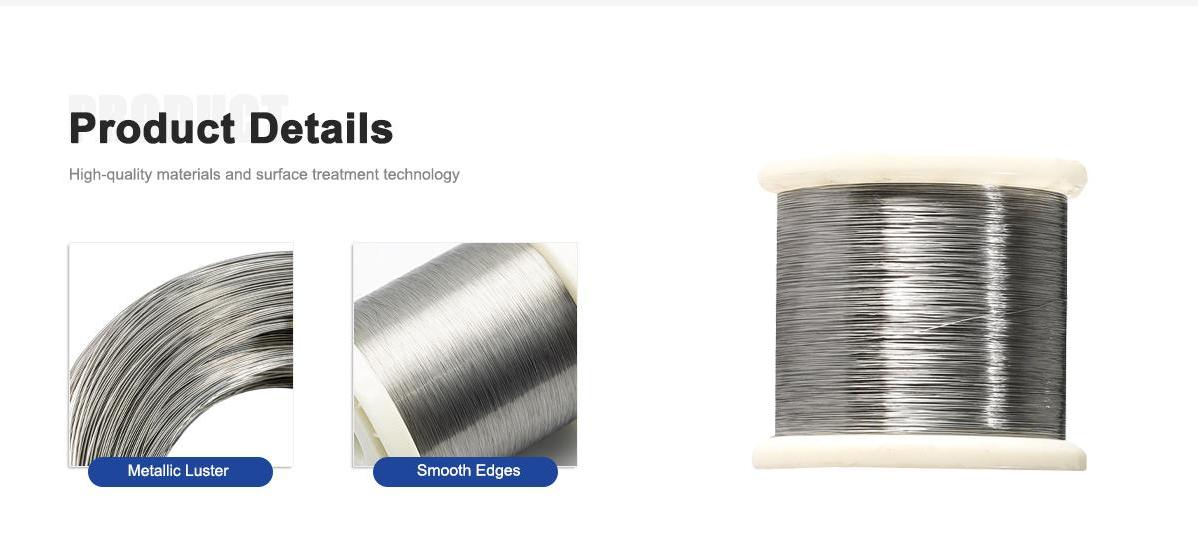

Our Pure Grade 2 Titanium Wire is a superstar in the medical world, designed specifically for implants and devices where biocompatibility and reliability are everything. As a commercially pure titanium product, it’s made of 99.2% titanium with small amounts of iron, oxygen, and carbon, giving it the perfect balance of strength, ductility, and corrosion resistance. This wire is a go-to for surgical implants like bone screws, dental implants, and orthopedic devices, thanks to its ability to integrate seamlessly with the human body.

We offer Grade 2 titanium wire in diameters ranging from 0.1mm to 8mm, available in coils, spools, or custom-cut lengths to fit your manufacturing needs. It meets strict ASTM F67 and ISO 5832-2 standards, ensuring it’s ready for the most demanding medical applications. Its high formability makes it easy to shape into intricate components, while its corrosion resistance ensures implants last for years without degrading. Whether you’re crafting spinal fixation devices or dental frameworks, our Grade 2 titanium wire delivers top-notch performance.

Grade 2 titanium wire is all about versatility and reliability. With a tensile strength of 345-450 MPa, it’s not as strong as Grade 5 (900-1000 MPa) or Grade 9 (620-860 MPa), but it’s way more ductile, making it easier to form into complex shapes for medical devices. Its corrosion resistance is a standout feature—it holds up against bodily fluids, saline, and even harsh chemical environments, ensuring implants stay safe and functional over time. Compared to alloyed grades, it’s also easier to weld and machine, which is a big win for manufacturers creating precision components.

The biocompatibility of Grade 2 titanium is what really sets it apart. It’s non-toxic, non-allergenic, and bonds well with bone and tissue, making it ideal for long-term implants like hip replacements or dental posts. Its moderate strength is more than enough for most medical applications, and its low density—around 4.51 g/cm³—keeps devices lightweight. Outside of medical use, this wire shines in industries like marine and chemical processing, where corrosion resistance is critical, but its real home is in the human body, where safety and performance are non-negotiable.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The medical device industry is booming, and Grade 2 titanium wire is riding the wave. With an aging global population and rising demand for advanced healthcare, the need for biocompatible materials is at an all-time high. The global market for medical implants is expected to grow steadily, driven by innovations in orthopedics, dental care, and minimally invasive surgeries. Our Grade 2 titanium wire is perfectly positioned to meet this demand, offering the flexibility and reliability needed for next-gen devices.

