Our medical-grade Nitinol Tube is a superstar for precision catheter manufacturing, bringing flexibility and reliability to life-saving medical procedures. Nitinol, a nickel-titanium alloy, is renowned for its superelasticity and shape memory—meaning it can bend like crazy and snap back to its original shape without kinking. With a nickel content of 54.5-57.0% and a transformation temperature range of -25°C to 35°C, our tubing meets ASTM F2063 standards, ensuring top-notch biocompatibility for medical use. Whether it’s navigating a complex artery or supporting a neurovascular procedure, our Nitinol tube delivers performance you can trust.

For more details, pls directly contact us.

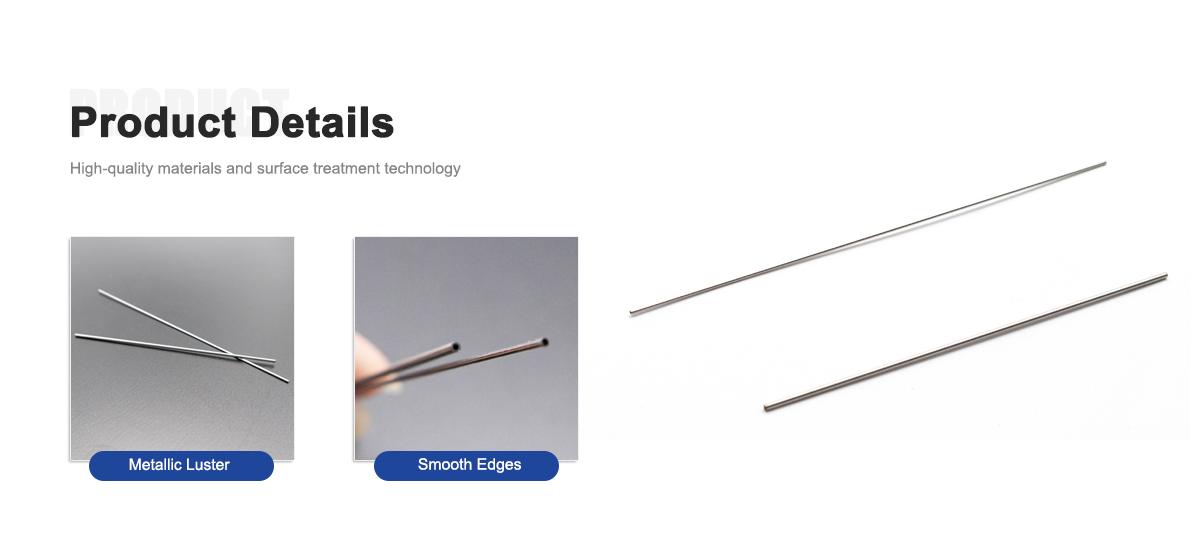

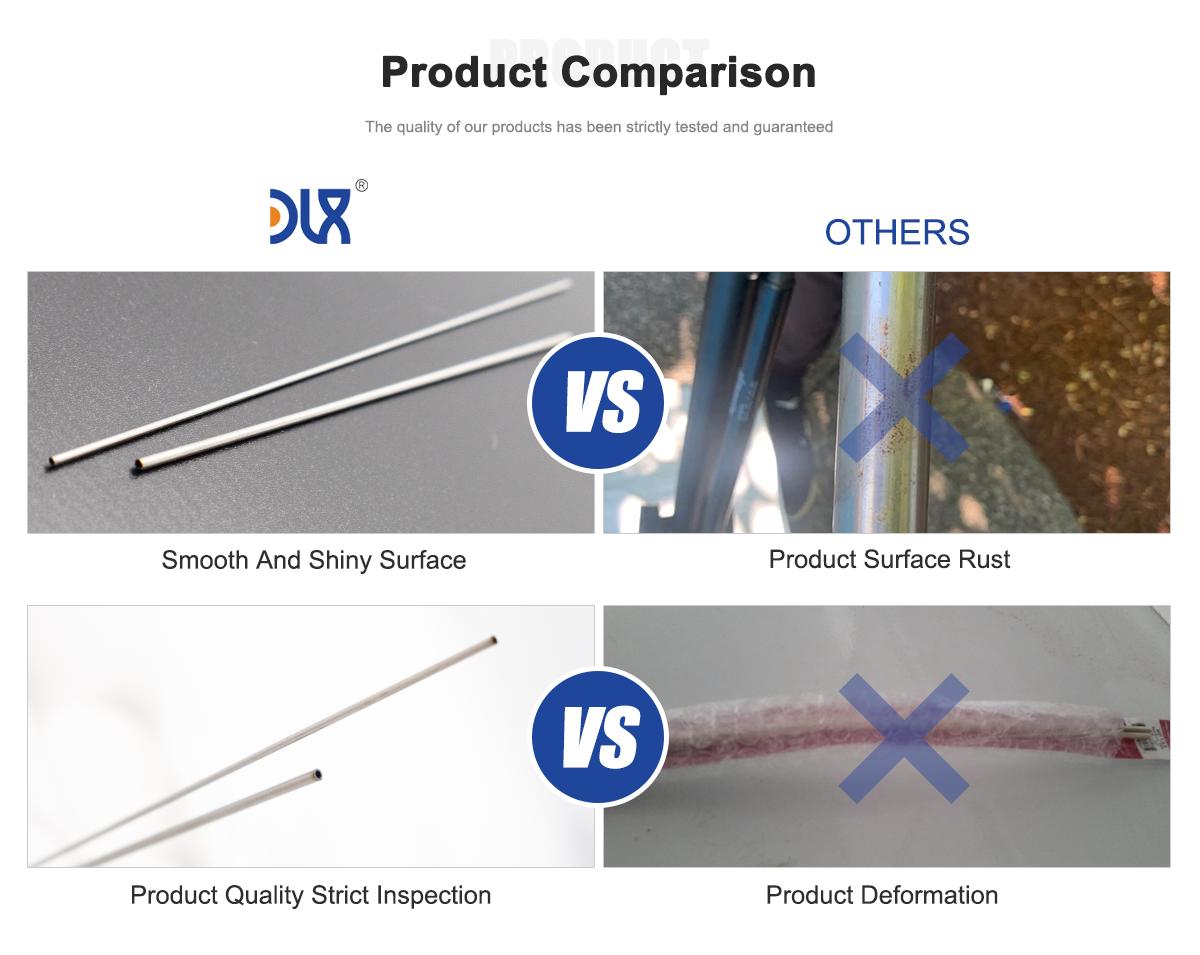

What sets our tubing apart? It’s engineered for precision and durability. With tensile strength of 1000-1400 MPa and excellent fatigue life, it’s built to handle the demands of intricate catheter designs. We’ve optimized it for cardiovascular and neurovascular catheters, where flexibility is critical. Our rigorous quality control ensures every batch is corrosion-resistant and biocompatible, with