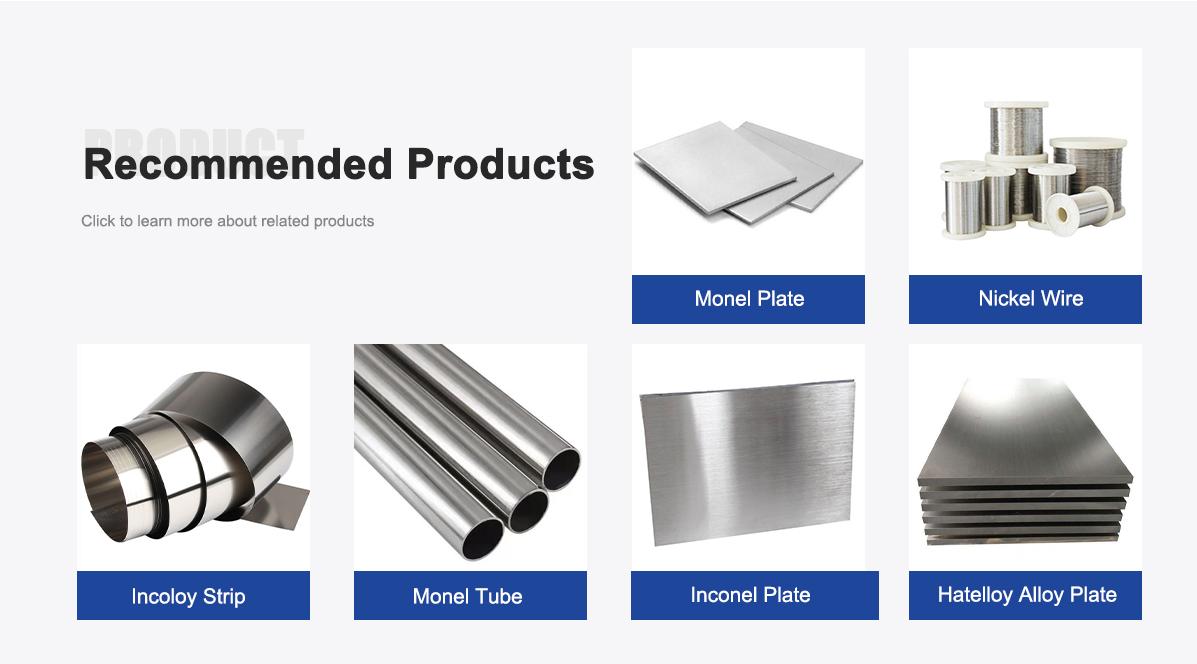

Pure Nickel Plate remains one of those materials that quietly solves problems most engineers eventually run into: corrosion, heat, conductivity, and long-term stability. In industrial environments where aggressive chemicals, high temperatures, or demanding electrical conditions exist, commercially pure nickel often outperforms more complex alloys. From a DLX company perspective, pure nickel plate is not just a catalog item — it is a core engineering material used across multiple critical industries.

Pure nickel grades such as UNS N02200 ( Nickel 200 ) and UNS N02201 ( Nickel 201 ) are widely recognized for their exceptional resistance to corrosion, particularly in alkaline and neutral environments. These materials are specified under ASTM B162, a standard covering nickel plate, sheet, and strip for pressure vessels and general industrial use. Despite the simplicity implied by the term “pure nickel,” the performance characteristics are far from basic.

For more details, pls directly contact us.

Nickel 200 and Nickel 201 are essentially the same base metal with a key difference: carbon content. Nickel 200 contains a slightly higher carbon level, while Nickel 201 is a low-carbon variation designed for elevated temperature service. This seemingly small adjustment significantly improves resistance to graphitization and embrittlement in high-temperature applications.

