Our medical-grade Titanium Wire is a top-tier choice for orthopedic surgical tools, delivering the strength, biocompatibility, and reliability that surgeons and patients depend on. Available in Grade 2 (99.2% pure titanium) and Grade 5 (Ti-6Al-4V with 6% aluminum and 4% vanadium), this wire meets stringent ASTM F136 and ISO 5832-3 standards for medical applications. It’s perfect for crafting screws, pins, plates, and wire-based tools like Kirschner wires or cerclage wires used in bone fixation.

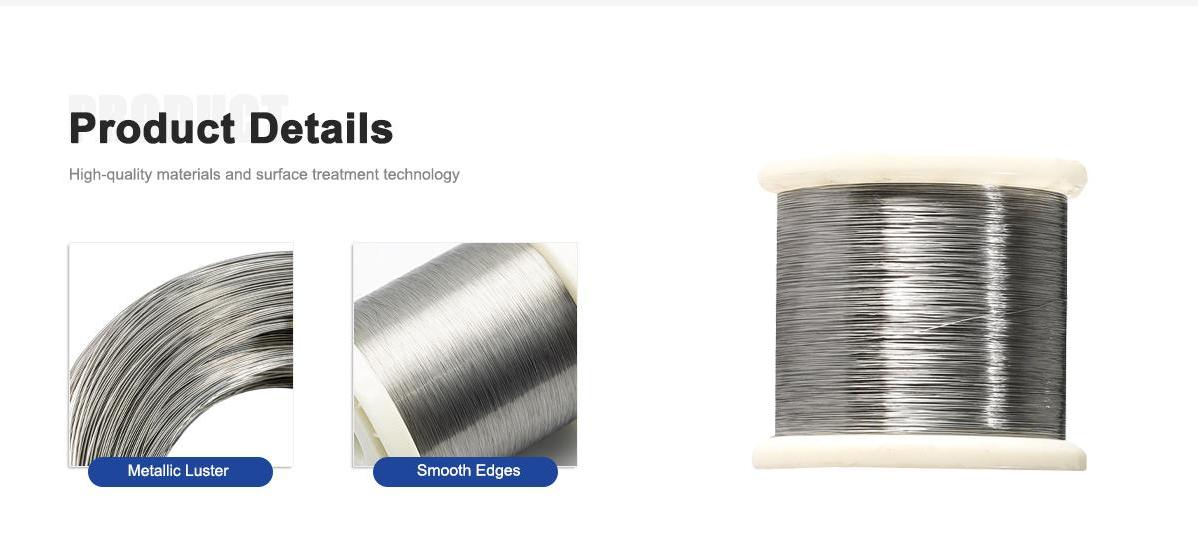

We offer this wire in diameters from 0.1mm to 8mm, in coils, spools, or custom-cut lengths to suit your manufacturing needs. Grade 2 is super formable, making it ideal for intricate tools, while Grade 5 brings extra strength for heavy-duty implants. Both grades resist corrosion from bodily fluids and sterilization processes, ensuring long-lasting performance. Lightweight and biocompatible, our titanium wire helps create tools that are safe, durable, and effective for orthopedic surgeries.

