Our customizable Nickel Foam for NiMH battery cathode substrates is a game-changer in the world of energy storage. Designed to supercharge battery performance, this lightweight, high-conductivity material is tailored to meet the demands of modern industries like electric vehicles, portable electronics, and renewable energy. Let’s break down what makes our nickel foam the go-to choice for NiMH battery manufacturers, explore its applications, dive into industry trends, and show why we’re leading the charge in this space.

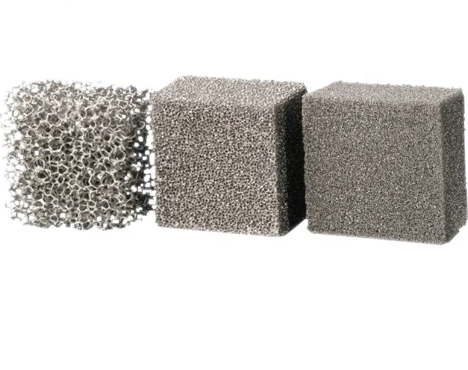

Our nickel foam is a porous, three-dimensional material made from high-purity nickel, engineered specifically for NiMH battery cathode substrates. With porosity levels reaching up to 95%, it offers a massive surface area for active material loading, boosting battery capacity and efficiency. Its open-cell structure ensures smooth electrolyte flow, while its excellent electrical and thermal conductivity reduces internal resistance and manages heat effectively. We take it a step further by offering customization—adjusting pore size, thickness, and density to match your battery’s unique needs. Whether you’re building batteries for electric cars or laptops, our foam delivers top-tier performance and durability.

What sets our product apart is its corrosion resistance. NiMH batteries operate in harsh chemical environments, and our nickel foam is built to withstand those conditions without breaking down. We use advanced electrodeposition techniques to ensure uniform pore structures and consistent quality, making our foam a reliable choice for high-performance applications.

Why Nickel Foam Matters for NiMH Batteries

NiMH batteries are a cornerstone of modern energy storage, powering everything from hybrid vehicles to renewable energy systems. The cathode substrate plays a critical role in determining battery efficiency, lifespan, and performance. Our nickel foam shines here because of its unique properties:

-

High Porosity: The open-cell structure maximizes contact between the active material and electrolyte, improving charge/discharge rates.

-

Superior Conductivity: Nickel’s excellent electrical conductivity reduces internal resistance, leading to higher energy efficiency.

-

Corrosion Resistance: It stands up to the battery’s chemical environment, ensuring long-term reliability.

-

Lightweight Design: With a density as low as 0.1 g/cm³, it keeps battery weight down, a must for EVs and portable devices.

By optimizing these factors, our nickel foam helps manufacturers create batteries that charge faster, last longer, and perform better under demanding conditions.

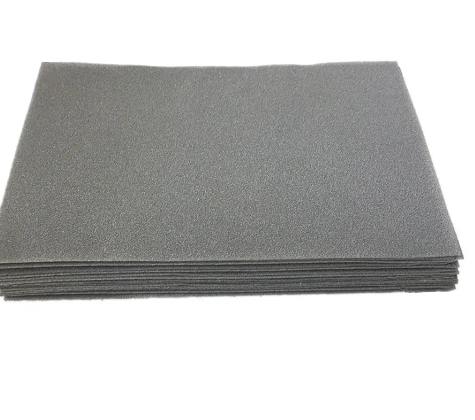

|

Material |

Nickel foam, Sold in sheet |

|

Dimension |

500*1000, or customized as request |

|

Thickness |

0.5mm, 1.0mm, 1.5mm, 2.0mm, etc |

|

The aperture |

80 PPI (5-80 PPI available) |

|

Porosity |

90-98% |

|

Through Hole Rate |

≥98% |

|

Bulk density |

0.15-0.45g/cm3 |

For more details, pls directly contact us.

The nickel foam market is booming, driven by the global shift toward clean energy and electrified transportation. Market data projects the nickel foam market to grow from $180.5 million in 2023 to $246.7 million by 2030, with a CAGR of 5.42%. The rise of electric vehicles (EVs) and hybrid electric vehicles (HEVs) is a major driver, as NiMH batteries remain a cost-effective, reliable choice for these applications. Meanwhile, the push for renewable energy storage and portable electronics is fueling demand for high-performance battery materials.

Sustainability is another key factor. Governments and industries are cracking down on waste and emissions, pushing manufacturers to adopt recyclable materials and eco-friendly production methods. Our nickel foam fits the bill—it’s fully recyclable and produced with energy-efficient processes. Plus, advancements like 3D printing and electroforming are making it easier to create customized foam structures, opening new possibilities for battery design.

The competitive landscape is heating up, too. As industries demand lighter, more efficient materials, nickel foam is outpacing alternatives like Copper Foam , carbon-based substrates, and Aluminum Foam . Its combination of conductivity, durability, and customization makes it a standout choice for next-gen batteries.

Applications: Where Our Nickel Foam Powers Up

Our customizable nickel foam is a versatile player in the NiMH battery world, with applications spanning multiple industries:

-

Electric Vehicles (EVs) and Hybrid Vehicles (HEVs): Our foam enhances cathode performance, boosting battery capacity and efficiency for longer driving ranges and faster charging.

-

Portable Electronics: From laptops to power tools, our foam enables compact, lightweight batteries with high energy density and long cycle life.

-

Renewable Energy Storage: It supports grid-scale energy storage systems, ensuring reliable performance for solar and wind power applications.

-

Aerospace: The lightweight, durable nature of our foam makes it ideal for high-performance batteries in satellites and aircraft.

-

Medical Devices: Its reliability and efficiency power portable medical equipment, where consistent performance is critical.

-

Consumer Electronics: Smartphones, tablets, and wearables benefit from our foam’s ability to create compact, high-capacity batteries.

Beyond batteries, our nickel foam can also serve as a catalyst support or heat exchanger in energy systems, showcasing its versatility across applications.

Comparison Parameters Table

|

Parameter |

Nickel Foam |

Copper Foam |

Carbon-Based Substrates |

Aluminum Foam |

|---|---|---|---|---|

|

Electrical Conductivity |

High (excellent for battery efficiency) |

High (but slightly lower than nickel) |

Moderate (higher resistance) |

Moderate (lower than nickel) |

|

Corrosion Resistance |

Excellent (resists battery electrolytes) |

Poor (prone to oxidation) |

Good (but degrades over time) |

Moderate (susceptible to some chemicals) |

|

Porosity |

High (up to 95%, customizable) |

High (but less uniform) |

Moderate (limited customization) |

Moderate (less porous than nickel) |

|

Weight |

Lightweight (0.1-1.0 g/cm³) |

Moderate (heavier than nickel) |

Lightweight (but less durable) |

Lightweight (but less porous) |

|

Mechanical Strength |

Good (maintains integrity under stress) |

Moderate (softer, less durable) |

Low (prone to cracking) |

Moderate (weaker under high stress) |

|

Thermal Conductivity |

High (effective heat dissipation) |

High (comparable to nickel) |

Low (poor heat management) |

Moderate (less effective than nickel) |

|

Recyclability |

Fully recyclable |

Recyclable (but energy-intensive) |

Limited (degrades over time) |

Recyclable (but complex process) |

|

Cost-Effectiveness |

Moderate (long lifespan, high performance) |

Low (cheaper but shorter lifespan) |

Low (frequent replacements needed) |

Moderate (higher production costs) |

The nickel foam market is evolving rapidly, and we’re keeping pace with the latest trends:

-

Electrification Boom: The surge in EVs and HEVs is driving demand for high-performance NiMH battery materials, with our foam leading the way.

-

Sustainability Focus: Eco-friendly manufacturing and recyclable materials are non-negotiable, and our foam aligns with these goals through sustainable production and recyclability.

-

Customization Demand: Advances in 3D printing and electroforming let us tailor foam structures for specific battery designs, improving performance and efficiency.

-

Lightweight Materials: Industries like automotive and aerospace are prioritizing weight reduction, and our low-density foam delivers without sacrificing strength.

-

Energy Efficiency: As batteries face higher charge/discharge demands, our foam’s low internal resistance and high conductivity keep performance high.

-

Global Regulations: Stricter environmental standards are pushing manufacturers toward materials like our nickel foam that support cleaner, greener energy solutions.

Why Choose Our Nickel Foam?

We’re not just making nickel foam—we’re redefining what it can do for NiMH batteries. Here’s why our product stands out:

-

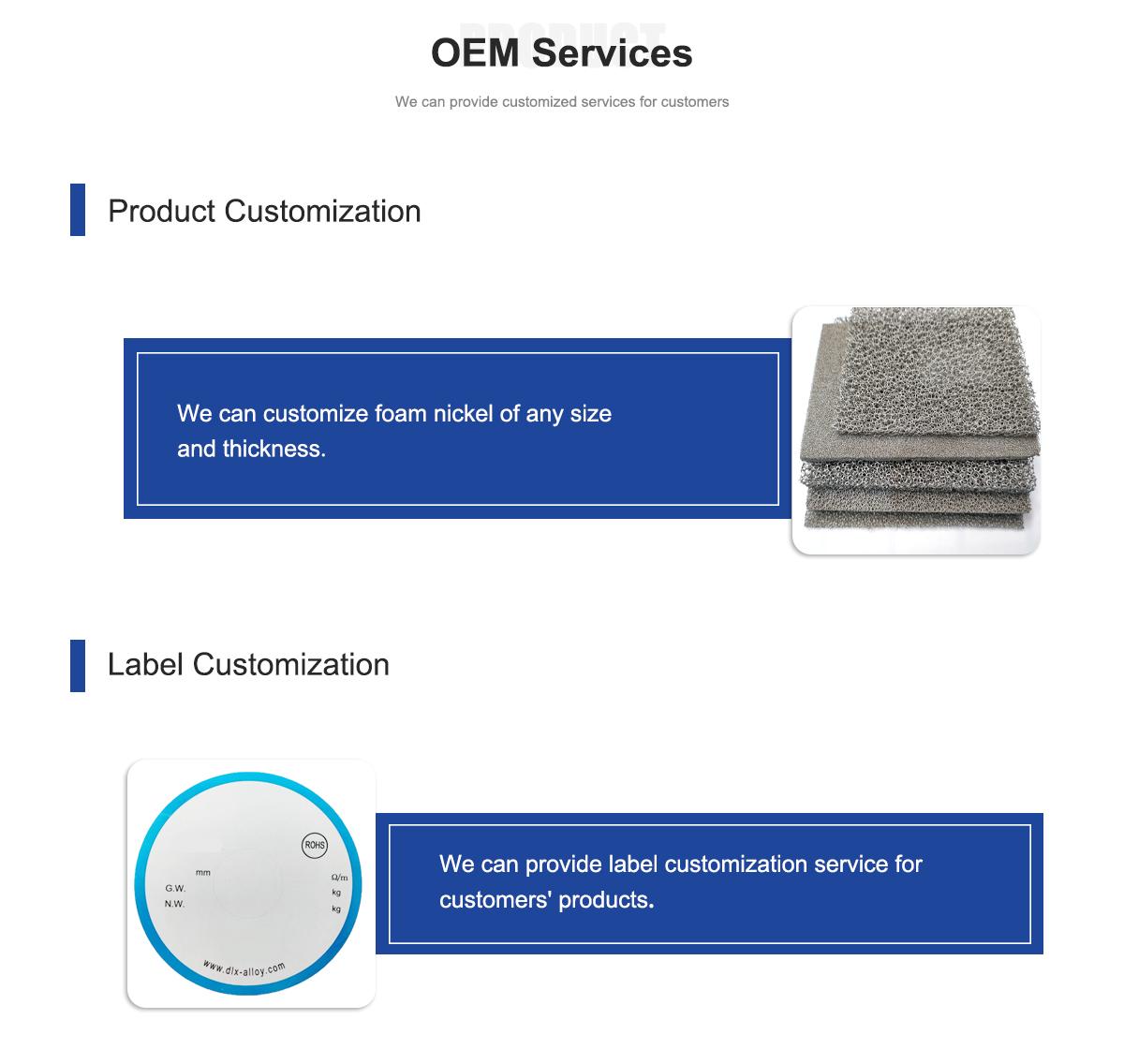

Tailored Customization: We fine-tune pore size, thickness, and density to match your battery’s exact specs, ensuring peak performance.

-

Unbeatable Conductivity: Our foam’s high electrical and thermal conductivity reduces energy loss and keeps batteries running cooler and longer.

-

Corrosion Resistance: Built to withstand harsh battery environments, our foam ensures long-lasting performance and fewer replacements.

-

Eco-Friendly Design: Fully recyclable and produced with sustainable methods, our foam supports your green initiatives.

-

Lightweight Strength: At just 0.1-1.0 g/cm³, it cuts battery weight without compromising durability, perfect for EVs and portable devices.

-

Industry Expertise: Our team works closely with you to design solutions that meet real-world challenges, from R&D to production.

A Competitive Edge: How We Stack Up

Compared to other cathode substrate materials, our nickel foam is a cut above. Copper foam, while conductive, struggles with corrosion in battery environments, leading to shorter lifespans. Carbon-based substrates are lightweight but lack the durability and conductivity needed for high-performance batteries. Aluminum foam offers decent weight savings but falls short in porosity and corrosion resistance. Our nickel foam hits the sweet spot: high conductivity, excellent corrosion resistance, customizable porosity, and lightweight design, all backed by sustainable production.

We also go the extra mile with support. From custom design consultations to post-production troubleshooting, we’re with you every step of the way. Our advanced manufacturing techniques, like electrodeposition and 3D printing, ensure consistent quality and tailored solutions that competitors can’t match.

Looking to the Future

The future of NiMH batteries—and our nickel foam—is electric. As EVs, renewable energy, and portable electronics continue to grow, the demand for high-performance, sustainable battery materials will only increase. We’re already pushing the envelope with innovations like ultra-fine pore structures for next-gen batteries and eco-friendly production methods to meet global sustainability goals. Our R&D team is constantly exploring new ways to enhance our foam’s performance, whether it’s for faster-charging EV batteries or compact energy storage systems.

Our customizable nickel foam isn’t just a product—it’s a solution for the energy challenges of tomorrow. It’s lightweight, durable, and built to power the next generation of batteries. Ready to take your NiMH batteries to the next level? Let’s talk about how our nickel foam can make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is customizable nickel foam for NiMH battery cathodes?

It’s a porous, high-conductivity nickel-based material tailored for use as a cathode substrate in NiMH batteries, offering high surface area and customizable pore structures. -

What makes nickel foam ideal for NiMH batteries?

Its high porosity and electrical conductivity maximize active material loading and improve charge/discharge efficiency, boosting battery performance. -

Which industries use this nickel foam?

It’s primarily used in electric vehicles, hybrid vehicles, portable electronics, renewable energy storage, and aerospace applications. -

How customizable is the nickel foam?

We can adjust pore size, thickness, and density to meet specific battery designs, optimizing performance for various applications. -

Why is corrosion resistance important for battery substrates?

It ensures the foam withstands the battery’s chemical environment, extending lifespan and maintaining performance under high charge/discharge cycles. -

What are the environmental benefits of nickel foam?

It’s recyclable, supports efficient battery production, and reduces waste in manufacturing processes, aligning with sustainable energy goals. -

What are the latest trends in nickel foam for batteries?

Demand is growing for lightweight, high-efficiency substrates, with innovations like 3D-printed foams and eco-friendly production methods leading the way. -

How does nickel foam improve battery performance?

Its open-cell structure enhances electrolyte flow, increases active material contact, and reduces internal resistance, leading to higher capacity and faster charging.