: We provide hands-on guidance, from design to integration, ensuring seamless adoption. Others may offer minimal support, leaving you to troubleshoot alone.

Our advantage stems from cutting-edge R&D, advanced manufacturing, and a commitment to customer success. We don’t just supply a product—we deliver solutions that keep your operations running smoothly.

Why Choose Our Corrosion-Resistant Nickel Foam?

Our corrosion-resistant nickel foam is more than a filter—it’s a game-changer for industrial filtration. It tackles the toughest contaminants, withstands the harshest environments, and delivers long-term value. Its lightweight, durable, and customizable design makes it ideal for industries facing complex filtration challenges. Whether you’re purifying chemicals, treating wastewater, or ensuring air quality, our product has you covered.

We’re passionate about pushing filtration technology forward. By focusing on innovation, sustainability, and customer needs, we ensure our nickel foam meets today’s demands while preparing for tomorrow’s challenges. Ready to elevate your filtration game? Our corrosion-resistant nickel foam is the way to go.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is corrosion-resistant nickel foam?

It’s a porous, lightweight material made from nickel with a high surface area, designed to resist corrosion in harsh environments while maintaining durability and conductivity. -

What industries use nickel foam for filtration?

It’s widely used in chemical processing, wastewater treatment, oil and gas, aerospace, automotive, and energy storage industries. -

How does nickel foam improve filtration?

Its open-cell structure traps particles efficiently, allows smooth fluid flow, and resists clogging, making it ideal for gas and liquid filtration. -

Why is corrosion resistance important?

It ensures the foam withstands harsh chemicals, moisture, and high temperatures, extending equipment life and reducing maintenance costs. -

What are the key applications of nickel foam?

It’s used in battery electrodes, catalyst supports, heat exchangers, hydrogen storage, and industrial filters for air, water, and chemical purification. -

How does nickel foam compare to other filtration materials?

It offers superior corrosion resistance, higher porosity, and better thermal/electrical conductivity than materials like stainless steel or polymers. -

What are the latest trends in nickel foam?

Growing demand for lightweight materials, eco-friendly production, and advancements like 3D printing for tailored pore structures are driving innovation. -

Is nickel foam environmentally friendly?

Yes, it’s recyclable, supports sustainable processes like wastewater treatment, and can be made with energy-efficient manufacturing methods.