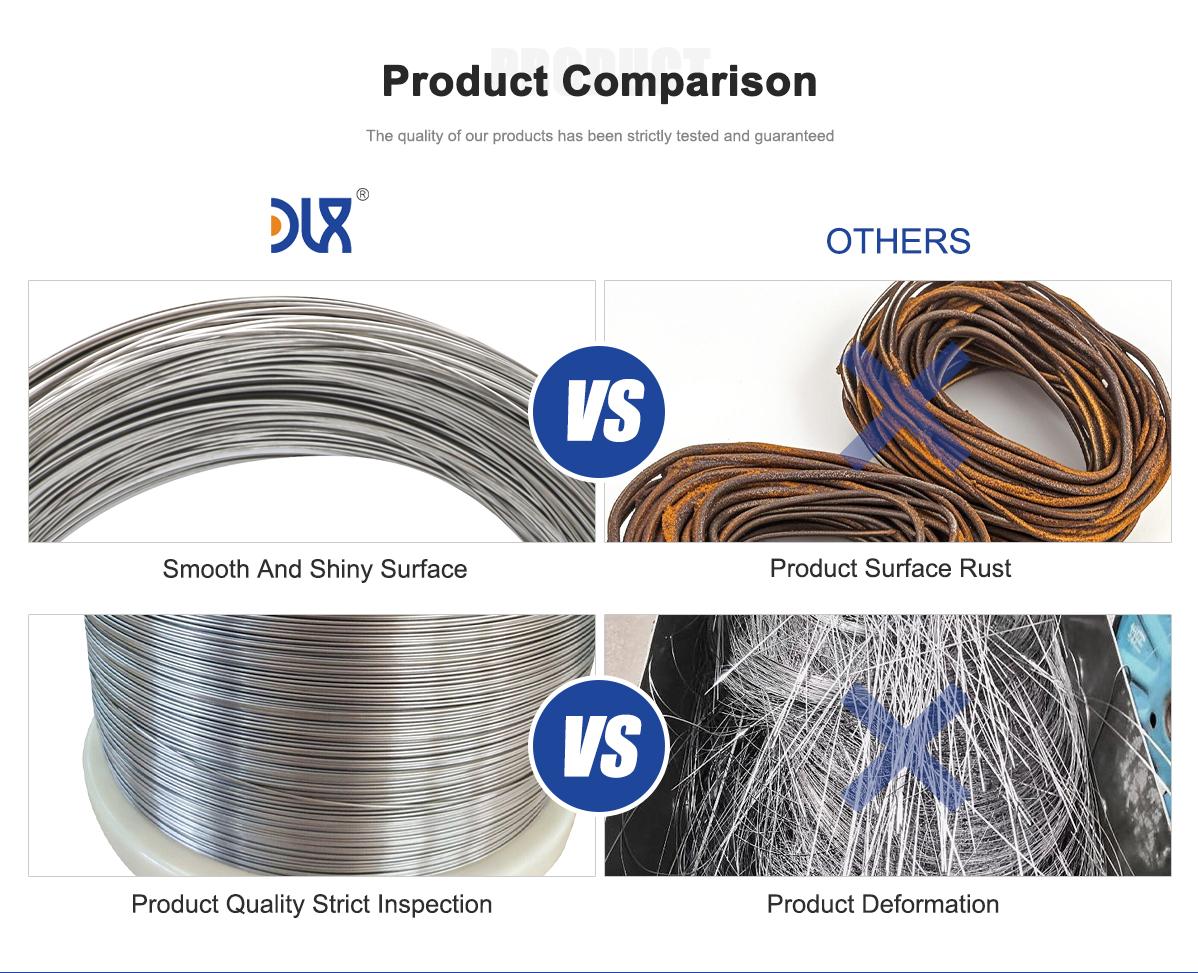

Our medical-grade titanium wire is a cut above for orthopedic applications. Grade 2’s tensile strength of 345-450 MPa is plenty for most surgical tools, with high ductility that makes it easy to shape into delicate components like bone pins. Grade 5, with a tensile strength of 900-1000 MPa, is a powerhouse for load-bearing implants like plates or screws, outpacing 316L stainless steel (485-620 MPa) in strength and biocompatibility. Unlike stainless steel, which can corrode in bodily fluids, our titanium wire stays corrosion-free, ensuring safety for long-term implants.

Titanium’s low density (4.43-4.51 g/cm³) compared to stainless steel (8.0 g/cm³) makes tools and implants lighter, reducing patient discomfort and surgical fatigue. Both grades are highly biocompatible, integrating seamlessly with bone and tissue without causing adverse reactions. Grade 2 is a breeze to machine and weld, while Grade 5’s hardness requires our advanced techniques to deliver flawless results. Both withstand autoclaving and chemical sterilization, making them reliable for repeated use in surgical settings.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The orthopedic industry is booming, and our medical-grade titanium wire is right at the heart of it. With an aging population and rising rates of musculoskeletal conditions, the global market for orthopedic devices is growing fast, expected to hit $60 billion by 2030. Titanium’s biocompatibility and corrosion resistance make it a go-to material for surgical tools and implants, especially as patients demand longer-lasting, safer solutions.

Minimally invasive surgeries are a big trend, requiring smaller, more precise tools. Our Grade 2 wire’s ductility is perfect for crafting fine components like micro-screws or flexible cerclage wires. Additive manufacturing is also transforming the industry, enabling custom implants and tools tailored to individual patients. Our wire is compatible with 3D printing, supporting innovative designs with less waste. Sustainability is another key driver, with manufacturers seeking eco-friendly materials and processes. We’re on board, using greener production methods to meet these demands.

Cost is a challenge, as titanium is pricier than stainless steel due to complex extraction. But advancements in recycling and production efficiency are making it more affordable, and our optimized processes keep prices competitive. The rise of robotic-assisted surgeries and smart implants is also creating new opportunities for titanium wire, and we’re ready to supply the materials needed for these cutting-edge technologies.

