At our company, we're all about delivering top-notch 304/316 stainless steel coil tubing that's perfect for healthcare and surgical tools. You know, in this fast-paced medical world, having reliable materials isn't just nice—it's essential. Let's dive into what makes our 304/316 stainless steel coil tubing stand out, especially when it comes to applications in healthcare and surgical tools. We're talking about products that combine durability, precision, and biocompatibility to help medical professionals do their jobs better.

For more details, pls directly contact us.

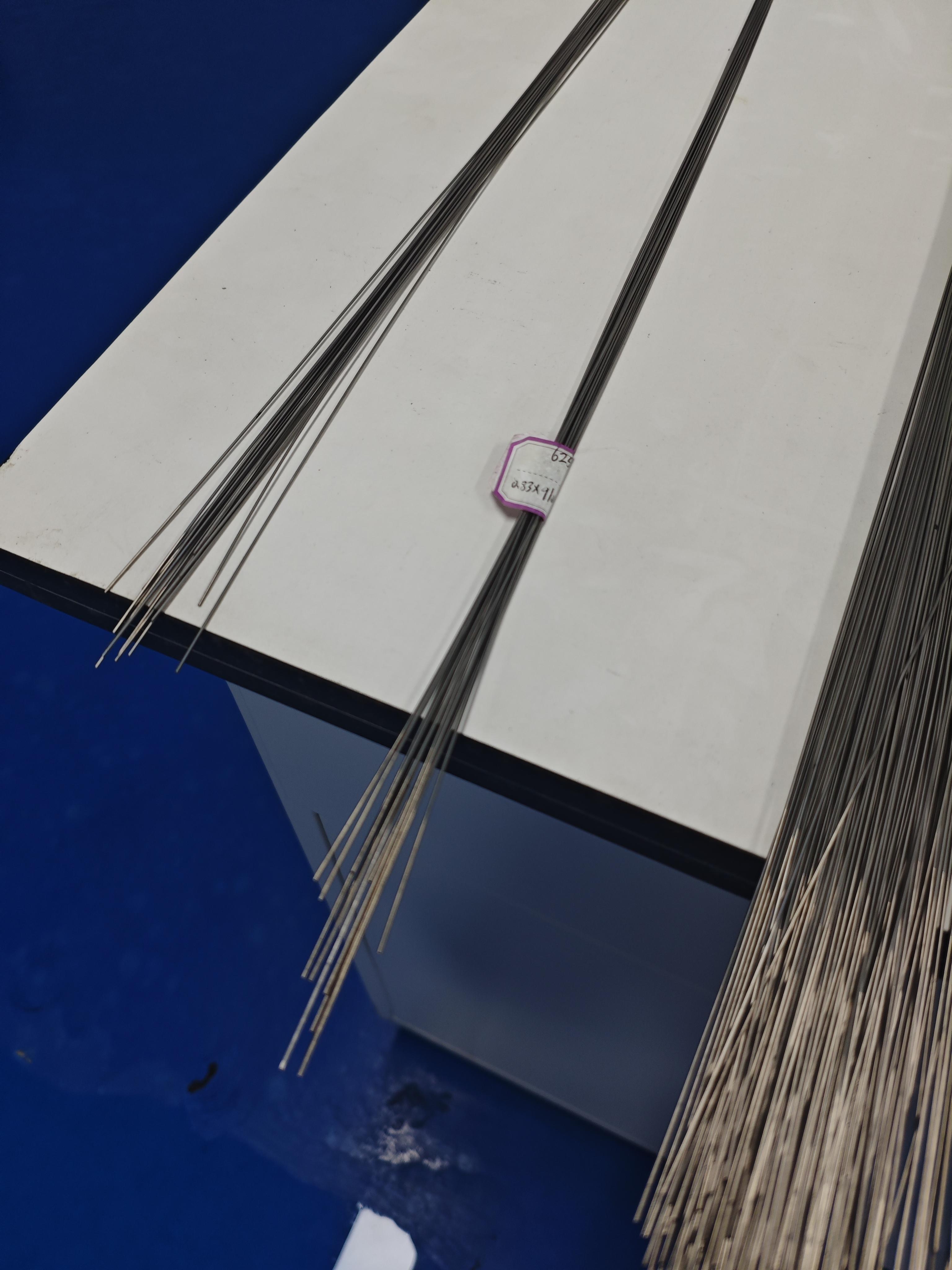

First off, our 304 stainless steel coil tubing is crafted from a high-quality austenitic alloy with 18% chromium and 8% nickel. This gives it fantastic corrosion resistance and makes it super formable, which is why it's a go-to for things like catheters and guidewires. On the other hand, our 316 stainless steel coil tubing amps it up with 2% molybdenum, boosting its resistance to pitting and crevice corrosion—ideal for environments with chlorides, like saline solutions in hospitals. Both grades are low-carbon, ensuring they weld easily and stay strong under stress. We source our raw materials from trusted suppliers and use advanced manufacturing processes to ensure every coil meets stringent standards like ASTM A269 and ISO 10993 for biocompatibility.

