At our company, we specialize in crafting ASTM F138 316LVM stainless steel tube for cardiovascular stents, delivering the kind of precision and reliability that modern heart procedures demand. These tubes are more than just metal—they're lifesavers, helping to keep arteries open and hearts beating strong in patients worldwide. Our focus on this material stems from its proven track record in tackling coronary artery disease, where durability meets biocompatibility in a way that truly makes a difference.

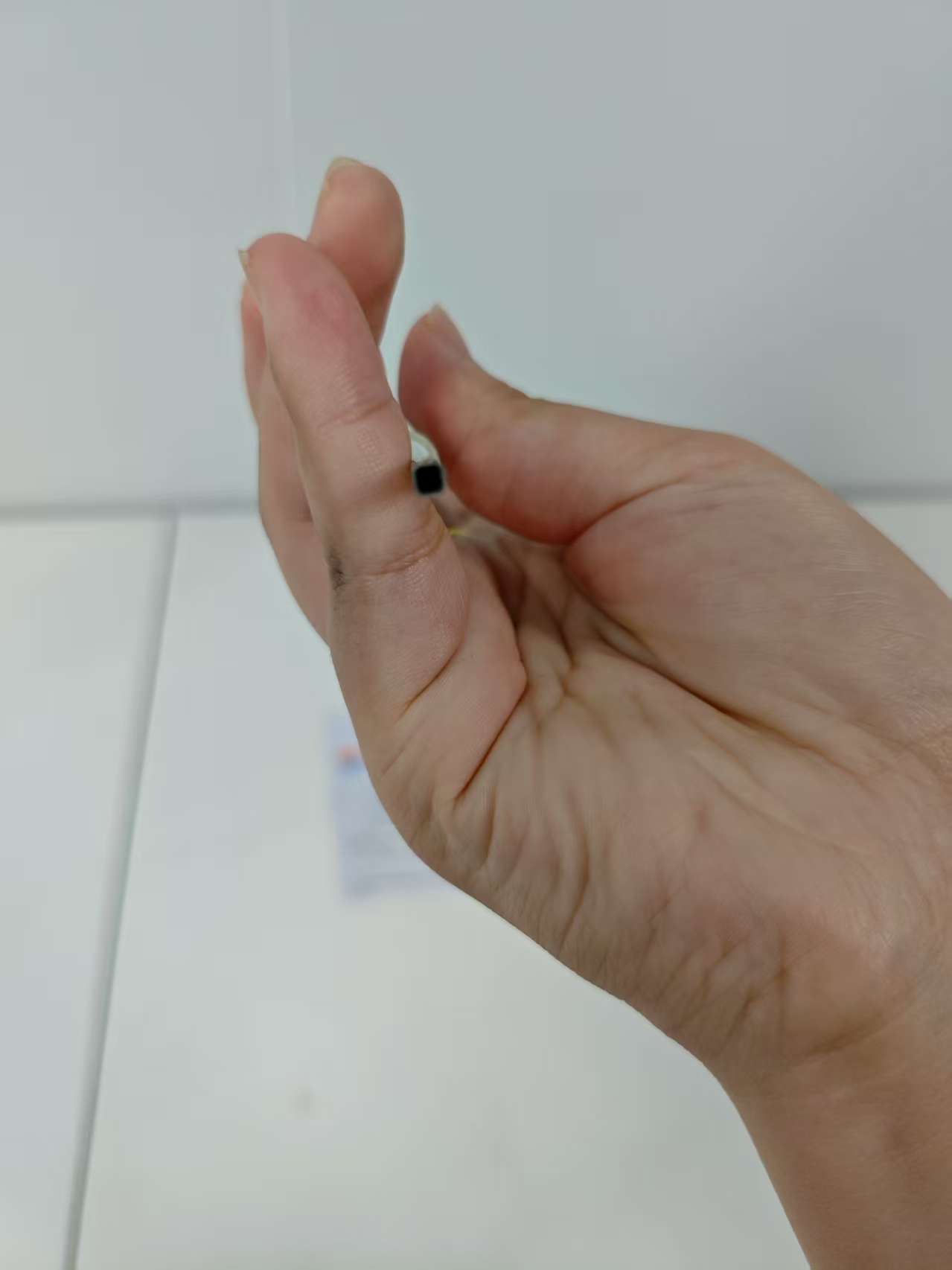

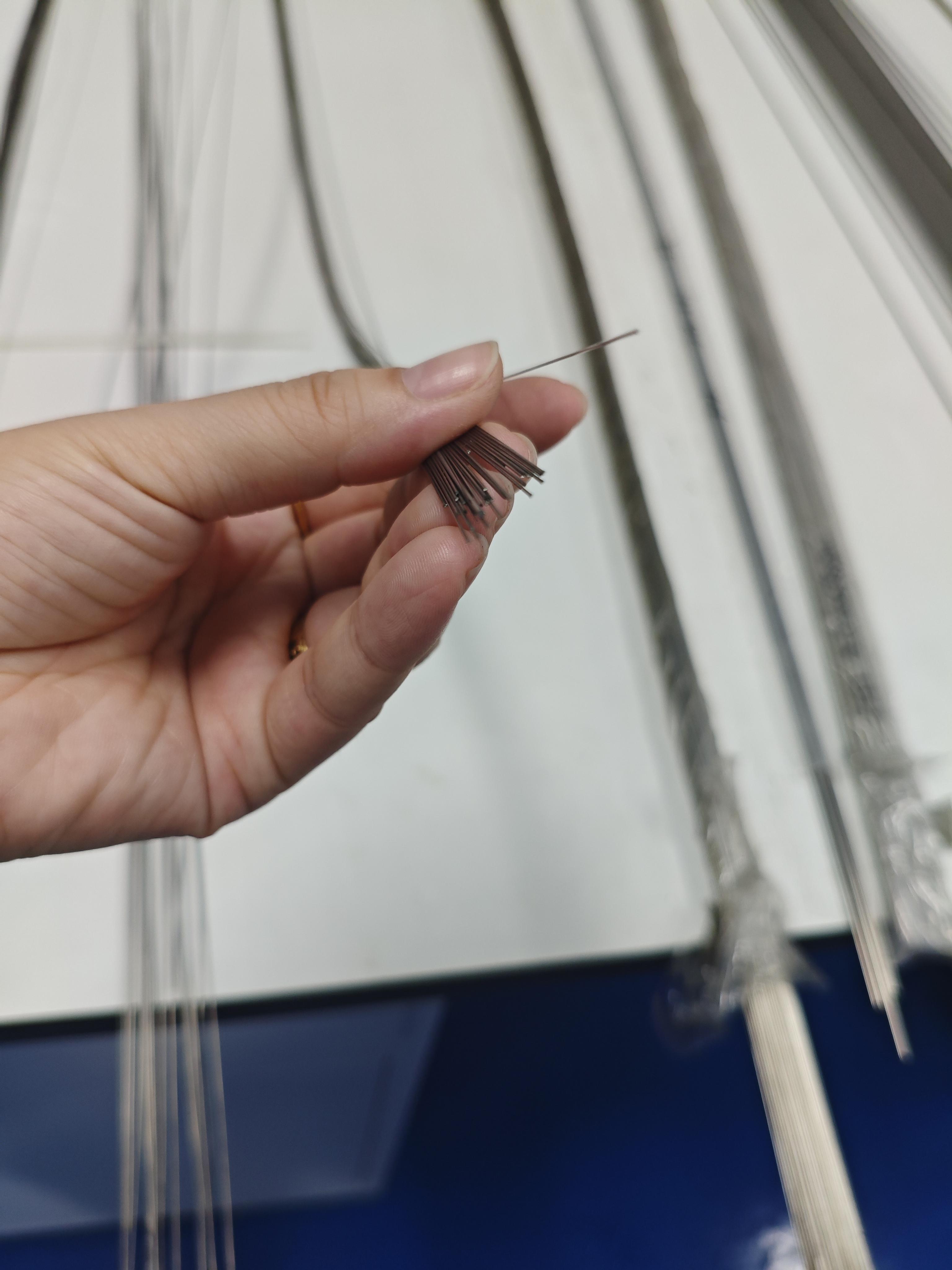

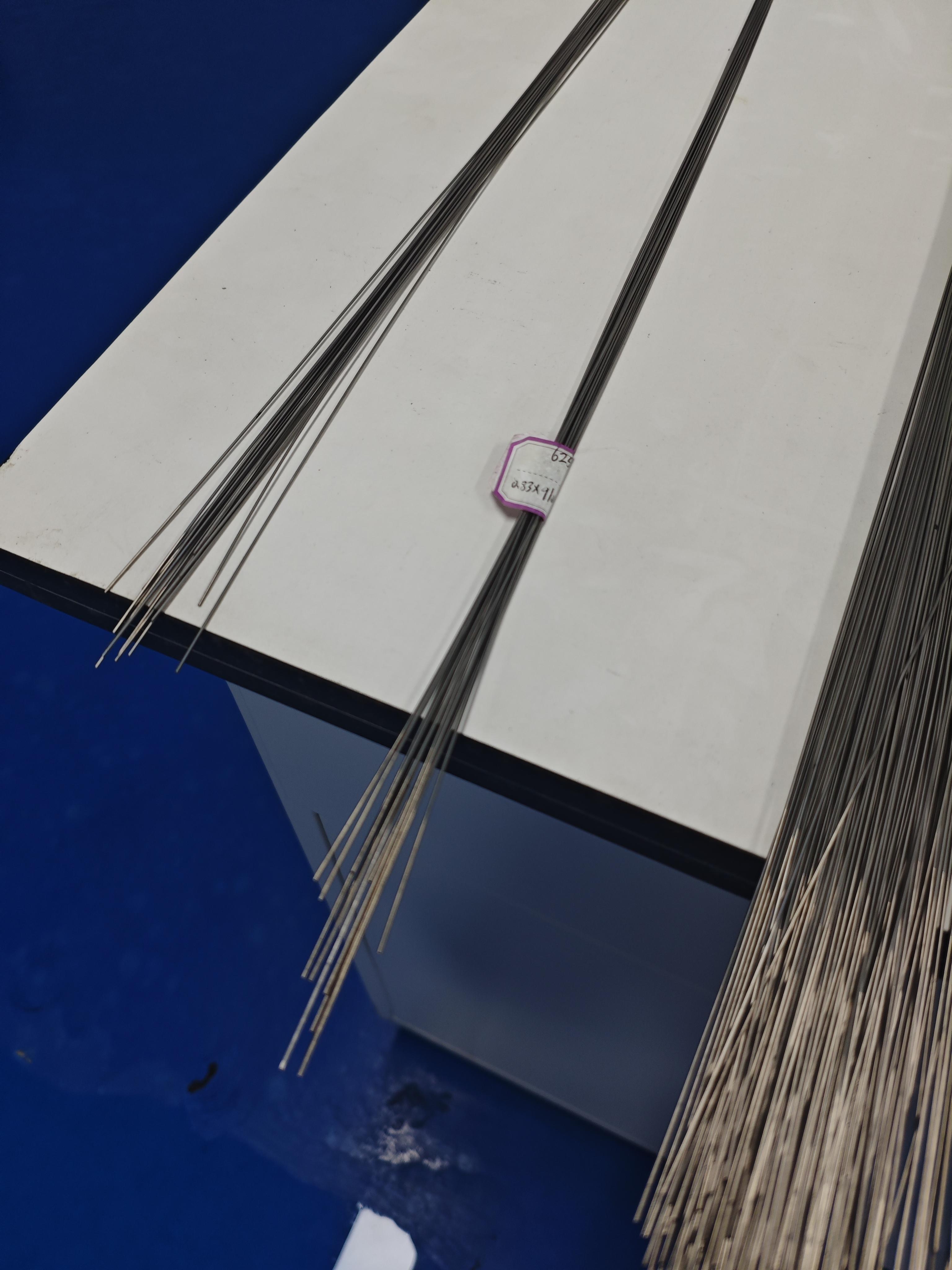

