Our seamless 304/316 capillary tubing is engineered to deliver unmatched durability and precision for medical fluid delivery systems. These tiny tubes are the unsung heroes behind life-saving devices, ensuring fluids flow smoothly and safely in critical healthcare settings. Let’s break down what makes our tubing a top pick, from its robust materials to its wide-ranging applications, while diving into industry trends and why our company stands out in this fast-moving field.

For more details, pls directly contact us.

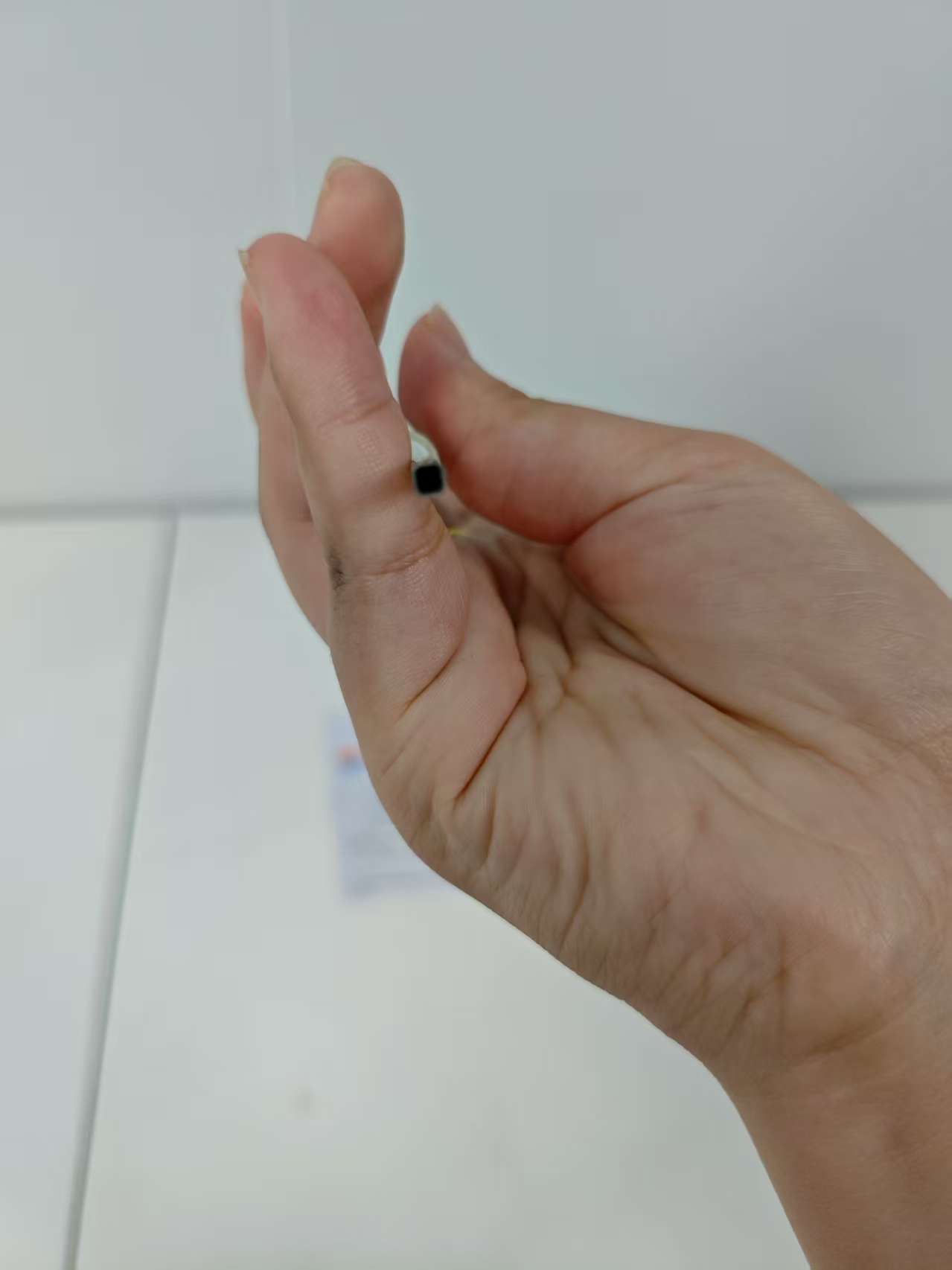

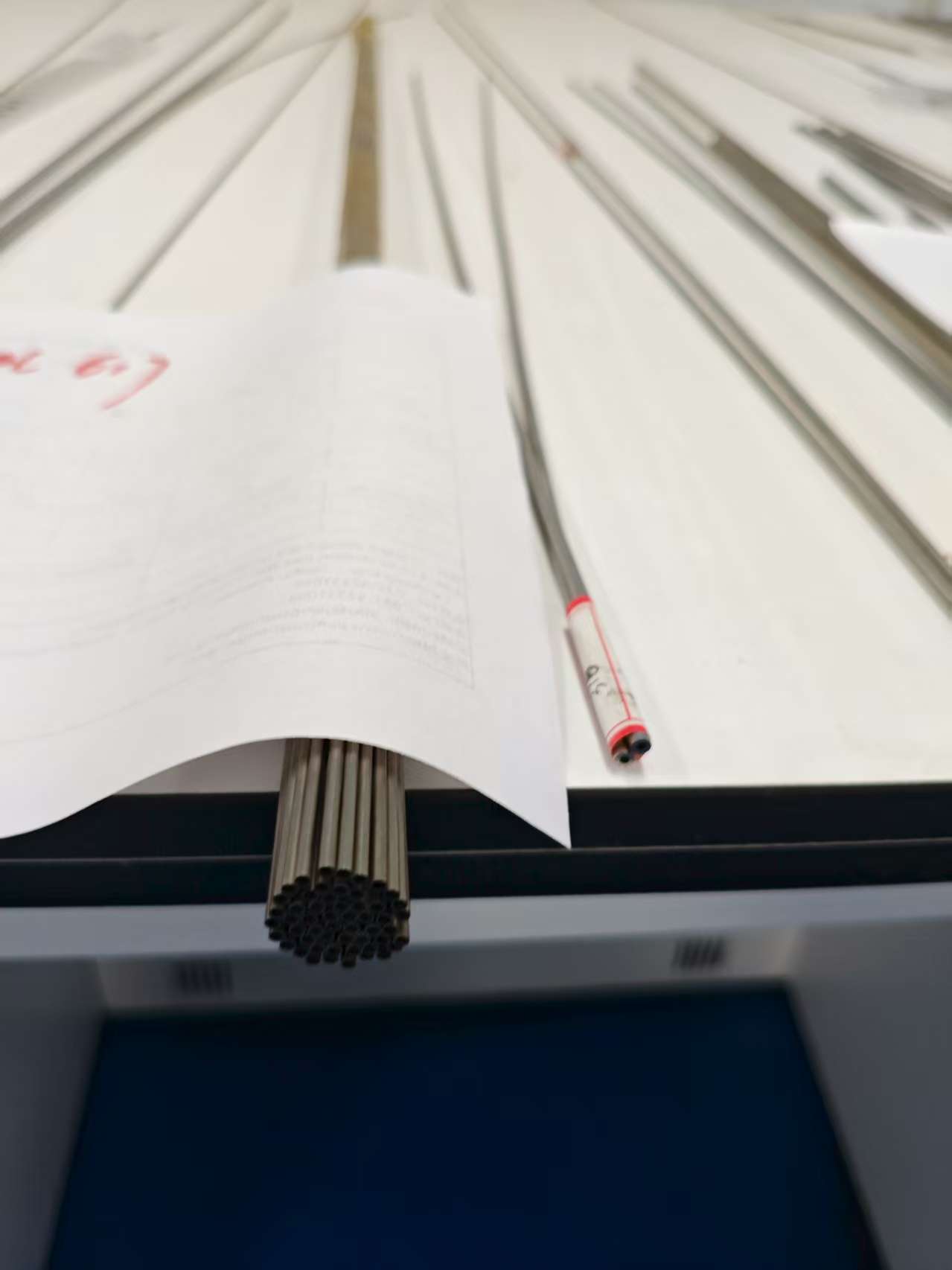

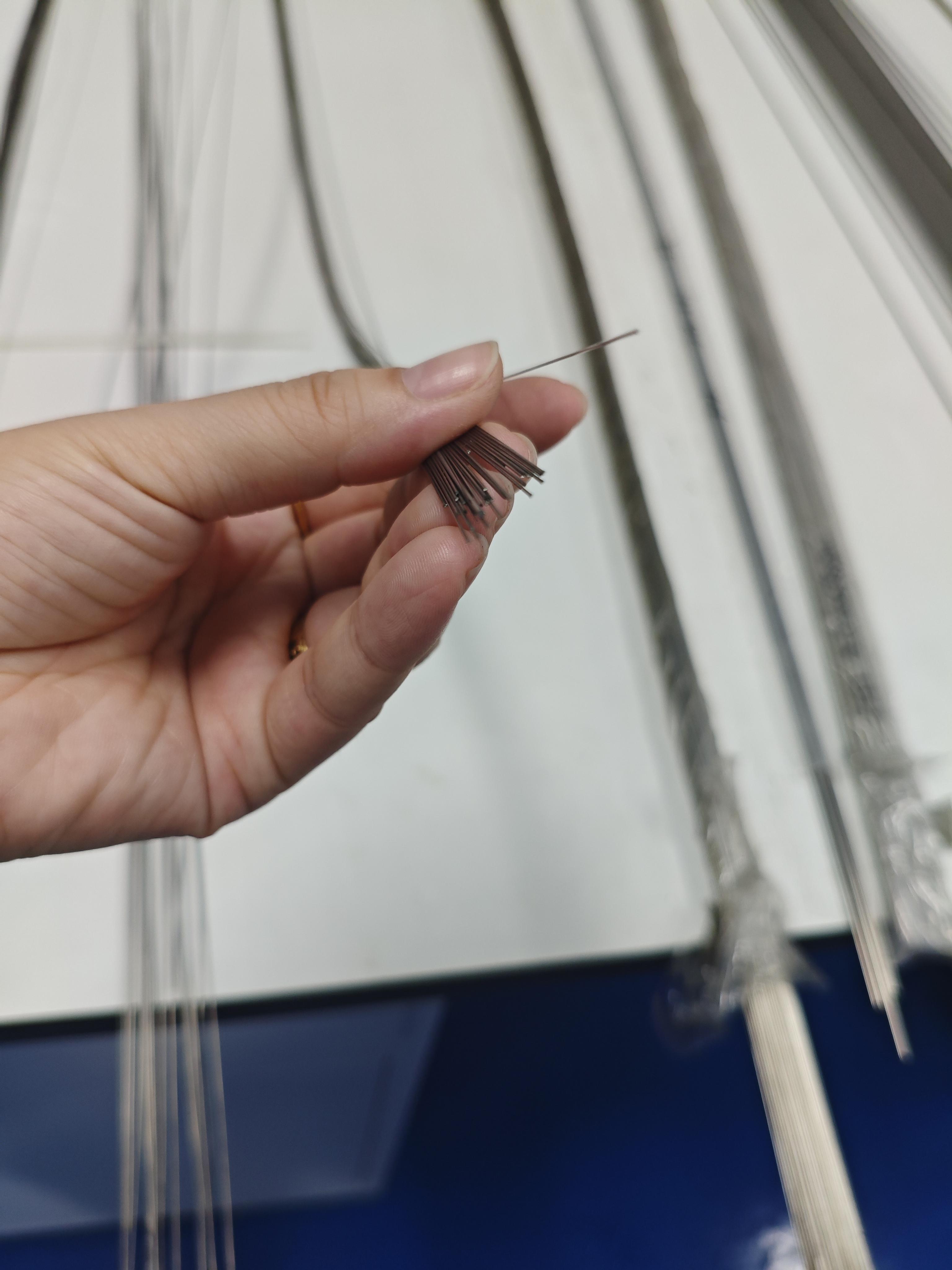

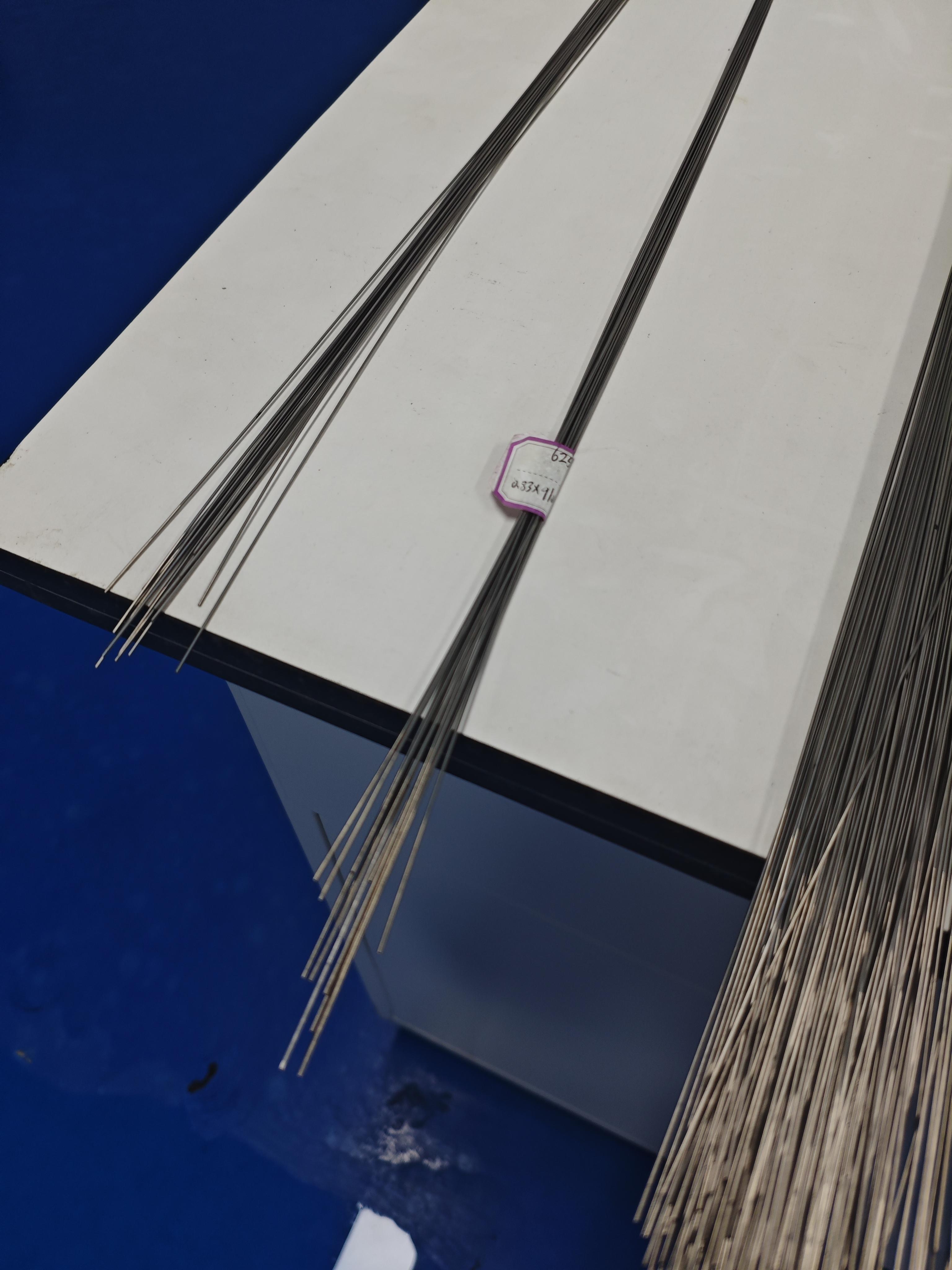

We craft our seamless 304/316 capillary tubing from high-quality stainless steel alloys, designed for performance and reliability. The 304 grade, with 18% chromium and 8% nickel, offers solid corrosion resistance and flexibility, making it a budget-friendly choice for general fluid delivery systems like IV lines. The 316 grade kicks it up a notch with 2-3% molybdenum, giving it superior resistance to pitting in salty environments like dialysis machines or saline-heavy IV setups. Both keep carbon below 0.08%, ensuring clean welds and no cracking, even when coiled into micro-diameters as small as 0.2mm with walls as thin as 0.05mm. Our seamless manufacturing process—extruding from a single billet—eliminates weak points, boosting strength and reliability. The electropolished finish is a big win, creating ultra-smooth surfaces that cut down on friction and bacterial buildup, meeting ISO 10993 and USP Class VI standards for biocompatibility. Compliant with ASTM A269, our tubing is built for the toughest medical challenges.

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

In medical fluid delivery systems, our seamless 304/316 capillary tubing is a superstar. It’s the backbone of IV lines, delivering medications or nutrients with precision and no leaks. In catheters, its flexibility and micro-dimensions allow for smooth navigation through veins, critical for procedures like chemotherapy or cardiac interventions. Infusion pumps rely on its seamless design to handle high-pressure fluids without failing, ensuring consistent dosing. For dialysis systems, the tubing’s corrosion resistance—especially in 316—stands up to prolonged saline exposure, keeping treatments safe. We’ve seen it used in portable insulin pumps, where its compact size fits wearable devices perfectly. The seamless construction also shines in high-sterility environments, enduring repeated autoclaving at 135°C without losing integrity. Whether it’s in hospitals or outpatient clinics, our tubing ensures fluids flow reliably, improving patient outcomes.

The medical device industry is growing like crazy, and our capillary tubing is right at the heart of it. The global medical tubing market is expected to hit $15 billion by 2030, growing at a CAGR of 8%, driven by rising chronic diseases and demand for minimally invasive treatments. Aging populations mean more need for reliable fluid delivery systems, and our tubing delivers the precision required. Sustainability is a hot topic—healthcare is leaning toward recyclable materials, and our 100% recyclable stainless steel fits the bill, backed by eco-friendly production processes. Regulatory bodies like the FDA and EU MDR are cracking down on material purity and traceability, which we nail with full documentation from mill to delivery. Smart tech is shaking things up, with tubing now integrating sensors for real-time fluid monitoring, like tracking flow rates in infusion pumps. Supply chain challenges, like nickel price volatility, are real, but our diversified sourcing keeps us steady. The shift to outpatient care and telemedicine is also boosting demand for compact, durable tubing solutions.

What makes our company the top choice? It’s our focus on precision, customization, and quality. We don’t just make tubing; we tailor it to your exact specs. Our R&D team optimizes alloys to hit purity levels that outperform standard options, ensuring better corrosion resistance and biocompatibility. Need a specific coil pitch or micro-diameter? We can hit tolerances down to microns, making our tubes a perfect fit for your fluid delivery systems. Our quality control is next-level—ultrasonic testing and helium leak checks catch flaws before they reach you, reducing risks in critical medical settings. We move fast, too, with automated production lines delivering quick turnarounds without cutting corners. Our green manufacturing, powered by renewable energy, appeals to clients chasing sustainability goals. This blend of innovation, reliability, and eco-consciousness sets us apart.

Let’s dive deeper into applications. Our seamless 304/316 capillary tubing is transforming medical fluid delivery. In IV therapy, it ensures precise delivery of medications, reducing dosing errors. For cardiac catheters, its flexibility navigates complex vascular paths without kinking, critical for procedures like stent placement. In dialysis, the 316’s molybdenum content handles saline exposure like a champ, extending system lifespans. Portable infusion pumps benefit from its compact coils, fitting into wearable devices for home care. In diagnostic labs, it’s used in fluid analysis systems, where its non-reactive surface keeps samples pure. It’s even making waves in veterinary medicine, supporting fluid delivery for animal treatments. As telemedicine grows, our tubing integrates into connected devices, enabling remote monitoring with real-time data.

Industry trends are opening new possibilities. Personalized medicine is a big deal—our custom tubing supports tailored fluid systems, like patient-specific infusion setups. Antimicrobial coatings are gaining traction to fight infections, and we’re exploring nanotechnology to enhance our tubing’s surfaces. AI-driven diagnostics are pushing for smarter tubing, like embedding sensors for flow or pressure data. Economic pressures, like rising raw material costs, are a challenge, but our lean processes keep prices competitive. Post-COVID, supply chain resilience is critical, and our global facilities ensure consistent delivery, even during disruptions.

Our company’s strength lies in our end-to-end support. From design consults to navigating regulatory approvals, we’re with you every step. Our testing mimics real-world conditions—saline exposure, high-pressure flows—so you know our tubes will perform. Compared to typical market offerings, our tubing has lower impurities, boosting longevity and safety. We also offer extras like PTFE coatings for added lubricity, which many overlook. This focus on quality and service builds trust with healthcare innovators.

Comparison Parameters Table for Seamless 304 vs 316 Capillary Tubing

| Parameter | Seamless 304 Capillary Tubing | Seamless 316 Capillary Tubing |

|---|---|---|

| Composition | 18% Chromium, 8% Nickel, ≤0.08% Carbon | 16-18% Chromium, 10-14% Nickel, 2-3% Molybdenum, ≤0.08% Carbon |

| Corrosion Resistance | Good; suitable for general medical environments | Excellent; resists pitting in saline/acidic conditions |

| Biocompatibility | High; ideal for short-term fluid delivery systems | Superior; preferred for long-term exposure to bodily fluids |

| Strength (Tensile) | 515 MPa minimum; reliable for moderate stress | 515-620 MPa; better for high-pressure fluid systems |

| Temperature Resistance | Up to 870°C; handles standard sterilization processes | Up to 925°C; excels in repeated high-heat sterilization |

| Cost | Cost-effective; suits high-volume applications | Higher; premium for critical, saline-heavy systems |

| Formability | Excellent; easy to coil for tight-radius fluid paths | Very good; maintains precision in micro-diameter coiling |

| Applications | IV lines, catheters, general infusion systems | Dialysis systems, long-term IV delivery, high-precision fluid systems |

| Surface Finish | Electropolished; smooth for low friction and hygiene | Electropolished; optimized for minimal bacterial adhesion in harsh environments |

| Durability | High; reliable in stable conditions but less resistant in chloride-rich settings | Superior; withstands prolonged sterilization and bodily fluid exposure |

Product-wise, our 304 capillary tubing is a cost-effective choice for general fluid systems like IV lines, offering great formability for tight coils. The 316 variant excels in harsh environments, resisting corrosion in saline-heavy dialysis or infusion systems. Both are seamless for uniform strength and come with custom fittings for easy integration. The electropolished finish minimizes contamination risks in sterile packaging.

Looking ahead, we’re excited about trends like bioresorbable materials, though our stainless steel remains unmatched for reliability. Stricter biocompatibility regulations are no issue—our tubes are pre-validated to save you time. The rise of 3D-printed medical devices opens new doors, but our seamless tubing is still the gold standard for fluid delivery.

In short, our seamless 304/316 capillary tubing delivers durability for medical fluid delivery systems, blending robust materials, precision applications, and forward-thinking innovation. With our focus on quality, customization, and sustainability, we’re not just meeting industry needs—we’re shaping the future of healthcare. (Word count: 1517)

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials are used in seamless 304/316 capillary tubing?

Seamless 304 capillary tubing contains 18% chromium, 8% nickel, and ≤0.08% carbon, while 316 includes 16-18% chromium, 10-14% nickel, 2-3% molybdenum, and ≤0.08% carbon for enhanced corrosion resistance.

What are the primary applications of seamless 304/316 capillary tubing in medical fluid delivery systems?

They’re used in IV lines, catheters, infusion pumps, and dialysis systems for precise fluid delivery due to their durability, biocompatibility, and seamless construction.

How does 304 capillary tubing compare to 316 in medical applications?

304 offers good corrosion resistance and affordability for general fluid delivery, while 316 provides superior resistance to pitting in saline-rich environments, ideal for critical systems.

What industry trends are driving demand for seamless 304/316 capillary tubing?

Trends include rising minimally invasive procedures, demand for biocompatible materials, integration with smart medical devices, and sustainable manufacturing practices.

Is seamless 304/316 capillary tubing biocompatible for medical use?

Yes, both grades meet ISO 10993 and USP Class VI standards, with smooth surfaces that minimize tissue irritation and ensure sterility.

How do you maintain seamless 304/316 capillary tubing in medical fluid systems?

Sterilize via autoclaving or ethylene oxide, clean with biocompatible solvents, and inspect for blockages or micro-abrasions to maintain performance.

How do environmental factors affect seamless 304/316 capillary tubing?

316 resists corrosion in chloride-heavy settings like IV systems, while 304 suits milder conditions, both enduring disinfectants and bodily fluids.

What future trends might impact seamless 304/316 capillary tubing in medical systems?

Trends include antimicrobial coatings, IoT integration for real-time fluid monitoring, and eco-friendly production to align with healthcare sustainability goals.