Our N4/Ni201 and N6/Ni200 nickel plates are high-purity materials (99.6%-99.9%) engineered for high-temperature industrial applications where performance is critical. N4/Ni201, with its ultra-low carbon content (≤0.02%), offers superior corrosion resistance in extreme environments, while N6/Ni200 (≤0.15% carbon) provides excellent durability for a wide range of uses. Both meet ASTM B162 and ASME SB161 standards, ensuring top-tier quality and reliability.

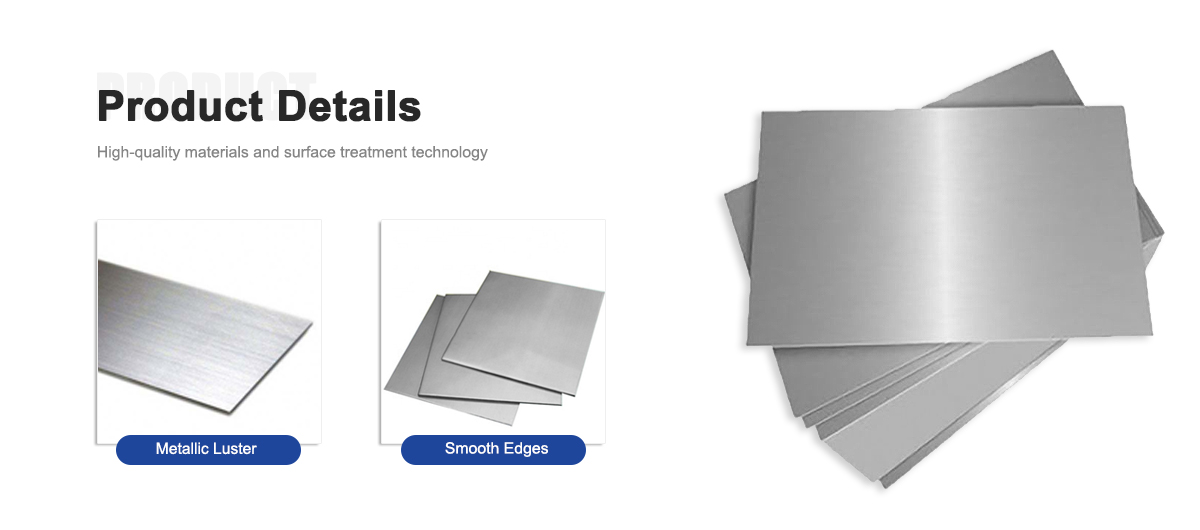