a smooth surface finish to minimize tissue irritation. When it comes to precision catheter manufacturing, our medical-grade Nitinol tube is the go-to choice for surgeons and manufacturers.

Nickel- Titanium Wire Grades and Composition Comparison

Grade | Chemical Composition (Main Elements, Balance Ti) | Transformation Temperature (Af) Range | Tensile Strength (MPa) | Elongation (%) | Main Applications |

|---|---|---|---|---|---|

NiTi-01M (Superelastic) | Ni: 54.5-57.0%, Ti: Balance | -25~35°C | 800-1100 | 10-20 | Medical orthodontic wires, root canal files, vascular stents |

NiTi-02 | Ni: 55.0-56.5%, Ti: Balance | 0~80°C | 700-1000 | 8-15 | Shape memory alloys, temperature control devices |

CuNiTi (Ternary Alloy) | Ni: 54.0-56.0%, Cu: 0.5-2.0%, Ti: Balance | -25~35°C | 850-1200 | 12-25 | Medical guidewires, sutures, staplers |

NiTiFe | Ni: 54.5-57.0%, Fe: 0.1-2.0%, Ti: Balance | -50~20°C | 900-1300 | 10-18 | Low-temperature applications, aerospace components |

NiTiCr | Ni: 54.5-57.0%, Cr: 0.1-0.5%, Ti: Balance | -20~40°C | 1000-1400 | 8-15 | High-strength medical devices, bone fixation devices |

For more details, pls directly contact us.