Applications of Medical-Grade Titanium Wire

Our medical-grade titanium wire is a star performer in orthopedic surgical tools. Grade 2 is ideal for flexible, wire-based tools like Kirschner wires and cerclage wires, used to stabilize fractures or secure bone fragments. Grade 5 shines in high-strength applications like bone screws, plates, and spinal fixation devices, where durability is critical. Both grades are used in trauma surgery, joint replacements, and spine procedures, thanks to their biocompatibility and corrosion resistance.

Beyond orthopedics, our wire finds use in other medical fields like dental implants and cardiovascular devices, where biocompatibility is key. Aerospace and marine industries also rely on it for corrosion-resistant components, and chemical processing uses it for durable piping. But in orthopedic surgery, this wire truly excels, helping surgeons repair bones and improve lives with tools that are safe, strong, and reliable.

Company Advantages: Why Choose Us

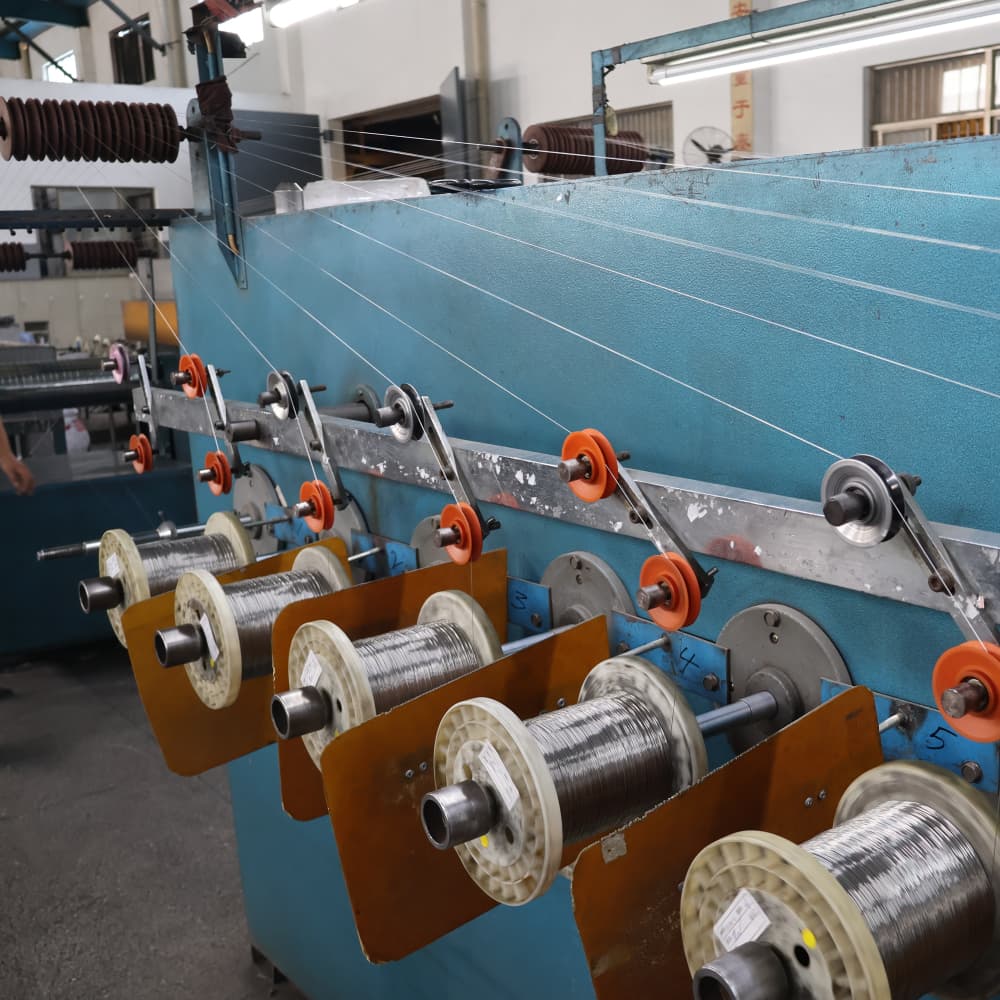

When it comes to medical-grade titanium wire, we’re the ones to trust. Our decades of experience in titanium production mean we deliver wire that meets the toughest medical standards, like ASTM F136 and ISO 5832-3. Every batch is rigorously tested for composition, strength, and surface quality, ensuring it’s ready for critical orthopedic applications. We use state-of-the-art facilities to produce wire that’s consistent and reliable, whether it’s for delicate pins or heavy-duty plates.

