High-purity Nickel 201 rods are one of our flagship products, and we’re proud to offer a material that’s a game-changer in industries where performance and reliability matter most. These rods, made from commercially pure nickel with at least 99.6% purity and a low carbon content (≤0.02%), deliver exceptional corrosion resistance, thermal stability, and electrical conductivity. Whether you’re building cutting-edge electronics or tackling harsh chemical environments, our Nickel 201 rods are engineered to meet your toughest demands. Let’s dive into what makes this product stand out, explore the industries driving its demand, and highlight why our company is your go-to supplier for this high-performance material.

For more details, pls directly contact us.

Our Nickel 201 rods are crafted from commercially pure nickel, a material prized for its versatility and strength. The low carbon content sets Nickel 201 apart from its close cousin, Nickel 200 , by preventing embrittlement at high temperatures (above 315°C or 600°F). This makes our rods ideal for applications where thermal stability is non-negotiable. With excellent resistance to corrosive environments like caustic alkalis, reducing acids, and neutral salts, these rods are a top choice for industries that can’t afford to compromise on durability or performance.

The rods are manufactured to strict standards, like ASTM B160 and ASME SB160, ensuring consistent quality and precision. They’re available in various diameters, lengths, and finishes to suit your specific needs, whether you’re machining them into electrodes, battery components, or structural parts. Their high ductility and low work-hardening rate also make them easy to form, weld, and machine, saving you time and effort in production.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

The magic of Nickel 201 rods lies in their unique properties. First, their corrosion resistance is unmatched in alkaline environments, such as sodium hydroxide or ammonia processing, making them a staple in chemical plants. They also shine in reducing acids and neutral salts, outperforming many stainless steels in harsh conditions. For example, while stainless steel 304 might struggle with pitting in chloride-rich environments, Nickel 201 holds strong, ensuring long-term reliability.

Second, their thermal stability is a big win for high-temperature applications. Unlike Nickel 200, which can suffer from graphitization above 315°C, our Nickel 201 rods stay structurally sound, making them perfect for heat exchangers, furnace components, and nuclear reactor parts. Plus, their high electrical and thermal conductivity makes them a go-to for electronics, from battery connectors to conductive wiring.

Finally, their mechanical properties—like high ductility and strength—make them easy to work with. Whether you’re cold-forming, spinning, or welding, these rods handle it all with ease, reducing production costs and boosting efficiency. It’s no wonder industries from aerospace to marine engineering rely on them.

Industry Analysis: What’s Driving Demand?

The global market for high-purity nickel, including Nickel 201 rods, is on fire, and for good reason. The push for sustainable technologies and advanced manufacturing is fueling demand across multiple sectors. In 2024, the high-purity nickel market was valued at around $15 billion, with projections estimating growth to $15.9 billion in 2025 at a CAGR of 6%. While exact figures for Nickel 201 rods are hard to pin down, their role in key industries like electronics and electric vehicles (EVs) makes them a critical piece of this growth puzzle.

The EV boom is a major driver. High-purity nickel is essential for lithium-ion battery production, and as companies like Tesla ramp up output, the need for materials like Nickel 201 rods for battery components is skyrocketing. Government incentives, like China’s infrastructure programs and the EU’s battery value chain investments, are also boosting demand. Add to that the rise of renewable energy systems—think wind turbines and solar panels—where Nickel 201’s corrosion resistance and durability are vital, and you’ve got a recipe for sustained market growth.

Electronics is another hotbed of opportunity. With global digitalization and 5G technology driving demand for high-performance materials, Nickel 201 rods are in high demand for microchips, connectors, and battery systems. The aerospace sector isn’t far behind, with Nickel 201’s lightweight strength and thermal stability making it a favorite for structural components and turbine parts. Meanwhile, the chemical processing industry continues to lean on Nickel 201 for handling caustic substances, ensuring product purity in food and synthetic fiber production.

Sustainability is also shaping the market. Recycling initiatives, like those from companies in Europe, are reducing reliance on virgin nickel while maintaining high purity standards. This aligns with global pushes for greener supply chains, making Nickel 201 rods a smart choice for eco-conscious manufacturers. However, challenges like high material costs and complex mining processes mean that efficient, high-quality production—like ours—is more important than ever.