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

In healthcare, our 304/316 stainless steel coil tubing shines in a variety of applications. For instance, in intravenous (IV) systems, the tubing's flexibility and smooth interior prevent blockages and ensure consistent fluid delivery. Surgeons love it for endoscopic tools because it can be coiled tightly without kinking, allowing for minimally invasive procedures that reduce patient recovery time. In surgical instruments like biopsy needles or orthopedic devices, the material's strength withstands repeated sterilization cycles—think autoclaving at high temperatures—without degrading. We've seen our products used in everything from dental tools to cardiovascular stents, where precision is key. The coil design also makes it lightweight and easy to handle, which is a big plus in operating rooms where every second counts.

Looking at the broader industry, the medical device sector is booming. According to recent reports, the global market for stainless steel in healthcare is projected to grow at a CAGR of over 5% through 2030, driven by aging populations and rising demand for advanced treatments. Trends like the shift toward outpatient care and telemedicine are pushing for more portable, durable devices, and our 304/316 stainless steel coil tubing fits right in. Sustainability is another hot topic—hospitals are looking for recyclable materials to cut down on waste, and stainless steel is 100% recyclable without losing quality. We're also seeing innovations in surface treatments, like electropolishing, which we apply to our tubing to make it even smoother and more resistant to bacterial adhesion. This aligns with stricter regulations from bodies like the FDA, emphasizing infection control.

