Our Ti-6Al-4V Titanium Wire , also known as Grade 5, is a beast for heavy-duty structural applications, delivering unmatched strength, lightweight properties, and corrosion resistance. Composed of 6% aluminum, 4% vanadium, and 90% titanium, this wire meets ASTM B863 and AMS 4928 standards, ensuring top-notch quality. It’s perfect for high-stress components like fasteners, cables, and reinforcement in construction, aerospace, and industrial projects.

Ti-6Al-4V titanium wire is a powerhouse for heavy-duty structural needs. With a tensile strength of 900-1000 MPa, it rivals AISI 4340 steel (980-1100 MPa) but weighs nearly half as much at 4.43 g/cm³ compared to steel’s 7.8 g/cm³. This makes it a game-changer for weight-sensitive structures like aircraft frames or high-rise buildings. Compared to Grade 2 titanium (345-450 MPa), it’s significantly stronger, perfect for high-stress applications.

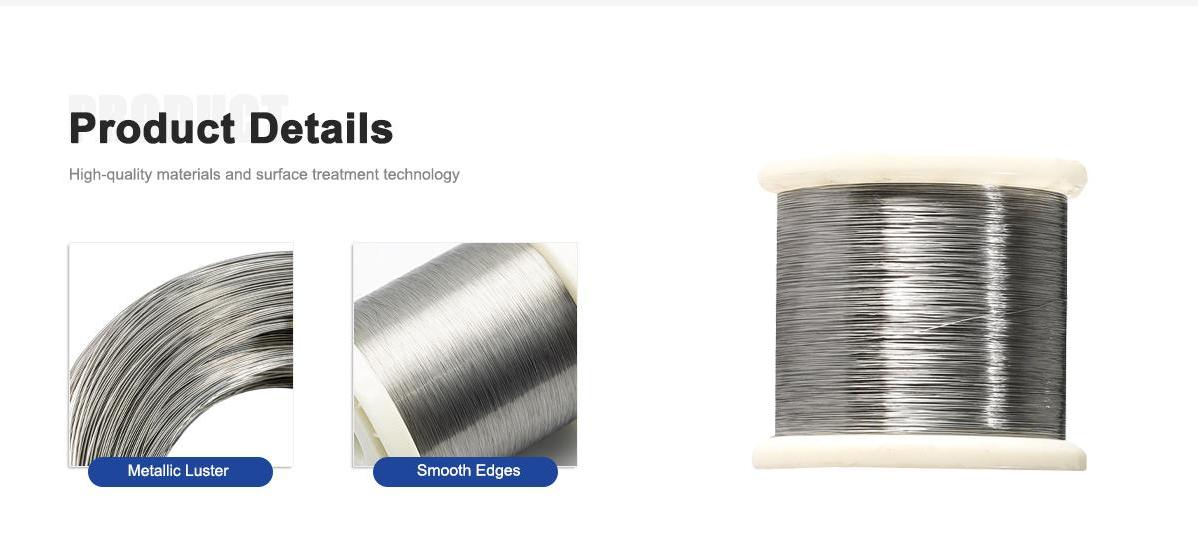

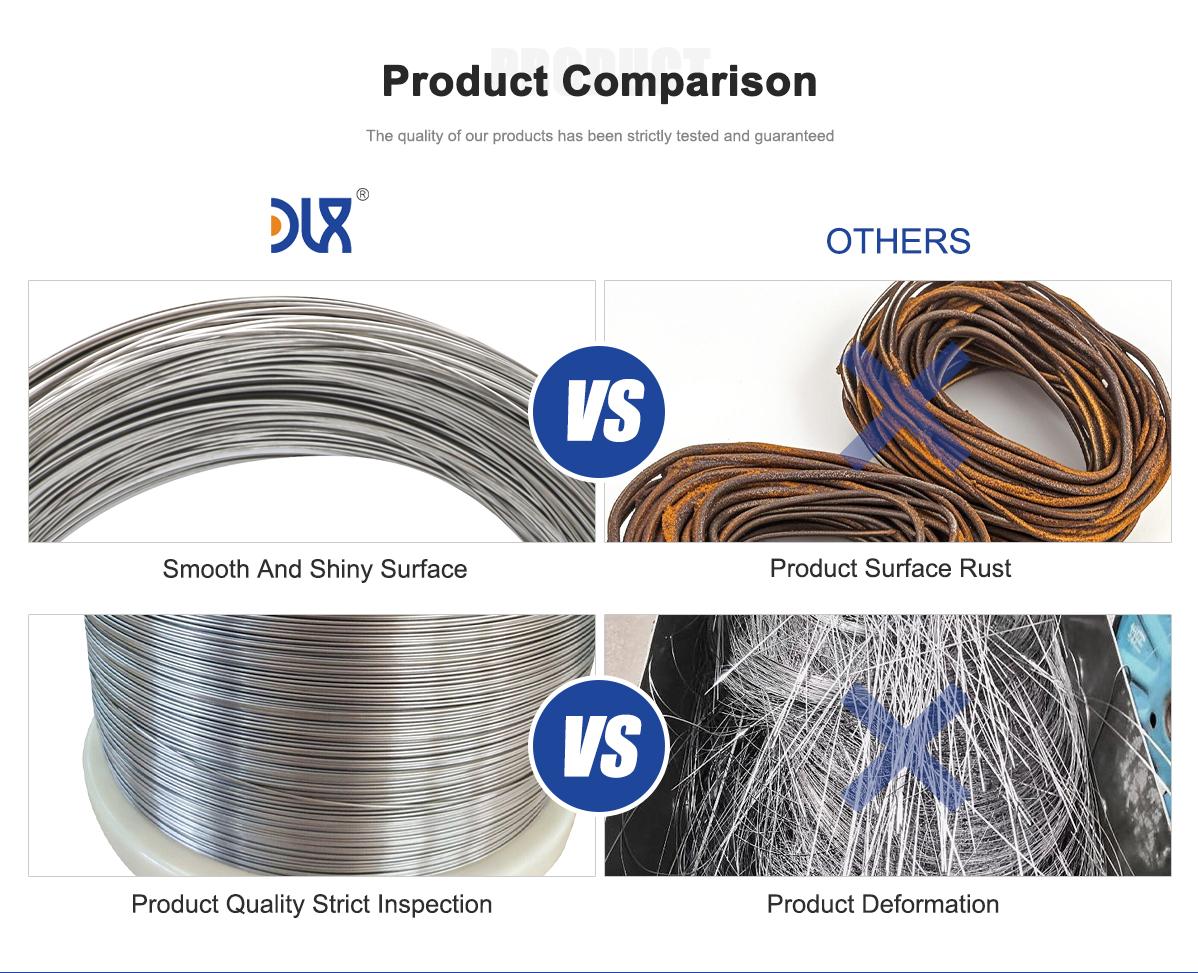

Corrosion resistance is a major advantage, as our wire stands up to chemicals, seawater, and harsh weather, unlike steel, which rusts without protective coatings. It handles temperatures up to 600°F (316°C), ensuring stability in high-heat environments like engine rooms or industrial furnaces. While less ductile than Grade 2, its moderate formability is supported by our advanced manufacturing, making it easy to work with. Weldability is solid with TIG methods and inert gas shielding, producing joints that hold up under extreme loads.

Industry Analysis: Trends Driving Titanium Wire Demand

The structural applications sector is thriving, and our Ti-6Al-4V titanium wire is at the forefront. With global construction and aerospace industries booming—think urban skyscrapers and next-gen aircraft—the demand for lightweight, high-strength materials is soaring. Titanium’s ability to reduce structural weight while maintaining durability makes it a top choice for modern engineering. The aerospace sector, in particular, is pushing for fuel-efficient designs, and our wire helps achieve that by cutting weight without compromising strength.

Additive manufacturing is shaking things up, enabling complex, lightweight components with minimal waste. Our wire is 3D-printing-ready, supporting innovative designs like custom fasteners or intricate reinforcements. Sustainability is another big trend, with industries seeking materials that lower energy use and environmental impact. Our wire’s lightweight properties reduce fuel consumption in aerospace, while its recyclability aligns with green manufacturing goals.

Cost is a hurdle, as titanium alloys are pricier than steel due to complex production. But advancements in titanium recycling and the Kroll process are driving costs down, and our optimized manufacturing keeps prices competitive. The rise of infrastructure projects in emerging markets and the push for reusable spacecraft are also boosting demand for high-performance materials, and our wire is ready to meet these challenges.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our Ti-6Al-4V titanium wire is a workhorse in heavy-duty structural applications. In construction, it’s used for high-strength cables, fasteners, and reinforcement in bridges, skyscrapers, and stadiums, where its strength and corrosion resistance shine. In aerospace, it’s perfect for airframe components, landing gear fasteners, and engine supports that need to withstand high stress and temperatures. Industrial applications include structural supports in chemical plants and power generation facilities exposed to corrosive environments.

