We’re proud to offer our ASTM F2063-compliant Nitinol Wire , a game-changer in the world of surgical implants. Nitinol, a nickel-titanium alloy, stands out for its incredible superelasticity and shape memory properties. This means it can bend, twist, and return to its original shape without breaking or deforming—perfect for the demanding environment of the human body. Our Nitinol wire is meticulously engineered to meet ASTM F2063 standards, ensuring top-notch quality, safety, and performance for medical applications. With nickel content tightly controlled between 54.5-57.0% and transformation temperatures tailored between -25°C and 35°C, our wire delivers the reliability surgeons and patients depend on.

What sets our product apart? It’s the combination of high tensile strength (1000-1400 MPa), excellent corrosion resistance, and a fatigue life that outlasts the competition. Whether it’s navigating the twists of a blood vessel or supporting a fractured bone, our Nitinol wire performs with precision. We’ve optimized it for applications like vascular stents, orthopedic implants, and dental braces, where flexibility and durability are non-negotiable. Plus, our rigorous quality control ensures every batch meets the strict biocompatibility requirements of ASTM F2063, making it a trusted choice for medical professionals worldwide.

For more details, pls directly contact us.

Nitinol’s magic lies in its unique composition. Made primarily of nickel and titanium, with trace elements like iron or chromium in some variants, our Nitinol wire strikes a perfect balance. The nickel content (54.5-57.0%) ensures superelasticity at body temperature, critical for implants that need to flex without breaking. The transformation temperature (Af) range of -25°C to 35°C is carefully tuned to activate shape memory or superelasticity in surgical environments. Compared to traditional materials like stainless steel or pure titanium, Nitinol offers unmatched advantages. Stainless steel, while strong, lacks shape memory and can be too rigid for minimally invasive procedures. Pure titanium is biocompatible but doesn’t match Nitinol’s flexibility or fatigue resistance.

Our Nitinol wire also excels in corrosion resistance, a must for implants exposed to bodily fluids. Its high fatigue life means it can endure millions of cycles without failure—think of a stent expanding and contracting with every heartbeat. We’ve also fine-tuned the elongation (10-20%) to balance flexibility and strength, ensuring our wire can handle the stresses of surgical applications without compromising performance.

Nickel- Titanium Wire Grades and Composition Comparison

Grade | Chemical Composition (Main Elements, Balance Ti) | Transformation Temperature (Af) Range | Tensile Strength (MPa) | Elongation (%) | Main Applications |

|---|---|---|---|---|---|

NiTi-01M (Superelastic) | Ni: 54.5-57.0%, Ti: Balance | -25~35°C | 800-1100 | 10-20 | Medical orthodontic wires, root canal files, vascular stents |

NiTi-02 | Ni: 55.0-56.5%, Ti: Balance | 0~80°C | 700-1000 | 8-15 | Shape memory alloys, temperature control devices |

CuNiTi (Ternary Alloy) | Ni: 54.0-56.0%, Cu: 0.5-2.0%, Ti: Balance | -25~35°C | 850-1200 | 12-25 | Medical guidewires, sutures, staplers |

NiTiFe | Ni: 54.5-57.0%, Fe: 0.1-2.0%, Ti: Balance | -50~20°C | 900-1300 | 10-18 | Low-temperature applications, aerospace components |

NiTiCr | Ni: 54.5-57.0%, Cr: 0.1-0.5%, Ti: Balance | -20~40°C | 1000-1400 | 8-15 | High-strength medical devices, bone fixation devices |

For more details, pls directly contact us.

The Nitinol wire market is booming, driven by the rise of minimally invasive surgeries and advancements in medical technology. In 2025, the global medical device market is projected to grow at a CAGR of 5.4%, with Nitinol playing a starring role due to its unique properties. Surgeons are increasingly opting for Nitinol-based implants because they allow smaller incisions, faster recovery times, and fewer complications. The demand for vascular stents, for example, is skyrocketing as cardiovascular diseases remain a leading health concern. Orthopedic applications, like bone fixation devices, are also on the rise, fueled by an aging population and increasing sports injuries.

Beyond medical, industries like aerospace and robotics are tapping into Nitinol’s potential for actuators and sensors, but healthcare remains the dominant force. A key trend is customization—manufacturers are tailoring Nitinol’s transformation temperatures and mechanical properties to specific procedures. Robotic-assisted surgeries are another growth area, with Nitinol guidewires enabling precise navigation in complex operations. However, challenges like high production costs and stringent regulatory requirements (like ASTM F2063) mean only top-tier manufacturers can compete. That’s where we shine, delivering consistent quality at scale.