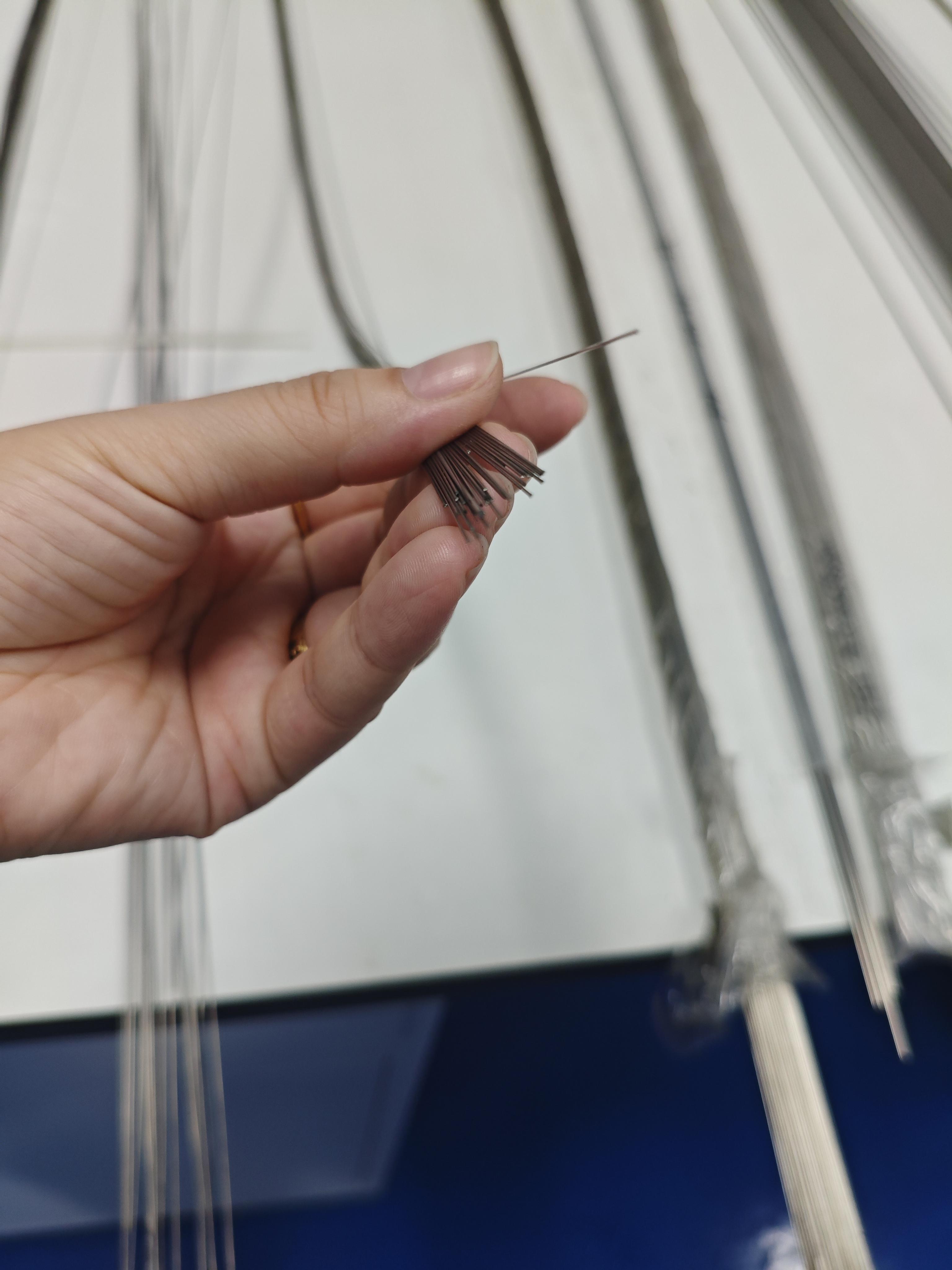

But what really sets our company apart? While there are options out there, we focus on customization that others might overlook. Our in-house engineering team can tailor coil dimensions—down to outer diameters as small as 0.25mm—with tolerances tighter than industry averages. This means better performance in high-precision surgical tools, reducing failure rates and improving patient outcomes. We invest heavily in quality control, using non-destructive testing like eddy current inspections to catch any imperfections early. Plus, our supply chain is streamlined for quick turnaround times, so you get your orders faster without compromising on quality. In a market where downtime can be costly, this reliability gives us an edge.

Diving deeper into applications, let's talk about how our 304/316 stainless steel coil tubing is revolutionizing surgical tools. In neurosurgery, for example, the tubing's hypoallergenic properties ensure it's safe for delicate brain procedures. We've optimized the alloy to maintain flexibility even after bending, which is crucial for navigating complex anatomies. In cardiology, it's used in angioplasty balloons and stents, where the material's fatigue resistance handles the heart's constant pulsing. Healthcare providers appreciate how our products integrate seamlessly with other components, like silicone coatings for added lubricity. And with the rise of robotic surgery, our tubing's consistency supports precise robotic arms, enhancing accuracy in procedures like laparoscopic surgeries.

Industry analysis shows that challenges like material shortages and rising raw material costs are pushing companies to innovate. We're ahead of the curve by adopting eco-friendly manufacturing, such as using renewable energy in our mills, which lowers our carbon footprint and appeals to green-conscious clients. The COVID-19 pandemic highlighted the need for resilient supply chains, and we've built redundancies to ensure steady production. Looking ahead, trends point to hybrid materials—combining stainless steel with polymers—but we believe pure 304/316 alloys remain superior for their proven track record in sterility and longevity.

Comparing to general market offerings, our company's advantage lies in our commitment to R&D. We run extensive lab tests simulating real-world healthcare scenarios, like exposure to bodily fluids or repeated flexing, to guarantee our 304/316 stainless steel coil tubing outperforms expectations. Others might cut corners on testing, but we don't—resulting in fewer recalls and higher customer satisfaction. Our pricing is competitive, too, because we optimize production efficiencies, passing savings to you without skimping on quality. In essence, choosing us means investing in peace of mind for your medical applications.

Expanding on product introduction, our 304 stainless steel coil tubing is versatile and cost-effective, making it suitable for high-volume healthcare items like disposable syringes or monitoring equipment. Its bright annealed finish reduces friction, aiding in smooth insertions during procedures. For more demanding uses, our 316 variant steps up with enhanced chemical resistance, perfect for long-term implants or tools in marine-like saline conditions. We offer various wall thicknesses and lengths, customizable to your specs, ensuring compatibility with existing systems.