What makes pure nickel plate particularly valuable is its balanced combination of properties:

Excellent corrosion resistance in caustic alkalis

Good mechanical strength across a wide temperature range

High thermal and electrical conductivity

Strong resistance to oxidation and scaling

Stable metallurgical structure

Unlike many specialty alloys, pure nickel does not rely on complex chemistry to achieve performance. The metal itself delivers the required characteristics.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Industrial design trends continuously evolve, but pure nickel plate maintains consistent demand. Chemical processing plants, electronics manufacturers, battery producers, and energy systems developers all continue to specify Nickel 200 and Nickel 201. The reason is straightforward: reliability.

In corrosive environments, failure is expensive. Material degradation leads to downtime, safety risks, and maintenance costs. Pure nickel provides predictable behavior, which engineers trust. When exposed to strong alkalis such as sodium hydroxide or potassium hydroxide, nickel exhibits outstanding resistance compared to many stainless steels.

At elevated temperatures, Nickel 201 becomes especially important. Its reduced carbon content minimizes carbide precipitation, preserving ductility and mechanical integrity. This makes it suitable for heat exchangers, reactors, and thermal systems.

Comparison of Key Parameters

Below is a simplified comparison of typical characteristics for UNS N02200 and UNS N02201 plates. Exact values vary with processing, thickness, and temper conditions.

| Property | UNS N02200 (Nickel 200) | UNS N02201 (Nickel 201) |

|---|---|---|

| Nickel Content | ≥ 99.0% | ≥ 99.0% |

| Carbon Content | Higher (≤ 0.15%) | Lower (≤ 0.02%) |

| Density | ~8.89 g/cm³ | ~8.89 g/cm³ |

| Melting Range | ~1435–1446°C | ~1435–1446°C |

| Electrical Conductivity | High | High |

| Thermal Conductivity | Excellent | Excellent |

| Corrosion Resistance | Excellent in alkalis | Excellent in alkalis |

| High-Temperature Stability | Good | Superior |

| Typical Applications | General corrosion service | Elevated temperature service |

The practical takeaway is simple: Nickel 200 fits most corrosion-resistant uses, while Nickel 201 is preferred when higher temperatures are involved.

Typical Applications of Pure Nickel Plate

Pure nickel plate appears in a surprisingly broad range of applications:

Chemical Processing

Nickel’s resistance to caustic solutions makes it ideal for reactors, storage vessels, and piping components handling alkaline media.

Electronics and Electrical Systems

High conductivity and stable surface behavior support use in conductive components, shielding structures, and specialty electrical hardware.

Battery and Energy Technologies

Nickel plays a role in battery production equipment, hydrogen systems, and electrochemical devices.

Heat Transfer Equipment

Nickel 201 plates are frequently selected for high-temperature service environments requiring both thermal stability and corrosion resistance.

Aerospace and Vacuum Systems

Low outgassing and oxidation resistance are beneficial in controlled-atmosphere applications.

Food and Pharmaceutical Processing

Nickel’s clean surface and chemical stability are advantageous in certain controlled process systems.

Industry Trends Driving Continued Demand

Several industrial shifts continue to support pure nickel consumption:

Growth of battery manufacturing and energy storage technologies

Expansion of hydrogen and electrolysis systems

Increased chemical processing capacity in developing markets

Higher reliability expectations for corrosion-critical equipment

Long service life requirements in harsh environments

Even with the emergence of advanced alloys, pure nickel remains economically attractive for many applications because it delivers performance without excessive material complexity.

DLX Company Perspective on Pure Nickel Plate

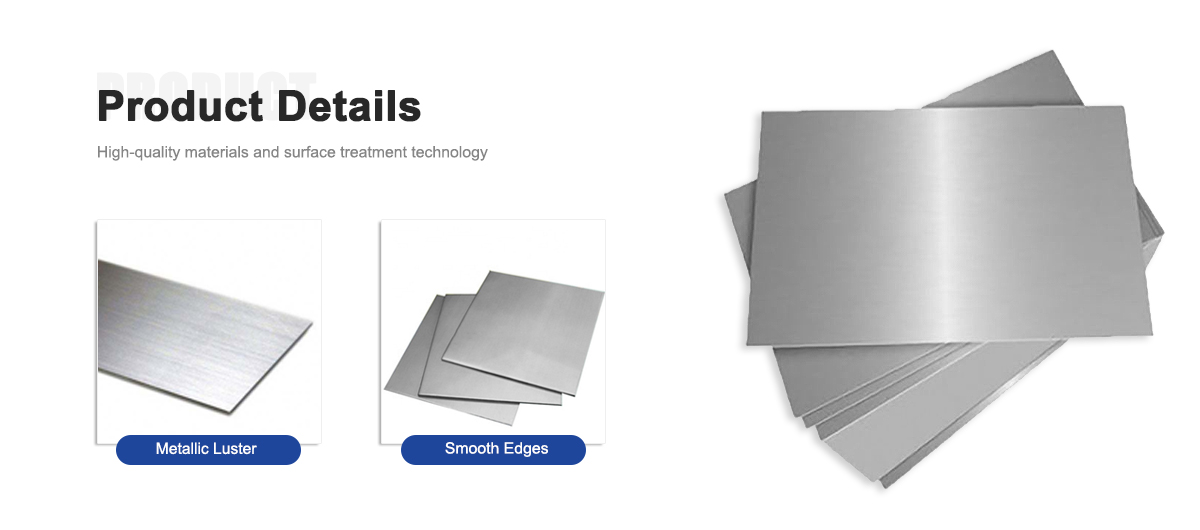

From the DLX company standpoint, supplying pure nickel plate is not just about material availability. Consistency, dimensional accuracy, surface quality, and metallurgical control are what truly matter to industrial buyers.

Pure nickel applications often involve fabrication — bending, welding, forming, machining. Poor material quality immediately causes production issues. Surface defects, thickness variations, or internal inconsistencies translate directly into customer losses.

DLX company production emphasizes:

Strict chemical composition control

Stable mechanical properties

Reliable flatness and tolerances

Clean surface finish

Custom sizing and cutting capabilities

Batch traceability

Industrial customers rarely need “just nickel plate.” They need material that integrates smoothly into manufacturing processes.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is the difference between Nickel 200 and Nickel 201?

The main difference is carbon content. Nickel 201 has lower carbon, improving performance at elevated temperatures and reducing embrittlement risks.

2. Is pure nickel plate resistant to acids?

Nickel performs well in many neutral and alkaline environments. Certain acids require careful evaluation, especially oxidizing acids.

3. Can pure nickel plate be welded easily?

Yes. Pure nickel generally exhibits good weldability when proper procedures and filler materials are used.

4. Why is pure nickel used instead of stainless steel?

In strong alkaline conditions, nickel often provides superior corrosion resistance compared to many stainless grades.

5. Does Nickel 201 always replace Nickel 200?

Not necessarily. Nickel 200 is suitable for most general applications. Nickel 201 is preferred for higher temperature service.

6. How does temperature affect pure nickel plate performance?

Nickel retains useful mechanical properties over a wide temperature range. Nickel 201 offers improved stability at elevated temperatures.

7. Is pure nickel plate suitable for electrical applications?

Yes. High electrical conductivity and stable surface behavior make nickel valuable in conductive and shielding uses.

8. What thicknesses are commonly available?

Pure nickel plates can be produced in a wide range of thicknesses depending on industrial requirements and processing capabilities.

Choosing the Right Supplier Matters

Pure nickel plate may seem standardized, but real-world performance depends heavily on manufacturing quality. Dimensional precision, surface condition, and internal structure influence forming behavior, weldability, and service life.

DLX company customers typically prioritize:

Consistent material quality

Fast delivery and custom cutting

Technical understanding of applications

Stable long-term supply

Clear documentation and certification

When nickel plate is used in critical systems, predictability becomes more important than nominal specifications.