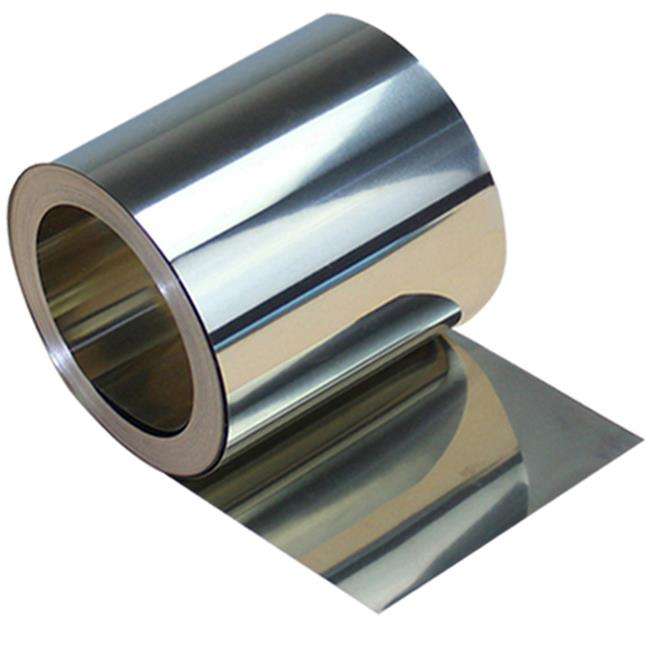

Our Pure Nickel Strip is a high-quality material designed for precision applications in battery and electronics manufacturing. Crafted from 99.6% or higher pure nickel, meeting ASTM B162 standards, these strips offer a tensile strength of 450-600 MPa and exceptional electrical and thermal conductivity. Available in thicknesses from 0.1mm to 2mm and widths from 2mm to 200mm, they’re perfect for industries requiring reliable, corrosion-resistant components. Their excellent resistance to acids, alkalis, and environmental degradation makes them a top choice for demanding applications like lithium-ion battery production and electronic connectors.

These strips are easy to weld, form, and cut, providing flexibility for custom designs in high-tech manufacturing. With a conductivity of around 20-25% IACS (International Annealed Copper Standard), they ensure efficient energy transfer in battery tabs and circuit components. Whether you’re building electric vehicle batteries or precision electronics, our pure nickel strips deliver consistent performance, minimizing downtime and ensuring long-term durability. Built for precision and reliability, they’re the go-to solution for cutting-edge industries.

For more details, pls directly contact us.

The nickel strip market is experiencing robust growth, driven by the booming demand for high-conductivity, corrosion-resistant materials in battery and electronics manufacturing. The rise of electric vehicles (EVs) and renewable energy systems, like solar and wind, has skyrocketed the need for pure nickel strips in lithium-ion battery production, where they serve as critical components for battery tabs and connectors. Our pure nickel strips are tailored for these applications, offering unmatched conductivity and durability. The electronics industry, with its focus on smaller, more efficient devices, also relies heavily on high-purity nickel for circuit components and connectors.

Sustainability is a major trend shaping the market. Nickel’s recyclability aligns with the global push for eco-friendly materials, making it a favorite for industries aiming to reduce environmental impact. The rapid growth of the EV market, coupled with increasing investments in energy storage systems, is driving demand for high-performance nickel strips. Aerospace and renewable energy sectors are also contributing to market growth, with nickel strips used in high-temperature and corrosion-resistant components. While additive manufacturing with nickel alloys is emerging, traditional nickel strips like ours remain essential for high-volume battery and electronics production. As global demand for clean energy and advanced electronics grows, the need for reliable nickel materials is set to keep climbing.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

