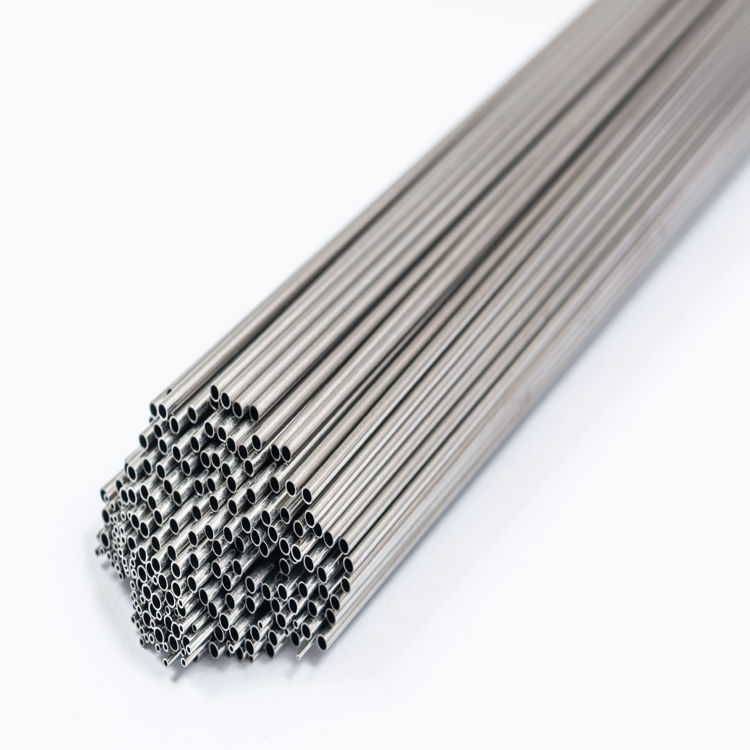

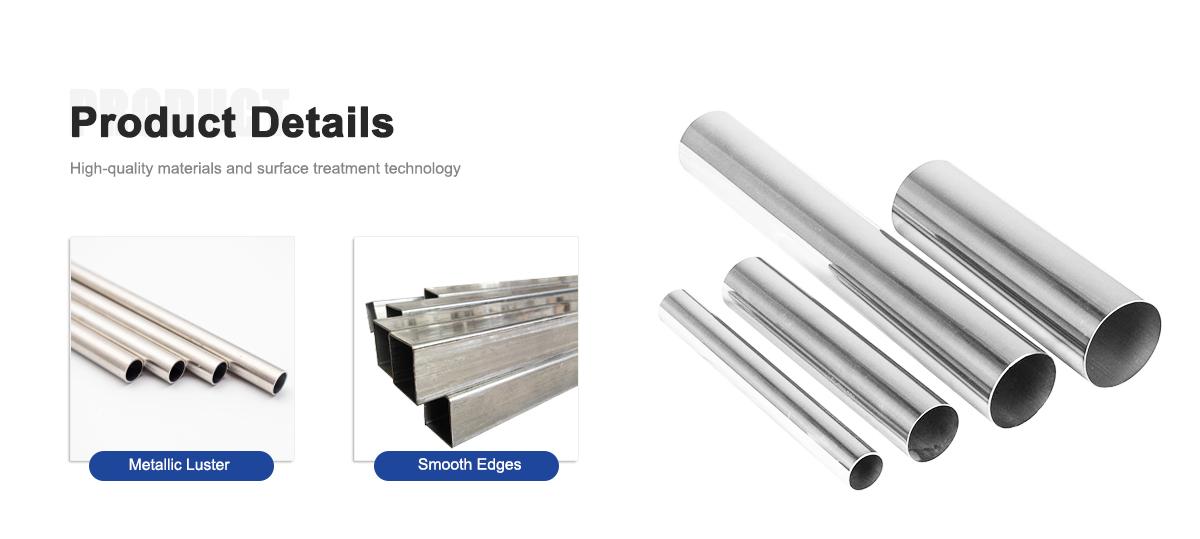

Cobalt-Chromium (CoCr) alloy tubes are a cornerstone material in modern medical and dental engineering. Known for their excellent biocompatibility, corrosion resistance, and mechanical strength, CoCr alloys provide long-lasting reliability inside the human body. At DLX, we manufacture dental and medical-grade CoCr tubes that meet international standards for precision, purity, and safety. Our tubes are widely used in dental implants, orthodontic devices, surgical instruments, and medical frameworks where durability, consistency, and stability of supply are essential.

For more details, pls directly contact us.

DLX CoCr tubes are designed for critical medical and dental components that demand flawless structural integrity and long-term performance:

Dental implants and abutments – resistant to wear, corrosion, and oral acidity.

Orthodontic wires and brackets – maintaining shape and elasticity for precise adjustment.

Surgical instruments – maintaining sharpness and structural reliability under repeated sterilization.

Prosthetics and frameworks – lightweight, strong, and biocompatible alternatives to titanium.

Medical device housings – for MRI-compatible and high-fatigue environments.

The high polishability and biocompatibility of DLX CoCr tubes make them ideal for contact with tissues and fluids, ensuring both functional and aesthetic benefits in medical applications.

Parameter | Typical Value/Range |

|---|---|

Chemical Composition | Cobalt (Co): 60-70% |

Density | 8.3-8.5 g/cm³ |

Melting Point | 1250-1450°C |

Hardness (Rockwell) | Soft: 20-30 HRC |

Tensile Strength | 800-1200 MPa (depending on alloy and heat treatment) |

Yield Strength | 500-900 MPa |

Young's Modulus | 200-230 GPa |

Elongation | 10-20% |

Corrosion Resistance | Excellent, resistant to acids, alkalis, saline, and high-temperature oxidation |

Biocompatibility | Good, widely used in dental restorations and orthopedic implants |

Wear Resistance | Excellent, suitable for high-wear environments like cutting tools, turbine blades |

High-Temperature Resistance | Maintains performance up to 600-800°C, ideal for aerospace engine components |

Processing Methods | Precision casting, 3D printing, CAD/CAM, laser cladding |

Typical Applications | Dental prosthetics (e.g., crowns, frameworks), aerospace parts, turbine blades, oil drilling rods, medical implants |

The global medical alloy market is evolving rapidly. As patients and manufacturers seek safer and longer-lasting materials, Cobalt-Chromium alloys are seeing strong demand across dental and orthopedic industries. Key trends include:

Shift from titanium to CoCr alloys for higher wear and corrosion resistance in implants.

Increased customization using precision CNC machining and additive manufacturing for complex shapes.

Growth in orthodontic applications where strength and flexibility are equally important.

Stricter medical standards pushing suppliers toward traceable, certified raw materials.

Global demand for stable supply chains — an area where DLX excels through consistent capacity and quality control.

DLX remains at the forefront by integrating advanced metallurgical control, vacuum melting technology, and automated tube drawing processes that guarantee precision and cleanliness at the medical level.

Comparison Table

| Property / Feature | DLX CoCr Alloy Tube | Titanium Tube | Stainless Steel Tube |

|---|---|---|---|

| Density (g/cm³) | 8.3–8.9 | 4.5 | 7.9 |

| Tensile Strength (MPa) | 1200–1500 | 900–1100 | 600–850 |

| Corrosion Resistance | Excellent | Excellent | Good |

| Biocompatibility | Excellent | Excellent | Moderate |

| Wear Resistance | Superior | Good | Moderate |

| Elastic Modulus (GPa) | 200–230 | 110 | 190 |

| Magnetic Properties | Low / Controlled | Non-Magnetic | Slightly Magnetic |

| Applications | Dental, Orthopedic, Surgical | Dental, Bone Implants | General Medical Use |

| Service Life | Very Long | Long | Medium |

In the medical and dental industries, reliability isn’t optional — it’s mandatory. Every material that goes into the human body must perform consistently under the most demanding conditions. This is why Cobalt-Chromium (CoCr) alloy tubes have become one of the top choices for manufacturers producing high-performance medical devices and dental implants.

At DLX, we specialize in medical-grade CoCr tubes designed for strength, safety, and long-term performance. Our tubes are produced using refined metallurgical processes that ensure purity and uniformity, key factors for applications that directly interact with human tissue.

Material Science and Purity

Cobalt-Chromium alloys stand out due to their high strength-to-weight ratio and resistance to wear, oxidation, and corrosion. For medical and dental uses, these properties mean longer service life and reduced risk of failure. At DLX, our alloys undergo strict vacuum melting to remove impurities and gas inclusions, creating a fine-grain structure ideal for machining into complex medical shapes.

Each batch is carefully analyzed through spectrometric chemical testing and non-destructive ultrasonic inspection, ensuring consistent results from raw material to finished product. This commitment to purity makes DLX’s CoCr tubes suitable for direct implantation and repeated sterilization environments.

Applications in Dentistry and Medicine

In dental fields, DLX CoCr tubes are used to produce abutments, bridges, and orthodontic components that must withstand constant movement and chemical exposure in the mouth. The excellent polishability of CoCr makes it both functional and aesthetic — an essential factor for visible dental applications.

In medicine, our tubes are used in joint prosthetics, spinal connectors, and surgical tool shafts. Their combination of rigidity and corrosion resistance provides surgeons with reliable instruments that maintain performance through repeated autoclaving cycles. The material’s low allergenic response further enhances patient safety.

Industry Growth and Innovation

The medical device sector is evolving toward materials that can perform under stress and remain biocompatible over decades. With rising global demand for implants and precision orthodontic components, Cobalt-Chromium is being recognized as a sustainable solution — particularly where titanium’s flexibility limits load-bearing strength.

DLX responds to this demand with automated tube production lines, real-time quality monitoring, and custom machining services to ensure that every client receives products tailored to their application. Our technical team collaborates with medical device designers to optimize material selection and improve production efficiency.

DLX’s Competitive Advantage

While many suppliers focus only on alloy production, DLX goes further by offering end-to-end support:

Material customization based on implant design and stress simulation data.

Cleanroom packaging for contamination-free delivery.

International certification compliance for medical use, ensuring easy integration into global supply chains.

Stable delivery schedules backed by long-term alloy sourcing contracts.

By combining manufacturing precision with reliable logistics, DLX has built a reputation as a trusted CoCr tube supplier for global dental and medical companies seeking quality and consistency.

Sustainability and Future Outlook

The next generation of medical materials will require even tighter control over purity, traceability, and recycling. DLX is already moving in that direction by developing low-carbon manufacturing processes and recyclable alloy solutions that align with modern environmental standards.

As the industry continues to evolve, DLX remains committed to providing a stable, high-quality supply of Cobalt-Chromium tubes, supporting the global medical community with products designed for both safety and performance. For implant producers and medical device manufacturers, DLX represents not just a supplier — but a dependable partner for innovation and quality.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What makes CoCr alloys suitable for dental and medical applications?

CoCr alloys combine high strength, corrosion resistance, and excellent biocompatibility, making them ideal for long-term use inside the human body.

2. How does DLX ensure medical-grade purity in CoCr tubes?

DLX uses vacuum induction melting (VIM) and electroslag remelting (ESR) to remove impurities, ensuring clean microstructures and consistent alloy chemistry.

3. Are CoCr tubes safe for dental implants and oral contact?

Yes. DLX CoCr alloys meet biocompatibility standards (ISO 5832 and ASTM F1537), ensuring no toxic or allergic reactions in dental or medical use.

4. Can DLX provide customized dimensions and tolerances?

Absolutely. DLX specializes in custom tube sizes, wall thicknesses, and surface finishes according to implant and orthodontic design needs.

5. How do CoCr alloys compare to titanium?

While titanium offers excellent biocompatibility, CoCr provides higher strength, wear resistance, and rigidity, which are beneficial in load-bearing dental and orthopedic components.

6. What surface treatments are available for CoCr tubes?

DLX provides mirror polishing, passivation, and precision machining for smooth, non-porous surfaces to prevent bacterial adhesion.

7. How does DLX maintain stable supply?

We maintain a large production capacity, multiple alloy sourcing channels, and long-term supply chain partnerships to ensure consistent material delivery.

8. Why choose DLX for CoCr alloy tubes?

DLX combines medical-grade alloy expertise, full traceability, stable global supply, and professional technical support to serve implant and medical manufacturers worldwide.