We’re proud to present our custom CoCr (cobalt chromium) tubing, a powerhouse material built for advanced engineering solutions. This high-performance alloy tubing is designed to tackle the toughest challenges in industries like aerospace, medical, and energy. With its strength, durability, and versatility, it’s setting a new standard for precision engineering. Let’s explore what makes our CoCr tubing special, dive into its applications, analyze industry trends, and show why our product leads the way.

For more details, pls directly contact us.

Our custom CoCr tubing is crafted from a high-purity cobalt chromium alloy, blending exceptional strength with corrosion resistance. It’s built for applications where reliability is non-negotiable—think jet engines, medical implants, or high-pressure energy systems. With tensile strengths of 1000–1500 MPa and the ability to withstand temperatures up to 1000°C, this tubing thrives in extreme conditions.

What sets it apart is its flexibility. We customize every aspect—outer diameters (0.5–100 mm), wall thicknesses (0.1–10 mm), and surface finishes—to match your project’s exact needs. Whether you need ultra-thin tubing for a medical device or robust pipes for an oil rig, we’ve got you covered. Its lightweight design (8.4–8.9 g/cm³) and wear resistance make it ideal for dynamic, high-stress environments.

Key features include:

-

High strength: Tensile strength up to 1500 MPa for heavy-duty applications.

-

Corrosion resistance: Stands up to acids, saltwater, and harsh chemicals.

-

Heat tolerance: Performs reliably at temperatures up to 1000°C.

-

Custom design: Tailored dimensions and finishes for seamless integration.

-

Sustainable: Long lifespan and recyclability reduce environmental impact.

Cobalt-Chromium Alloy Parameters Table

|

Parameter |

Typical Value/Range |

|---|---|

|

Chemical Composition |

Cobalt (Co): 60-70% |

|

Density |

8.3-8.5 g/cm³ |

|

Melting Point |

1250-1450°C |

|

Hardness (Rockwell) |

Soft: 20-30 HRC |

|

Tensile Strength |

800-1200 MPa (depending on alloy and heat treatment) |

|

Yield Strength |

500-900 MPa |

|

Young's Modulus |

200-230 GPa |

|

Elongation |

10-20% |

|

Corrosion Resistance |

Excellent, resistant to acids, alkalis, saline, and high-temperature oxidation |

|

Biocompatibility |

Good, widely used in dental restorations and orthopedic implants |

|

Wear Resistance |

Excellent, suitable for high-wear environments like cutting tools, turbine blades |

|

High-Temperature Resistance |

Maintains performance up to 600-800°C, ideal for aerospace engine components |

|

Processing Methods |

Precision casting, 3D printing, CAD/CAM, laser cladding |

|

Typical Applications |

Dental prosthetics (e.g., crowns, frameworks), aerospace parts, turbine blades, oil drilling rods, medical implants |

The advanced engineering sector is evolving rapidly, driven by innovation and the need for materials that can keep up with cutting-edge applications. The global market for high-performance alloys is growing steadily, fueled by advancements in aerospace, energy, and medical technologies. Cobalt chromium alloys are in high demand for their ability to deliver strength, durability, and corrosion resistance in extreme conditions.

Key trends shaping the industry include:

-

Aerospace innovation: Lightweight, strong materials are critical for fuel efficiency and performance in aircraft and spacecraft.

-

Energy transition: Renewable energy and oil/gas systems require durable tubing for high-pressure and corrosive environments.

-

Medical advancements: Biocompatible, high-strength materials are essential for next-generation implants and devices.

-

Sustainability focus: Industries are prioritizing recyclable materials to meet environmental goals.

-

Precision engineering: Customizable components are in demand for specialized applications.

Challenges persist, though. Traditional materials like stainless steel often corrode in harsh environments, while titanium, though lightweight, may lack the wear resistance needed for dynamic systems. Our CoCr tubing addresses these issues, offering a robust, versatile solution that outperforms conventional options.

Applications: Where Our CoCr Tubing Excels

Our custom CoCr tubing is a game-changer across multiple industries. Here’s where it’s making a difference:

-

Aerospace: Used in jet engine components, hydraulic systems, and structural supports, where its strength and heat resistance shine.

-

Medical Devices: Forms stents, orthopedic implants, and surgical tools, offering biocompatibility and durability.

-

Oil and Gas: Handles high-pressure pipelines and corrosive fluids in drilling and refining operations.

-

Renewable Energy: Supports solar thermal systems and geothermal plants, resisting extreme temperatures and corrosion.

-

Automotive: Used in high-performance exhaust systems and turbochargers, balancing strength and weight.

-

Chemical Processing: Manages aggressive chemicals in reactors and filtration systems without degrading.

Its ability to perform under high stress, heat, or corrosion makes it a top choice for demanding applications. Plus, its customizability ensures it fits perfectly into innovative designs, from micro-tubing to heavy-duty pipes.

Comparison Parameters Table

|

Parameter |

Custom CoCr Tubing |

Titanium Tubing |

Stainless Steel Tubing |

|---|---|---|---|

|

Tensile Strength |

High (1000–1500 MPa) |

Moderate (800–1100 MPa) |

Moderate (600–1000 MPa) |

|

Corrosion Resistance |

Excellent (resists acids, saltwater, chemicals) |

Excellent |

Moderate (prone to pitting) |

|

Heat Resistance |

Up to 1000°C |

Up to 600°C |

Up to 800°C |

|

Weight |

Moderate (8.4–8.9 g/cm³) |

Lightweight (4.5 g/cm³) |

Moderate (7.9–8.0 g/cm³) |

|

Wear Resistance |

Superior (ideal for dynamic applications) |

Good |

Moderate |

|

Customizability |

High (tailored dimensions, finishes) |

Moderate |

Limited |

|

Fatigue Resistance |

Excellent (handles cyclic loading) |

Good |

Moderate |

|

Recyclability |

High (fully recyclable) |

High |

High (but shorter lifespan) |

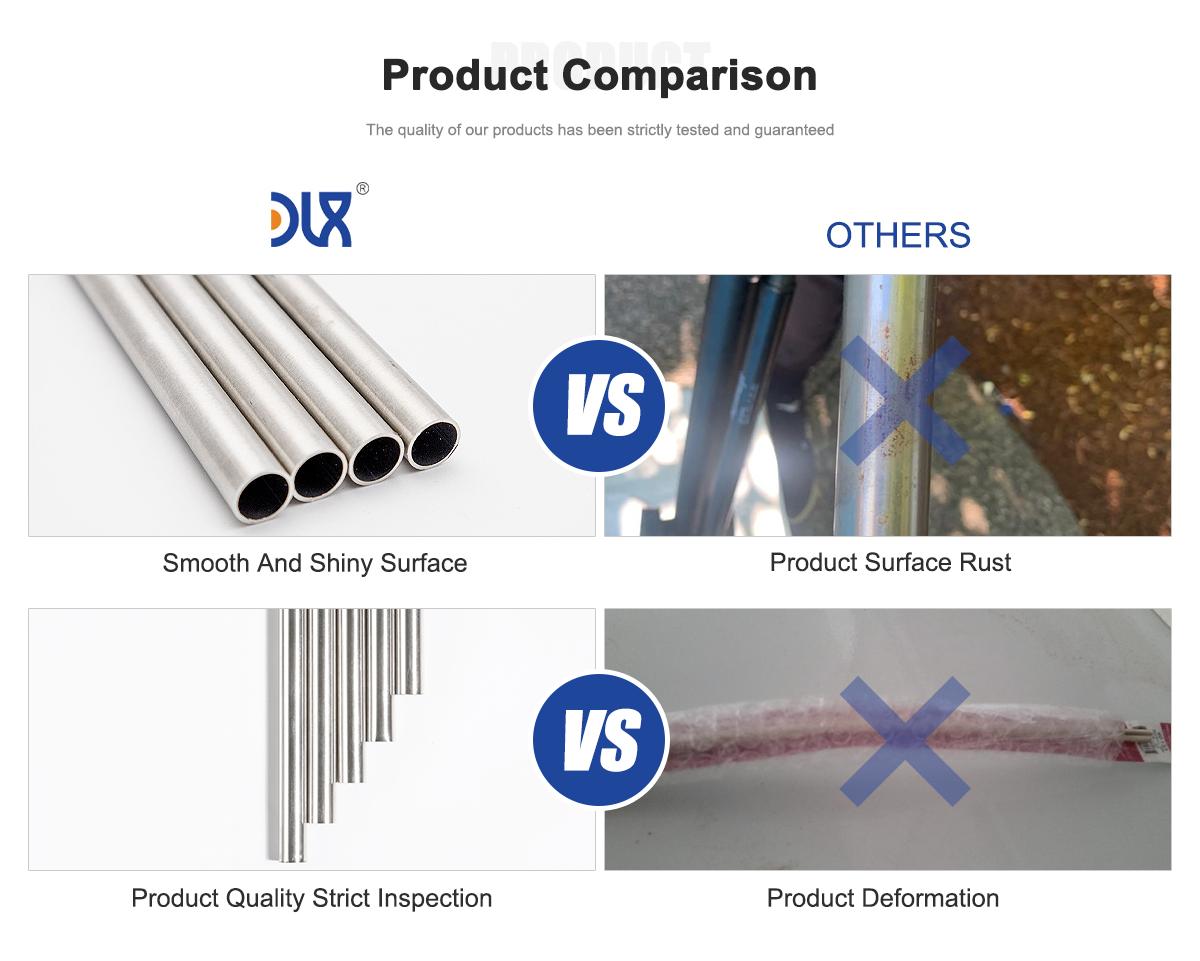

When it comes to custom CoCr tubing, we’re not just keeping up—we’re setting the pace. Here’s how our product stacks up against a typical competitor in the high-performance alloy space:

-

Material Quality: Our tubing is made from high-purity cobalt chromium, ensuring consistent performance and reliability. Others may use lower-grade alloys, risking defects.

-

Precision Customization: We offer tailored dimensions, thicknesses, and finishes with tolerances down to ±0.01 mm. Competitors often stick to standard sizes, limiting flexibility.

-

Performance Edge: Our tubing delivers superior tensile strength (up to 1500 MPa) and wear resistance, perfect for dynamic applications. Alternatives may fall short in high-stress conditions.

-

Durability: With excellent corrosion and heat resistance, our tubing lasts longer in extreme environments. Other materials degrade faster, increasing maintenance costs.

-

Sustainability: Our recyclable tubing and eco-friendly production align with green engineering trends. Many competitors lag in sustainable practices.

-

Support: We provide end-to-end guidance, from design to integration, ensuring your project succeeds. Others may offer minimal support, leaving you to figure things out.

Our edge comes from cutting-edge R&D, advanced manufacturing, and a relentless focus on customer needs. We’re here to deliver solutions that power your innovations.

Why Choose Our Custom CoCr Tubing?

Our custom CoCr tubing is more than a component—it’s a foundation for advanced engineering. Its strength, corrosion resistance, and versatility make it ideal for industries pushing the limits of performance. Whether you’re building aircraft, medical devices, or energy systems, our tubing delivers reliability and precision.

We’re committed to driving engineering forward through innovation, quality, and sustainability. By delivering tailored solutions and unmatched support, we help our clients stay ahead in a competitive world. Ready to take your project to the next level? Our custom CoCr tubing is the answer.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What’s the main use of custom CoCr tubing?

It’s used in high-performance engineering applications like aerospace, medical devices, and energy systems. -

Why is cobalt chromium ideal for engineering?

It combines high strength, corrosion resistance, and heat tolerance for extreme environments. -

Can it handle harsh conditions?

Yes, it resists corrosion from chemicals, saltwater, and high temperatures up to 1000°C. -

Is it customizable for specific projects?

Absolutely, we tailor dimensions, wall thickness, and finishes to meet precise requirements. -

What industries benefit most from this tubing?

Aerospace, medical, oil and gas, automotive, and renewable energy sectors rely on it. -

How does it compare to other materials?

It offers better strength-to-weight ratio and wear resistance than stainless steel or titanium. -

Is it suitable for high-pressure systems?

Definitely, its high tensile strength makes it ideal for demanding pressure applications. -

Are there eco-friendly benefits?

Yes, its durability and recyclability make it a sustainable choice for engineering solutions.