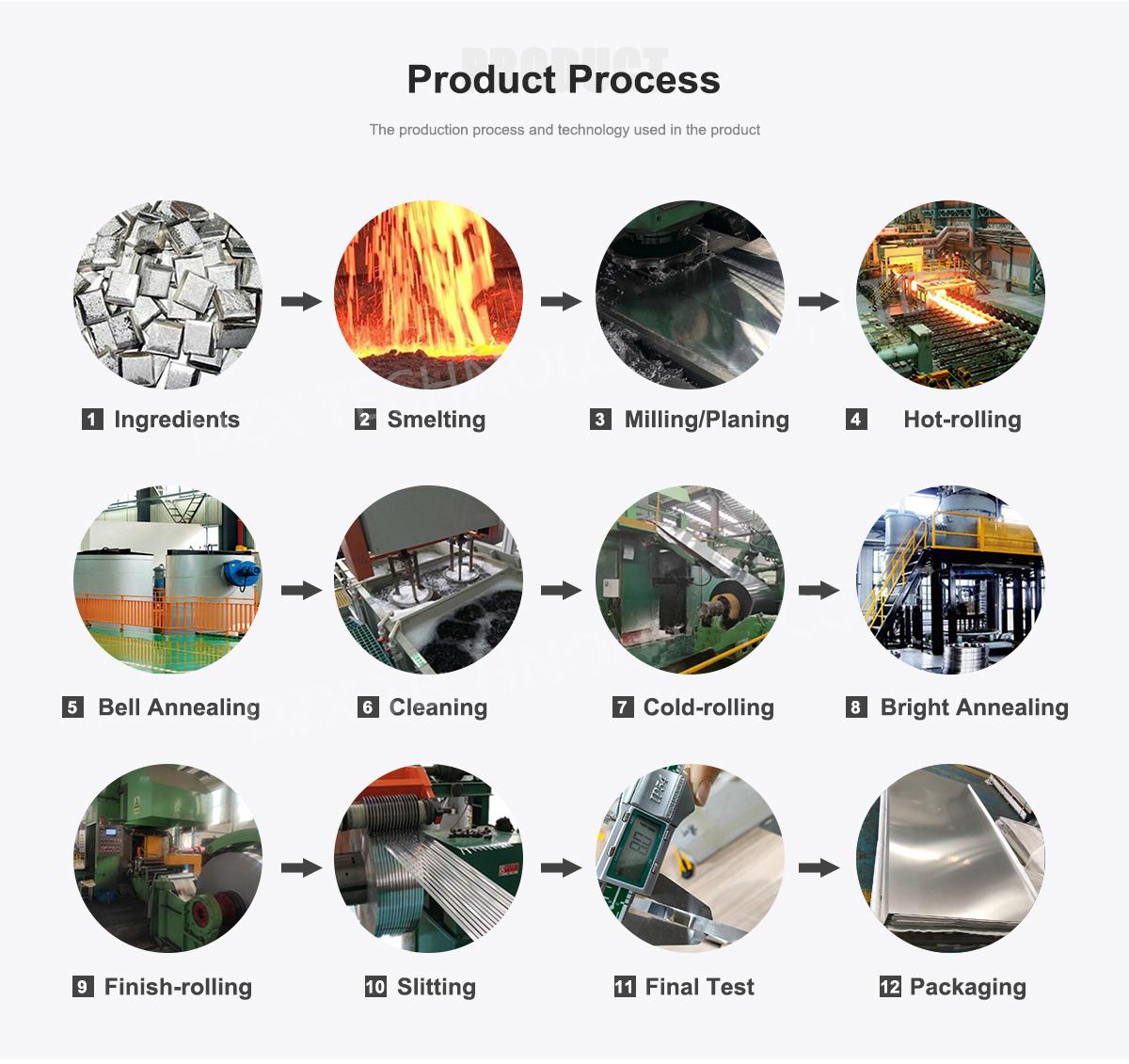

We offer customizable options, with thicknesses from 0.5mm to 50mm and sizes up to 2000mm x 1000mm, available in polished or pickled finishes to fit your project’s needs. Using advanced manufacturing processes like powder metallurgy, hot rolling, and precise annealing, we produce plates with uniform strength and purity. From chemical reactors to aerospace components, our nickel plates are built to deliver in the toughest conditions.

