Cobalt-Chromium (CoCr) precision tubes are engineered for extreme environments that demand superior strength, dimensional accuracy, and corrosion resistance. These tubes are widely used in aerospace, medical, energy, and instrumentation applications where reliability under stress and long-term performance are critical.

At DLX, we produce CoCr precision tubes through advanced vacuum melting, cold drawing, and heat treatment processes that ensure exceptional purity and uniform microstructure. Our goal is simple — deliver stable, high-quality CoCr tubes that outperform conventional alloys in both mechanical and environmental durability.

For more details, pls directly contact us.

DLX Cobalt-Chromium precision tubes are highly versatile and find use across multiple industries:

-

Aerospace components – resistant to heat, oxidation, and mechanical fatigue.

-

Medical devices and surgical tools – combining biocompatibility with high hardness and corrosion resistance.

-

Fiber optic protection systems – shielding delicate optical fibers in harsh environments.

-

Instrumentation and metrology – offering dimensional precision and structural stability.

-

Energy and nuclear systems – performing reliably under radiation and chemical exposure.

-

Automotive and turbine parts – providing excellent wear and temperature resistance.

These tubes maintain performance across temperature extremes, corrosive conditions, and continuous mechanical stress, making them a preferred choice in advanced engineering sectors.

|

Parameter |

Typical Value/Range |

|---|---|

|

Chemical Composition |

Cobalt (Co): 60-70% |

|

Density |

8.3-8.5 g/cm³ |

|

Melting Point |

1250-1450°C |

|

Hardness (Rockwell) |

Soft: 20-30 HRC |

|

Tensile Strength |

800-1200 MPa (depending on alloy and heat treatment) |

|

Yield Strength |

500-900 MPa |

|

Young's Modulus |

200-230 GPa |

|

Elongation |

10-20% |

|

Corrosion Resistance |

Excellent, resistant to acids, alkalis, saline, and high-temperature oxidation |

|

Biocompatibility |

Good, widely used in dental restorations and orthopedic implants |

|

Wear Resistance |

Excellent, suitable for high-wear environments like cutting tools, turbine blades |

|

High-Temperature Resistance |

Maintains performance up to 600-800°C, ideal for aerospace engine components |

|

Processing Methods |

Precision casting, 3D printing, CAD/CAM, laser cladding |

|

Typical Applications |

Dental prosthetics (e.g., crowns, frameworks), aerospace parts, turbine blades, oil drilling rods, medical implants |

For more details, pls directly contact us.

The demand for Cobalt-Chromium alloys continues to grow due to their superior mechanical and chemical properties. Current market developments include:

-

Rising use in high-precision manufacturing — such as fiber optics, robotics, and medical implants.

-

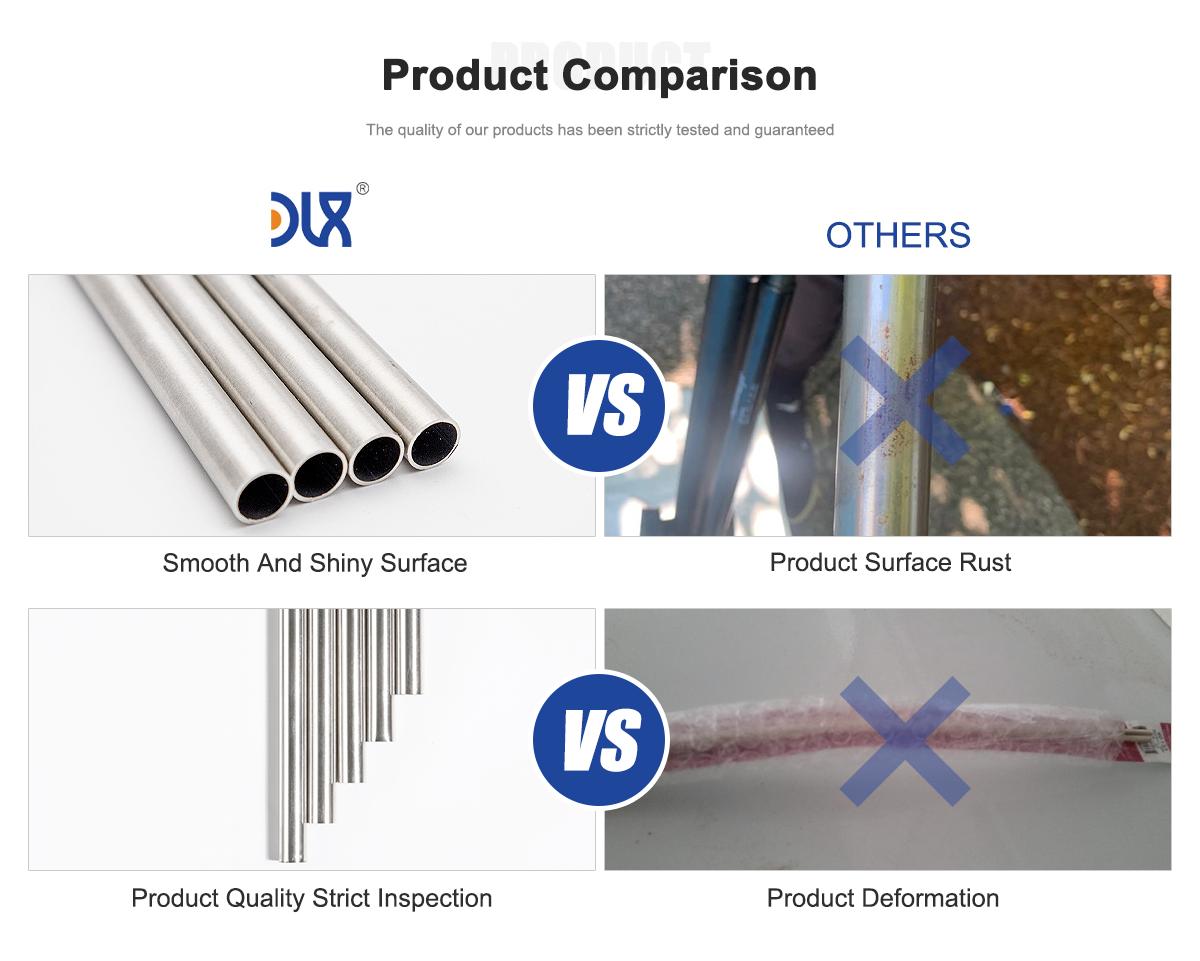

Shift from traditional stainless steel to CoCr for better corrosion resistance and fatigue strength.

-

Increased miniaturization — driving demand for micro-diameter CoCr tubing in precision applications.

-

Expansion in aerospace and defense — due to heat and wear performance at extreme temperatures.

-

Focus on sustainability — encouraging longer-lasting, recyclable materials that reduce replacement costs.

DLX stays aligned with these global trends by combining metallurgical innovation, strict quality management, and flexible production capacity to serve both small and large-volume customers efficiently.

Precision, reliability, and performance — these are the qualities that define DLX’s Cobalt-Chromium precision tubes. As industries evolve toward smarter, more durable materials, CoCr alloys have become an essential solution for manufacturers who demand exceptional strength and resistance under challenging environments.

Comparison Table

| Property / Feature | DLX CoCr Alloy Tube | Stainless Steel Tube | Titanium Tube |

|---|---|---|---|

| Density (g/cm³) | 8.3–8.9 | 7.9 | 4.5 |

| Tensile Strength (MPa) | 1200–1500 | 600–850 | 900–1100 |

| Corrosion Resistance | Excellent | Good | Excellent |

| Wear Resistance | Outstanding | Moderate | Good |

| Elastic Modulus (GPa) | 200–230 | 190 | 110 |

| Thermal Stability (°C) | Up to 1100 | Up to 800 | Up to 600 |

| Biocompatibility | Excellent | Moderate | Excellent |

| Applications | Aerospace, Medical, Instrumentation | General Industry | Medical, Aerospace |

Material Excellence and Manufacturing Precision

Cobalt-Chromium alloys are recognized for their superior hardness, corrosion resistance, and mechanical stability. They outperform most conventional materials when exposed to heat, pressure, or wear. DLX has refined the art of producing CoCr precision tubes using vacuum induction melting (VIM) and cold drawing technology to create ultra-clean, uniform microstructures.

Each tube undergoes heat treatment and precision calibration, ensuring tight tolerances, smooth surfaces, and consistent wall thickness — essential for aerospace, medical, and precision engineering applications.

By controlling the entire production process, DLX guarantees low defect rates and high consistency, enabling customers to integrate our CoCr tubes into systems where performance failure is not an option.

