At our company, we pride ourselves on delivering cutting-edge 316LVM stainless steel tube for minimally invasive surgery, crafted to elevate precision and patient outcomes in today's fast-paced medical landscape. These tubes represent the pinnacle of material science, blending unmatched purity with robust performance to support surgeons in performing less traumatic procedures that get patients back on their feet quicker.

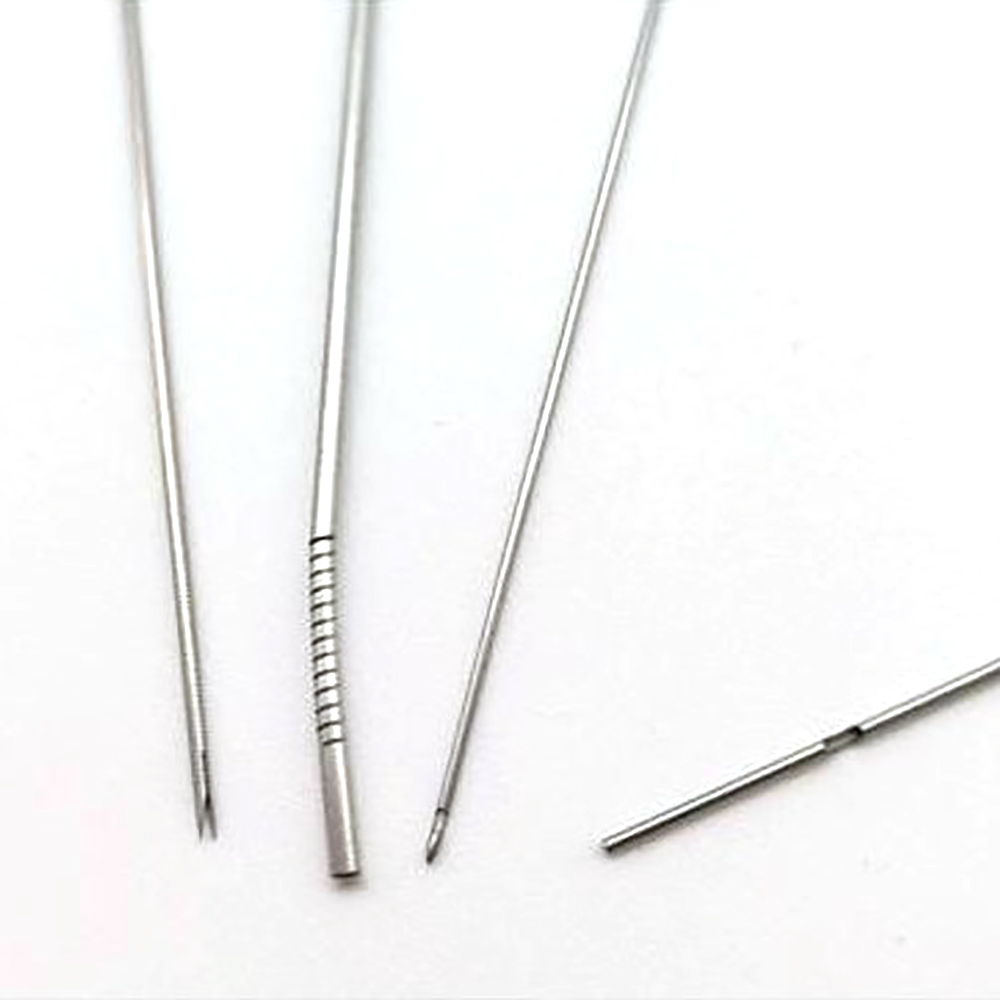

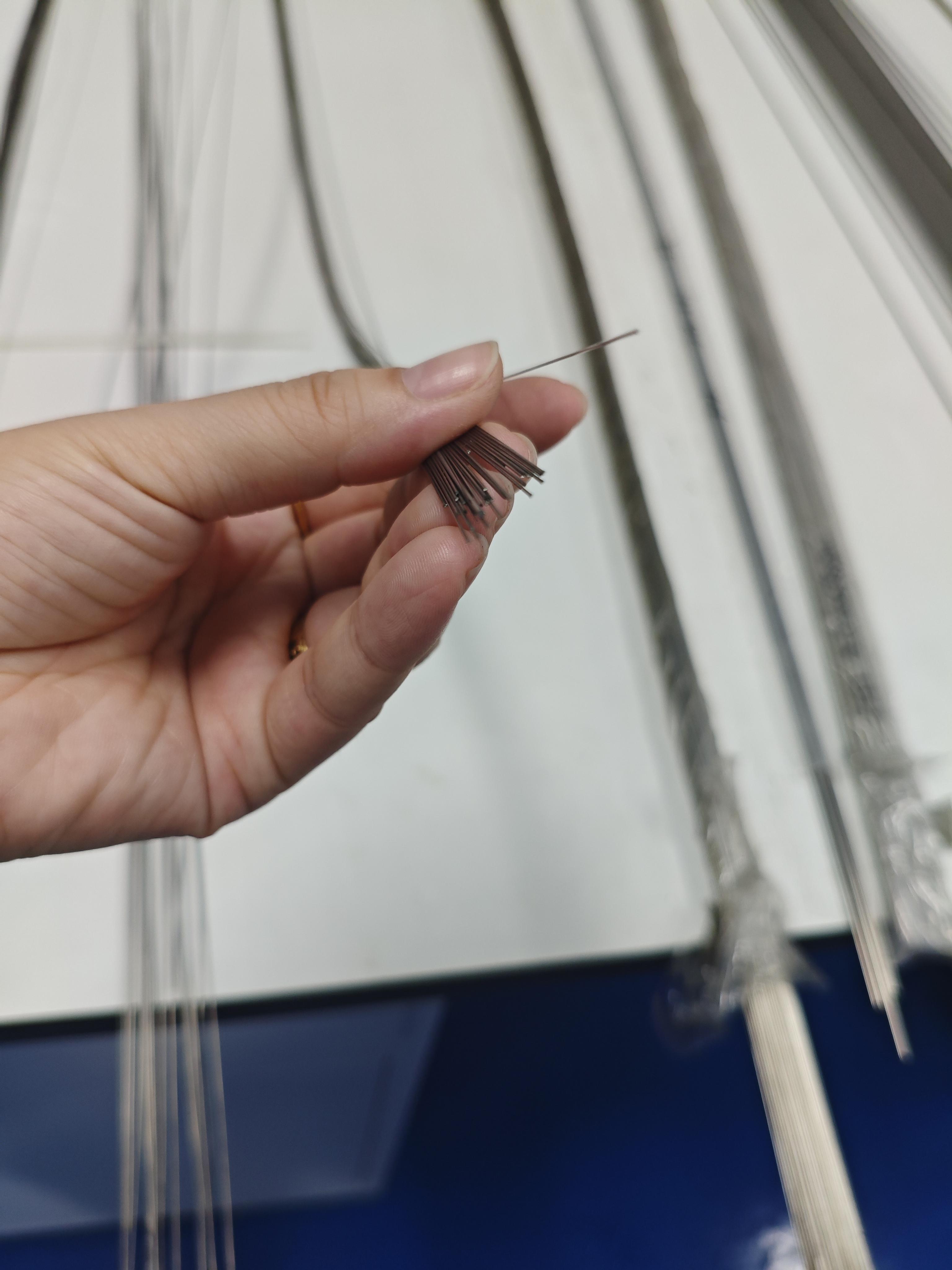

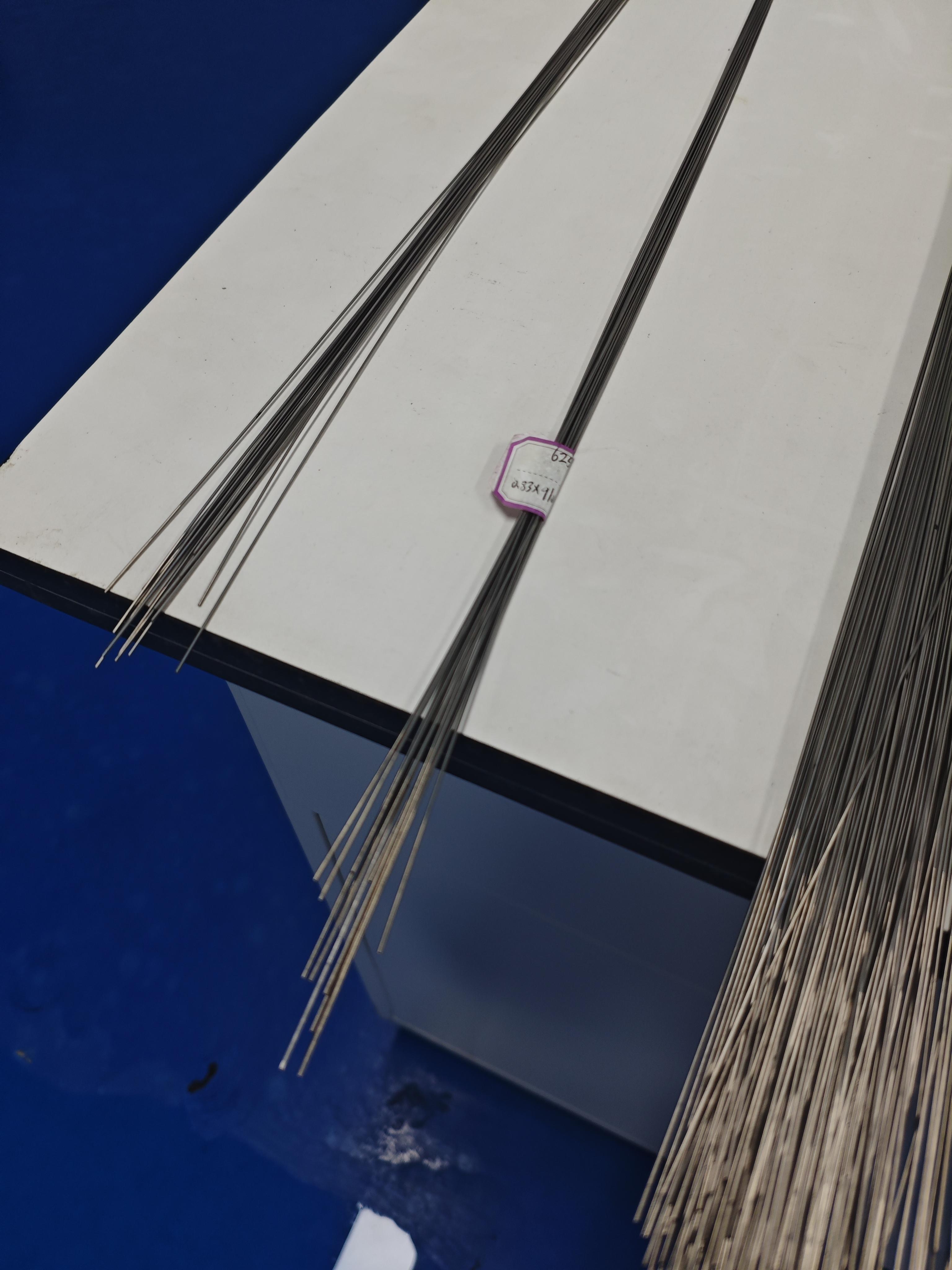

Diving right into our 316LVM stainless steel tube for minimally invasive surgery, it's engineered from a vacuum-remelted alloy that takes the classic 316L formula and amps it up for medical excellence. With a composition boasting 17-19% chromium for that shiny corrosion barrier, 13-15% nickel for toughness, and 2.5-3.5% molybdenum to fight off pitting in salty body environments, plus ultra-low carbon under 0.03% to avoid sensitization during welding—this stuff is built to last. The vacuum melting process eliminates impurities like gases and inclusions, resulting in a cleaner, more uniform microstructure that's perfect for delicate applications. Our tubes come in diameters as small as 0.5mm with wall thicknesses down to 0.05mm, ensuring they slip through tiny incisions without a hitch, all while meeting stringent standards like ASTM F138 for implant-grade safety.

For more details, pls directly contact us.