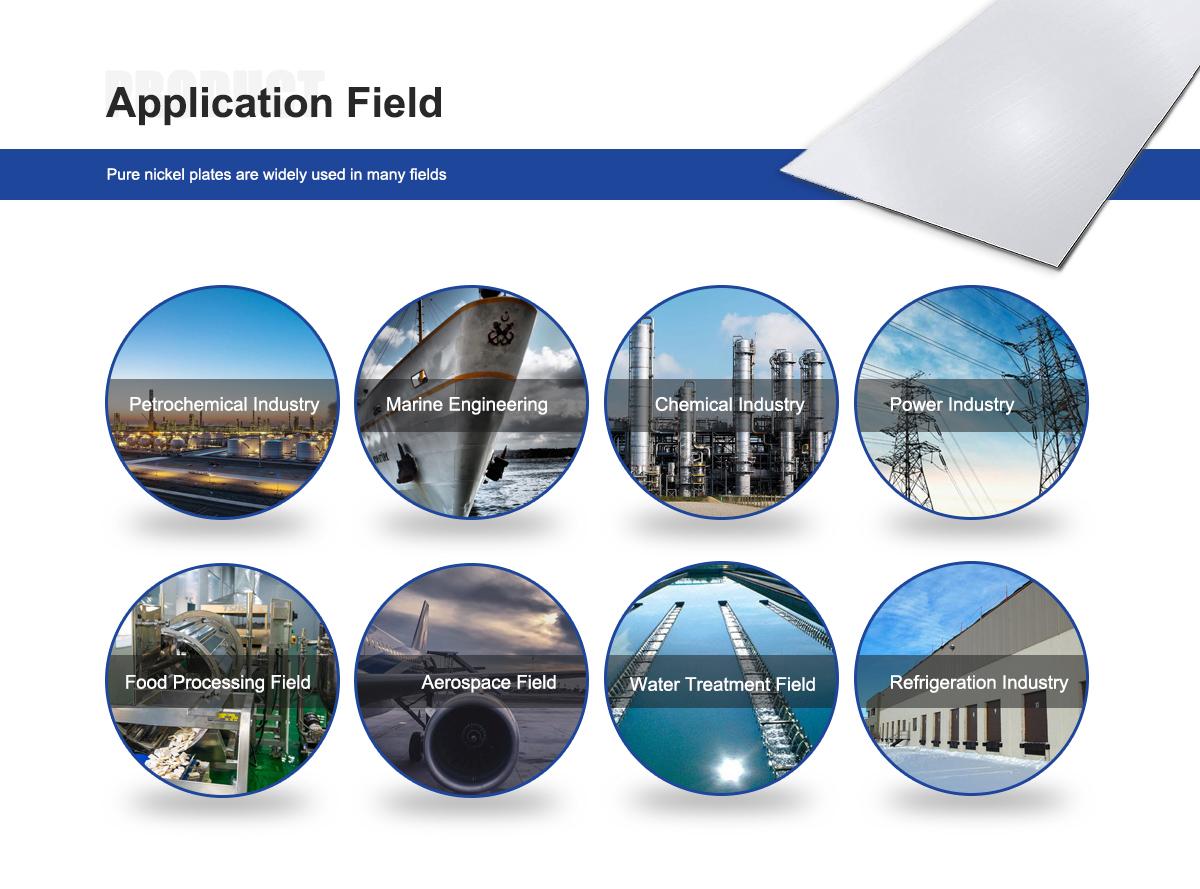

The nickel plate market is on a strong growth trajectory, driven by demand in chemical processing, aerospace, electronics, and renewable energy. High-purity materials like N4/Ni201 and N6/Ni200 are in high demand as industries prioritize corrosion resistance, conductivity, and durability. Chemical processing relies on these plates for equipment that withstands aggressive acids and alkalis, while aerospace uses them for components exposed to extreme temperatures.

Market projections estimate a CAGR of around 4.7% for the global nickel market through 2030, with renewable energy and electric vehicles (EVs) as key drivers. The rise of green hydrogen production is boosting demand for nickel in electrolysis systems, where its catalytic properties and durability are critical. Electronics and battery manufacturing also contribute, with nickel plates used in connectors and electrodes for high-performance devices and EV batteries.

Challenges like raw material price volatility and supply chain constraints exist, but our efficient production and global sourcing ensure a steady supply and competitive pricing. Trends show a shift toward sustainable materials, with N4/Ni201’s low carbon content and N6/Ni200’s recyclability aligning with eco-friendly goals across industries.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

Our N4/Ni201 and N6/Ni200 nickel plates are versatile solutions for demanding applications. In chemical processing, they’re used in reactors, heat exchangers, and pipelines, where N4/Ni201’s superior corrosion resistance handles harsh acids, alkalis, and temperatures up to 760°C (in non-sulfur conditions). N6/Ni200, with its excellent durability, is ideal for slightly less extreme chemical environments, reducing maintenance costs and downtime.

In aerospace, these plates are used for components like turbine blades, exhaust systems, and connectors, where their strength and corrosion resistance withstand high temperatures and harsh conditions. N4/Ni201’s low carbon content makes it particularly suited for extreme environments, while N6/Ni200 offers reliable performance for broader aerospace applications.

Battery manufacturing is a key area, with both plates used as electrodes in lithium-ion and nickel-metal hydride batteries for EVs and energy storage systems. Their high electrical conductivity ensures efficient power delivery and long battery life. In electronics, they’re used for connectors, lead frames, and transistor housings, where their purity and conductivity minimize signal loss in devices like smartphones and industrial controls.

Renewable energy applications include hydrogen production systems, where both plates serve as electrodes in electrolyzers. Their corrosion resistance and catalytic efficiency support cost-effective hydrogen generation, aligning with the global push for clean energy. This versatility makes our nickel plates a go-to choice across industries.