Beyond structural uses, our wire finds a home in medical applications for biocompatible implants, in marine industries for seawater-resistant fittings, and in high-performance automotive for lightweight components. But in heavy-duty structural applications, this wire truly excels, delivering the strength and durability needed for projects that push engineering limits.

Company Advantages: Why Choose Us

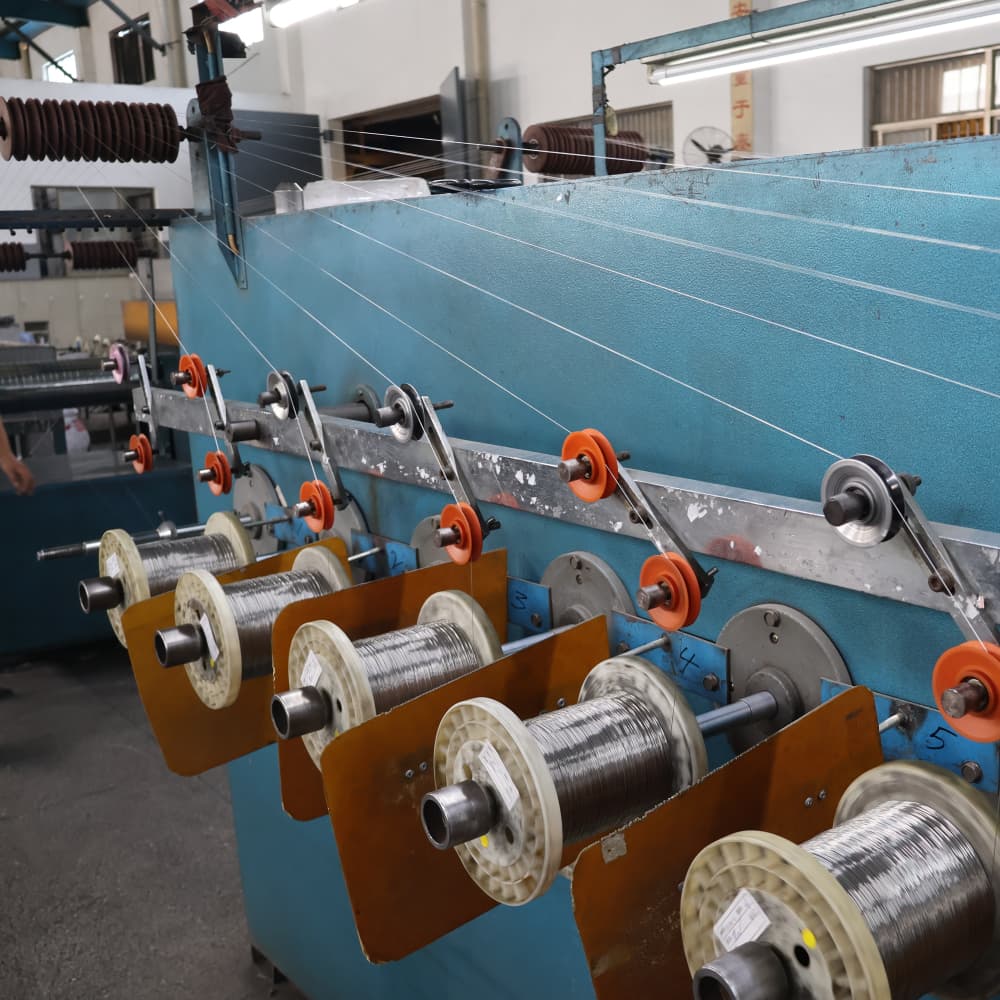

When it comes to Ti-6Al-4V titanium wire, we’re the ones to trust. Our decades of expertise in titanium production mean we deliver wire that meets ASTM B863 and AMS 4928 standards with unmatched consistency. Every batch is rigorously tested for composition, strength, and surface quality, ensuring it performs flawlessly in your structural projects. We use state-of-the-art facilities to produce wire that’s strong, weldable, and ready for the toughest applications.

Flexibility is a huge part of our advantage. Need a specific diameter or custom length for a bridge cable or aircraft fastener? We tailor our wire to your specs. Our just-in-time supply chain delivers exactly what you need, when you need it, keeping your costs down. We’re also ahead of the curve on trends like additive manufacturing and sustainable production, investing in R&D to ensure our wire supports the future of structural engineering.

