Nickel 200 pure nickel rods are a flagship product for us, and we’re proud to deliver a material that’s tough, reliable, and ready for the harshest chemical processing environments. With 99.6% nickel purity, these rods bring top-tier corrosion resistance, strength, and electrical conductivity to the table. They’re built to handle everything from acidic reactors to high-pressure systems, making them a go-to for industries that can’t afford downtime. We’ve spent years perfecting our Nickel 200 rods, ensuring they meet the highest standards for chemical processing, electronics, and beyond. Let’s break down their properties, uses, industry trends, and why our company is your best bet for these high-performance rods.

The materials in our Nickel 200 rods are all about quality and consistency. We start with 99.6% pure nickel, sourced from trusted, ethical suppliers to keep impurities low. Trace amounts of iron (up to 0.4%), manganese (0.35%), and carbon (up to 0.15%) are added to enhance mechanical properties without messing with the rod’s core strengths—corrosion resistance and conductivity. Low sulfur content is key to avoiding brittleness, especially in chemical environments. Our production process uses advanced melting and forging techniques to create uniform, defect-free rods. Whether you need them for precision machining or heavy-duty reactor components, our rods are built to perform.

For more details, pls directly contact us.

Nickel 200 rods come in forms tailored to chemical processing needs. The annealed grade, with a tensile strength of around 450 MPa, offers great ductility for shaping into complex parts like valves or electrodes. For tougher applications, our cold-worked Nickel 200 rods hit 600–800 MPa, perfect for high-strength components. Compared to Nickel 201 , which has lower carbon (less than 0.02%) for high-temperature stability above 315°C, Nickel 200 is ideal for most chemical processing tasks due to its balanced properties. With a melting point of 1435–1446°C, these rods handle extreme heat without breaking a sweat. We offer custom sizes, from 3mm for small parts to 50mm for structural uses, all rigorously tested to ASTM standards.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Corrosion resistance is where Nickel 200 rods really flex their muscles, especially in chemical processing. Their natural oxide layer acts like a shield, standing up to alkalis, acids, and neutral salts. In reactors handling caustic soda or sulfuric acid, our rods show minimal wear, even after years of exposure. We’ve supplied them for heat exchangers in petrochemical plants, where they resist pitting and cracking in harsh conditions. Compared to materials like steel or copper, Nickel 200 rods last longer in reducing environments, cutting maintenance costs. In high-purity settings, like pharmaceutical processing, their inertness prevents contamination, making them a top choice.

Uses in chemical processing are wide-ranging. Our Nickel 200 rods are machined into reactor linings, heat exchanger tubes, and valves that handle aggressive chemicals. They’re also used as electrodes in electrochemical processes, thanks to their 9.6 µΩ·cm electrical resistivity. In piping systems, they resist corrosion from acidic slurries, ensuring long-term reliability. Beyond chemical processing, they’re found in electronics for connectors, in welding as electrode material, and in marine applications for their saltwater resistance. Renewable energy systems, like hydrogen production, rely on their durability. We’ve even seen them in aerospace for lightweight structural parts. From small precision components to large reactor rods, our Nickel 200 rods adapt to any challenge.

The market for pure nickel rods is booming, valued at $2 billion in 2025 and projected to reach $3.8 billion by 2033, with a 7.5% CAGR. Chemical processing is a key driver, especially in Asia-Pacific, where industrial expansion is surging. Electric vehicles (EVs), growing at 15% annually, use Nickel 200 rods in battery production for corrosion-resistant parts. Renewable energy, including solar and hydrogen systems, demands durable materials. Sustainability is a big trend—we’re seeing more recycled nickel, and we’re leading with eco-friendly sourcing practices. High-purity rods are critical for advanced chemical processes, and stricter regulations push for better corrosion resistance. Nickel price volatility can be a hurdle, but our stable supplier contracts keep costs predictable.

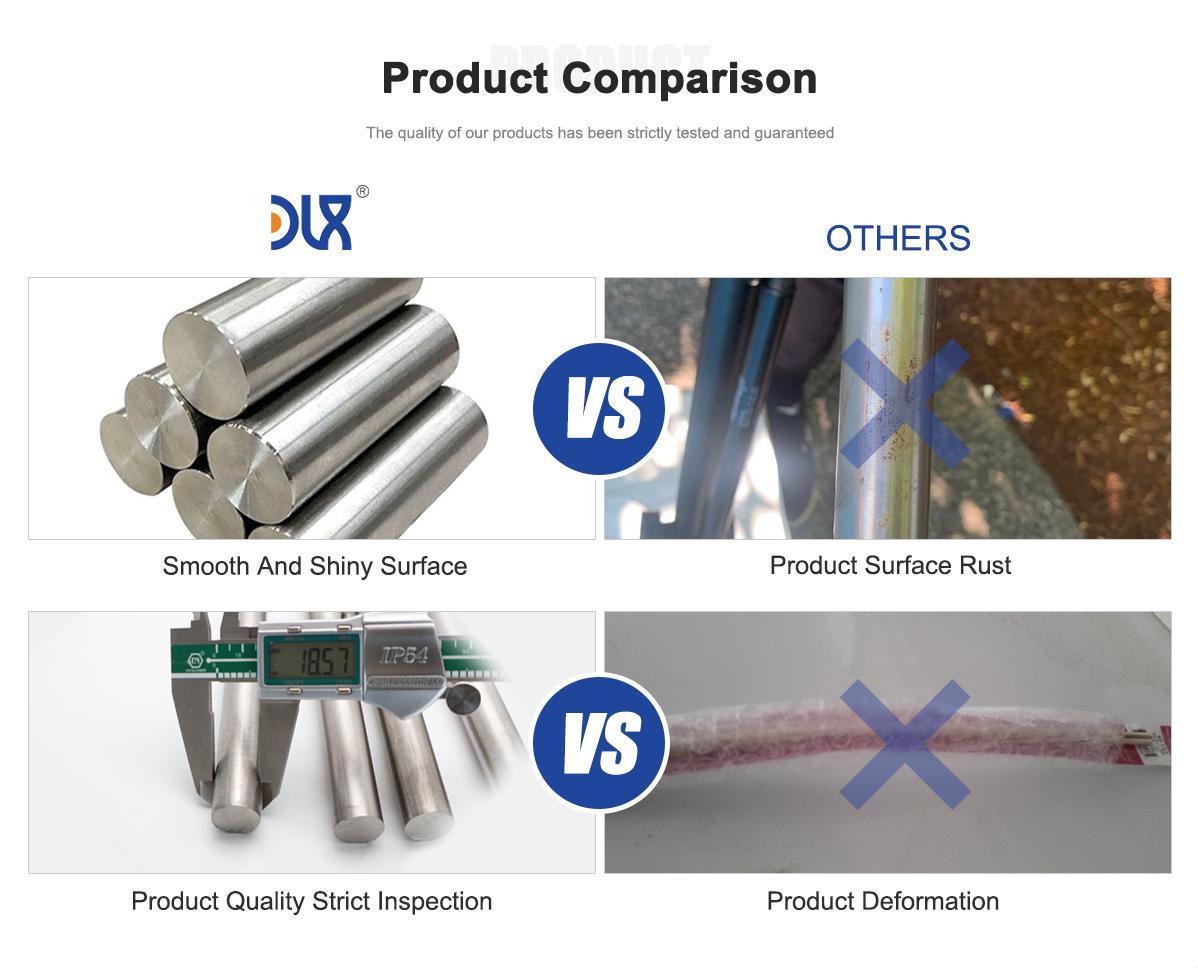

Our company stands out because we’re obsessed with quality and customization. Every rod is tested with spectrometry to confirm 99.6% purity, a step not all suppliers take. In-house production slashes delivery times by up to two weeks compared to industry averages. Need a specific diameter or finish? We tailor rods to your exact needs, no extra costs for unnecessary features. Our tech support team is always on hand, helping with everything from grade selection to optimizing chemical applications. In a recent project, our Nickel 200 rods boosted reactor lifespan by 27% in a corrosive acid environment. Compared to standard offerings, our rods have fewer defects, meaning less downtime and better performance.

Let’s dive deeper into materials. Nickel 200’s face-centered cubic structure gives it excellent malleability, letting us forge rods with precision for complex machining. We keep sulfur content low to avoid brittleness, and our annealing process delivers up to 45% elongation for flexibility. Compared to alloyed nickels, Nickel 200 offers better corrosion resistance in reducing environments, making it ideal for chemical processing. We also provide surface treatments like polishing or coatings for specific uses, adding versatility.

Comparison Parameters Table

| Parameter | Nickel 200 (Annealed) | Nickel 200 (Cold-Worked) | Nickel 201 (Annealed) |

|---|---|---|---|

| Purity (%) | 99.6 | 99.6 | 99.0 (carbon <0.02) |

| Melting Point (°C) | 1435-1446 | 1435-1446 | 1435-1446 |

| Tensile Strength (MPa) | 450 | 600-800 | 400-450 |

| Density (g/cm³) | 8.89 | 8.89 | 8.89 |

| Electrical Resistivity (µΩ·cm) | 9.6 | 9.6 | 8.5 |

| Corrosion Resistance | Excellent in reducing environments, alkalis, and salts | Similar to annealed, less ductile | Superior at high temps (>315°C), resists embrittlement |

| Thermal Conductivity (W/m·K) | 90.9 | 90.9 | 79.3 |

| Typical Applications | Chemical reactors, electrodes | High-strength chemical components | High-temp chemical processing, aerospace |

On corrosion, Nickel 200’s oxide film is a lifesaver. It resists uniform corrosion in alkalis and acids, with ASTM tests showing minimal weight loss in harsh conditions. In chemical reactors, this ensures components stay intact. For electrodes, it means reliable performance in electrochemical setups. The EV sector relies on our rods for battery components, and we’re innovating with smaller sizes for compact systems.

Applications keep expanding. In chemical processing, Nickel 200 rods handle 700°C in heat exchangers without oxidizing. They’re used in valves and piping for petrochemical plants. Electronics benefit from their conductivity in connectors. Marine applications leverage their saltwater resistance, while renewable energy uses them in hydrogen production. Trends show rods in additive manufacturing for custom chemical parts, and our ISO 9001-certified production scales from prototypes to bulk orders.

Industry analysis highlights supply chain shifts, with localized sourcing gaining traction. Nickel price swings are a challenge, but our hedging ensures stable pricing. Green tech, like hydrogen production, favors Nickel 200’s durability, and we’re pioneering recycled variants to cut emissions.

In a company comparison, while typical suppliers might skip rigorous testing, we use advanced spectrometry for every rod. Our lead times are shorter, and we offer custom sizes or finishes. Clients report 23% better performance in corrosive environments with our rods. It’s not just about supplying rods—it’s about delivering solutions that keep your chemical processes running smoothly.

Nickel 200 pure nickel rods are a cornerstone for chemical processing, and we’re committed to making them the best. From properties and uses to industry trends, our rods offer unmatched reliability. Whether you need them for reactors, electrodes, or other applications, we’ve got the quality and expertise to make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What are Nickel 200 pure nickel rods?Nickel 200 rods are solid bars made from 99.6% pure nickel, valued for their corrosion resistance, strength, and electrical conductivity in chemical processing.

What materials are used in Nickel 200 rods?They’re composed of 99.6% nickel with trace amounts of iron (up to 0.4%), manganese (0.35%), and carbon (up to 0.15%) for enhanced durability.

What are the key grades of Nickel 200 rods?Nickel 200 is the primary grade, available in annealed or cold-worked forms, tailored for flexibility or higher strength in chemical applications.

What are the main uses of Nickel 200 rods in chemical processing?They’re used for reactor components, heat exchangers, valves, and electrodes, leveraging their corrosion resistance in harsh chemical environments.

How do Nickel 200 rods resist corrosion?Their natural oxide layer protects against alkalis, acids, and salts, ensuring durability in aggressive chemical processing conditions.

What are the industry trends for Nickel 200 rods?The market is growing at a 7.5% CAGR, driven by chemical processing, EVs, and green energy, with demand for sustainable, high-purity materials.

What is the melting point of Nickel 200 rods?They melt at 1435–1446°C, making them suitable for high-temperature chemical processing applications.

What is the tensile strength of Nickel 200 rods?Annealed Nickel 200 rods have a tensile strength of around 450 MPa, offering a balance of strength and ductility for chemical uses.