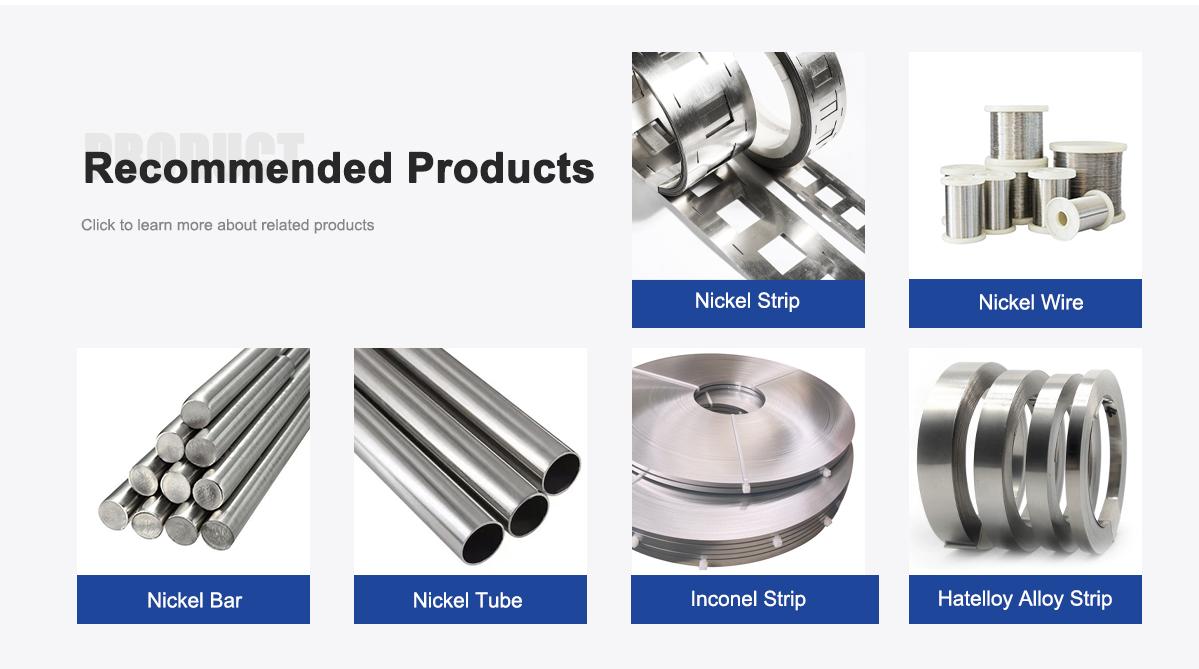

Our pure nickel strips are designed for precision and performance across a range of high-tech applications. In battery manufacturing, they’re used as tabs and connectors in lithium-ion batteries for electric vehicles, consumer electronics, and energy storage systems. Their high electrical conductivity ensures efficient energy transfer, while their corrosion resistance protects against degradation in humid or chemically active environments. In the electronics industry, our strips are ideal for connectors, busbars, and circuit components, where their conductivity and durability support reliable performance in compact devices.

Aerospace applications benefit from our strips’ heat resistance and strength, making them suitable for sensor components and electrical connectors in high-temperature environments. In renewable energy, they’re used in solar inverters and wind turbine electronics, leveraging their thermal conductivity for efficient energy management. Their weldability and formability make them perfect for custom fabrication, from intricate battery packs to robust aerospace parts. Whether you’re building EV batteries or high-performance electronics, our nickel strips deliver the reliability and precision needed for cutting-edge projects.

Comparison Parameters Table

Parameter | Our Pure Nickel Strips | Standard Nickel Alloy Strips |

|---|---|---|

Composition | Ni (99.6%+), trace impurities | Ni (95-99%), variable additives |

Tensile Strength | 450-600 MPa | 400-550 MPa |

Corrosion Resistance | Excellent (Acids, Alkalis, Moisture) | High (General corrosion, less in acids) |

Electrical Conductivity | High, ~20-25% IACS | Moderate, ~15-20% IACS |

Thermal Conductivity | High, ideal for battery components | Moderate, less efficient heat transfer |

Weldability | Excellent, supports multiple methods | Good, limited by alloy composition |

Applications | Battery, electronics, EVs, aerospace | General industrial, less specialized |

Size Options | 0.1mm-2mm thick, 2mm-200mm wide, customizable | 0.2mm-1.5mm thick, limited customization |

We’ve been delivering top-quality nickel materials for over a decade, and our pure nickel strips reflect our expertise and commitment to excellence. Every strip is manufactured to meet ASTM B162 standards, with rigorous testing in our state-of-the-art labs to ensure consistent quality. Our strips offer superior electrical and thermal conductivity, excellent corrosion resistance, and high weldability, making them a standout for battery and electronics applications. Their customizable sizes and finishes mean you get exactly what your project needs, no compromises.

We set ourselves apart with our flexibility. Our OEM and ODM services allow us to tailor strip dimensions, grades, and surface finishes to meet your specific requirements, from small-scale electronics to large battery production lines. Our technical team is always on hand to provide expert guidance, helping you select the right material and fabrication techniques for optimal results. Sustainability is a core focus for us—we use recyclable materials and eco-friendly production methods to align with modern industry standards. With a global supply chain and fast delivery, we ensure your materials arrive on time, whether you’re working on an EV battery plant or an aerospace facility. Our dedication to quality, customization, and customer support makes us the top choice for nickel strip solutions.

Why Choose Our Pure Nickel Strips?

Our pure nickel strips are built for precision and performance, offering exceptional conductivity, corrosion resistance, and durability for battery and electronics manufacturing. Their weldability and formability make them ideal for custom designs, while their high conductivity ensures efficient energy transfer in demanding applications. Whether you’re producing EV batteries, electronic connectors, or aerospace components, our strips deliver results that stand up to tough conditions. Our focus on precision manufacturing and customizable options ensures you get a product tailored to your needs, backed by years of industry expertise.

The demand for high-purity nickel materials is surging, driven by trends in electric vehicles, renewable energy, and sustainable manufacturing. Our pure nickel strips meet these needs, offering versatility and reliability across industries. From battery production to electronics, they’re designed to keep your projects running smoothly and efficiently. With global demand for advanced materials on the rise, our strips are the perfect choice for components that need to perform under pressure. Trust us to provide the materials and support you need to succeed in today’s fast-paced industrial landscape.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: