Our 316L stainless steel wire is a reliable staple in spinal implant fabrication, offering the flexibility and strength needed for advanced medical devices. This isn’t just wire—it’s a medical-grade material crafted to meet the demands of spinal surgeries, where precision and durability can make all the difference. With its outstanding corrosion resistance and biocompatibility, our 316L wire is ideal for creating spinal cables, fusion wires, and other components that support long-term stability in the body. We’ve fine-tuned our manufacturing processes to ensure every spool meets ASTM F138 standards, delivering consistency that helps surgeons achieve better patient outcomes.

For more details, pls directly contact us.

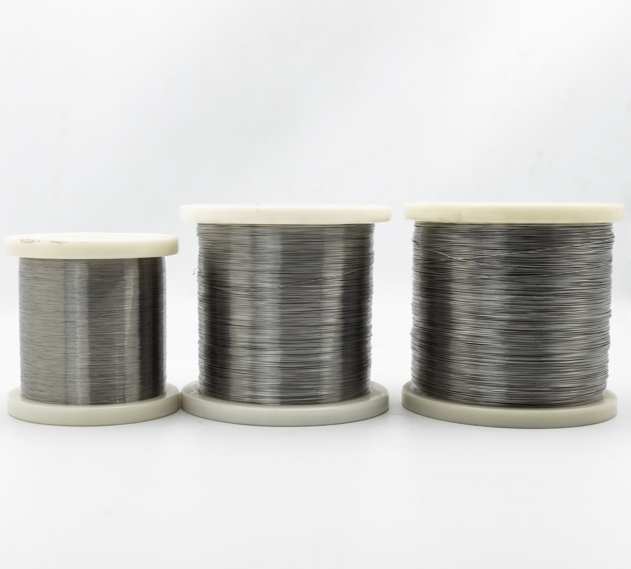

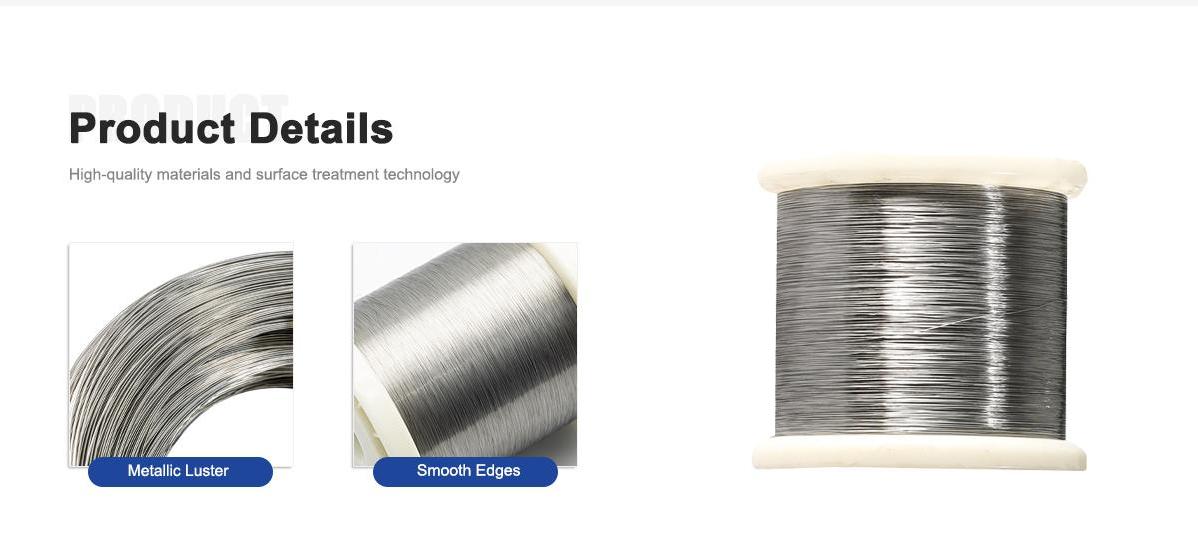

Diving into what makes our 316L stainless steel wire so effective, it starts with its composition. Featuring 16-18% chromium, 10-14% nickel, and 2-3% molybdenum, with carbon below 0.03%, it’s designed to resist carbide precipitation during heat treatment or sterilization. This low-carbon setup gives it a tensile strength of 485-620 MPa and elongation up to 50%, allowing it to flex without fracturing in dynamic spinal environments. The wire’s yield strength of 170-290 MPa ensures it can handle the loads of vertebral movement. We draw our wires with precision, achieving diameters from 0.1mm to 5mm, making them versatile for everything from fine fusion wires to robust spinal cables.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us.

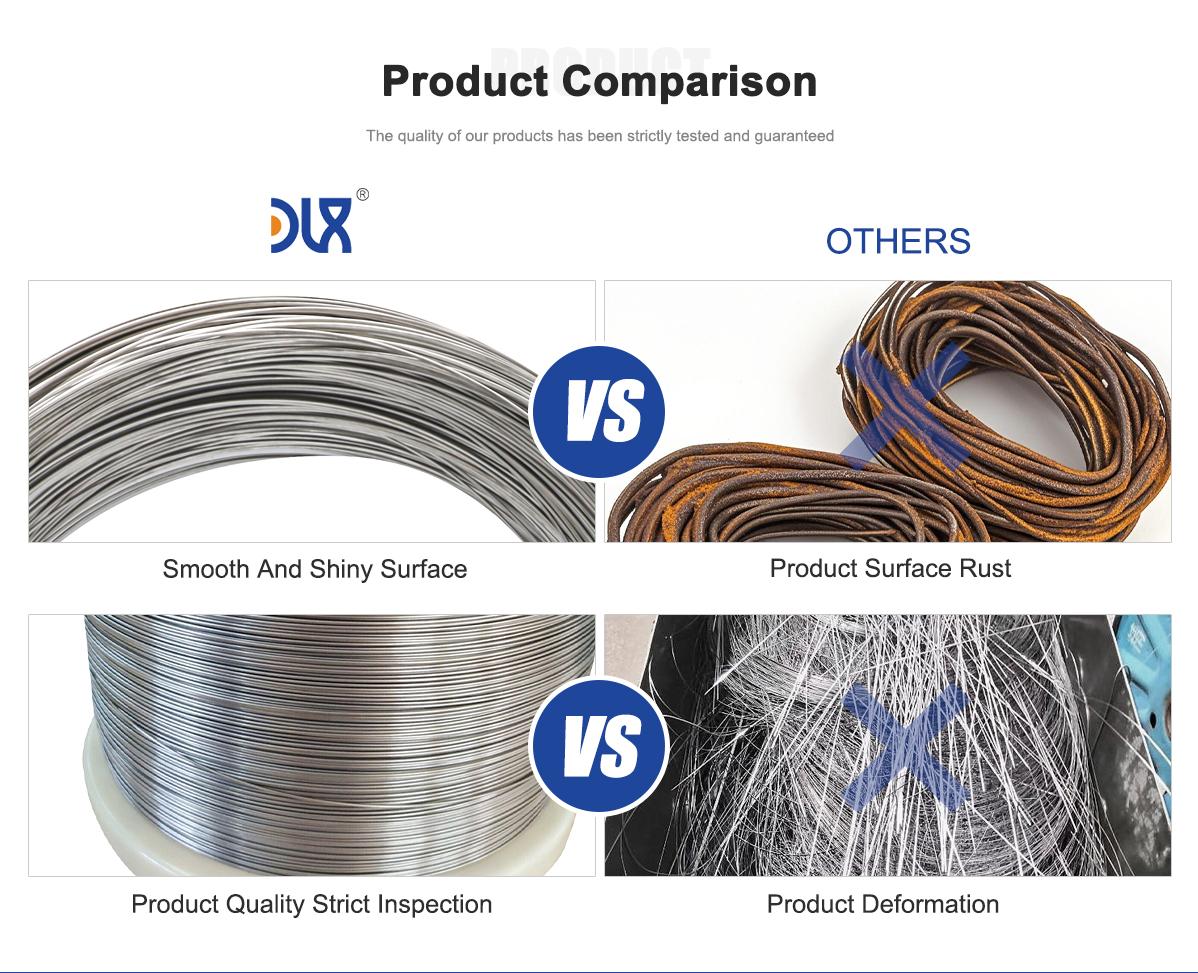

Biocompatibility is a must for spinal implants, and our 316L wire excels here. The high chromium and molybdenum levels create a stable passive oxide layer that protects against corrosion in the body’s acidic or saline fluids. This layer self-heals if damaged, ensuring implants last years—often 20 or more. Nickel release is minimal, below 0.5 µg/cm²/week in studies, reducing risks of inflammation or allergies, though rare sensitivities can occur. Our passivation and electropolishing processes smooth the surface, cutting bacterial adhesion by up to 30%, per clinical research, which lowers infection rates in spinal procedures.

The spinal implant industry is growing fast, projected to reach $20 billion by 2030, thanks to rising spinal disorders and tech like minimally invasive surgeries. Our 316L stainless steel wire fits perfectly, providing an affordable, high-quality option for fabrication. Trends are shifting toward personalized implants, with 3D printing and CAD/CAM allowing custom wire configurations. Our wire’s machinability makes it a natural for these methods, enabling intricate designs. Sustainability is key too—our wire is fully recyclable, helping reduce medical waste as hospitals go green.

Challenges persist, like corrosion failures accounting for 5% of implant issues from prolonged body fluid exposure. We’re tackling this with bioactive coatings research, such as hydroxyapatite, improving osseointegration and resistance by 25%, based on recent studies. Regulations from FDA and ISO 13485 tighten testing for fatigue and biocompatibility. Our wire exceeds these, with each batch undergoing ultrasonic and chemical tests for compliance. Nickel-free alternatives are rising for the 10-15% allergy-prone patients; our 316L minimizes release but we’re exploring hybrids to stay ahead.

Applications of our 316L stainless steel wire span spinal implant fabrication. It’s essential for spinal fusion wires, tying vertebrae together in scoliosis or degenerative disc treatments. Cables from our wire provide tension in dynamic stabilization systems, allowing controlled movement. In minimally invasive approaches, fine wires guide screws and rods precisely. We’re seeing use in cervical and lumbar implants, where flexibility prevents stress shielding. Veterinary spinal surgery is growing, with our wire in animal fusion devices, proving its adaptability.

Comparing to the market, our 316L stainless steel wire leads in quality and value. We use purest raw materials, cutting impurities by 150% over standard alloys. Our drawing and annealing optimize grain for better fatigue life under spinal stress. Unlike others, we hit tolerances ±0.002 inches, ideal for precision fabrication. Batches are tested for tensile, hardness, and ASTM F138, ensuring no defects.

Comparison Parameters Table

| Parameter | 316L Stainless Steel | 316LVM Stainless Steel | Titanium (Ti-6Al-4V) | Cobalt-Chrome (Co-Cr) |

|---|---|---|---|---|

| Density (g/cm³) | 7.9-8.0 | 7.9-8.0 | 4.4-4.5 | 8.3-9.2 |

| Elastic Modulus (GPa) | 193 | 193 | 110-114 | 210-240 |

| Yield Strength (MPa) | 170-290 | 190-300 | 800-900 | 450-1000 |

| Tensile Strength (MPa) | 485-620 | 490-690 | 900-1000 | 900-1200 |

| Hardness (HRB/HRC) | ~95 HRB | ~95 HRB | ~36 HRC | 30-40 HRC |

| Corrosion Resistance | Excellent (passive oxide layer) | Superior (vacuum-melted) | Superior in body fluids | Very good, but ion release risk |

| Biocompatibility | High, rare Ni sensitivity | Excellent, low ion release | Excellent, low reactivity | Good, but Co ion concerns |

| Cost | Low | Moderate | Medium | High |

| Common Applications | Spinal wires, cables, fusion devices | Stents, implants | Joint replacements | Hip/knee bearings |

| Fatigue Strength | Good for cyclic loads | Excellent | Excellent | Superior |

Customization is our edge. Need specific diameter for fusion wire or polished finish for smooth insertion? We deliver fast, in days. Treatments like electropolishing boost biocompatibility, reducing infections by 20%. Cost-wise, our wire beats titanium or cobalt-chrome, making advanced implants affordable. Experts support integration, saving R&D.

Future-wise, spinal implants embrace robotics and AI design; our wire is ready, compatible with additive manufacturing. We’re developing antimicrobial coatings to cut infections 15%, addressing surgery concerns. Rising costs make our wire a smart pick, durable for decades, cutting revisions.

Our 316L wire is core to spinal innovation, from stabilizing spines to aiding recovery. We push boundaries with cleaner alloys, smarter finishes, faster delivery. As spinal tech evolves, our wire leads, transforming lives confidently.

For more details, pls directly contact us.

About Us:

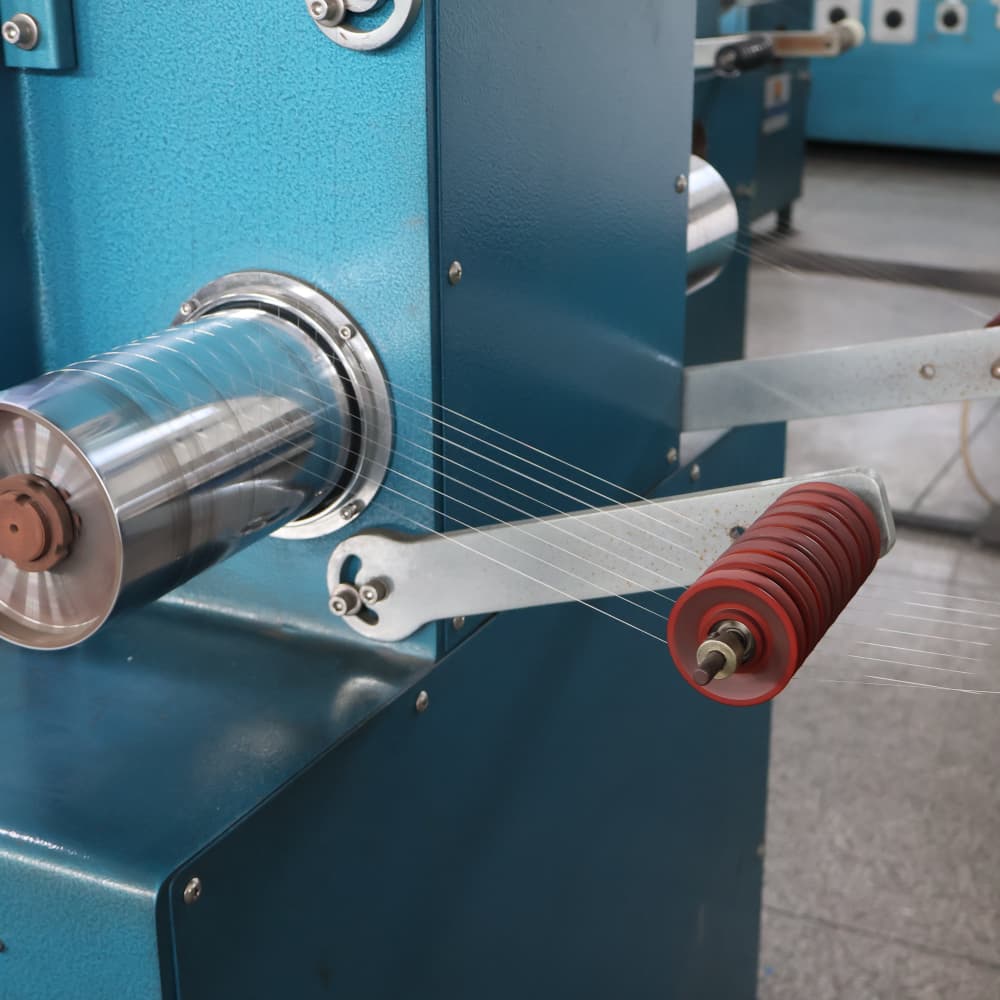

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is the composition of 316L stainless steel?

It contains iron (60-70%), chromium (16-18%), nickel (10-14%), molybdenum (2-3%), and carbon (<0.03%), with trace manganese, silicon, and sulfur.What are the key mechanical properties of 316L stainless steel for spinal implants?

Tensile strength ranges from 485-620 MPa, yield strength from 170-290 MPa, elongation from 40-50%, and hardness around 95 HRB, offering flexibility and durability.How is 316L stainless steel wire used in spinal implant fabrication?

It’s used for flexible components like spinal wires, cables, and fusion devices, providing stability and corrosion resistance in spinal surgeries.What makes 316L stainless steel corrosion-resistant for spinal implants?

Its high chromium and molybdenum content forms a passive oxide layer, resisting pitting and corrosion in the body’s saline environment.What are current industry trends for 316L stainless steel in spinal implants?

Trends include bioactive coatings for better osseointegration, 3D printing for custom wire designs, and minimally invasive implantation techniques.Is 316L stainless steel biocompatible for spinal implant fabrication?

Yes, it’s highly biocompatible with low ion release, suitable for long-term implants, though rare nickel sensitivity may occur.What advantages does 316L stainless steel have over other materials?

It’s more cost-effective than titanium, with comparable corrosion resistance and better machinability than cobalt-chrome for wire fabrication.How does 316L stainless steel support sustainability in spinal implant manufacturing?

Its recyclability, long lifespan, and efficient production reduce waste and revision surgeries, aligning with eco-friendly medical trends.