Let's break down what our ASTM F138 316LVM stainless steel tube for cardiovascular stents brings to the table. This vacuum-remelted alloy is the gold standard, with a composition that includes 17-19% chromium for that tough oxide layer against corrosion, 13-15% nickel for added toughness, and 2.25-3.5% molybdenum to fend off pitting in the bloodstream's salty setup. The low carbon content—under 0.03%—prevents sensitization during processing, and the ASTM F138 certification ensures it's implant-ready. We produce these tubes in ultra-fine diameters from 0.2mm to 5mm, with walls as thin as 0.05mm, perfect for crimping onto balloons or self-expanding designs. Our manufacturing tweaks the grain structure for optimal flexibility, so stents deploy smoothly without kinking, reducing procedural risks like vessel perforation.

For more details, pls directly contact us.

We don't stop at basics; our ASTM F138 316LVM stainless steel tube for cardiovascular stents gets advanced treatments like electropolishing for a super-smooth surface that cuts down on thrombus formation. This means better blood flow and lower restenosis rates, which is huge for patient recovery. Plus, its non-magnetic nature keeps it safe for MRI scans post-implant, a must in today's diagnostic world. We've run exhaustive tests, simulating millions of heartbeats to confirm fatigue resistance, ensuring these tubes hold up in the pulsing arteries where failure isn't an option.