Comparison Parameters Table for 304 vs 316 Stainless Steel Coil Tubing

| Parameter | 304 Stainless Steel Coil Tubing | 316 Stainless Steel Coil Tubing |

|---|---|---|

| Composition | 18% Chromium, 8% Nickel, low Carbon (≤0.08%) | 16% Chromium, 10% Nickel, 2% Molybdenum, low Carbon (≤0.08%) |

| Corrosion Resistance | Good in general environments; susceptible to chloride pitting | Excellent; superior resistance to pitting and crevice corrosion in chloride-rich settings |

| Biocompatibility | High; suitable for non-implantable devices | Higher; ideal for implants and tools in contact with bodily fluids |

| Strength (Tensile) | 515 MPa minimum | 515 MPa minimum; slightly higher yield strength in some forms |

| Temperature Resistance | Up to 870°C in intermittent service | Up to 925°C; better in continuous high-heat exposure |

| Cost | Lower; more economical for bulk applications | Higher due to molybdenum content; premium for specialized uses |

| Formability | Excellent; easy to coil and bend without cracking | Good; similar but requires careful handling in thin coils |

| Applications in Healthcare | Catheters, guidewires, general surgical instruments | Endoscopes, orthopedic implants, IV tubing in saline environments |

| Weldability | Excellent; maintains integrity post-welding | Excellent; enhanced by molybdenum for corrosion post-weld |

| Durability in Surgical Tools | Reliable for short-term use; may need frequent replacement in harsh conditions | Superior longevity; withstands repeated sterilization and exposure to acids |

In terms of industry trends, the push for personalized medicine is huge. Our tubing supports this by enabling custom coil designs for patient-specific devices, like tailored catheters for unique vascular structures. Digital health integration is another area—imagine tubing embedded with sensors for real-time data on fluid flow, which we're exploring in prototypes. Regulatory landscapes are evolving, with emphasis on traceability; we provide full documentation from mill to delivery, complying with EU MDR and US FDA guidelines.

Applications extend beyond hospitals to research labs, where our 304/316 stainless steel coil tubing is used in chromatography columns for drug development. Its non-reactive nature preserves sample integrity, crucial for accurate results. In veterinary medicine, it's adapted for animal surgical tools, proving its versatility across species.

Our company's strength is in our people—experienced metallurgists who fine-tune alloys for optimal performance. We offer technical support, from design consultations to post-sale troubleshooting, something not every supplier provides. This holistic approach builds long-term partnerships, helping clients innovate in healthcare.

To wrap up the industry analysis, competition is fierce, but we differentiate through sustainability initiatives, like water recycling in production, aligning with global ESG standards. Future trends include nanotechnology enhancements for antibacterial properties, and we're investing in that to stay ahead.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What materials are used in 304/316 stainless steel coil tubing?

304 stainless steel coil tubing is made from an austenitic alloy with 18% chromium and 8% nickel, offering excellent corrosion resistance and formability. 316 stainless steel coil tubing includes 16% chromium, 10% nickel, and 2% molybdenum for enhanced resistance to chlorides and acids.

What are the key applications of 304/316 stainless steel coil tubing in healthcare?

In healthcare, 304/316 stainless steel coil tubing is used for intravenous lines, catheters, endoscopic tools, and fluid delivery systems due to its biocompatibility, sterility, and flexibility.

How does 304 stainless steel coil tubing differ from 316 in surgical tools?

304 offers good general corrosion resistance and is cost-effective for non-aggressive environments, while 316 provides superior pitting resistance, making it ideal for surgical tools exposed to saline or bodily fluids.

What industry trends are driving the use of 304/316 stainless steel coil tubing?

Trends include rising demand for minimally invasive procedures, advancements in biocompatible materials, and sustainability efforts focusing on recyclable alloys in medical manufacturing.

Is 304/316 stainless steel coil tubing biocompatible for medical use?

Yes, both grades meet ISO 10993 standards for biocompatibility, ensuring they don't cause adverse reactions in contact with human tissue or fluids.

What maintenance is required for 304/316 stainless steel coil tubing in surgical applications?

Regular cleaning with non-abrasive solutions, sterilization via autoclaving, and inspection for pitting or cracks to maintain hygiene and performance.

How do environmental factors affect 304/316 stainless steel coil tubing in healthcare settings?

316 performs better in chloride-rich environments like hospitals with saline solutions, while 304 suits drier or less corrosive conditions, extending tool lifespan.

What future trends might impact 304/316 stainless steel coil tubing in the medical industry?

Integration with smart sensors for real-time monitoring, increased use in telemedicine devices, and shifts toward eco-friendly production to reduce carbon footprints in medical supply chains.