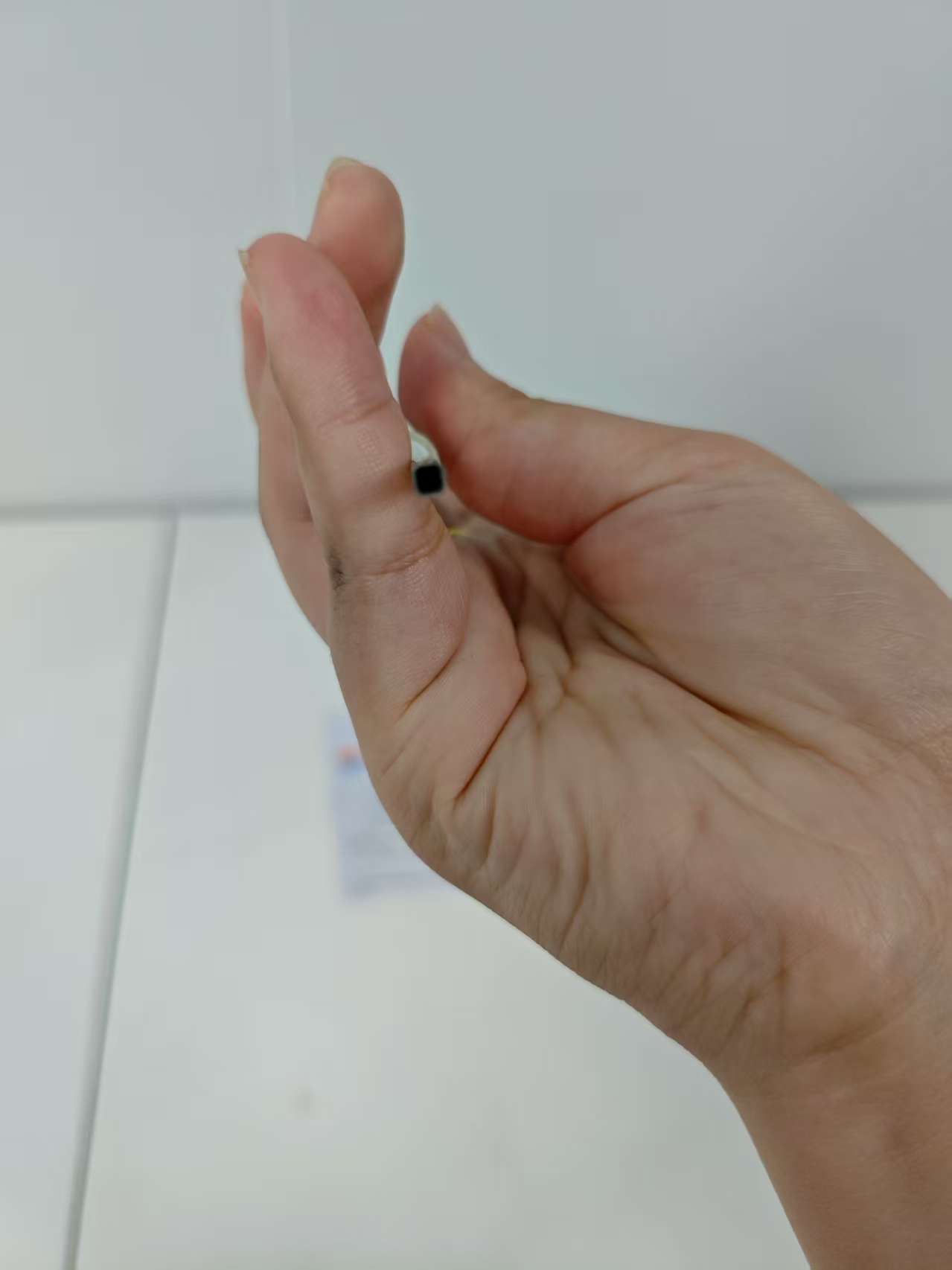

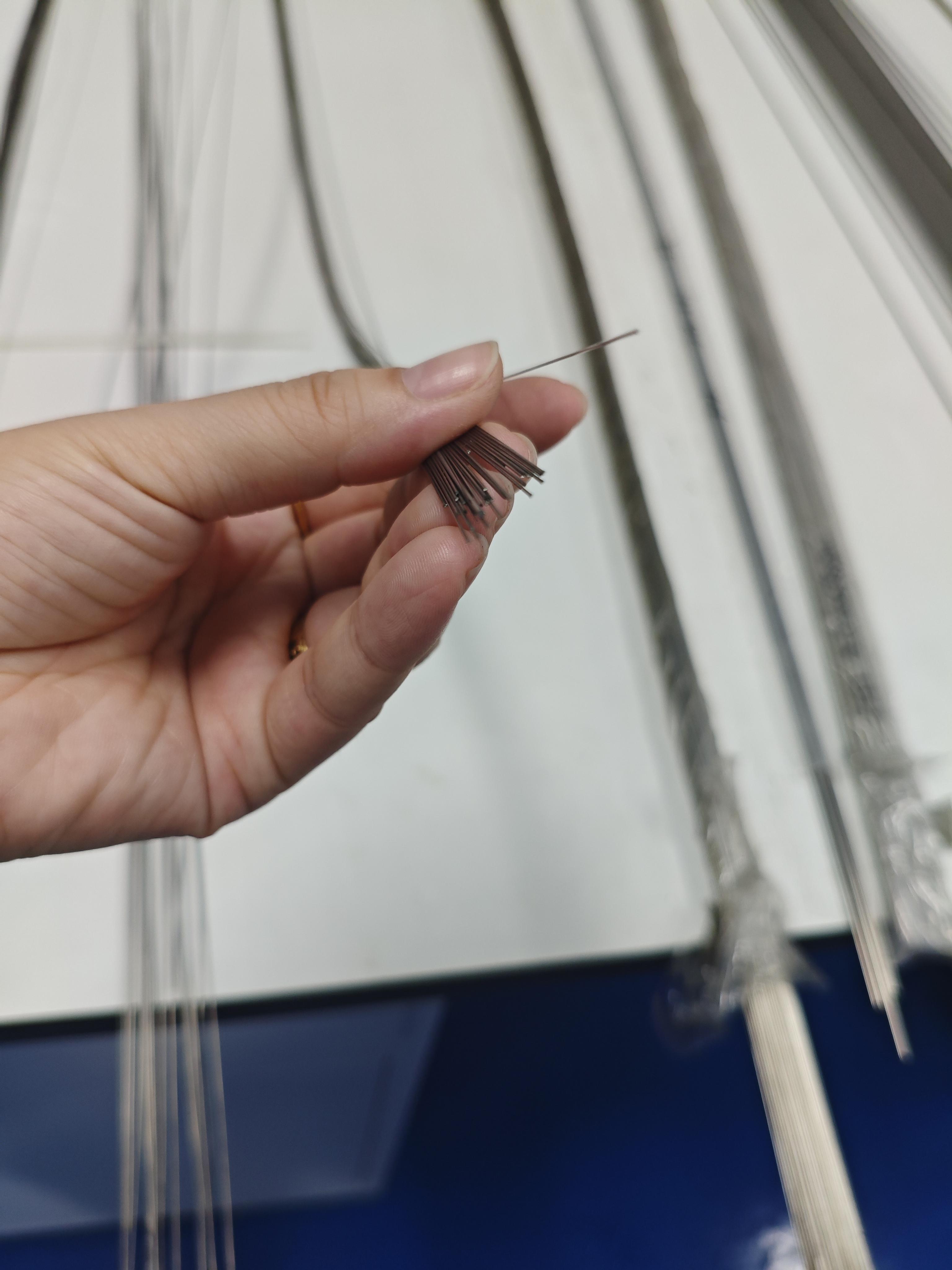

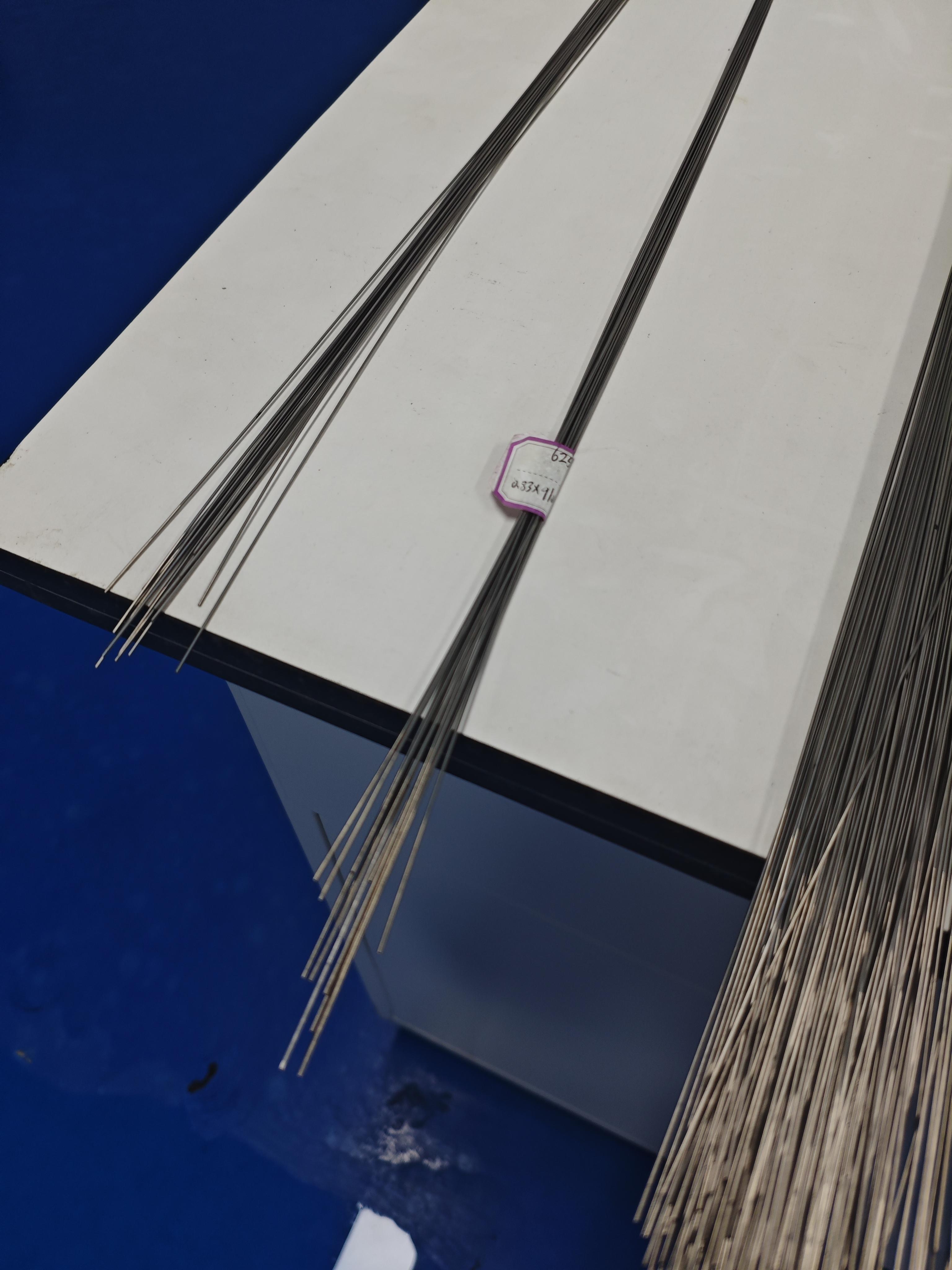

Our Medical Grade Stainless Steel Coil Tubing is a premium material designed for precision medical devices, offering unmatched biocompatibility, corrosion resistance, and durability. Crafted from high-purity 304 and 316L stainless steel alloys, meeting ASTM A269 and ISO 13485 standards, these tubes provide a tensile strength of 515-690 MPa and excellent resistance to bodily fluids and sterilization processes. Available in outer diameters from 0.5mm to 6mm and wall thicknesses from 0.1mm to 1mm, they’re ideal for applications in minimally invasive surgery and implantable devices. Their seamless or welded construction ensures reliability in high-pressure systems.

These tubes are highly formable, weldable, and easy to machine, making them perfect for custom medical applications. With a smooth surface finish and thermal conductivity of 15-20 W/m·K, they ensure efficient fluid transfer and heat management in medical equipment. Whether you’re building catheters, stents, or surgical tools, our coil tubing delivers consistent performance, reducing risks and ensuring patient safety. It’s the go-to choice for medical manufacturers who need precision and reliability in critical applications.

For more details, pls directly contact us.

The medical stainless steel tubing market is growing steadily, driven by the rising demand for precision medical devices and minimally invasive procedures. Valued at USD 5.1 billion in 2025, it’s projected to grow at a CAGR of 8.5% through 2033, fueled by advancements in healthcare technology and an aging global population. Our medical grade stainless steel coil tubing meets these needs, offering biocompatibility and durability for critical applications. The increasing prevalence of chronic diseases, like cardiovascular issues and diabetes, drives demand for devices such as catheters and stents, where precision tubing is essential.

Sustainability is a key trend shaping the market. Stainless steel’s recyclability aligns with the push for eco-friendly materials, making it a preferred choice for medical manufacturers aiming to reduce environmental impact. The rise of outpatient clinics and home-based healthcare is boosting demand for compact, high-performance tubing in portable devices like insulin pumps. North America leads the market due to its advanced healthcare infrastructure, while Asia-Pacific is seeing rapid growth from expanding medical device industries in China and India. Despite challenges like stringent regulations and competition from polymers, the market outlook remains strong as demand for reliable, biocompatible materials grows.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

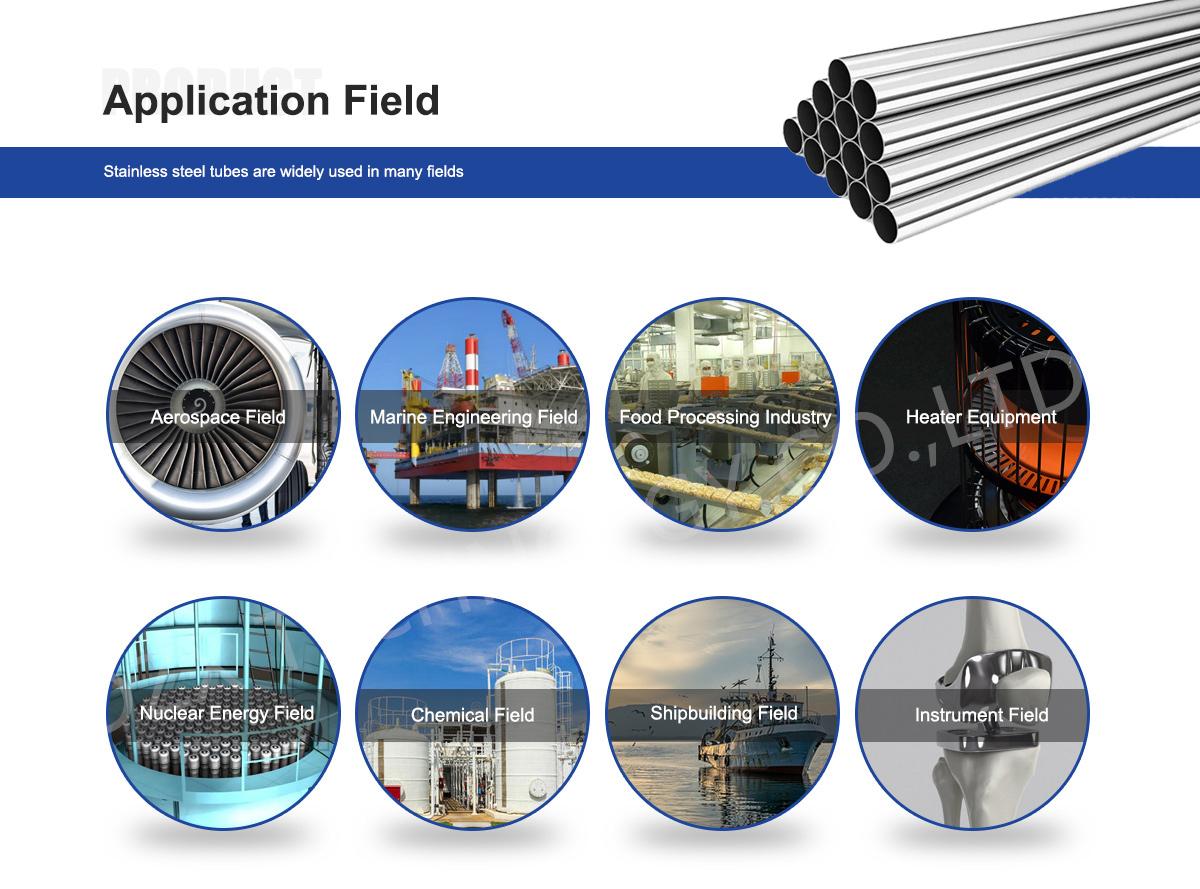

Our medical grade stainless steel coil tubing is designed for precision and reliability in critical medical applications. In minimally invasive surgery, it’s used for catheters, guidewires, and endoscopes, where its small diameter and biocompatibility ensure safe interaction with human tissues. Its corrosion resistance makes it ideal for fluid transfer systems in dialysis machines and IV delivery, handling bodily fluids without degradation. In implantable devices, our 316L tubing is used for stents and orthopedic components, offering strength and long-term compatibility with the body.

Diagnostic equipment, such as MRI and ultrasound devices, benefits from our tubing’s smooth surface finish and thermal conductivity, ensuring efficient fluid and heat management. In pharmaceuticals, it’s used for high-purity fluid transfer systems, meeting strict hygiene standards. The tubing’s formability and weldability make it perfect for custom fabrication, from intricate surgical tools to robust implantable devices. Whether you’re developing cutting-edge medical devices or diagnostic tools, our coil tubing delivers the performance needed for patient safety and device reliability.

Parameter | Our Medical Grade Coil Tubing | Standard Stainless Steel Tubing |

|---|---|---|

Composition | 304/316L (Ni 8-10%, Cr 16-18%, Mo 2-3%) | Variable alloys, lower Ni/Cr content |

Tensile Strength | 515-690 MPa | 400-600 MPa |

Corrosion Resistance | Excellent (Bodily fluids, sterilization) | Moderate, less resistant to bodily fluids |

Biocompatibility | High, FDA-approved for implants | Variable, not always biocompatible |

Thermal Conductivity | 15-20 W/m·K, ideal for medical devices | 10-15 W/m·K, less efficient |

Weldability | Excellent, supports TIG/laser welding | Good, limited by alloy composition |

Applications | Catheters, stents, surgical tools | General industrial, less specialized |

Size Options | 0.5mm-6mm OD, 0.1mm-1mm wall, customizable | 1mm-10mm OD, limited customization |

We’ve been delivering high-quality stainless steel materials for over a decade, and our medical grade coil tubing reflects our expertise and commitment to excellence. Every tube is manufactured to meet ASTM A269 and ISO 13485 standards, with rigorous testing in our advanced labs to ensure biocompatibility, precision, and durability. Our tubing offers superior corrosion resistance, high tensile strength, and excellent formability, making it a standout for medical device applications. Its customizable sizes and finishes ensure you get exactly what your project needs, no compromises.

We set ourselves apart with our flexibility. Our OEM and ODM services allow us to tailor tubing dimensions, grades, and surface finishes to meet your specific requirements, from small-scale catheters to large diagnostic systems. Our technical team is always available to provide expert guidance, helping you select the right material and fabrication techniques for optimal results. Sustainability is a core focus for us—we use recyclable materials and eco-friendly production methods to align with modern industry standards. With a global supply chain and fast delivery, we ensure your materials arrive on time, whether you’re working on a surgical tool or an implantable device. Our dedication to quality, customization, and customer support makes us the top choice for medical grade stainless steel coil tubing solutions.

Why Choose Our Medical Grade Stainless Steel Coil Tubing?

Our medical grade stainless steel coil tubing is built for precision and performance, offering exceptional biocompatibility, corrosion resistance, and durability for medical devices. Its formability and weldability make it ideal for custom designs, while its high strength ensures reliability in high-pressure systems. Whether you’re crafting catheters, stents, or diagnostic equipment, our tubing delivers results that meet the strictest medical standards. Our focus on precision manufacturing and customizable options ensures you get a product tailored to your needs, backed by years of industry expertise.

The demand for medical grade tubing is surging, driven by trends in minimally invasive procedures, chronic disease management, and sustainable manufacturing. Our coil tubing meets these needs, offering versatility and reliability across medical applications. From surgical tools to implantable devices, it’s designed to keep your projects running smoothly and safely. With global demand for high-performance medical materials on the rise, our tubing is the perfect choice for devices that need to perform under pressure. Trust us to provide the materials and support you need to succeed in today’s fast-paced medical industry.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is medical grade stainless steel coil tubing used for?

It’s used in catheters, stents, guidewires, and surgical tools for minimally invasive procedures and implantable devices.What are the key properties of medical grade coil tubing?

It offers tensile strength of 515-690 MPa, excellent corrosion resistance, biocompatibility, and high formability.Can medical grade stainless steel coil tubing be welded?

Yes, it’s weldable using TIG or laser welding with compatible stainless steel fillers for seamless joints.What industries benefit from medical grade coil tubing?

Medical device manufacturing, surgical equipment, diagnostics, and pharmaceuticals rely on its precision and durability.What size options are available for medical grade coil tubing?

Outer diameters range from 0.5mm to 6mm, wall thicknesses from 0.1mm to 1mm, with custom sizes available.Is medical grade coil tubing suitable for sterilization processes?

Absolutely, it withstands autoclaving and chemical sterilization without corrosion or degradation.How does medical grade coil tubing perform in high-pressure systems?

Its seamless construction and high tensile strength ensure reliable performance in high-pressure fluid transfer systems.Can medical grade coil tubing be customized for specific devices?

Yes, we offer OEM and ODM services to tailor tubing dimensions, grades, and finishes to your project needs.