Our Grade 5 Titanium Wire , also known as Ti-6Al-4V, is the go-to choice for aerospace applications where strength, lightweight properties, and durability are non-negotiable. This alloy, made up of 6% aluminum, 4% vanadium, and 90% titanium, is the workhorse of the titanium industry, accounting for over 50% of global titanium alloy use. Its high strength-to-weight ratio, corrosion resistance, and ability to withstand extreme conditions make it a game-changer for aircraft, spacecraft, and beyond. Whether it’s used in airframes, engine components, or fasteners, our Grade 5 titanium wire delivers unmatched performance.

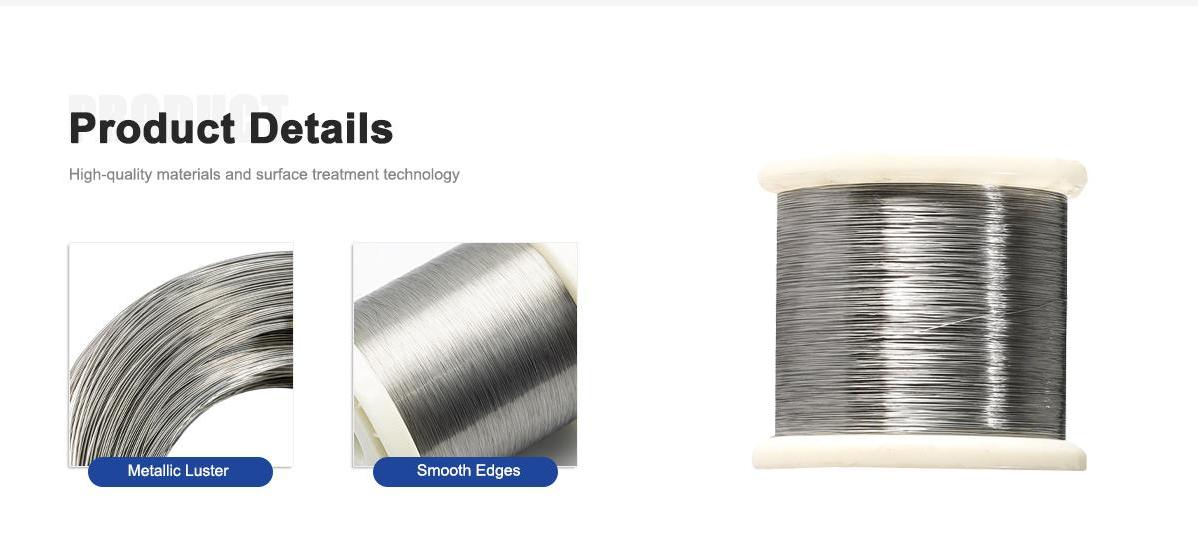

We produce this wire in a range of diameters, typically from 0.1mm to 10mm, and offer it in forms like coils, strands, or custom-cut lengths to suit your project needs. It’s heat-treatable, allowing for tailored strength enhancements, and its low density—about half that of steel—makes it ideal for reducing aircraft weight without sacrificing structural integrity. Plus, its excellent corrosion resistance ensures longevity in harsh environments like high-altitude atmospheres or marine settings. Our Grade 5 titanium wire is manufactured to meet stringent ASTM B863 and AMS 4928 standards, ensuring top-tier quality for aerospace demands.

Grade 5 titanium wire isn’t just another material—it’s a powerhouse. Its tensile strength, ranging from 900 to 1000 MPa, far surpasses that of commercially pure titanium grades (1-4), which top out around 345-550 MPa. Compared to Grade 9 (Ti-3Al-2.5V), it offers superior strength, though it’s slightly less formable. This makes it perfect for high-stress applications where every ounce of weight matters, like jet engine components or airframe fasteners. Its ability to resist corrosion in seawater, acids, and high temperatures up to 600°F (316°C) sets it apart from other metals like aluminum or even some steels, which can weaken or corrode under similar conditions.

The alloy’s biocompatibility also makes it a favorite beyond aerospace, finding use in medical implants like orthopedic screws and plates. Its non-magnetic properties and low thermal conductivity add versatility, ensuring it performs reliably in sensitive electronics or high-heat environments. While it’s trickier to machine than pure titanium due to its hardness, our advanced processing techniques minimize challenges like galling or work hardening, delivering a smooth, high-quality product every time.

Industry Analysis: Trends Driving Titanium Wire Demand

The aerospace industry is soaring, and titanium wire is along for the ride. With global air travel rebounding and space exploration pushing new boundaries, the demand for lightweight, durable materials is skyrocketing. Grade 5 titanium wire is at the heart of this trend, driven by the need for fuel-efficient aircraft and spacecraft that can withstand extreme conditions. The push for sustainability is also reshaping the industry, with manufacturers seeking materials that reduce weight to cut fuel consumption and emissions. Our Grade 5 titanium wire fits the bill, offering a strength-to-density ratio that’s among the highest of any metal.

Additive manufacturing, or 3D printing, is another game-changer. It’s revolutionizing how aerospace components are made, allowing for complex designs with less material waste. Our Grade 5 titanium wire, available in forms compatible with additive manufacturing, is helping innovators create intricate parts like turbine blades or lightweight brackets. The rise of reusable spacecraft, like those used in commercial space ventures, is also boosting demand for materials that can endure repeated exposure to extreme temperatures and stresses—exactly what our wire delivers.

Cost remains a challenge, as titanium alloys are pricier than aluminum or steel due to complex extraction and processing. However, advancements in production, like the Kroll process and improved recycling methods, are making Grade 5 titanium more cost-effective. We’re also seeing increased investment in sustainable sourcing, with eco-friendly mining and refining practices gaining traction. These trends align with our commitment to delivering high-quality titanium wire while keeping costs competitive through efficient manufacturing and supply chain optimization.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our Grade 5 titanium wire shines in a variety of aerospace applications. In airframes, it’s used for structural components like beams, ribs, and skins, where its strength-to-weight ratio reduces aircraft weight while maintaining rigidity. Fasteners made from this wire, such as bolts and rivets, provide secure connections that resist corrosion and fatigue, critical for long-term safety in high-vibration environments. Jet engine components, including compressor blades and discs, benefit from the wire’s ability to handle high temperatures and cyclic loading without cracking.

Beyond aerospace, the wire’s versatility extends to other industries. In medical applications, it’s a top choice for implants like bone screws and spinal fixation devices due to its biocompatibility and ability to integrate with human tissue. Marine industries use it for corrosion-resistant cables and fittings in seawater environments. Even high-performance automotive and sports equipment, like racing car suspensions or bicycle frames, leverage its lightweight strength. Whatever the application, our Grade 5 titanium wire delivers reliability and performance.

Company Advantages: Why Choose Us

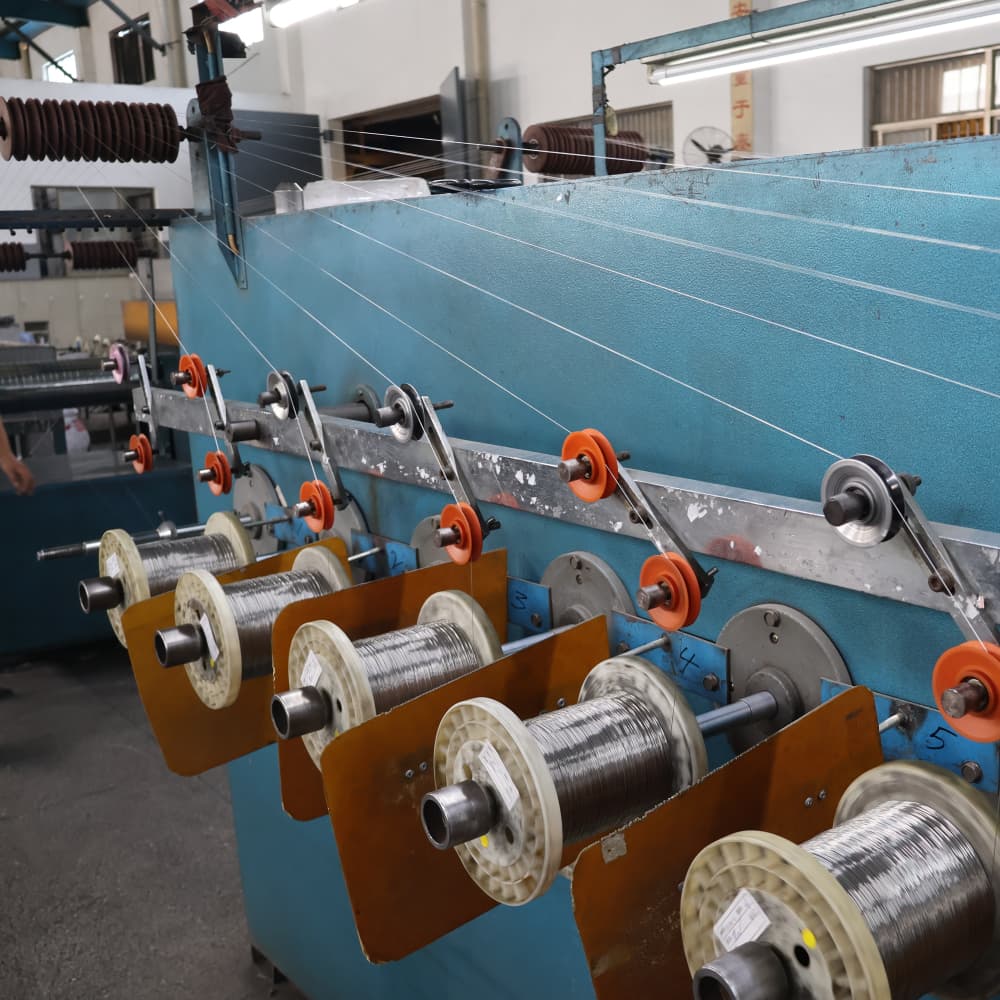

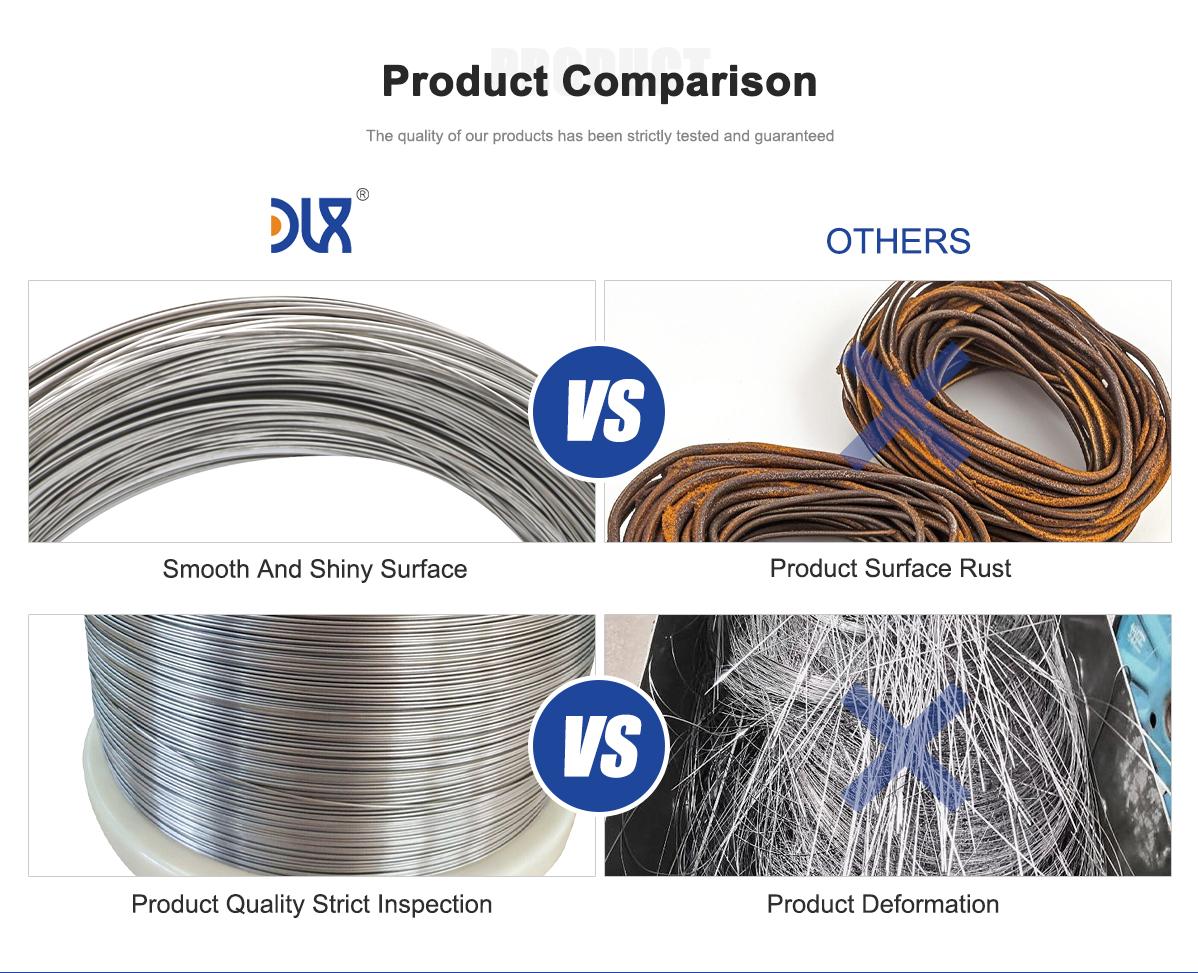

When it comes to Grade 5 titanium wire, our company stands out for all the right reasons. We’ve been in the titanium game for decades, and our expertise shows in every product we deliver. Our state-of-the-art manufacturing facilities use advanced techniques like precision rolling and heat treatment to produce wire that meets the toughest aerospace standards. We prioritize quality control, with every batch tested to ensure consistent composition, strength, and surface finish.

Unlike others, we offer unmatched flexibility. Need a specific diameter or custom-cut length? We’ve got you covered. Our just-in-time (JIT) supply chain means you get what you need, when you need it, without costly stockpiling. We also invest heavily in R&D to stay ahead of industry trends, like additive manufacturing and sustainable production, ensuring our wire is ready for the next generation of aerospace innovation. Our team of experts is always on hand to provide technical support, helping you choose the right specifications for your project.

Cost-effectiveness is another area where we shine. By optimizing our production processes and sourcing high-quality raw materials, we keep prices competitive without compromising on quality. Plus, our commitment in sustainability means we’re exploring greener ways to produce titanium, aligning with the industry’s push for eco-friendly solutions. When you choose our Grade 5 titanium wire, you’re getting a product backed by experience, innovation, and a relentless focus on quality.

Comparison Parameters Table

|

Parameter |

Grade 5 Titanium Wire (Ti-6Al-4V) |

Grade 2 Titanium Wire |

Grade 9 Titanium Wire (Ti-3Al-2.5V) |

|---|---|---|---|

|

Composition |

6% Al, 4% V, 90% Ti |

99.2% Ti (pure) |

3% Al, 2.5% V, 93.5% Ti |

|

Tensile Strength |

900-1000 MPa |

345-450 MPa |

620-860 MPa |

|

Yield Strength |

~830 MPa |

~275 MPa |

~550 MPa |

|

Density |

4.43 g/cm³ |

4.51 g/cm³ |

4.48 g/cm³ |

|

Corrosion Resistance |

Excellent (seawater, chemicals) |

Excellent |

Excellent |

|

Heat Resistance |

Up to 600°F (316°C) |

Up to 400°F (204°C) |

Up to 600°F (316°C) |

|

Formability |

Moderate (less ductile) |

High (very ductile) |

High (cold-formable) |

|

Weldability |

Good (inert gas shielding needed) |

Excellent |

Excellent |

|

Applications |

Aerospace, medical, marine |

Medical, industrial |

Aerospace, medical, automotive |

|

Cost |

Higher due to alloying |

Lower (pure titanium) |

Moderate |

The future of Grade 5 titanium wire in aerospace looks bright. As aircraft manufacturers aim for greater fuel efficiency and lower emissions, lightweight materials like our wire will play a bigger role. The rise of urban air mobility, like eVTOL (electric vertical takeoff and landing) vehicles, is creating new opportunities for titanium in compact, high-strength components. Space exploration, from reusable rockets to lunar habitats, will also drive demand for materials that can handle extreme conditions without adding weight.

We’re already preparing for these shifts. Our ongoing investments in additive manufacturing and sustainable production are positioning us to meet the needs of tomorrow’s aerospace innovators. Whether it’s a next-gen airliner or a spacecraft headed for Mars, our Grade 5 titanium wire is ready to help make it happen.

Conclusion

Our Grade 5 titanium wire is more than just a material—it’s a solution for the toughest aerospace challenges. Its unbeatable strength, lightweight properties, and corrosion resistance make it a cornerstone of modern aircraft and spacecraft design. From airframes to engine components, it delivers performance you can count on. With industry trends leaning toward sustainability and advanced manufacturing, we’re proud to offer a product that’s both cutting-edge and reliable. Choose our Grade 5 titanium wire, and you’re choosing a partner with the expertise, flexibility, and commitment to quality that sets us apart in the titanium industry.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Grade 5 titanium wire made of?

Grade 5 titanium wire, also known as Ti-6Al-4V, is an alloy composed of 6% aluminum, 4% vanadium, and 90% titanium, offering high strength and corrosion resistance. -

What are the main applications of Grade 5 titanium wire in aerospace?

It’s used for airframe components, fasteners, engine parts, and structural supports due to its strength-to-weight ratio and durability in extreme conditions. -

How does Grade 5 titanium wire compare to other titanium grades?

Compared to commercially pure grades (1-4), Grade 5 has higher strength but lower ductility. It’s stronger than Grade 9 but less formable. -

Is Grade 5 titanium wire corrosion-resistant?

Yes, it offers excellent resistance to corrosion in harsh environments like seawater, chemicals, and high temperatures, ideal for aerospace. -

Can Grade 5 titanium wire be heat-treated?

Absolutely, it’s heat-treatable to enhance strength, making it suitable for high-stress aerospace applications up to 600°F (316°C). -

What industries besides aerospace use Grade 5 titanium wire?

It’s used in medical implants, marine equipment, automotive components, and high-performance sports gear due to its durability and biocompatibility. -

What are the challenges of working with Grade 5 titanium wire?

It’s tougher to machine and form than pure titanium grades, requiring specialized tools and techniques to avoid galling or work hardening. -

What are the industry trends for Grade 5 titanium wire?

Demand is growing in aerospace for lightweight, fuel-efficient designs, with additive manufacturing and sustainable production methods gaining traction.