What sets our 316LVM stainless steel tube for minimally invasive surgery apart is the focus on customization. We offer seamless or welded options, with surface finishes polished to a mirror-like Ra <0.2µm to minimize friction and bacterial adhesion. This means smoother insertion for tools like cannulas or endoscopes, reducing tissue trauma and infection risks. Plus, its low magnetic permeability keeps it MRI-friendly, so no worries about interference during post-op imaging. We've tested these tubes rigorously for fatigue life, simulating thousands of cycles to mimic real surgical maneuvers, ensuring they hold up under the twists and turns of laparoscopic work.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

Turning to industry analysis, the minimally invasive surgery sector is exploding, thanks to tech advancements and a push for quicker recoveries. The global MIS market is set to skyrocket from USD 94.45 billion in 2025 to a whopping USD 199.30 billion by 2030, cruising at a 16.1% CAGR. This boom is fueled by an aging population dealing with more chronic issues like obesity and heart disease, where traditional open surgeries just don't cut it anymore. Robotic systems, like those in da Vinci setups, are becoming standard, demanding tubing that's flexible yet strong—exactly what our 316LVM delivers. Meanwhile, the medical stainless steel tubing market is on a solid upswing, valued at around USD 5,188 million in 2025 and eyeing even bigger numbers as demand for durable, biocompatible components surges.

Regulatory shifts are playing a big role too. With bodies like the FDA tightening rules on material traceability and biocompatibility, our 316LVM stainless steel tube for minimally invasive surgery shines by exceeding ISO 10993 testing for cytotoxicity and sensitization. Sustainability is another hot trend; we're seeing a move toward recyclable metals to cut down on medical waste, and stainless steel fits the bill perfectly. The rise of outpatient clinics and ambulatory surgery centers is pushing for cost-effective yet high-quality tools, where our tubes help reduce procedure times and hospital stays, ultimately lowering healthcare costs.

On the application front, our 316LVM stainless steel tube for minimally invasive surgery is a versatile powerhouse. In laparoscopy, it forms the backbone of trocars and graspers, allowing surgeons to access abdominal cavities through keyhole incisions for gallbladder removals or hernia repairs. For cardiovascular interventions, think guidewires and catheters threading through vessels to place stents without cracking open the chest—our tubes' high tensile strength (up to 1000 MPa) ensures they don't kink under pressure. In urology, they're essential for cystoscopes and ureteral stents, providing clear pathways with minimal discomfort.

Orthopedics benefits hugely too; arthroscopic procedures for knee or shoulder repairs rely on these tubes for cannulated drills and scopes, where the material's ductility lets them bend without breaking. Even in gynecology, like hysteroscopies, the purity of 316LVM minimizes allergic reactions, making it safe for sensitive tissues. Emerging uses include robotic-assisted MIS, where our tubes integrate with haptic feedback systems for enhanced precision in delicate neurosurgeries. With the medical metal tubing market projected to hit USD 1,547.53 million by 2034 at a 6.7% CAGR, the emphasis on thin, high-performance tubing for hybrid devices is clear. Our products also excel in biopsy tools, where sharp, hollow tubes extract samples with pinpoint accuracy, reducing the need for repeat procedures.

When stacking up against typical market offerings, our company's approach to 316LVM stainless steel tube for minimally invasive surgery really stands out. While standard tubes might skimp on purity, leading to potential inclusions that cause failures, we invest in double vacuum melting for unparalleled cleanliness, boosting biocompatibility and longevity. This means fewer revisions for patients and more confidence for surgeons. Our in-house R&D team uses advanced simulations like computational fluid dynamics to optimize tube designs for better flow in irrigation systems, something not every supplier bothers with.

We also prioritize scalability and speed—our production lines can turn around custom orders in weeks, not months, thanks to automated drawing and annealing processes. This agility helps hospitals stock up without delays, especially amid supply chain crunches. Cost-wise, we keep things competitive by optimizing material use, passing savings on without cutting corners on quality. Feedback from users highlights how our tubes' superior weldability simplifies assembly into complex devices, reducing manufacturing defects.

Comparison Parameters Table

| Parameter | 316LVM Stainless Steel | 316L Stainless Steel | 304L Stainless Steel | Titanium Alloy (e.g., Ti-6Al-4V) |

|---|---|---|---|---|

| Carbon Content (%) | ≤0.03 | ≤0.03 | ≤0.03 | N/A (No carbon) |

| Corrosion Resistance | Superior (vacuum-melted purity, excellent in chlorides and acids) | Excellent (Mo addition, but less pure) | Moderate (no Mo, susceptible to pitting) | Outstanding (passive oxide film) |

