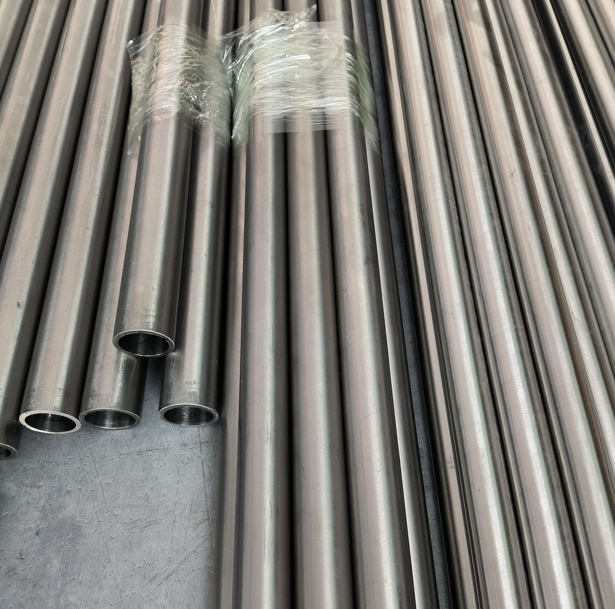

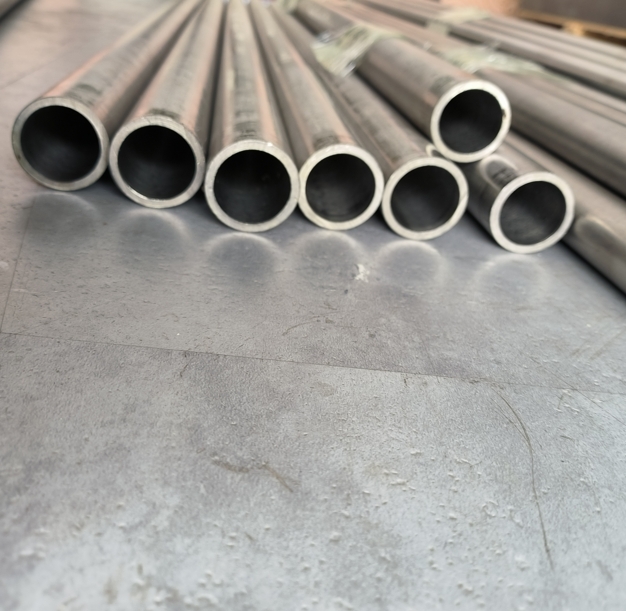

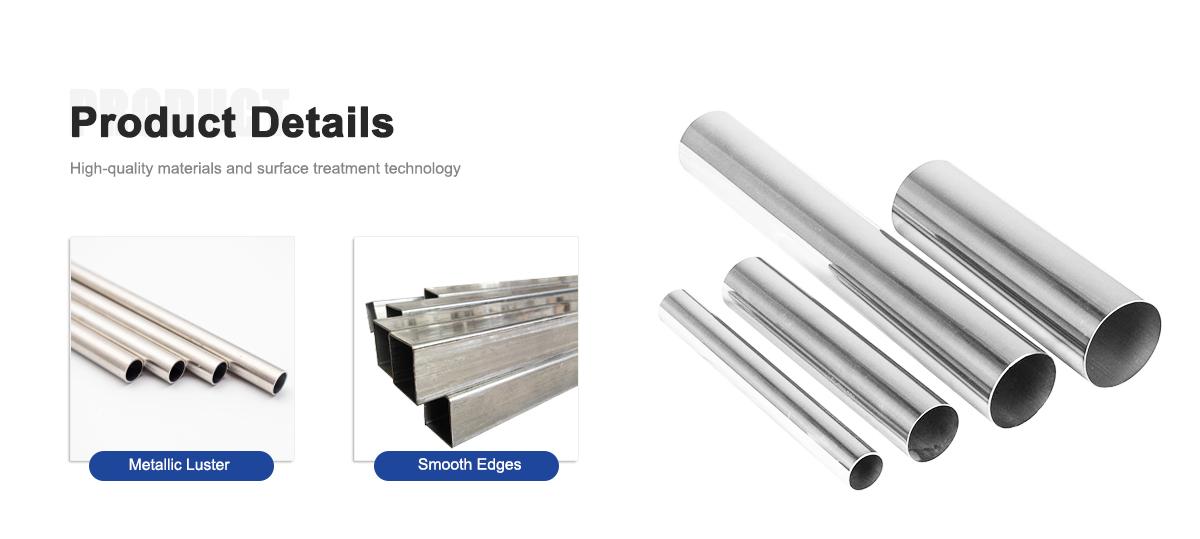

Cobalt Chromium (Co-Cr) alloy tubes are known for their outstanding mechanical strength, superior corrosion resistance, and high-temperature performance. These alloys combine the hardness of cobalt with the oxidation resistance of chromium, creating a material that can withstand extreme environments found in the nuclear, oil, and energy sectors. At DLX, our Cobalt Chromium Tube s are precisely manufactured for demanding applications that require both structural integrity and long-term durability under stress, heat, and corrosive conditions.

For more details, pls directly contact us.

Cobalt Chromium tubes play a crucial role in high-stress and corrosive industries, including:

Nuclear power systems: for control rods, heat exchangers, and reactor cooling circuits.

Oil and gas exploration: for deep-well drilling equipment, high-pressure tubing, and chemical injection systems.

Energy conversion and turbines: for components exposed to high-temperature oxidation and mechanical wear.

Medical and aerospace: due to biocompatibility and resistance to fatigue and creep.

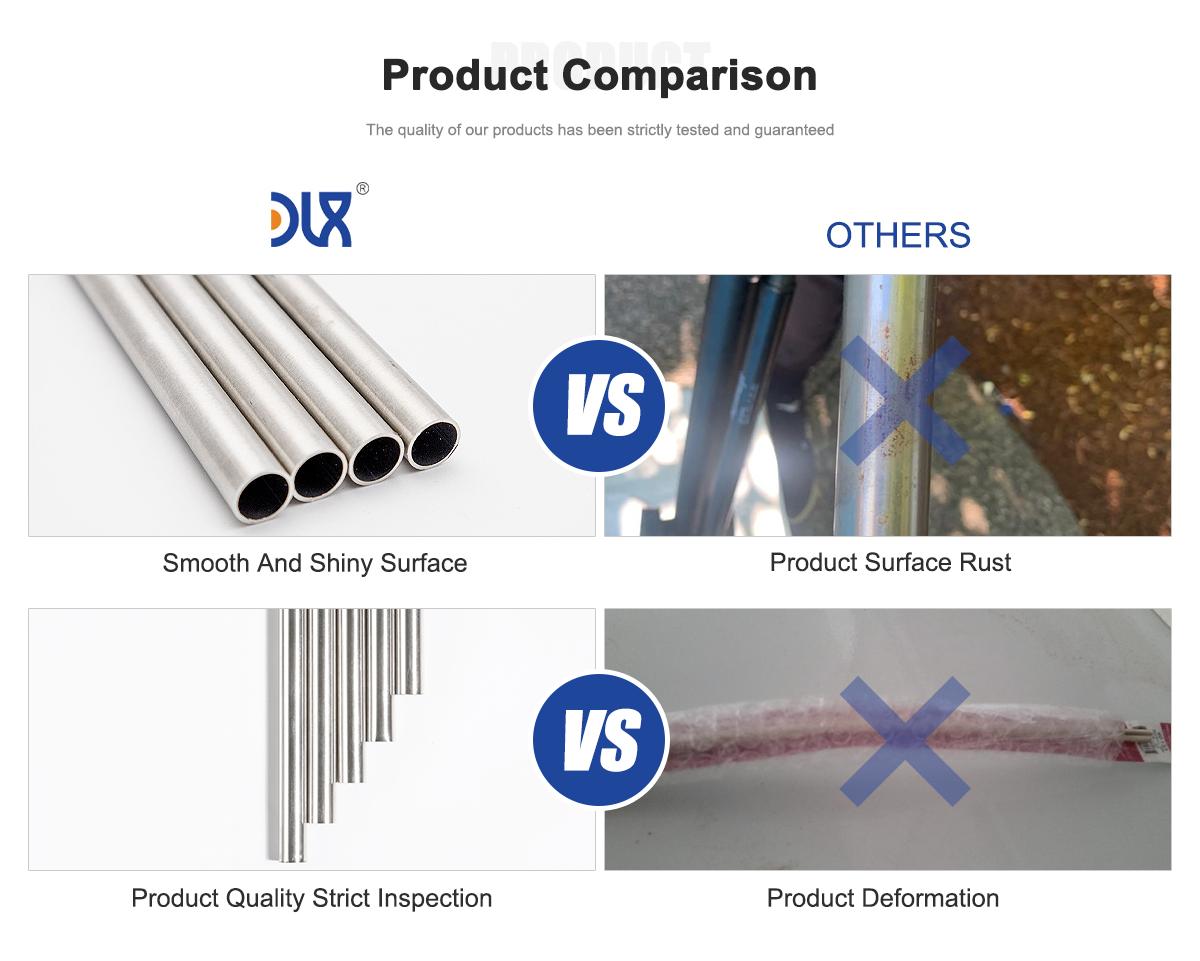

These applications demand precision-engineered materials that can perform consistently even in the harshest operating conditions — a standard that DLX maintains through strict quality control and alloy purity management.

Parameter | Typical Value/Range |

|---|---|

Chemical Composition | Cobalt (Co): 60-70% |

Density | 8.3-8.5 g/cm³ |

Melting Point | 1250-1450°C |

Hardness (Rockwell) | Soft: 20-30 HRC |

Tensile Strength | 800-1200 MPa (depending on alloy and heat treatment) |

Yield Strength | 500-900 MPa |

Young's Modulus | 200-230 GPa |

Elongation | 10-20% |

Corrosion Resistance | Excellent, resistant to acids, alkalis, saline, and high-temperature oxidation |

Biocompatibility | Good, widely used in dental restorations and orthopedic implants |

Wear Resistance | Excellent, suitable for high-wear environments like cutting tools, turbine blades |

High-Temperature Resistance | Maintains performance up to 600-800°C, ideal for aerospace engine components |

Processing Methods | Precision casting, 3D printing, CAD/CAM, laser cladding |

Typical Applications | Dental prosthetics (e.g., crowns, frameworks), aerospace parts, turbine blades, oil drilling rods, medical implants |

For more details, pls directly contact us.

With the global shift toward sustainable and long-term energy solutions, industries are investing in materials that reduce maintenance and extend equipment lifespan. Cobalt Chromium alloys are increasingly preferred due to:

Rising demand in nuclear and hydrogen power industries for corrosion-proof tubing.

Material innovation improving high-temperature fatigue resistance.

Growing interest in additive manufacturing for complex tube geometries using Co-Cr alloys.

Stringent safety standards in oil, gas, and nuclear applications encouraging the use of higher-grade alloys.

DLX continues to stay ahead by adopting advanced melting technologies, precision drawing techniques, and continuous testing to meet international standards.

Comparison Table

| Property / Feature | Cobalt Chromium Tube (DLX) | Stainless Steel Tube | Inconel Tube |

|---|---|---|---|

| Tensile Strength (MPa) | 1200–1500 | 600–850 | 950–1250 |

| Max Operating Temperature (°C) | 1100 | 800 | 1050 |

| Corrosion Resistance | Excellent (acid & gas) | Good | Excellent |

| Creep Resistance | Outstanding | Moderate | High |

| Oxidation Resistance | Superior | Average | High |

| Wear Resistance | Excellent | Moderate | Good |

| Typical Applications | Nuclear, Oil, Energy | General Industry | Aerospace, Gas Turbines |

| Longevity / Life Cycle | Very Long | Medium | Long |

Cobalt Chromium tubes have become indispensable in modern energy systems where extreme pressure, heat, and corrosion meet. These materials are engineered to perform flawlessly under stress while offering extended service life — a balance that many traditional alloys cannot achieve.

At DLX, our engineering team focuses on precision metallurgy and surface treatment to produce tubing that not only meets but exceeds global industry standards. Whether used in nuclear reactor systems or deep-sea oil extraction, DLX Cobalt Chromium tubes offer unmatched reliability.

Material Science and Performance

The secret behind the exceptional performance of Co-Cr alloys lies in their microstructure. Cobalt provides a stable base matrix that retains strength at elevated temperatures, while chromium contributes an adherent oxide layer that resists scaling and corrosion. This makes DLX’s Cobalt Chromium tubes perfect for continuous exposure to oxidizing gases, saltwater, and aggressive chemicals.

Our advanced vacuum induction melting (VIM) and precision extrusion processes ensure fine-grain structures and uniform wall thickness, giving every DLX tube the ability to withstand high-stress operational cycles without deformation or cracking.

The energy sector demands stability, and DLX tubes deliver it. In nuclear applications, they maintain mechanical properties even under neutron bombardment and high radiation fields. In oil and gas systems, they resist sour gas corrosion and mechanical erosion from sand and drilling fluids.

We collaborate with engineers to design tailor-made tubing that meets the most stringent project specifications, including tight tolerance control and certified chemical composition for traceability and safety assurance.

Industry Evolution and DLX’s Commitment

With sustainability becoming central to energy operations, the industry is moving toward longer-lasting, recyclable, and performance-optimized materials. DLX has aligned its R&D efforts with this shift — developing alloys that minimize maintenance intervals and maximize system uptime.

Our production process integrates real-time monitoring, non-destructive evaluation, and environmental control to achieve uniform metallurgical consistency. This ensures every tube from DLX is ready to handle the operational intensity of the nuclear, oil, and energy industries.

DLX stands out by combining technical expertise with responsive service. From prototype development to mass production, we provide full support — material consultation, design optimization, and post-sale technical guidance. Our tubes are exported globally and trusted by clients who value precision, performance, and partnership.

In a market where reliability defines reputation, DLX’s commitment to metallurgical excellence and long-term collaboration makes us the go-to supplier for Cobalt Chromium tubes in high-performance energy systems.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

1. What makes Cobalt Chromium tubes suitable for high-pressure environments?

Their superior yield strength and creep resistance allow them to maintain dimensional stability and integrity under extreme pressure and temperature conditions.

2. How does Co-Cr alloy resist corrosion compared to stainless steel?

Cobalt Chromium forms a dense, self-healing oxide layer that provides stronger protection against oxidation, acids, and hot gases than conventional stainless steels.

3. Are DLX Co-Cr tubes customizable?

Yes. DLX offers customized dimensions, wall thicknesses, and surface finishes to match specific industrial requirements.

4. Can Cobalt Chromium tubes be used in nuclear reactors?

Absolutely. Their radiation resistance, strength retention, and corrosion resistance make them ideal for nuclear applications such as heat exchangers and structural components.

5. How are DLX tubes tested before delivery?

Each tube undergoes ultrasonic inspection, hydrostatic pressure testing, and chemical composition analysis to ensure consistent performance and reliability.

6. What temperatures can these tubes withstand?

DLX Cobalt Chromium tubes perform effectively up to 1100°C (2012°F) depending on the alloy grade and environment.

7. Are Co-Cr alloys environmentally friendly?

Yes. They offer a long service life and reduce material replacement frequency, lowering overall resource consumption in industrial systems.

8. Why choose DLX for Cobalt Chromium tubing?

DLX provides consistent metallurgical quality, precision machining, and comprehensive technical support, ensuring reliability in the most demanding energy applications.