Comparison Table: Nickel 201 Rods vs. Nickel 200 and Stainless Steel 304

|

Parameter |

Nickel 201 Rods |

Nickel 200 Rods |

Stainless Steel 304 |

|---|---|---|---|

|

Nickel Content |

≥99.6% (low carbon ≤0.02%) |

≥99.6% (carbon ≤0.15%) |

~8-10.5% |

|

Corrosion Resistance |

Excellent in alkalis, reducing acids |

Good, but less in high-temp alkalis |

Good, but susceptible to pitting |

|

Temperature Stability |

Stable above 315°C, resists graphitization |

Graphitization risk above 315°C |

Limited to ~870°C |

|

Electrical Conductivity |

High (better than stainless steel) |

High (similar to Nickel 201) |

Moderate |

|

Ductility |

High, ideal for cold forming |

High, slightly less at high temps |

Moderate |

|

Applications |

Electronics, chemical, aerospace |

General chemical, electronics |

General industrial, construction |

|

Cost |

Higher due to purity |

Slightly lower than Nickel 201 |

Lower, less specialized |

Our Nickel 201 rods are incredibly versatile, finding their way into a wide range of applications:

-

Electronics: Their high electrical conductivity makes them ideal for battery components, electrodes, and conductive wiring in devices like smartphones and EVs.

-

Chemical Processing: Used in pipes, containers, and tanks for handling caustic alkalis like sodium hydroxide, ensuring product purity and equipment longevity.

-

Aerospace: Perfect for structural parts and turbine components, where their strength and high-temperature stability shine.

-

Marine: Their resistance to seawater corrosion makes them a go-to for propeller shafts, pump bodies, and other marine hardware.

-

Nuclear Industry: Employed in reactor components due to their ability to withstand extreme temperatures and corrosive environments.

-

Heat Exchangers: Used in plate-type exchangers and linings, leveraging their thermal conductivity and corrosion resistance.

These applications highlight why Nickel 201 rods are a cornerstone of industries that demand reliability under pressure.

Our Company’s Edge

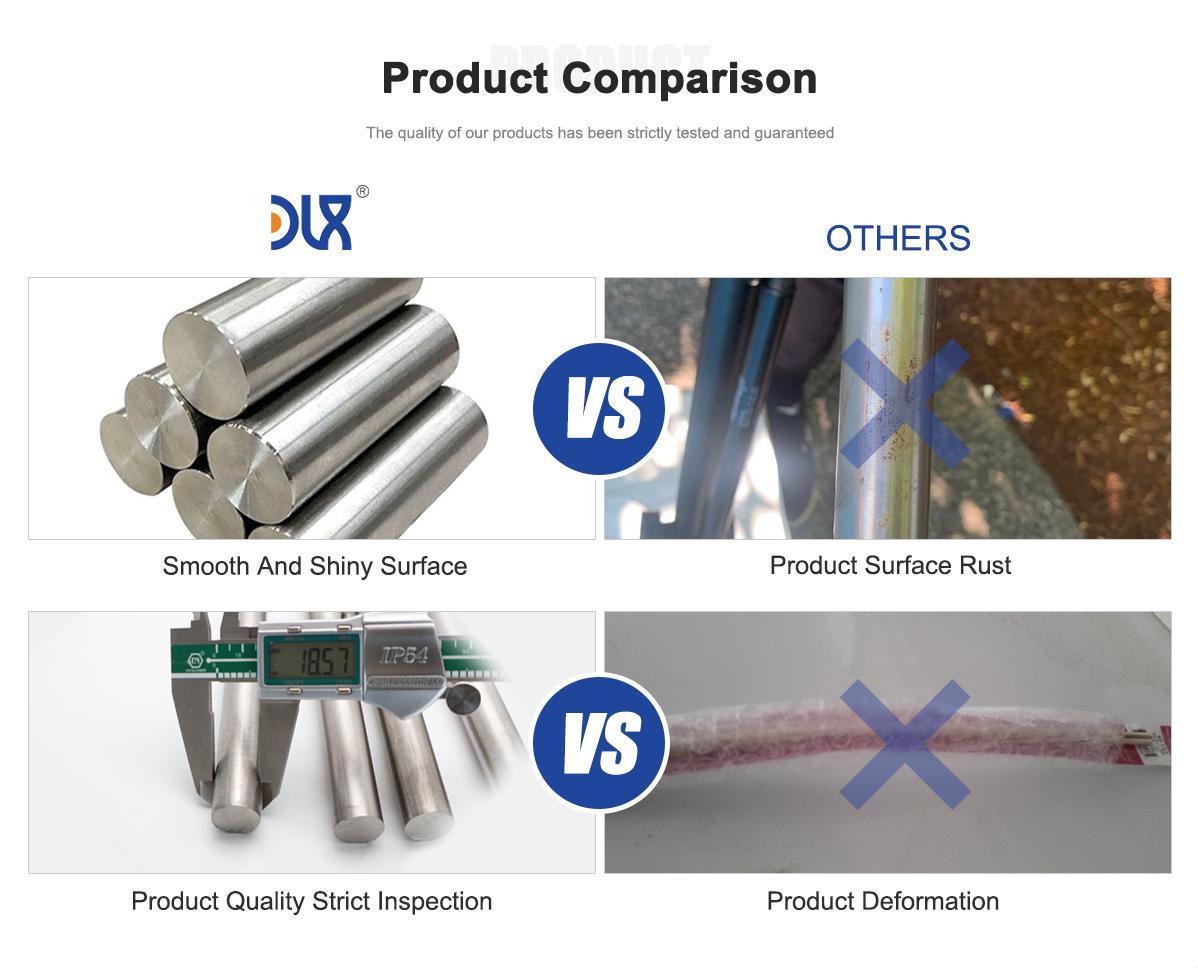

When it comes to high-purity Nickel 201 rods, we’re not just another supplier—we’re a partner you can trust to deliver unmatched quality and service. Our rods are produced using state-of-the-art refining and manufacturing processes, ensuring purity levels of 99.6% or higher and strict adherence to ASTM and ASME standards. This guarantees consistency, whether you’re ordering a small batch or a large-scale supply.

We also prioritize customization. Need a specific diameter, length, or surface finish? We’ve got you covered. Our advanced machining capabilities mean we can tailor rods to your exact specifications, whether it’s for precision electronics or heavy-duty chemical equipment. Plus, our rigorous quality control—including mill test certificates and PMI testing—ensures every rod meets your performance expectations.

Sustainability is at the heart of what we do. We’ve invested in efficient production methods that minimize waste and energy use, aligning with global trends toward greener manufacturing. Our supply chain is streamlined to reduce lead times, so you get your materials when you need them, without delays. And with our global distribution network, we can deliver to your doorstep, whether you’re in North America, Europe, or Asia.

Compared to others in the market, our focus on innovation sets us apart. We’re constantly exploring new ways to enhance the performance of our Nickel 201 rods, from optimizing microstructures for better strength to improving weldability for easier integration into your projects. Our team of experts is always ready to provide technical support, helping you choose the right material and troubleshoot any challenges.

Looking Ahead

The future of high-purity Nickel 201 rods is bright, with demand set to grow as industries like EVs, electronics, and renewable energy continue to expand. Emerging technologies, like additive manufacturing and high-entropy alloys, could further elevate the role of nickel in cutting-edge applications. We’re committed to staying ahead of the curve, investing in R&D to ensure our rods meet the evolving needs of our customers.

In a world where reliability, sustainability, and performance are non-negotiable, our Nickel 201 rods deliver on all fronts. They’re not just a product—they’re a solution that empowers your projects to succeed, no matter the challenge. Ready to see the difference for yourself? Let’s talk about how our high-purity Nickel 201 rods can take your applications to the next level.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What are High-Purity Nickel 201 Rods made of?

Commercially pure nickel with at least 99.6% nickel and low carbon content (≤0.02%) to prevent embrittlement at high temperatures. -

What makes Nickel 201 Rods corrosion-resistant?

Their high nickel purity offers excellent resistance to caustic alkalis, reducing acids, and neutral salts, especially in harsh chemical environments. -

Where are Nickel 201 Rods commonly used?

Electronics, chemical processing, aerospace, marine, and nuclear industries for components like electrodes, battery parts, and heat exchangers. -

How do Nickel 201 Rods perform at high temperatures?

They remain stable above 315°C (600°F), resisting graphitization, which makes them ideal for high-temperature applications. -

What are the key mechanical properties of Nickel 201 Rods?

High ductility, good strength, and excellent thermal and electrical conductivity, with low work-hardening rates for easy forming. -

How do Nickel 201 Rods compare to Nickel 200?

Nickel 201 has lower carbon content, making it better for temperatures above 315°C, while Nickel 200 is stronger below this threshold. -

Are Nickel 201 Rods suitable for electronics?

Yes, their high electrical conductivity and corrosion resistance make them perfect for battery components and conductive materials. -

What industry trends are driving demand for Nickel 201 Rods?

Growing demand in electric vehicle batteries, renewable energy systems, and advanced electronics due to their purity and performance.