Flexibility is a big part of our edge. Need a specific diameter or custom length? We tailor our wire to your specs. Our just-in-time supply chain keeps your costs down by delivering exactly what you need, when you need it. We’re also ahead of the curve on trends like additive manufacturing and sustainable production, investing in R&D to ensure our wire supports the future of orthopedic innovation.

Our technical support team is always ready to help, whether you’re selecting the right grade or optimizing a manufacturing process. We keep prices competitive by streamlining production and sourcing high-quality raw materials, so you get premium wire without the premium price. Our commitment to sustainability means we’re adopting greener methods, aligning with the industry’s eco-friendly push. When you choose our titanium wire, you’re getting a partner dedicated to quality, innovation, and your success.

Comparison Parameters Table

|

Parameter |

Grade 2 Titanium Wire |

Grade 5 Titanium Wire (Ti-6Al-4V) |

316L Stainless Steel Wire |

|---|---|---|---|

|

Composition |

99.2% Ti (pure) |

6% Al, 4% V, 90% Ti |

Fe, 16-18% Cr, 10-14% Ni, 2-3% Mo |

|

Tensile Strength |

345-450 MPa |

900-1000 MPa |

485-620 MPa |

|

Yield Strength |

~275 MPa |

~830 MPa |

~170 MPa |

|

Density |

4.51 g/cm³ |

4.43 g/cm³ |

8.0 g/cm³ |

|

Corrosion Resistance |

Excellent (bodily fluids) |

Excellent (seawater, chemicals) |

Good (prone to corrosion) |

|

Biocompatibility |

Excellent |

Excellent |

Good (less compatible) |

|

Formability |

High (very ductile) |

Moderate (less ductile) |

High |

|

Weldability |

Excellent |

Good (inert gas needed) |

Excellent |

|

Applications |

Orthopedic tools, implants |

Orthopedic tools, aerospace |

Surgical tools, industrial |

|

Cost |

Lower (pure titanium) |

Higher (alloyed) |

Lowest |

The future for medical-grade titanium wire in orthopedics is bright. As demand for minimally invasive procedures and personalized implants grows, our wire’s versatility and biocompatibility will be in high demand. Advances in 3D printing will enable more custom tools and implants, and our wire is ready for these technologies. The rise of robotic surgery and smart implants will also create new opportunities, with titanium’s reliability making it a top choice.

Sustainability will continue to shape the industry, and we’re committed to eco-friendly production to meet these goals. With healthcare systems investing in advanced orthopedic solutions, our wire will play a key role in improving patient outcomes. Whether it’s a fracture repair or a complex spinal surgery, our medical-grade titanium wire is poised to power the next generation of orthopedic tools.

Conclusion

Our medical-grade titanium wire is the ultimate choice for orthopedic surgical tools, offering unmatched biocompatibility, corrosion resistance, and strength. From screws to cerclage wires, it delivers performance surgeons can rely on. With industry trends leaning toward precision, sustainability, and innovation, our wire is ready to meet the challenges of modern orthopedics. Backed by our expertise, flexible production, and commitment to quality, choosing our titanium wire means choosing a partner built for success in the medical field.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is medical-grade titanium wire made of?

It’s typically Grade 2 (99.2% pure titanium) or Grade 5 (Ti-6Al-4V with 6% aluminum, 4% vanadium), designed for biocompatibility and corrosion resistance. -

What are the main uses of medical-grade titanium wire in orthopedic tools?

It’s used for surgical screws, pins, plates, and wire-based tools like Kirschner wires and cerclage wires for bone fixation. -

How does medical-grade titanium wire compare to stainless steel for orthopedic tools?

Titanium wire offers superior biocompatibility and corrosion resistance, with a better strength-to-weight ratio than stainless steel. -

Is medical-grade titanium wire safe for long-term use in the body?

Yes, it’s highly biocompatible, non-toxic, and integrates well with bone and tissue, making it ideal for permanent implants. -

Can medical-grade titanium wire withstand sterilization processes?

Absolutely, it resists corrosion and degradation during autoclaving and chemical sterilization, ensuring tool reliability. -

What industries besides medical use medical-grade titanium wire?

It’s used in aerospace, marine, and chemical processing for its corrosion resistance and lightweight properties. -

How easy is it to shape medical-grade titanium wire for surgical tools?

Grade 2 is highly formable for intricate tools, while Grade 5 is stronger but less ductile, requiring precision machining. -

What are the industry trends for medical-grade titanium wire?

Demand is rising for biocompatible materials in orthopedics, with trends toward minimally invasive tools and sustainable production methods.