Our Nitinol tube is a carefully crafted blend of nickel (54.5-57.0%) and titanium, delivering the superelasticity and shape memory that make it ideal for precision catheters. The transformation temperature range (-25°C to 35°C) is tuned for body-temperature performance, ensuring the tubing flexes and recovers perfectly during procedures. Compared to stainless steel or PTFE, our Nitinol is a game-changer. Stainless steel is strong but prone to kinking, which can disrupt delicate catheter navigation. PTFE is flexible but lacks Nitinol’s strength and shape memory, critical for dynamic medical applications.

Our tubing’s corrosion resistance is exceptional, standing up to bodily fluids without degrading. Its high fatigue life ensures it can handle constant bending—think of a catheter weaving through a tortuous artery. With an elongation range of 10-20%, our tubing balances flexibility and strength, making it perfect for intricate catheter designs. We offer customization options, such as adjusting transformation temperatures or tubing dimensions, to meet specific catheter needs, all while maintaining ASTM F2063 compliance for medical safety.

Industry Analysis

The Nitinol tubing market is booming, especially for precision catheter manufacturing. In 2025, the global catheter market is growing at a CAGR of 6.8%, with Nitinol leading the charge for its unique properties. The rise of minimally invasive procedures is a big driver—patients want faster recoveries, and surgeons need catheters that can navigate complex anatomy with ease. Our medical-grade Nitinol tube is tailor-made for this, excelling in applications like cardiovascular and neurovascular catheters where precision and flexibility are critical.

Beyond medical, industries like robotics and aerospace are tapping into Nitinol’s potential, but healthcare remains the focus. Trends show a push toward smaller, more flexible catheters, with manufacturers optimizing alloys for better biocompatibility and performance. The growing prevalence of cardiovascular and neurological conditions is fueling demand for Nitinol-based catheters. Challenges like high production costs and strict regulations (like ASTM F2063) keep the market competitive, but our advanced manufacturing and rigorous testing give us a clear edge in delivering reliable Nitinol tubing.

Applications of Our Medical-Grade Nitinol Tube

Our Nitinol tubing is a powerhouse for precision catheter manufacturing, shining in a range of medical applications:

Cardiovascular Catheters: Its superelasticity ensures kink-free navigation through coronary arteries, improving procedural accuracy.

Neurovascular Catheters: The tubing’s flexibility supports precise navigation in delicate brain vessels, minimizing risks.

Guidewires: Its shape memory enables guidewires to maneuver through complex anatomy, enhancing catheter delivery.

Diagnostic Catheters: The tubing’s durability powers tools for imaging and diagnostics, ensuring reliable performance.

Interventional Catheters: Its flexibility supports minimally invasive treatments, reducing patient recovery time.

These applications highlight why our Nitinol tubing is a top choice for catheters that demand precision and reliability.

Company Comparison

When it comes to medical-grade Nitinol tubing for precision catheter manufacturing, we’re setting the standard. Our tubing is crafted with precision, from tightly controlled nickel content to a smooth surface finish that minimizes tissue irritation. We invest heavily in R&D to optimize superelasticity, tensile strength, and biocompatibility, ensuring our tubing meets the demands of catheter applications. Our advanced testing for corrosion resistance and fatigue life guarantees performance in the body’s toughest conditions.

Our supply chain is a major strength. We’ve streamlined production to deliver Nitinol tubing quickly, whether it’s a small batch for prototyping or a large order for global manufacturers. Our team works closely with clients to customize tubing specs, like adjusting transformation temperatures or wall thickness for specific catheters. With state-of-the-art manufacturing, we achieve tighter tolerances than industry standards, reducing risks and ensuring reliability. This blend of innovation, speed, and quality makes us the top choice for catheter manufacturers.

Comparison Table of Nitinol Tube Parameters

Parameter | Our Nitinol Tube (ASTM F2063) | Stainless Steel | PTFE |

|---|---|---|---|

Nickel Content | 54.5-57.0% | 0% | 0% |

Transformation Temp (Af) | -25~35°C | N/A | N/A |

Tensile Strength (MPa) | 1000-1400 | 500-1000 | 20-40 |

Elongation (%) | 10-20 | 15-40 | 200-400 |

Superelasticity | Yes | No | No |

Shape Memory | Yes | No | No |

Corrosion Resistance | Excellent | Good | Excellent |

Biocompatibility | High (ASTM F2063 compliant) | Moderate | High |

Applications | Catheters, guidewires | Surgical tools | Catheter linings |

Our Nitinol tubing is built for precision and trust. Here’s why it’s the best pick for catheter manufacturing:

Unmatched Flexibility: Our tubing’s superelasticity ensures kink-free navigation in complex catheter applications.

Top-Tier Quality: Every batch meets ASTM F2063 standards, with rigorous testing for biocompatibility and corrosion resistance.

Customizable: We tailor transformation temperatures and tubing dimensions to fit your specific catheter needs.

Fast Delivery: Our optimized supply chain delivers high-quality Nitinol tubing on time, every time.

Expert Support: Our material scientists and engineers are here to collaborate, ensuring your catheters exceed expectations.

Future Trends and Our Commitment

The Nitinol tubing market is evolving, and we’re leading the way. Advances in micro-alloy technology could enhance our tubing’s properties, like improving flexibility for smaller catheters. The rise of minimally invasive procedures and robotic-assisted surgeries is driving demand for precise, biocompatible materials, and our Nitinol tubing is ready to meet those needs. We’re investing in next-gen manufacturing to stay ahead, exploring ways to optimize performance while keeping costs competitive.

Sustainability is a priority too. We’re reducing our environmental footprint through energy-efficient production and Nitinol recycling programs. As healthcare demands greener solutions and regulations tighten, we’re committed to delivering eco-friendly, high-performance materials. Our goal is to keep pushing the limits of what Nitinol can do, ensuring our tubing remains the top choice for precision catheter innovation.

Conclusion

Our medical-grade Nitinol tube is transforming precision catheter manufacturing, delivering unmatched flexibility and reliability for minimally invasive procedures. Its superelasticity, shape memory, and biocompatibility make it the ideal choice for cardiovascular and neurovascular applications. With a booming market and trends favoring precision solutions, our tubing is built for the future. By choosing us, you’re getting more than a product—you’re partnering with a company dedicated to innovation, quality, and your success. Let’s create catheters that save lives together.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is medical-grade Nitinol tube for precision catheter manufacturing?

Our medical-grade Nitinol tube is a nickel-titanium alloy designed for precision catheters, offering superelasticity and biocompatibility for medical applications.How does superelasticity benefit catheter manufacturing?

It allows our tubing to bend without kinking and recover its shape, ensuring precise navigation in complex vascular systems.What are the main applications of our Nitinol tube?

It’s used in cardiovascular catheters, neurovascular catheters, and guidewires, leveraging its flexibility and durability.Is our Nitinol tube safe for medical use?

Yes, it meets ASTM F2063 standards, ensuring biocompatibility and safety for medical applications.How does our Nitinol tube compare to other materials?

Unlike stainless steel or PTFE, our Nitinol offers superior superelasticity and shape memory, ideal for precision catheters.Which industries use our medical-grade Nitinol tube?

Primarily medical for catheters, but also robotics and aerospace for flexible components.What are the market trends for Nitinol tubing in catheters?

Growing demand for minimally invasive procedures, advancements in alloy flexibility, and increased use in neurovascular applications drive market growth.How does our Nitinol tube perform in complex procedures?

Its superelasticity ensures kink-free navigation and reliable performance in precision catheter applications.