One big trend is the shift toward minimally invasive procedures, which require smaller, more precise components. Our wire’s high ductility makes it ideal for crafting tiny, intricate parts like stents or micro-screws. Additive manufacturing is also shaking things up, allowing manufacturers to create custom implants with less waste. We’re seeing more companies use 3D printing with titanium wire to produce patient-specific devices, and our Grade 2 wire is compatible with these cutting-edge processes.

Sustainability is another key driver. The titanium industry is moving toward greener production methods, like recycling scrap titanium and optimizing the Kroll process to reduce energy use. We’re committed to these trends, ensuring our wire is produced with eco-friendly practices without compromising quality. Cost is always a concern with titanium, but as a pure grade, Grade 2 is more affordable than alloyed options like Grade 5, making it a cost-effective choice for medical manufacturers looking to balance performance and budget.

Applications of Grade 2 Titanium Wire

Our Grade 2 titanium wire is a rockstar in medical applications. It’s widely used for orthopedic implants like bone screws, plates, and pins, where its biocompatibility and strength ensure long-term stability. In dental applications, it’s a top pick for frameworks, implants, and orthodontic wires, thanks to its corrosion resistance and ability to withstand the oral environment. Spinal fixation devices, like rods and screws, also rely on this wire for its flexibility and durability.

Beyond medical, Grade 2 titanium wire finds a home in industries where corrosion resistance is key. In chemical processing, it’s used for equipment like heat exchangers and piping that handle corrosive substances. Marine applications, like underwater cables and fittings, benefit from its ability to resist seawater. Even aerospace uses it for non-structural components where weight and corrosion resistance matter more than high strength. But make no mistake—medical is where this wire truly shines, helping improve lives one implant at a time.

Company Advantages: Why Choose Us

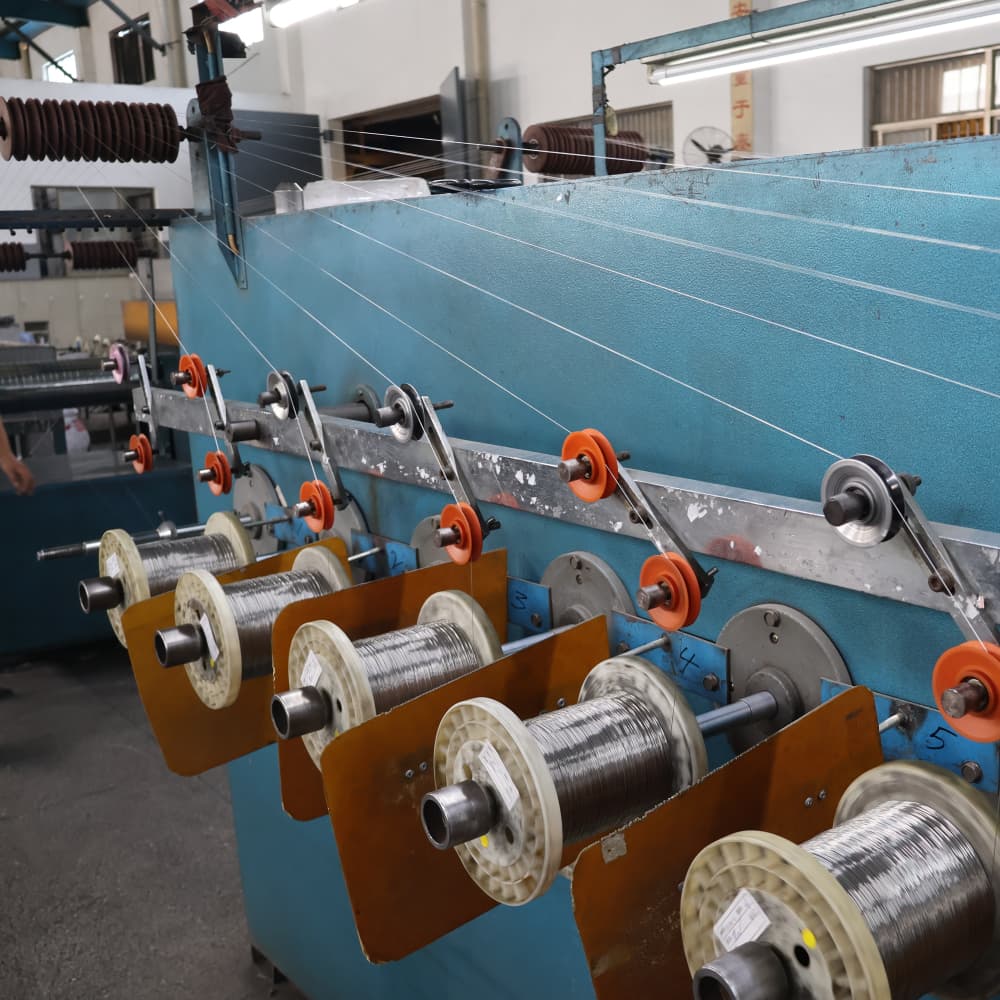

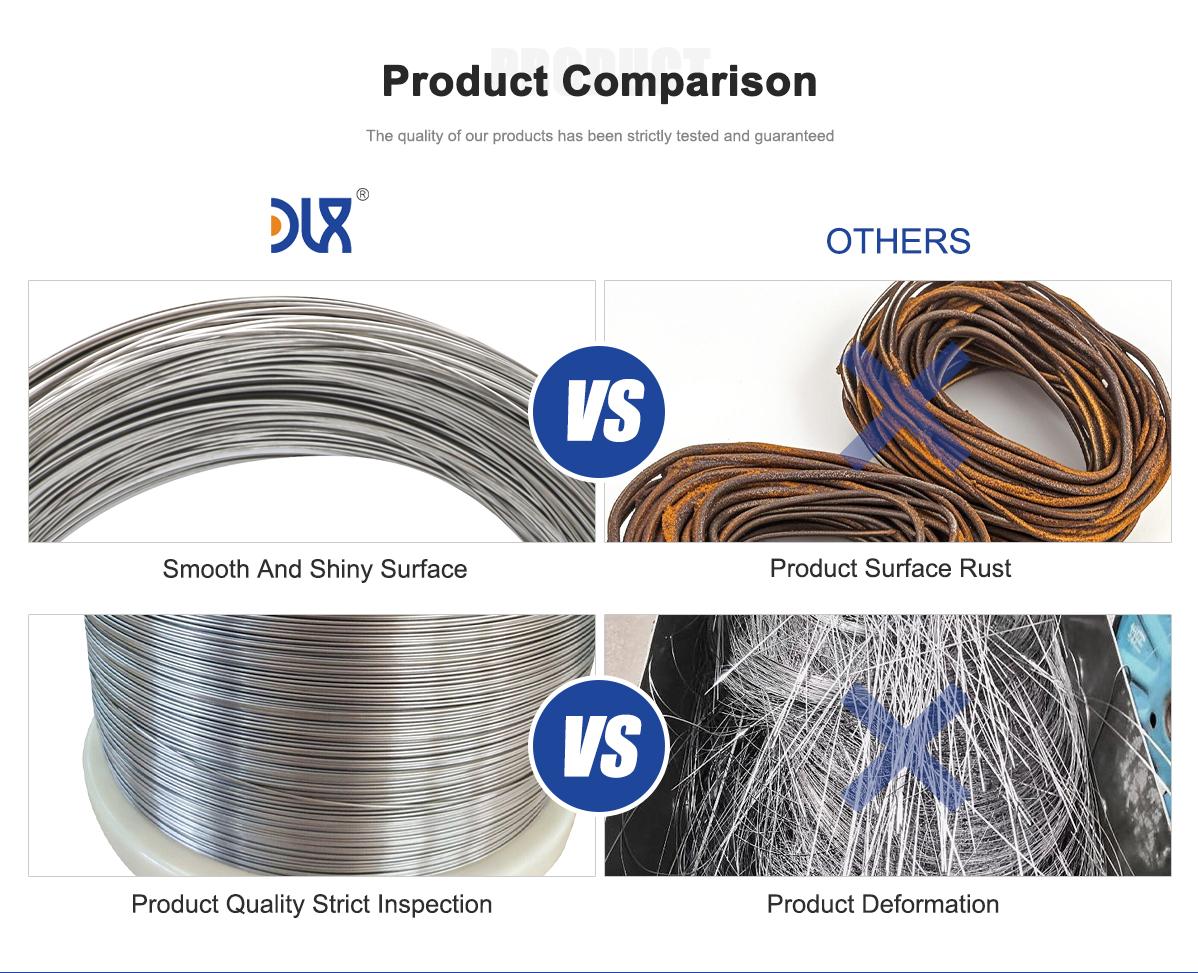

When it comes to Grade 2 titanium wire, we’re a cut above. Our decades of experience in titanium manufacturing mean we know this material inside and out. We use state-of-the-art facilities to produce wire with consistent quality, meeting the strictest medical standards like ASTM F67 and ISO 5832-2. Every batch is rigorously tested for composition, surface finish, and mechanical properties, so you can trust it for critical applications.