Our technical support team is always ready to help, whether you’re selecting the right specifications or optimizing a manufacturing process. We keep prices competitive by streamlining production and sourcing high-quality raw materials, so you get premium wire without the premium price tag. Our commitment to sustainability means we’re adopting greener methods, aligning with the industry’s eco-friendly push. Choosing our Ti-6Al-4V titanium wire means choosing a partner dedicated to quality, innovation, and your success.

Comparison Parameters Table

Parameter | Ti-6Al-4V (Grade 5) Titanium Wire | Grade 2 Titanium Wire | AISI 4340 Steel Wire |

|---|---|---|---|

Composition | 6% Al, 4% V, 90% Ti | 99.2% Ti (pure) | Fe, 0.4% C, 1.8% Ni, 0.8% Cr |

Tensile Strength | 900-1000 MPa | 345-450 MPa | 980-1100 MPa |

Yield Strength | ~830 MPa | ~275 MPa | ~860 MPa |

Density | 4.43 g/cm³ | 4.51 g/cm³ | 7.8 g/cm³ |

Corrosion Resistance | Excellent (chemicals, seawater) | Excellent (chemicals, seawater) | Poor (prone to rust) |

Heat Resistance | Up to 600°F (316°C) | Up to 400°F (204°C) | Up to 800°F (427°C) |

Formability | Moderate (less ductile) | High (very ductile) | Moderate |

Weldability | Good (inert gas needed) | Excellent | Good |

Applications | Structural, aerospace, medical | Structural, medical, marine | Structural, industrial |

Cost | Higher (alloyed) | Lower (pure titanium) | Lower |

The future for Ti-6Al-4V titanium wire in heavy-duty structural applications is looking strong. As construction and aerospace industries continue to grow, the demand for lightweight, high-strength materials will soar. The rise of sustainable infrastructure projects, like green buildings and renewable energy facilities, will drive the need for durable, eco-friendly components, and our wire is ready to deliver. Additive manufacturing will keep pushing boundaries, enabling custom structural designs, and our wire is poised to support these advancements.

Sustainability will remain a key focus, and our eco-friendly production methods will keep us ahead of the game. With industries prioritizing energy efficiency and reduced environmental impact, our wire’s lightweight properties and recyclability will be a big draw. Whether it’s a next-gen skyscraper or a reusable spacecraft, our Ti-6Al-4V titanium wire is set to power the future of heavy-duty structural engineering.

Conclusion

Our Ti-6Al-4V titanium wire is the ultimate choice for heavy-duty structural applications, offering unmatched strength, lightweight properties, and corrosion resistance. From skyscraper cables to aircraft fasteners, it delivers performance you can count on in the toughest conditions. With industry trends leaning toward sustainability and innovation, our wire is ready to shape the future of structural engineering. Backed by our expertise, flexible production, and commitment to quality, choosing our titanium wire means choosing a partner built for success in high-stress, high-stakes projects.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Ti-6Al-4V titanium wire made of?

It’s Grade 5 titanium alloy, composed of 6% aluminum, 4% vanadium, and 90% titanium, known for high strength and corrosion resistance.What are the main uses of Ti-6Al-4V titanium wire in structural applications?

It’s used for heavy-duty components like fasteners, cables, and reinforcement in construction, aerospace, and industrial structures.How does Ti-6Al-4V titanium wire compare to steel for structural uses?

It’s lighter, stronger per weight, and more corrosion-resistant than steel, ideal for high-stress, weight-sensitive applications.Can Ti-6Al-4V titanium wire withstand extreme temperatures?

Yes, it performs reliably up to 600°F (316°C), making it suitable for high-temperature structural environments.Is Ti-6Al-4V titanium wire weldable for structural projects?

Absolutely, it’s weldable with TIG methods and inert gas shielding, creating robust joints for heavy-duty applications.What industries besides structural applications use Ti-6Al-4V titanium wire?

It’s used in aerospace, medical, and marine industries for its strength, lightweight properties, and corrosion resistance.How does Ti-6Al-4V titanium wire contribute to structural weight reduction?

Its low density (4.43 g/cm³) compared to steel (7.8 g/cm³) reduces structural weight, enhancing efficiency and performance.What are the industry trends for Ti-6Al-4V titanium wire in structural applications?

Demand is growing for lightweight, durable materials in construction and aerospace, with trends toward additive manufacturing and sustainability.