| Tensile Strength (MPa) | 860-1000 | 485-620 | 485-620 | 860-950 |

| Yield Strength (MPa) | 690-860 | 170-310 | 170-310 | 760-830 |

| Biocompatibility | Exceptional (high purity, low inclusions for implants) | High (standard for medical use) | Good (but higher allergy risk) | Excellent (bone integration, lightweight) |

| Density (g/cm³) | 8.0 | 8.0 | 8.0 | 4.5 |

| Magnetic Properties | Very low permeability | Non-magnetic | Non-magnetic | Non-magnetic |

| Cost Effectiveness | Premium for purity, but value in long-term devices | Affordable | Lowest cost | High, for specialized lightweight needs |

| Common Medical Use | MIS tubes, implants, surgical wires | General tubing, instruments | Basic tools | Orthopedic implants, where weight matters |

Sustainability is baked into our ethos; we recycle over 90% of scrap metal, aligning with green initiatives in healthcare. Unlike generic options that might degrade after a few sterilizations, our 316LVM holds its edge through hundreds of cycles, thanks to enhanced corrosion resistance from the molybdenum boost. This durability translates to lower lifecycle costs and less environmental impact.

Looking forward, we're gearing up for the next wave in MIS, like AI-integrated tools where our tubes could house sensors for real-time data during operations. With trends pointing to personalized medicine, our customizable 316LVM stainless steel tube for minimally invasive surgery positions us to lead in tailoring solutions for individual patient anatomies.

In short, opting for our 316LVM stainless steel tube for minimally invasive surgery means choosing reliability, innovation, and a partner dedicated to advancing surgical care. We craft these tubes not just as products, but as enablers of better health, helping turn complex procedures into routine successes. As the industry evolves with faster tech and higher expectations, we're right there, refining our offerings to stay ahead.

To sum it up, our advantages shine through in every aspect: from material excellence that ensures safety and performance, to responsive service that supports your needs. Whether it's for routine endoscopies or groundbreaking robotic surgeries, our 316LVM stainless steel tube for minimally invasive surgery is the smart choice for forward-thinking medical professionals.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What makes 316LVM stainless steel superior for minimally invasive surgery applications?

316LVM is vacuum-melted for higher purity, offering exceptional biocompatibility, corrosion resistance in bodily fluids, and low magnetic permeability, ideal for MRI-compatible surgical tools like guidewires and catheters.How does the material composition of 316LVM enhance its performance in medical devices?

With carbon content under 0.03%, chromium (17-19%), nickel (13-15%), and molybdenum (2.5-3.5%), plus vacuum remelting to minimize inclusions, it provides superior pitting resistance and cleanliness for sterile environments.What are the primary applications of 316LVM stainless steel tubes in minimally invasive procedures?

These tubes are used in endoscopic instruments, biopsy needles, stents, trocars, and laparoscopic tools, enabling precise delivery through small incisions while maintaining structural integrity under torque and flexion.How are industry trends influencing the adoption of 316LVM tubes in minimally invasive surgery?

The MIS market is projected to grow from USD 94.45 billion in 2025 to USD 199.30 billion by 2030 at a 16.1% CAGR, driven by robotic surgery advancements and rising chronic disease cases, favoring high-purity materials like 316LVM.What mechanical properties make 316LVM ideal for surgical tubing?

It features tensile strength of 860-1000 MPa, yield strength around 690 MPa, excellent ductility (elongation >40%), and high fatigue resistance, allowing thin-walled tubes to withstand repeated bending in procedures like arthroscopy.Is 316LVM stainless steel fully biocompatible for minimally invasive implants?

Yes, compliant with ASTM F138 and ISO 5832-1, it's hypoallergenic, non-toxic, and promotes minimal tissue reaction, making it suitable for long-term contact in vascular or orthopedic minimally invasive devices.What emerging trends in the medical tubing market support 316LVM usage?

The medical metal tubing market is expected to reach USD 1,547.53 million by 2034 from USD 812.59 million in 2025, with a 6.7% CAGR, emphasizing customizable, biocompatible tubing for outpatient procedures and telemedicine-integrated surgeries.How does 316LVM handle sterilization and durability in minimally invasive tools?

It endures gamma radiation, ethylene oxide, and autoclaving without degradation, with its vacuum-melted structure ensuring no oxide inclusions that could compromise surface finish or lead to contamination during reuse.