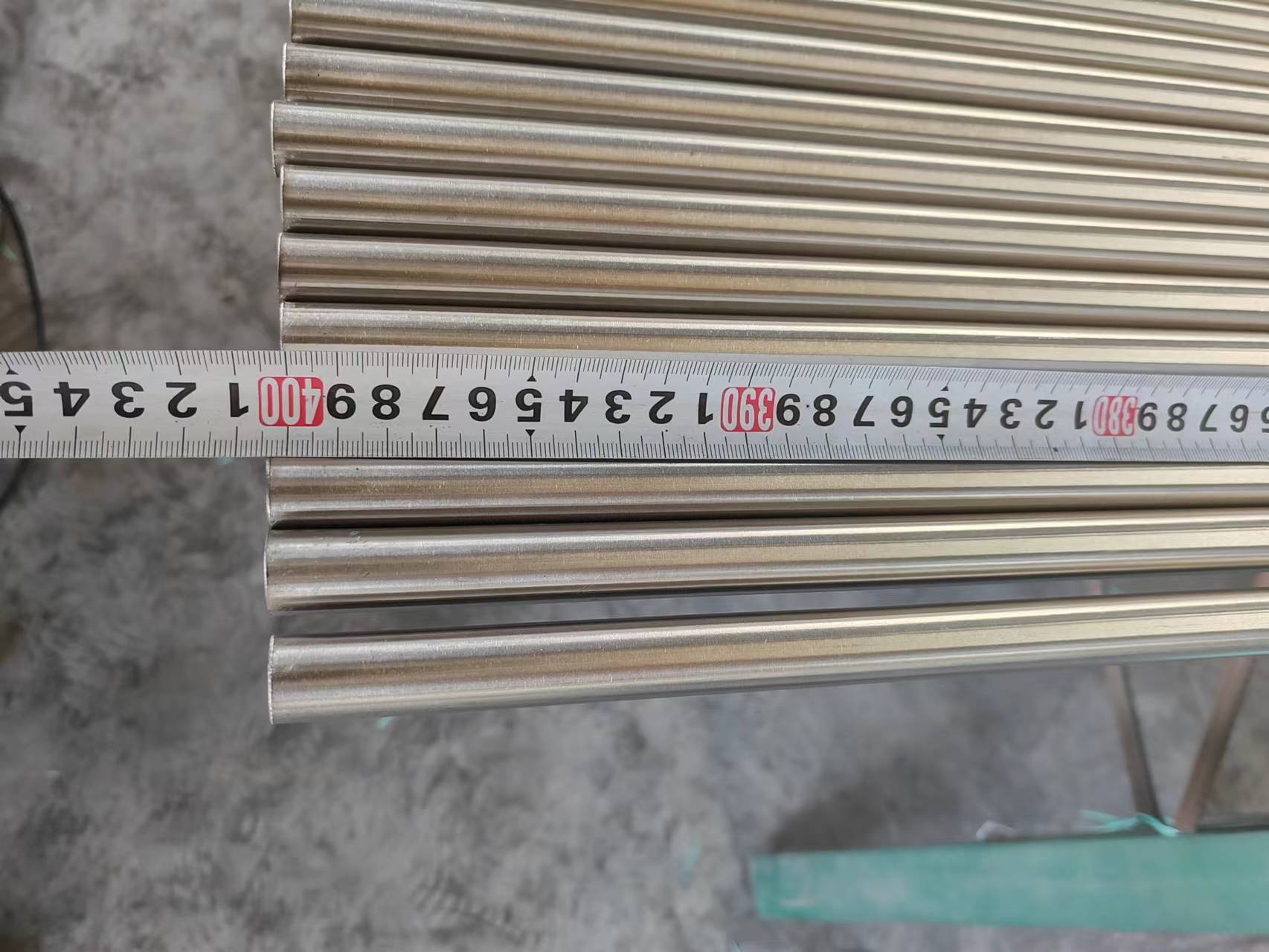

Our High-Purity N6 Nickel Tubing is a top-notch material designed for industries that demand exceptional corrosion resistance and reliability in tough conditions. Made from 99.6% pure nickel (N6 grade), meeting ASTM B161 standards, these tubes boast a tensile strength of 450-600 MPa and excellent thermal and electrical conductivity. Available in outer diameters from 6mm to 100mm and wall thicknesses from 0.5mm to 5mm, they’re built for applications in chemical processing, power generation, and aerospace. Their ability to resist acids, alkalis, and chloride corrosion makes them a go-to choice for harsh environments.

These tubes are easy to weld, form, and machine, offering flexibility for custom fabrication. Their high thermal conductivity makes them ideal for heat exchangers, while their electrical conductivity (~20-25% IACS) suits precision components in electrical systems. Whether you’re constructing chemical reactors or aerospace fluid systems, our N6 nickel tubing delivers consistent performance, cutting maintenance costs and ensuring long-term durability. It’s the perfect solution for industries that need materials to perform under pressure.

For more details, pls directly contact us.

