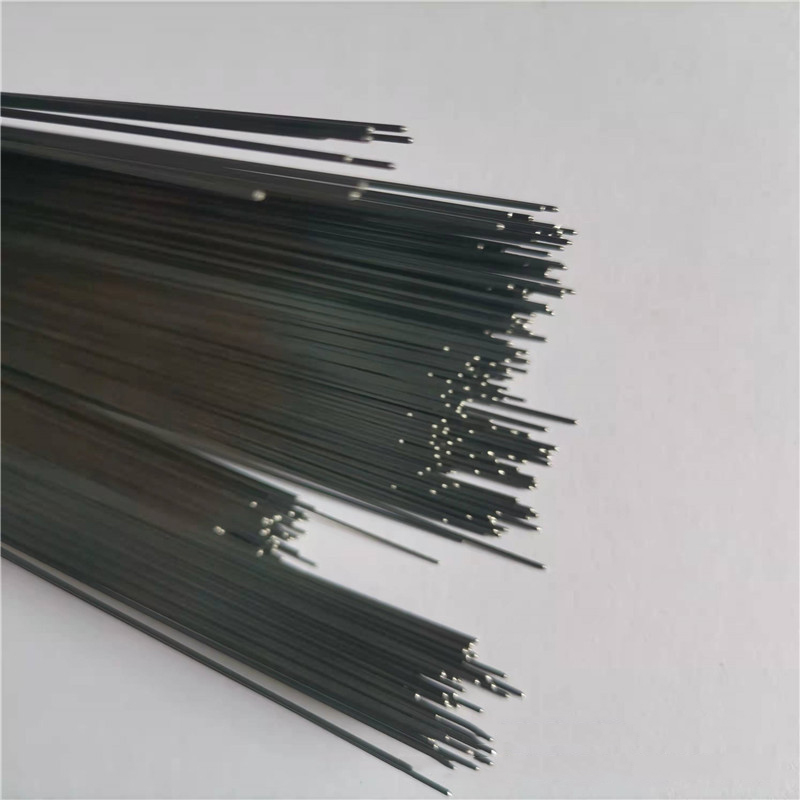

Our TiNi Alloy Spring Wire, crafted from high-quality nickel-titanium (NiTi) alloy, is a top-tier choice for biomedical devices, delivering an unbeatable mix of shape memory, superelasticity, and biocompatibility. Typically made with a 50:50 or 55:45 Ni:Ti ratio, this wire meets stringent ASTM F2063 standards, ensuring it’s safe and reliable for medical applications. Its unique shape memory allows it to return to its original shape after deformation, while its superelasticity provides flexibility for dynamic applications. Plus, its corrosion resistance and biocompatibility make it ideal for long-term use in the body.

This wire is built for high-stakes biomedical environments, from vascular stents to orthodontic wires, where precision and durability are critical. Available in various grades with tailored transformation temperatures and mechanical properties, it’s versatile enough to meet diverse medical needs. Whether you’re designing a heart stent or a dental archwire, our TiNi alloy spring wire delivers consistent, high-quality performance that manufacturers and clinicians can trust.

For more details, pls directly contact us.

The biomedical device industry is booming, driven by an aging population, rising demand for minimally invasive procedures, and advancements in medical technology. The global market for NiTi-based medical devices is projected to grow steadily through 2035, with strong demand in North America, Europe, and Asia-Pacific. Factors like increasing cardiovascular diseases, dental corrections, and orthopedic conditions are fueling the need for biocompatible, flexible materials like our TiNi alloy spring wire.

Key trends include the rise of minimally invasive devices, where NiTi’s superelasticity enables smaller, more precise tools. Personalized medical devices are gaining traction, with advanced manufacturing techniques like laser cutting and 3D printing allowing custom NiTi components. Sustainability is a focus, with healthcare providers prioritizing durable devices to reduce replacements and environmental impact. Innovations like bioresorbable coatings and AI-driven alloy optimization are enhancing device performance, while strict regulatory standards ensure patient safety and compliance.

Supply chain reliability is critical, as delays can disrupt manufacturing and clinical schedules. Our TiNi alloy spring wire is backed by a robust global supply chain, ensuring fast delivery and consistent quality. The industry’s push for high-performance, cost-effective materials aligns perfectly with our wire’s biocompatibility, shape memory, and durability, making it a top choice for biomedical applications.

|

Grade |

Chemical Composition (Main Elements, Balance Ti) |

Transformation Temperature (Af) Range |

Tensile Strength (MPa) |

Elongation (%) |

Main Applications |

|---|---|---|---|---|---|

|

NiTi-01M (Superelastic) |

Ni: 54.5-57.0%, Ti: Balance |

-25~35°C |

800-1100 |

10-20 |

Medical orthodontic wires, root canal files, vascular stents |

|

NiTi-02 |

Ni: 55.0-56.5%, Ti: Balance |

0~80°C |

700-1000 |

8-15 |

Shape memory alloys, temperature control devices |

|

CuNiTi (Ternary Alloy) |

Ni: 54.0-56.0%, Cu: 0.5-2.0%, Ti: Balance |

-25~35°C |

850-1200 |

12-25 |

Medical guidewires, sutures, staplers |

|

NiTiFe |

Ni: 54.5-57.0%, Fe: 0.1-2.0%, Ti: Balance |

-50~20°C |

900-1300 |

10-18 |

Low-temperature applications, aerospace components |

|

NiTiCr |

Ni: 54.5-57.0%, Cr: 0.1-0.5%, Ti: Balance |

-20~40°C |

1000-1400 |

8-15 |

High-strength medical devices, bone fixation devices |

For more details, pls directly contact us.

Our TiNi Alloy Spring Wire is versatile and built for a range of biomedical applications where shape memory and superelasticity are key. Here’s where it excels:

-

Vascular Devices: Used in stents and guidewires for cardiovascular procedures, leveraging superelasticity for flexibility.

-

Orthodontic Applications: Ideal for archwires and braces, providing gentle, continuous force for tooth alignment.

-

Orthopedic Devices: Supports flexible implants like bone staples and spinal correction wires.

-

Neurovascular Devices: Employed in coils and stents for treating aneurysms and neurovascular conditions.

-

Endoscopy Tools: Applied in flexible endoscopic wires for minimally invasive surgeries.

-

Surgical Instruments: Supports shape-memory tools for precise, minimally invasive procedures.

-

Dental Retainers: Used in retainers that maintain tooth position with flexibility and durability.

-

Implantable Sensors: Employed in biocompatible sensors for monitoring physiological conditions.

Its shape memory and superelasticity make our wire ideal for devices requiring precision and resilience. From vascular stents to orthodontic wires, it delivers reliable performance in demanding biomedical environments.

|

Parameter |

Our TiNi Alloy Spring Wire |

Competitor’s Product |

|---|---|---|

|

Biocompatibility |

Exceptional, ideal for long-term implants |

Good, but less consistent in bodily fluids |

|

Shape Memory |

Precise, reliable shape recovery |

Moderate, less consistent recovery |

|

Superelasticity |

High elasticity for flexible applications |

Moderate elasticity, limited flexibility |

|

Corrosion Resistance |

Outstanding resistance to bodily fluids |

Moderate resistance, some degradation risk |

|

Purity and Cleanliness |

High-purity, minimal impurities for safe use |

Standard purity, some risk of imperfections |

|

Machinability |

Easy to process and customize for devices |

More difficult, less adaptable in production |

|

Certifications |

Fully compliant with ASTM F2063, ISO 5832-1 |

Meets basic standards, limited certifications |

|

Fatigue Resistance |

Excellent, withstands repeated stress cycles |

Moderate, higher risk of fatigue failure |

Our wire’s high purity and optimized Ni:Ti ratio deliver unmatched biocompatibility and shape memory, making it ideal for critical biomedical devices. Its ease of processing and superior fatigue resistance ensure reliable performance in demanding applications.

Our TiNi Alloy Spring Wire is the result of decades of expertise and cutting-edge manufacturing. We’ve honed our process to produce wire with consistent composition and mechanical properties, ensuring top-notch performance in every device. Its high purity minimizes impurities, reducing complications and ensuring safe, long-term use in the body, making it perfect for stents, orthodontic wires, and more.

Versatility is a major strength. Available in grades with tailored transformation temperatures and mechanical properties, our TiNi wire meets diverse biomedical needs, from superelastic stents to shape-memory orthopedic devices. It’s easy to process and customize, giving manufacturers flexibility to create precise, patient-specific solutions. Its durability and fatigue resistance ensure devices perform reliably over time.

We back our product with unmatched customer support. From material selection guidance to on-call technical expertise, we help manufacturers and clinicians optimize outcomes. Our global supply chain delivers fast, reliable shipments, so you’re never stuck waiting for critical materials. Sustainability is a priority—our wire’s durability reduces the need for device replacements, cutting costs and environmental impact. Whether you’re designing a vascular stent or an orthodontic archwire, our TiNi alloy spring wire delivers the reliability you need for successful biomedical outcomes.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is TiNi Alloy Spring Wire used for?

It’s used for stents, orthodontic wires, and orthopedic implants, leveraging shape memory and superelasticity. -

What makes our TiNi wire stand out?

Its high purity, precise shape memory, and superelasticity ensure reliable, long-lasting devices. -

Which grades are available?

We offer various NiTi grades with tailored transformation temperatures for specific applications. -

What industries benefit from our wire?

Cardiovascular, orthodontic, orthopedic, and neurovascular sectors rely on its flexibility and durability. -

How does it perform in the body?

It resists corrosion from bodily fluids and is biocompatible for safe, long-term use. -

Is it suitable for long-term implants?

Yes, it’s designed for decades of performance with minimal degradation. -

Can it be customized for specific devices?

Yes, it’s easy to process and tailor for patient-specific medical devices. -

Is it MRI-safe?

Yes, its non-ferromagnetic properties make it safe for MRI and NMRI scans.

Why Choose Our TiNi Alloy Spring Wire?

Our TiNi Alloy Spring Wire is built for the toughest challenges in biomedical applications. Its exceptional biocompatibility, shape memory, and superelasticity make it a top choice for vascular stents, orthodontic wires, and orthopedic implants. With reliable performance and long-lasting durability, it helps improve patient outcomes and reduces the need for device replacements. Backed by our commitment to quality, innovation, and customer support, our wire delivers the performance you need for high-stakes biomedical procedures. Trust us to provide the NiTi solution that powers successful outcomes in demanding healthcare environments.