Shifting gears to industry analysis, the cardiovascular stents market is on a steady climb, hitting USD 10.35 billion in 2025 and eyeing USD 17.40 billion by 2034 with a 6% CAGR. This growth is fueled by skyrocketing cases of heart disease—think diabetes and obesity epidemics—plus an aging population that's more prone to blockages. Minimally invasive techniques are the big driver, with percutaneous coronary interventions (PCI) becoming routine, demanding materials like 316LVM that can handle tight navigations through vessels. We're also seeing a push toward drug-eluting stents (DES) to prevent re-narrowing, where our tubes serve as the sturdy base for coatings that release meds slowly.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

Regulatory landscapes are evolving too, with the FDA and EU MDR emphasizing long-term safety data, which plays to 316LVM's strengths in biocompatibility testing. Sustainability is creeping in, as hospitals seek recyclable metals to cut waste—stainless steel recycles beautifully, aligning with green healthcare trends. The medical metal tubing market mirrors this, starting at USD 812.59 million in 2025 and projected to hit USD 1,547.53 million by 2034 at a 6.7% CAGR. Emerging markets in Asia-Pacific are exploding, with rising healthcare access driving demand for affordable yet high-quality stents. Challenges like bioresorbable alternatives are out there, but stainless steel holds firm for its cost-effectiveness and reliability in complex cases.

Trends wise, surface functionalization is hot—think coatings that promote endothelial growth or antimicrobial layers to fight infections. Magnesium-based bioresorbables are gaining traction for temporary support, but they can't match 316LVM's mechanical prowess in permanent fixes. We're spotting more hybrid stents blending metals with polymers for better flexibility, and AI-driven design is optimizing tube geometries for personalized implants. With global stents market growth at 3.7% CAGR to USD 18.46 billion by 2030, the emphasis on durable, MRI-compatible materials like ours is clear. Post-pandemic, telemedicine and remote monitoring are integrating with smart stents, where our tubes could house sensors for real-time data on blood flow.

Diving into applications, our ASTM F138 316LVM stainless steel tube for cardiovascular stents shines in treating atherosclerosis, where narrowed arteries get propped open to prevent heart attacks. In coronary interventions, these tubes form the scaffold for balloon-expandable stents, inflating to push plaque aside and restore flow. For peripheral artery disease in legs or arms, the material's strength handles higher pressures without collapsing. We've seen it in transcatheter aortic valve replacements (TAVR), supporting frames that deliver valves minimally invasively—no open-heart surgery needed.

Another key spot is in bifurcation stents for branched vessels, where our precise tubing allows Y-shaped designs that cover multiple paths without gaps. In acute myocardial infarctions, quick deployment is critical, and 316LVM's ductility ensures rapid expansion under pressure. Emerging uses include neurovascular stents for aneurysms, adapting the same purity for brain applications. With coronary stents alone valued at USD 8.29 billion in 2025, growing to USD 10.43 billion by 2030 at 4.69% CAGR, the versatility drives adoption. Our tubes also excel in drug-eluting versions, where the smooth surface holds polymers that release anti-proliferative drugs, cutting re-intervention rates by up to 50%.

When comparing to standard industry practices, our company pulls ahead by prioritizing innovation in every step. While typical suppliers might offer off-the-shelf 316LVM, we customize with proprietary annealing for enhanced radiopacity, making stents easier to visualize under X-ray. This reduces procedure time and radiation exposure, a win for both docs and patients. Our quality control is top-notch—100% inspection with ultrasonic testing catches micro-defects that others might miss, ensuring zero recalls.

We stand out in scalability too; our automated production lines handle high volumes without compromising precision, perfect for meeting surging demand in emerging markets. Cost-wise, we optimize through efficient sourcing, keeping prices competitive while delivering premium features like nanostructured surfaces for better cell adhesion. Feedback from cardiologists praises our tubes' consistency, leading to smoother crimps and fewer deployment failures compared to generic options.