Applications Across Advanced Industries

In the aerospace industry, CoCr precision tubes are used in jet engine components, actuators, and exhaust systems due to their ability to withstand extreme heat and pressure. Their oxidation resistance ensures long operational lifetimes even in aggressive environments.

In medical applications, DLX CoCr tubes are favored for surgical tools, implants, and medical devices. Their excellent biocompatibility and resistance to sterilization cycles make them ideal for both reusable and implantable instruments.

The fiber optics and instrumentation industries rely on CoCr tubes to protect fragile components from mechanical stress and chemical exposure, ensuring accurate measurements and stable signal transmission over long periods.

Finally, in energy and nuclear systems, these tubes provide reliable performance under radiation and corrosive fluids — an area where material stability directly impacts system safety and longevity.

Industry Insights and Future Growth

As precision engineering, automation, and communication technologies advance, the demand for stronger, thinner, and more durable tubing is accelerating. Cobalt-Chromium’s unique mechanical and chemical stability makes it a preferred alternative to stainless steel and titanium in specific high-performance sectors.

Global market trends also show a growing need for micro-diameter CoCr tubes, especially for use in robotics, sensors, and medical instruments. DLX has expanded its production capability to include ultra-fine tubing with internal diameters below 0.2 mm — a benchmark in precision manufacturing.

What makes DLX stand out is not just the quality of our material, but the depth of our engineering control. From raw alloy refining to final inspection, every stage is optimized for precision and reliability.

Our production systems include automated process monitoring, laser dimensional measurement, and microstructure inspection, ensuring consistency that meets the most demanding customer specifications.

DLX also offers flexible production scheduling and custom alloy compositions, giving clients the ability to align their procurement and engineering timelines without compromising quality.

Our global supply network and long-term partnerships with reliable alloy suppliers guarantee stability in both pricing and delivery — an increasingly important factor in today’s industrial landscape.

Sustainability and Long-Term Commitment

DLX is committed to building a more sustainable materials industry. CoCr alloys are fully recyclable, and our manufacturing process minimizes waste and energy consumption. We continuously invest in cleaner melting technologies and recycling initiatives to reduce the environmental impact of production.

Our philosophy is simple — deliver materials that last longer, perform better, and reduce replacement frequency. With CoCr precision tubes, we’re helping customers achieve higher performance while supporting global sustainability goals.

Looking Ahead

As industries push toward higher precision and reliability, Cobalt-Chromium alloys will play a leading role in defining the next generation of engineered materials. With decades of metallurgical expertise, DLX remains a trusted partner for companies that demand exceptional precision, certified quality, and reliable delivery.

Whether it’s for aerospace turbines, medical implants, or precision optical systems, DLX’s Cobalt-Chromium precision tubes represent the perfect balance of strength, stability, and innovation — built for the future of performance engineering.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What makes Cobalt-Chromium alloy superior to stainless steel?

CoCr alloys have higher tensile strength, greater wear resistance, and superior corrosion stability, especially in high-temperature and acidic environments.

2. How does DLX ensure precision in CoCr tube manufacturing?

DLX applies precision cold-drawing, heat treatment, and dimensional control under ISO standards to ensure accurate internal diameters and wall thicknesses.

3. Are DLX CoCr tubes suitable for medical and aerospace use?

Yes. Our alloys meet international standards for medical-grade and aerospace-grade materials, with traceable certification for every batch.

4. Can DLX produce customized dimensions and tolerances?

Absolutely. We manufacture custom CoCr tubes with diameters ranging from 0.2 mm to 60 mm and tolerances down to ±0.01 mm depending on requirements.

5. How do CoCr tubes perform under high heat?

CoCr maintains strength and oxidation resistance up to 1100°C, making it ideal for turbine engines and heat-resistant components.

6. What surface finishes are available?

DLX offers mirror polishing, passivation, sandblasting, and precision machining for smooth internal or external surfaces.

7. How does DLX guarantee consistent quality?

We perform non-destructive testing (NDT), ultrasonic inspection, and spectral analysis to ensure uniform microstructure and chemical composition.

8. Why choose DLX as your CoCr tube supplier?

DLX provides stable supply, precision customization, and technical expertise, supporting clients across aerospace, medical, and industrial sectors with consistent quality.