Flexibility is a big part of our edge. Whether you need ultra-thin wire for micro-devices or custom lengths for large-scale production, we tailor our products to your specs. Our just-in-time supply chain keeps your costs down by delivering exactly what you need, when you need it. We also invest heavily in R&D to stay ahead of trends like additive manufacturing and sustainable production, ensuring our wire is ready for the future of medical device innovation.

Our technical support team is another reason to choose us. Got a question about wire diameter or biocompatibility? We’re here to help with expert guidance. Plus, our focus on cost-effective production means you get high-quality Grade 2 titanium wire without breaking the bank. We’re also committed to sustainability, using eco-friendly practices to produce wire that aligns with the industry’s green goals. When you pick our wire, you’re getting a partner dedicated to quality, innovation, and your success.

Comparison Parameters Table

|

Parameter |

Grade 2 Titanium Wire |

Grade 5 Titanium Wire (Ti-6Al-4V) |

Grade 9 Titanium Wire (Ti-3Al-2.5V) |

|---|---|---|---|

|

Composition |

99.2% Ti (pure) |

6% Al, 4% V, 90% Ti |

3% Al, 2.5% V, 93.5% Ti |

|

Tensile Strength |

345-450 MPa |

900-1000 MPa |

620-860 MPa |

|

Yield Strength |

~275 MPa |

~830 MPa |

~550 MPa |

|

Density |

4.51 g/cm³ |

4.43 g/cm³ |

4.48 g/cm³ |

|

Corrosion Resistance |

Excellent |

Excellent (seawater, chemicals) |

Excellent |

|

Heat Resistance |

Up to 400°F (204°C) |

Up to 600°F (316°C) |

Up to 600°F (316°C) |

|

Formability |

High (very ductile) |

Moderate (less ductile) |

High (cold-formable) |

|

Weldability |

Excellent |

Good (inert gas shielding needed) |

Excellent |

|

Applications |

Medical, marine, chemical |

Aerospace, medical, marine |

Aerospace, medical, automotive |

|

Cost |

Lower (pure titanium) |

Higher due to alloying |

Moderate |

The future for Grade 2 titanium wire in the medical field is bright. As demand for personalized implants and minimally invasive devices grows, our wire’s formability and biocompatibility will be in high demand. Advances in 3D printing are opening new doors for custom implants, and we’re ready to supply wire that works seamlessly with these technologies. The push for sustainable materials will also drive innovation, with our company leading the way in eco-friendly titanium production.

Emerging fields like bioengineering and regenerative medicine are creating new opportunities for titanium wire. Think tissue scaffolds or bioactive implants—our Grade 2 wire is poised to play a role. With healthcare systems worldwide investing in advanced treatments, the need for reliable, biocompatible materials like ours will only grow. We’re excited to be at the forefront, delivering wire that powers the next generation of medical breakthroughs.

Conclusion

Our Pure Grade 2 titanium wire is a standout choice for medical implants and devices, offering unmatched biocompatibility, corrosion resistance, and formability. From orthopedic screws to dental implants, it’s helping save lives and improve outcomes. With industry trends leaning toward precision, sustainability, and innovation, our wire is ready to meet the challenges of today and tomorrow. Backed by our expertise, flexible production, and commitment to quality, choosing our Grade 2 titanium wire means choosing a partner you can rely on for your most critical medical applications.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What is Grade 2 titanium wire made of?

Grade 2 titanium wire is commercially pure titanium, containing 99.2% titanium with trace amounts of iron, oxygen, and carbon for enhanced strength and formability. -

What are the primary uses of Grade 2 titanium wire in medical applications?

It’s used for surgical implants like bone screws, dental implants, and orthopedic devices due to its biocompatibility and corrosion resistance. -

How does Grade 2 titanium wire compare to other titanium grades?

It’s more ductile and formable than Grade 5 or Grade 9 but has lower strength, making it ideal for medical applications requiring flexibility. -

Is Grade 2 titanium wire biocompatible?

Yes, it’s highly biocompatible, non-toxic, and integrates well with human tissue, making it perfect for long-term implants. -

Can Grade 2 titanium wire withstand corrosion in the body?

Absolutely, it resists corrosion from bodily fluids, ensuring durability and safety in medical implants. -

What industries besides medical use Grade 2 titanium wire?

It’s used in chemical processing, marine applications, and aerospace for components needing high corrosion resistance and moderate strength. -

How easy is it to work with Grade 2 titanium wire?

It’s highly formable and weldable, easier to machine than alloyed grades, making it a favorite for intricate medical device manufacturing. -

What are the industry trends for Grade 2 titanium wire?

Demand is rising for biocompatible materials in medical implants, with trends toward minimally invasive devices and sustainable titanium production.