The nickel tubing market is on a steady rise, fueled by the growing demand for corrosion-resistant and thermally efficient materials in industries like chemical processing, power generation, and aerospace. Chemical processing is a major driver, with equipment like reactors and heat exchangers requiring materials that can handle aggressive acids and alkalis without degrading. Our N6 nickel tubing is designed to meet these challenges, offering top-tier corrosion resistance and durability. The power generation sector, including both fossil fuel and renewable energy systems, is another key growth area, relying on nickel tubing for efficient heat transfer in heat exchangers.

Sustainability is a defining trend in the market. Nickel’s recyclability aligns with global efforts to adopt eco-friendly materials, making it a preferred choice for industries aiming to reduce their environmental impact. The rise of renewable energy, particularly solar and geothermal systems, is boosting demand for nickel tubing in heat exchangers and fluid transfer systems. Aerospace is also contributing, with nickel tubing used in high-temperature fluid systems and electrical components. While additive manufacturing with nickel alloys is gaining traction, traditional tubing like our N6 grade remains critical for large-scale industrial applications. As global infrastructure and clean energy projects expand, the demand for high-performance nickel materials is set to keep growing.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Our N6 nickel tubing is built for versatility and reliability across demanding industrial applications. In chemical processing, it’s used to fabricate heat exchangers, reactors, and pipelines that handle corrosive media like acids, alkalis, and chlorides. Its corrosion resistance ensures long-lasting performance, reducing maintenance and downtime. In power generation, our tubing is ideal for heat exchangers and boiler components in fossil fuel plants and renewable energy systems, leveraging its high thermal conductivity for efficient energy transfer.

Aerospace applications benefit from our tubing’s heat resistance and durability, making it perfect for fluid transfer systems and electrical components in high-temperature environments. The oil and gas industry uses it for pipelines and heat exchangers in refineries and offshore platforms, where it withstands harsh chemical and seawater conditions. In pharmaceuticals, our tubing supports high-purity fluid transfer, meeting strict hygiene standards. Its weldability and formability make it ideal for custom fabrication, from small-scale pharmaceutical systems to large industrial heat exchangers. Whether you’re building power plant components or aerospace systems, our N6 nickel tubing delivers the durability needed for critical projects.

Comparison Parameters Table

Parameter | Our N6 Nickel Tubing | Standard Nickel Alloy Tubing |

|---|---|---|

Composition | Ni (99.6%+), trace impurities | Ni (95-99%), variable additives |

Tensile Strength | 450-600 MPa | 400-550 MPa |

Corrosion Resistance | Excellent (Acids, Alkalis, Chlorides) | High (General corrosion, less in acids) |

Thermal Conductivity | High, ideal for heat exchangers | Moderate, less efficient heat transfer |

Electrical Conductivity | High, ~20-25% IACS | Moderate, ~15-20% IACS |

Weldability | Excellent, supports multiple methods | Good, limited by alloy composition |

Applications | Chemical, power, aerospace, oil/gas | General industrial, less specialized |

Size Options | 6mm-100mm OD, 0.5mm-5mm wall, customizable | 10mm-80mm OD, limited customization |

We’ve been delivering high-quality nickel materials for over a decade, and our N6 nickel tubing showcases our expertise and commitment to excellence. Every tube is manufactured to meet ASTM B161 standards, with rigorous testing in our state-of-the-art labs to ensure consistent quality. Our tubing offers superior corrosion resistance, high thermal and electrical conductivity, and excellent weldability, making it a standout for chemical processing, power generation, and aerospace applications. Its customizable sizes and finishes ensure you get exactly what your project needs, no compromises.

We set ourselves apart with our flexibility. Our OEM and ODM services allow us to tailor tube dimensions, grades, and surface finishes to meet your specific requirements, from small-scale fluid systems to large industrial pipelines. Our technical team is always available to provide expert guidance, helping you select the right material and fabrication techniques for optimal results. Sustainability is a core focus for us—we use recyclable materials and eco-friendly production methods to align with modern industry standards. With a global supply chain and fast delivery, we ensure your materials arrive on time, whether you’re working on a chemical plant or an aerospace facility. Our dedication to quality, customization, and customer support makes us the top choice for nickel tubing solutions.

Why Choose Our N6 Nickel Tubing?

Our N6 nickel tubing is designed for performance, offering exceptional corrosion resistance, conductivity, and durability for industrial applications. Its weldability and formability make it ideal for custom designs, while its high thermal and electrical conductivity ensure efficient performance in demanding environments. Whether you’re fabricating heat exchangers, chemical reactors, or aerospace components, our tubing delivers results that stand up to harsh conditions. Our focus on precision manufacturing and customizable options ensures you get a product tailored to your needs, backed by years of industry expertise.

The demand for high-purity nickel materials is growing, driven by trends in renewable energy, chemical processing, and aerospace manufacturing. Our N6 nickel tubing meets these needs, offering versatility and reliability across industries. From power generation to pharmaceuticals, it’s designed to keep your projects running smoothly and efficiently. With global demand for durable materials on the rise, our tubing is the perfect choice for components that need to perform under pressure. Trust us to provide the materials and support you need to succeed in today’s fast-paced industrial landscape.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing: