We’re fired up about our wear-resistant cobalt chrome tubing, a rock-solid solution for industrial applications where durability and performance are non-negotiable. As a company committed to delivering top-tier materials, we’ve engineered tubing that stands up to the toughest wear and tear in industrial settings. This article dives into what makes our cobalt chrome tubing a game-changer, explores its applications, breaks down industry trends, and shows why we’re the go-to choice for industrial engineers.

For more details, pls directly contact us.

Our wear-resistant cobalt chrome tubing is built to take a beating in industrial environments. Crafted from cobalt-chromium-molybdenum (CoCrMo) alloys, like those meeting ASTM F1537 or similar standards, these tubes boast tensile strengths of 900–1450 MPa and exceptional wear resistance. They’re perfect for components like pump shafts, valve linings, and conveyor rollers that face constant abrasion and stress.

The alloy’s strength comes from its composition—27–30% chromium, 5–7% molybdenum, and trace elements like carbon. Chromium forms a tough oxide layer (Cr2O3) that resists corrosion from harsh chemicals, while molybdenum boosts strength and fatigue resistance, ensuring our tubes hold up in demanding industrial conditions. We use advanced manufacturing techniques, like seamless forging and precision casting, to produce tubes with exact dimensions and flawless finishes, tailored to your specific needs.

Every tube is rigorously tested to meet industry standards, ensuring reliability in high-stakes industrial applications. Whether you need robust tubing for heavy-duty machinery or precision components for chemical processing, we deliver customized solutions that perform. Our focus on quality and durability makes our tubing a trusted choice for industrial challenges.

Cobalt-Chromium Alloy Parameters Table

|

Parameter |

Typical Value/Range |

|---|---|

|

Chemical Composition |

Cobalt (Co): 60-70% |

|

Density |

8.3-8.5 g/cm³ |

|

Melting Point |

1250-1450°C |

|

Hardness (Rockwell) |

Soft: 20-30 HRC |

|

Tensile Strength |

800-1200 MPa (depending on alloy and heat treatment) |

|

Yield Strength |

500-900 MPa |

|

Young's Modulus |

200-230 GPa |

|

Elongation |

10-20% |

|

Corrosion Resistance |

Excellent, resistant to acids, alkalis, saline, and high-temperature oxidation |

|

Biocompatibility |

Good, widely used in dental restorations and orthopedic implants |

|

Wear Resistance |

Excellent, suitable for high-wear environments like cutting tools, turbine blades |

|

High-Temperature Resistance |

Maintains performance up to 600-800°C, ideal for aerospace engine components |

|

Processing Methods |

Precision casting, 3D printing, CAD/CAM, laser cladding |

|

Typical Applications |

Dental prosthetics (e.g., crowns, frameworks), aerospace parts, turbine blades, oil drilling rods, medical implants |

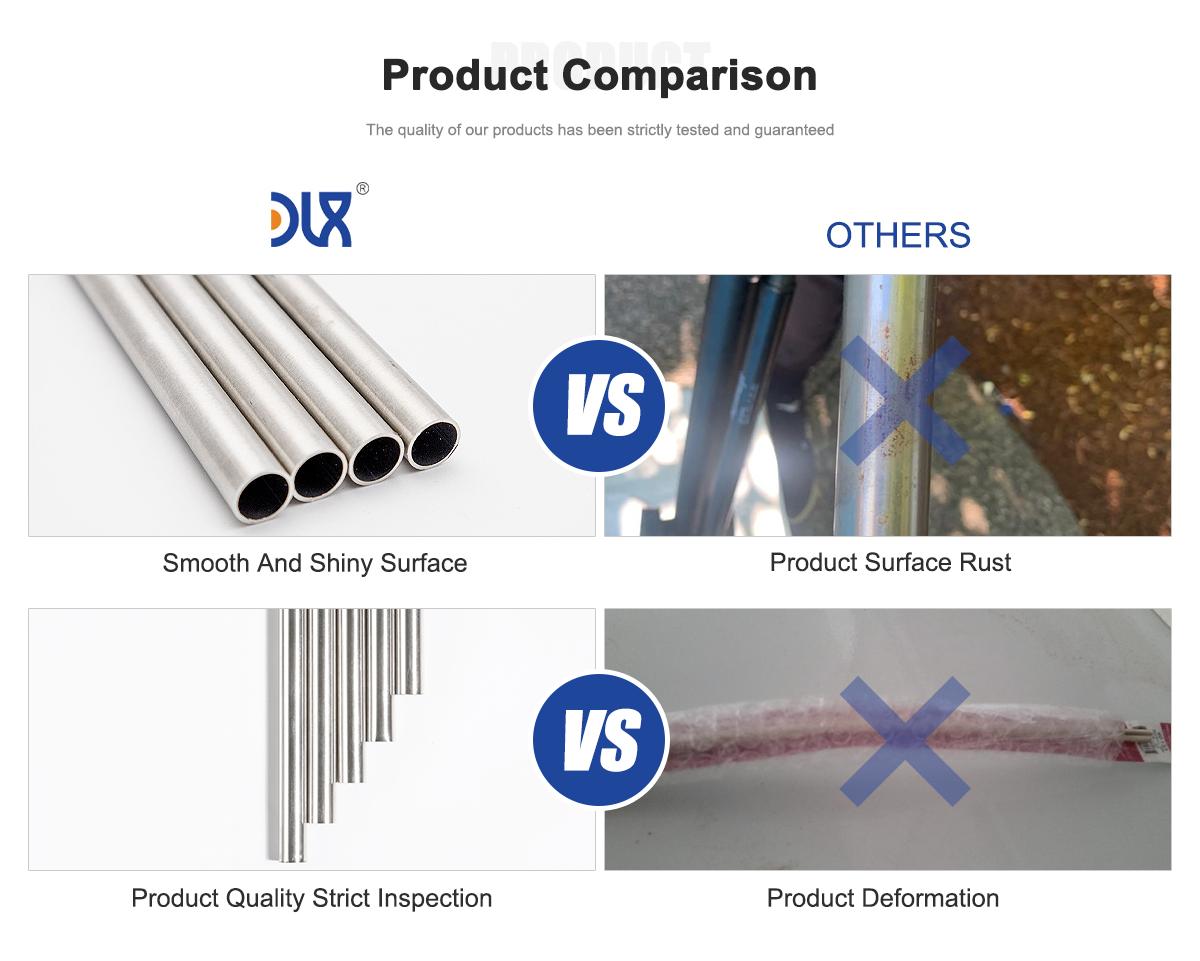

Cobalt chrome alloys are a powerhouse for industrial applications, and here’s why. Their high tensile strength (900–1450 MPa) and hardness (550–800 MPa) make them ideal for components that face intense mechanical stress, like pump shafts or conveyor rollers. Wear resistance is a standout feature—our tubing stands up to abrasion and erosion, even in environments with gritty materials or high friction.

Corrosion resistance is critical in industrial settings, where components are exposed to acids, alkalis, or salty conditions. The chromium content creates a passive oxide layer that protects against degradation, ensuring long-term performance and reduced maintenance costs. The alloy’s ability to maintain strength at elevated temperatures—up to 1000°C—makes it perfect for high-heat industrial processes.

One challenge? Cobalt chrome’s hardness makes it tougher to machine than materials like titanium or stainless steel. That’s where our expertise comes in. We’ve invested in state-of-the-art machining and additive manufacturing to deliver precise, high-quality tubing without driving up costs. It’s a tough material, but we’ve got it under control.

Applications: Where Our Tubing Makes an Impact

Our wear-resistant cobalt chrome tubing is a star in industrial applications, but its versatility extends to other fields. In industry, it’s used for:

-

Pump Shafts: Our tubing’s wear and corrosion resistance make it ideal for pumps handling abrasive or corrosive fluids.

-

Valve Linings: Its durability ensures reliable performance in valves exposed to harsh chemicals and high pressure.

-

Conveyor Rollers: The tubing’s strength and wear resistance are perfect for rollers in heavy-duty material handling systems.

Beyond industrial applications, our cobalt chrome tubing excels in:

-

Aerospace: Its high-temperature strength is ideal for turbine blades and engine components.

-

Medical Implants: Its biocompatibility makes it perfect for orthopedic and cardiovascular devices.

-

Jewelry: Its durability and wear resistance make it a premium choice for high-end accessories.

Industry Analysis: What’s Driving the Market?

The cobalt chrome tubing market is thriving, with a projected value of around $500 million in 2025 and a growth rate of 5–12.5% through 2033. We’re at the forefront, meeting the rising demand for high-performance materials. What’s fueling this growth?

The industrial sector is a major driver. With global manufacturing and processing industries expanding, especially in emerging markets, the need for durable, wear-resistant components is skyrocketing. Industries like chemical processing, mining, and energy are investing in robust materials to handle increasingly harsh conditions, and our tubing is perfectly positioned to meet this demand.

Technology is a big game-changer too. Additive manufacturing, like selective laser melting, allows us to create complex tubing designs with better efficiency and precision. We’re also seeing a push for advanced coatings that enhance wear and corrosion resistance, a trend we’re incorporating into our R&D. These innovations are making industrial components more reliable and cost-effective.

Challenges include high raw material costs for cobalt and chromium, which can squeeze margins. Stringent industry standards, like those from ASME and API, add complexity too. Competition from Titanium Alloy s (lighter) and stainless steel (cheaper) is a factor, but cobalt chrome’s superior wear resistance and strength keep it ahead for industrial applications. We’re leveraging these advantages to stay competitive.

North America and Europe dominate the market with their established industrial sectors, but Asia-Pacific is gaining fast, with countries like China and India investing heavily in manufacturing and energy. We’re expanding our presence to tap into these growing markets.

Comparison Parameters Table

|

Parameter |

Cobalt Chrome Tube |

Titanium Alloy Tube |

Stainless Steel Tube |

|---|---|---|---|

|

Tensile Strength (MPa) |

900–1450 |

800–1100 |

500–1000 |

|

Corrosion Resistance |

Excellent |

Very Good |

Good |

|

Wear Resistance |

Excellent |

Good |

Moderate |

|

High-Temperature Strength |

Excellent |

Good |

Moderate |

|

Density (g/cm³) |

8.3–8.9 |

4.5 |

7.8–8.0 |

|

Machinability |

Difficult |

Moderate |

Moderate |

|

Cost |

High |

Moderate |

Low |

|

Primary Applications |

Industrial, aerospace, medical |

Aerospace, medical implants |

General industrial, medical |

Our wear-resistant cobalt chrome tubing sets us apart because we’re all about quality, precision, and innovation. We use advanced techniques like 3D printing and seamless forging to deliver tubes with tighter tolerances and fewer defects than traditional methods. That means you get reliable, high-performing components every time.

We prioritize performance in harsh environments. Our alloys are formulated to maximize wear and corrosion resistance, ensuring your industrial systems run smoothly with less downtime. Every tube is tested to exceed industry standards, like those from ASTM and ASME, so you can trust them in critical applications.

Flexibility is a big deal for us. Whether you need precision tubing for valve linings or robust pipes for pump systems, we customize to your exact needs. Cobalt chrome’s hardness can make machining tough, but our state-of-the-art equipment and expertise deliver flawless results without inflating costs.

We’re also ahead on industry trends. Our R&D team is exploring new alloy compositions and protective coatings to boost performance, keeping us at the forefront of industrial innovation. From next-gen pump systems to durable conveyor components, we’re ready to support your projects.

Looking Ahead: The Future of Cobalt Chrome Tubing

The future of cobalt chrome tubing is bright, and we’re leading the charge. As additive manufacturing evolves, we’re pushing the limits with more complex, lightweight designs for industrial applications. The demand for efficient, durable industrial systems is driving innovation, and our tubing is at the forefront.

Sustainability is a priority too. We’re optimizing our processes to reduce waste and energy use, aligning with eco-conscious industrial initiatives. With the global industrial market set to keep growing, we’re scaling up while staying true to our commitment to quality.

Wrapping It Up

Our wear-resistant cobalt chrome tubing is a game-changer for industrial applications, offering unmatched strength, wear resistance, and corrosion resistance. From pump shafts to valve linings, it’s the go-to choice for engineers and extends to aerospace, medical, and jewelry applications. Backed by our advanced manufacturing, rigorous testing, and innovative approach, we’re delivering tubing that exceeds expectations. Whether you’re building heavy-duty industrial systems or durable components, our cobalt chrome tubing has you covered.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is wear-resistant cobalt chrome tubing used for in industrial applications?

It’s used for components like pump shafts, valve linings, and conveyor rollers that face heavy wear and abrasion. -

Why is cobalt chrome tubing preferred for industrial use?

Its exceptional wear resistance, high strength, and corrosion resistance make it ideal for harsh industrial environments. -

What are the key properties of wear-resistant cobalt chrome tubing?

Tensile strength of 900–1450 MPa, superior wear resistance, corrosion resistance, and high fatigue resistance. -

How is cobalt chrome tubing manufactured for industrial applications?

Through seamless forging, precision casting, or additive manufacturing like selective laser melting for durability. -

Can cobalt chrome tubing withstand abrasive industrial conditions?

Yes, its high hardness and wear resistance ensure long-term performance in abrasive and corrosive settings. -

What other industries use wear-resistant cobalt chrome tubing?

Aerospace for turbine components, medical for implants, and jewelry for durable designs. -

What challenges come with using cobalt chrome tubing in industry?

High material costs and difficult machining due to its hardness can increase production expenses. -

What are the latest trends in cobalt chrome tubing for industrial applications?

Advances in additive manufacturing, improved alloy formulations, and coatings for enhanced wear and corrosion resistance.