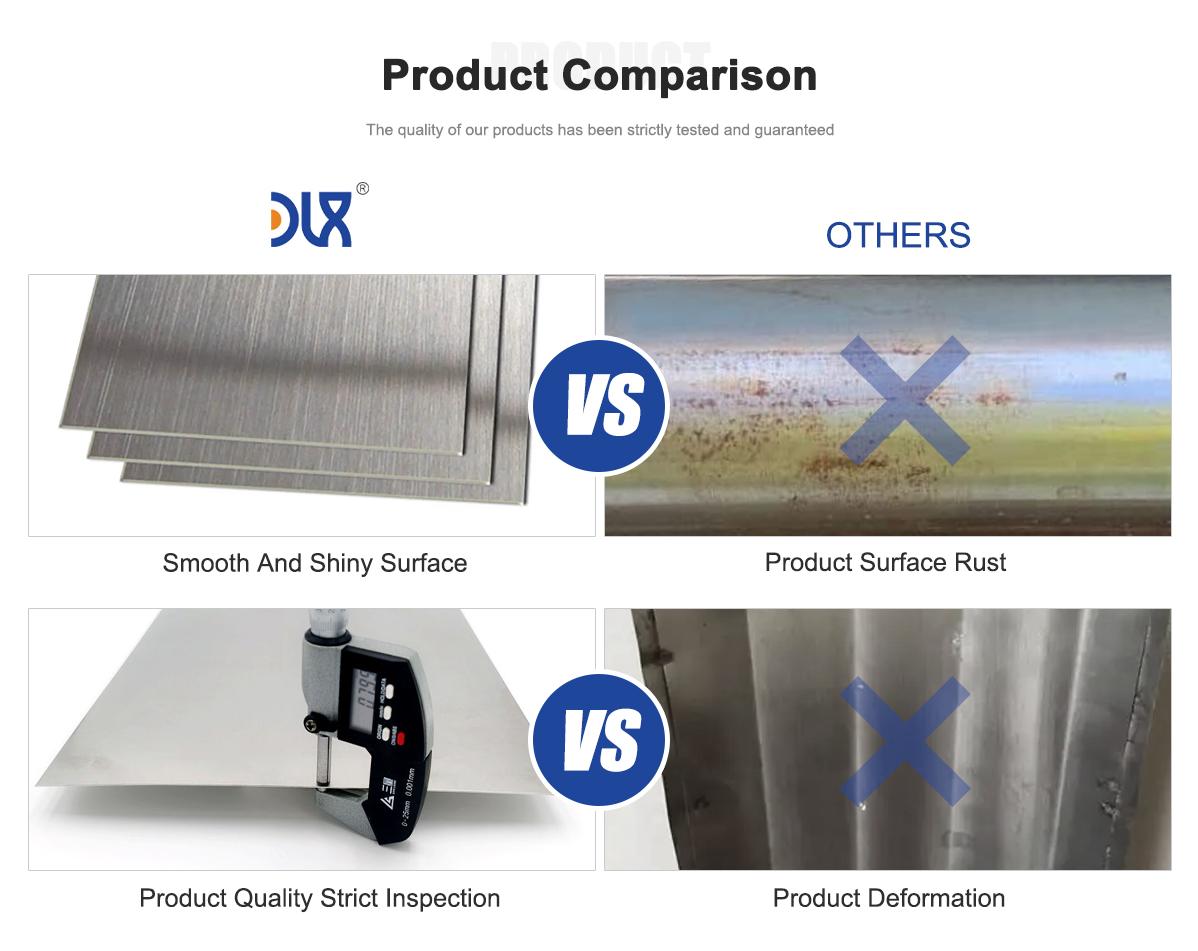

Company Comparison and Our Advantages

We’re not just another supplier—we’re a leader in the nickel plate market. Our N4/Ni201 and N6/Ni200 plates are produced in an ISO 9001-certified facility, where we oversee every step, from raw material selection to final finishing. This control ensures unmatched quality and lets us offer customized solutions, like specific sizes, thicknesses, or surface treatments, delivered in as little as a week.

Our investment in R&D keeps us ahead. We’ve optimized N4/Ni201 for extreme corrosion resistance in chemical and aerospace applications, while N6/Ni200 balances performance and cost for broader uses. Our advanced manufacturing techniques, including precision rolling and annealing, deliver consistent purity and strength, ensuring reliable performance every time.

Sustainability is a core focus. We use energy-efficient production and responsibly sourced materials to minimize our environmental impact, aligning with the green priorities of our customers. Our global supply chain and robust inventory management ensure reliable delivery, even in volatile markets. Unlike others, we prioritize quality with rigorous testing to meet ASTM and ASME standards.

Our technical support is a game-changer. Our engineers collaborate with you to tailor solutions, whether it’s optimizing plate dimensions for battery efficiency or ensuring compatibility with chemical processes. We’re here to help you solve challenges and boost performance, not just supply a product.

Why Choose Our N4/Ni201 & N6/Ni200 Nickel Plates?

Our N4/Ni201 and N6/Ni200 nickel plates are built for excellence. With purities of 99.6%-99.9%, they offer exceptional corrosion resistance, conductivity, and strength, making them ideal for chemical processing, aerospace, electronics, and renewable energy. Their versatility shines in high-stakes applications, from powering EVs to enabling green hydrogen production.

We’re aligned with industry trends, from the aerospace boom to the clean energy revolution. Our customization options ensure you get exactly what you need, whether for prototypes or large-scale production. With strict quality control and fast delivery, we keep your projects on track and on budget.

Comparison Table: N4/Ni201 vs. N6/Ni200 vs. Industry Standard Nickel Plates

Parameter | N4/Ni201 | N6/Ni200 | Industry Standard Nickel Plate |

|---|---|---|---|

Nickel Purity | ≥99.9% | ≥99.6% | ≥99.0% |

Carbon Content | ≤0.02% (Low Carbon) | ≤0.15% | ≤0.25% |

Corrosion Resistance | Superior in alkaline and high-temp settings | Excellent in acidic and alkaline settings | Moderate, varies by alloy |

Temperature Limit | Stable up to 760°C (non-sulfur conditions) | Stable up to 315°C | Varies, typically lower |

Electrical Conductivity | Excellent | High | Moderate to high |

Thermal Conductivity | Excellent | Excellent | Good |

Applications | Chemical, aerospace, electronics, hydrogen | Aerospace, batteries, electronics, chemical | General industrial, less specialized |

Standards | ASTM B162, ASME SB161 | ASTM B162, ASME SB161 | Varies, often less stringent |

To maximize visibility, we’ve optimized this content with keywords like “N4/Ni201 nickel plate,” “N6/Ni200 nickel plate,” “high-purity nickel plate,” and “corrosion-resistant nickel” to capture searches from engineers, manufacturers, and procurement teams. Clear headings, a comparison table, and FAQs improve readability and boost search engine rankings, ensuring our nickel plates stand out.

In a world where performance and sustainability are critical, our N4/Ni201 and N6/Ni200 nickel plates deliver. They’re the reliable choice for high-temperature industrial applications, offering unmatched durability and precision. Contact us today to see how our high-purity nickel plates can elevate your projects, backed by our industry-leading quality and support.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What are N4/Ni201 and N6/Ni200 nickel plates?

N4/Ni201 is a ≥99.9% pure nickel plate with low carbon content, and N6/Ni200 is ≥99.6% pure, both designed for high-temperature industrial applications.What industries use these nickel plates?

They’re used in chemical processing, aerospace, electronics, battery manufacturing, and renewable energy for their corrosion resistance and durability.How do N4/Ni201 and N6/Ni200 differ?

N4/Ni201 has lower carbon (≤0.02%) for superior corrosion resistance in extreme conditions, while N6/Ni200 (≤0.15% carbon) is ideal for general high-performance uses.What are the key properties of these plates?

They offer excellent corrosion resistance, high electrical and thermal conductivity, and stability up to 760°C (N4/Ni201) or 315°C (N6/Ni200).Can these plates be customized?

Yes, we offer tailored thicknesses (0.5mm-50mm), sizes (up to 2000mm x 1000mm), and finishes (polished or pickled) to meet project needs.What are typical applications for these plates?

They’re used in chemical reactors, aerospace components, battery electrodes, electronic connectors, and hydrogen production systems.How do these plates perform in high-temperature settings?

N4/Ni201 excels up to 760°C in non-sulfur environments, while N6/Ni200 is stable up to 315°C, both resisting oxidation and corrosion.What are the industry trends for nickel plates?

Demand is growing in renewable energy, electric vehicles, and aerospace due to the need for high-purity, corrosion-resistant materials.