Applications of Our Nitinol Wire

Our ASTM F2063-compliant Nitinol wire is a versatile workhorse in surgical implants. Here’s where it makes a difference:

Vascular Stents: Our wire’s superelasticity allows stents to collapse for delivery through a catheter and expand perfectly inside a blood vessel. This minimizes trauma and speeds up recovery.

Orthopedic Implants: From bone plates to spinal fixation devices, our Nitinol wire provides the strength and flexibility needed to support healing bones without restricting movement.

Dental Braces: The shape memory effect ensures consistent pressure on teeth, making orthodontic treatments more effective and comfortable.

Guidewires: Surgeons rely on our Nitinol wire for its kink resistance and precise control, essential for navigating delicate vascular or neurological pathways.

Sutures and Staplers: The wire’s ability to return to a preset shape makes it ideal for self-closing sutures and minimally invasive stapling devices.

These applications highlight why Nitinol is the go-to material for next-generation medical devices. Its ability to adapt to the body’s dynamic environment sets it apart from traditional materials.

Comparison Table of Nitinol Wire Parameters

Parameter | Our Nitinol Wire (ASTM F2063) | Stainless Steel | Pure Titanium |

|---|---|---|---|

Nickel Content | 54.5-57.0% | 0% | 0% |

Transformation Temp (Af) | -25~35°C | N/A | N/A |

Tensile Strength (MPa) | 1000-1400 | 500-1000 | 240-550 |

Elongation (%) | 10-20 | 15-40 | 20-30 |

Superelasticity | Yes | No | No |

Shape Memory | Yes | No | No |

Corrosion Resistance | Excellent | Good | Excellent |

Biocompatibility | High (ASTM F2063 compliant) | Moderate | High |

Applications | Stents, guidewires, orthopedic implants | Screws, plates | Bone implants |

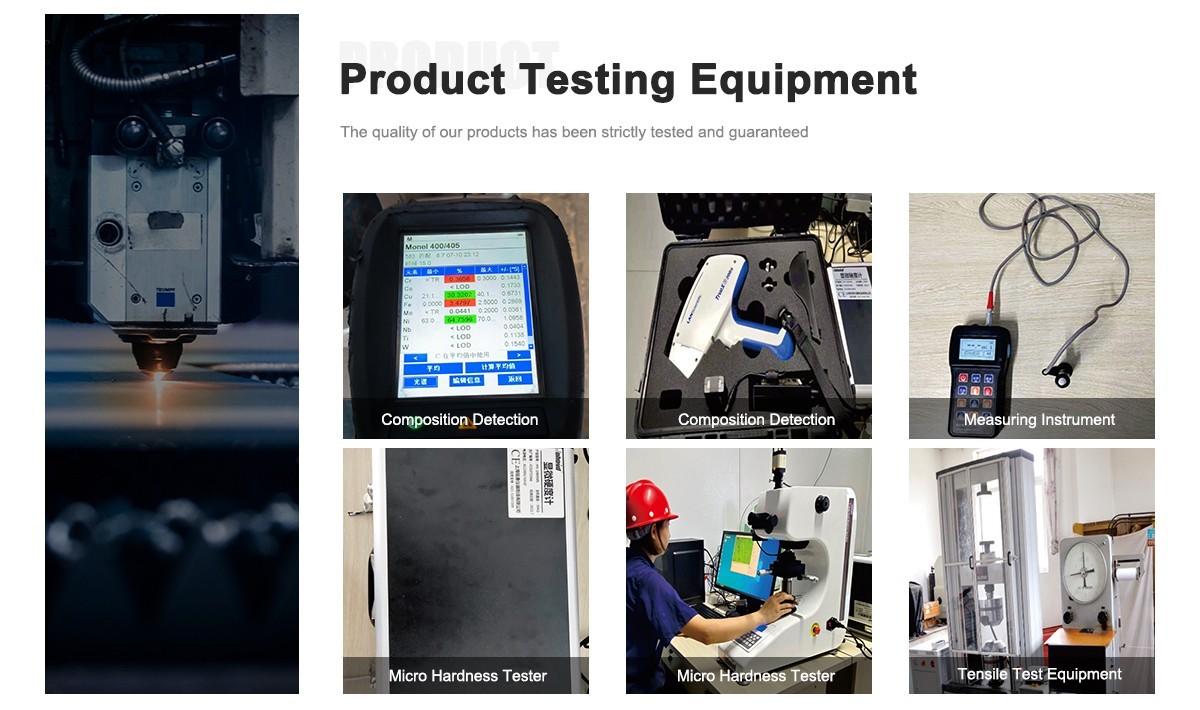

When it comes to Nitinol wire, we’re in a league of our own. While other manufacturers produce quality Nitinol, our ASTM F2063-compliant wire stands out for its precision and reliability. We invest heavily in R&D to fine-tune transformation temperatures and mechanical properties, ensuring our wire meets the exact needs of surgeons. Our production process uses state-of-the-art equipment to achieve tighter tolerances on nickel content and surface finish, reducing the risk of implant failure. Unlike competitors, we prioritize biocompatibility testing beyond ASTM standards, giving medical professionals peace of mind.

Our supply chain is another advantage. We’ve streamlined operations to deliver Nitinol wire faster without compromising quality, which is critical for medical device manufacturers facing tight deadlines. Plus, our customer support team works closely with clients to customize wire specifications, whether it’s adjusting the Af temperature or enhancing fatigue resistance for a specific implant. We also offer scalable production, from small batches for prototyping to high-volume orders for global distributors. This flexibility, combined with our unwavering commitment to quality, makes us the preferred partner for medical device innovators.

Why Choose Our Nitinol Wire?

Our Nitinol wire isn’t just a product—it’s a solution. Here’s why it’s the best choice for surgical implants:

Unmatched Quality: Every batch meets ASTM F2063 standards, with rigorous testing for biocompatibility, corrosion resistance, and mechanical performance.

Customization: We tailor transformation temperatures, tensile strength, and elongation to match your specific application, from stents to orthopedic devices.

Reliability: Our wire’s high fatigue life ensures implants perform flawlessly over millions of cycles, critical for long-term patient outcomes.

Fast Delivery: Our optimized supply chain means you get high-quality Nitinol wire when you need it, without delays.

Expert Support: Our team of material scientists and engineers is ready to collaborate, ensuring your implants meet the highest standards.

Future Trends and Our Commitment

Looking ahead, the Nitinol wire market is set to evolve. Advances in 3D printing and nanotechnology could unlock new ways to enhance Nitinol’s properties, like improving its radiopacity for better imaging during surgery. The rise of robotic-assisted procedures will also drive demand for ultra-precise guidewires, an area where our Nitinol excels. We’re already exploring these frontiers, investing in cutting-edge manufacturing techniques to stay ahead of the curve.

Sustainability is another focus. We’re working to reduce the environmental impact of our production processes, from energy-efficient smelting to recycling scrap Nitinol. This aligns with the healthcare industry’s growing emphasis on eco-friendly practices. As regulations tighten and patient expectations rise, our commitment to innovation and quality ensures we’ll remain a leader in the Nitinol wire market.

Conclusion

Our ASTM F2063-compliant Nitinol wire is more than just a material—it’s a cornerstone of modern surgical implants. Its superelasticity, shape memory, and biocompatibility make it indispensable for everything from stents to dental braces. With a booming medical device market and trends favoring minimally invasive solutions, our Nitinol wire is perfectly positioned to meet the needs of today and tomorrow. By choosing our product, you’re not just getting high-quality Nitinol—you’re partnering with a company dedicated to precision, reliability, and innovation. Let’s shape the future of healthcare together.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Nitinol wire, and why is it used in surgical implants?

Nitinol wire is a nickel-titanium alloy known for its superelasticity and shape memory, ideal for surgical implants like stents and guidewires due to its flexibility, strength, and biocompatibility.What does ASTM F2063 compliance mean for Nitinol wire?

ASTM F2063 ensures the Nitinol wire meets strict standards for chemical composition, mechanical properties, and biocompatibility, guaranteeing safety and performance in medical applications.What are the key applications of Nitinol wire in surgery?

It’s used in vascular stents, orthopedic implants, dental braces, and guidewires, leveraging its ability to return to a preset shape and withstand repeated deformation.How does Nitinol’s superelasticity benefit surgical procedures?

Superelasticity allows Nitinol to bend without permanent deformation, enabling minimally invasive procedures with precise control and reduced patient trauma.What industries benefit from ASTM F2063 Nitinol wire?

Primarily medical and healthcare, but also aerospace and robotics, where shape memory and durability are critical.What are the material advantages of our Nitinol wire?

Our Nitinol wire offers superior corrosion resistance, high fatigue life, and precise transformation temperatures, optimized for surgical reliability.How does Nitinol wire compare to other materials for implants?

Compared to stainless steel or titanium, Nitinol provides unique shape memory and superelasticity, allowing for smaller, more flexible implants.What are the current trends in the Nitinol wire market?

Growing demand for minimally invasive surgeries, advancements in alloy customization, and increasing use in robotic-assisted procedures are driving market growth.