Comparison Parameters Table

| Parameter | 316LVM Stainless Steel (ASTM F138) | 316L Stainless Steel | 304L Stainless Steel | Cobalt-Chromium Alloy (e.g., L605) |

|---|---|---|---|---|

| Carbon Content (%) | ≤0.03 | ≤0.03 | ≤0.03 | ≤0.15 |

| Corrosion Resistance | Superior (vacuum-melted, high Mo for blood/vessel environments) | Excellent (Mo addition, but less pure) | Moderate (no Mo, prone to chloride attack) | Excellent (Cr content, but higher density) |

| Tensile Strength (MPa) | 860-1000 | 485-620 | 485-620 | 1000-1200 |

| Yield Strength (MPa) | 690-860 | 170-310 | 170-310 | 450-650 |

| Biocompatibility | Exceptional (low inclusions, minimal ion release for stents) | High (standard medical grade) | Good (higher allergy potential) | High (used in stents, but costlier) |

| Density (g/cm³) | 8.0 | 8.0 | 8.0 | 9.1 |

| Magnetic Properties | Very low permeability | Non-magnetic | Non-magnetic | Non-magnetic |

| Cost Effectiveness | Premium for purity, ideal for long-term implants | Affordable | Lowest | Higher, for high-strength needs |

| Common Medical Use | Cardiovascular stents, hypotubes | General instruments | Surgical tools | Stents where thinner profiles matter |

Sustainability sets us apart—we recycle 95% of process scraps, reducing our carbon footprint in an industry under scrutiny for waste. Unlike basic providers, we offer full traceability from melt to market, complying with MDR ahead of curves. This builds trust, especially as regulations tighten on ion release; our vacuum-melted 316LVM leaches far less nickel, minimizing allergies.

Looking ahead, we're investing in R&D for bioabsorbable coatings on our stainless cores, blending the best of both worlds. With trends leaning toward personalized stents via 3D printing, our adaptable tubing is ready to integrate. In a market where coronary stents are expected to reach USD 9.7 billion by 2030 at 2.6% CAGR, our focus on reliability positions us as leaders.

In wrapping up, choosing our ASTM F138 316LVM stainless steel tube for cardiovascular stents means betting on excellence. We craft these with passion, knowing they save lives daily. From robust materials that endure to custom solutions that innovate, we're your go-to for advancing cardiac care. As the field grows with tech and demographics, we're here, pushing boundaries to keep hearts healthy.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes ASTM F138 316LVM stainless steel ideal for cardiovascular stents?

ASTM F138 316LVM offers high purity through vacuum melting, excellent corrosion resistance in vascular environments, superior biocompatibility to minimize thrombosis, and low magnetic properties for MRI compatibility, ensuring reliable performance in stent deployment and long-term implantation.How does the material composition of 316LVM enhance its use in stents?

Featuring carbon under 0.03%, chromium (17-19%), nickel (13-15%), molybdenum (2.25-3.5%), and vacuum-remelted for reduced inclusions, it provides enhanced pitting resistance, mechanical strength, and cleanliness, complying with ASTM F138 for implant-grade safety in blood-contact applications.What are the key applications of ASTM F138 316LVM tubes in cardiovascular stents?

These tubes are used in self-expanding and balloon-expandable stents for coronary artery disease treatment, peripheral vascular interventions, and structural heart devices, enabling precise crimping, expansion, and radial support to restore blood flow without vessel damage.How do industry trends impact the adoption of 316LVM tubes in cardiovascular stents?

The coronary stents market is valued at USD 10.35 billion in 2025 and projected to reach USD 17.40 billion by 2034 at a 6% CAGR, driven by rising cardiovascular diseases, minimally invasive procedures, and demand for durable materials amid bioresorbable alternatives.What mechanical properties make 316LVM suitable for stent tubing?

It delivers tensile strength of 860-1000 MPa, yield strength of 690-860 MPa, elongation over 40%, and high fatigue endurance, allowing thin-walled tubes to withstand expansion stresses and cyclic loading in dynamic arterial conditions.Is ASTM F138 316LVM fully biocompatible for cardiovascular implants?

Yes, it's hypoallergenic, non-cytotoxic, and promotes endothelialization while reducing platelet adhesion, meeting ISO 10993 and ASTM F138 standards to prevent inflammation or restenosis in stent applications.What emerging trends in stent materials favor 316LVM usage?

Trends include surface modifications for better drug elution, hybrid designs combining stainless steel with polymers, and a focus on cost-effective, proven alloys as the medical metal tubing market grows from USD 812.59 million in 2025 to USD 1,547.53 million by 2034 at 6.7% CAGR, emphasizing purity for personalized medicine.How does 316LVM handle processing and sterilization for stent manufacturing?

It supports laser cutting, electropolishing, and coating applications without degradation, enduring gamma irradiation or ethylene oxide sterilization, with its vacuum-melted structure maintaining surface integrity to avoid contamination in cleanroom production.