At our company, we’re all about crafting high-quality 17-4PH stainless steel tube for guidewire production that helps doctors navigate the trickiest blood vessels with precision and confidence. These tubes aren’t just metal—they’re the backbone of guidewires that make minimally invasive procedures like angioplasty and stenting possible, saving lives one vessel at a time. We focus on strength, flexibility, and reliability to deliver guidewires that perform flawlessly in high-stakes vascular interventions.

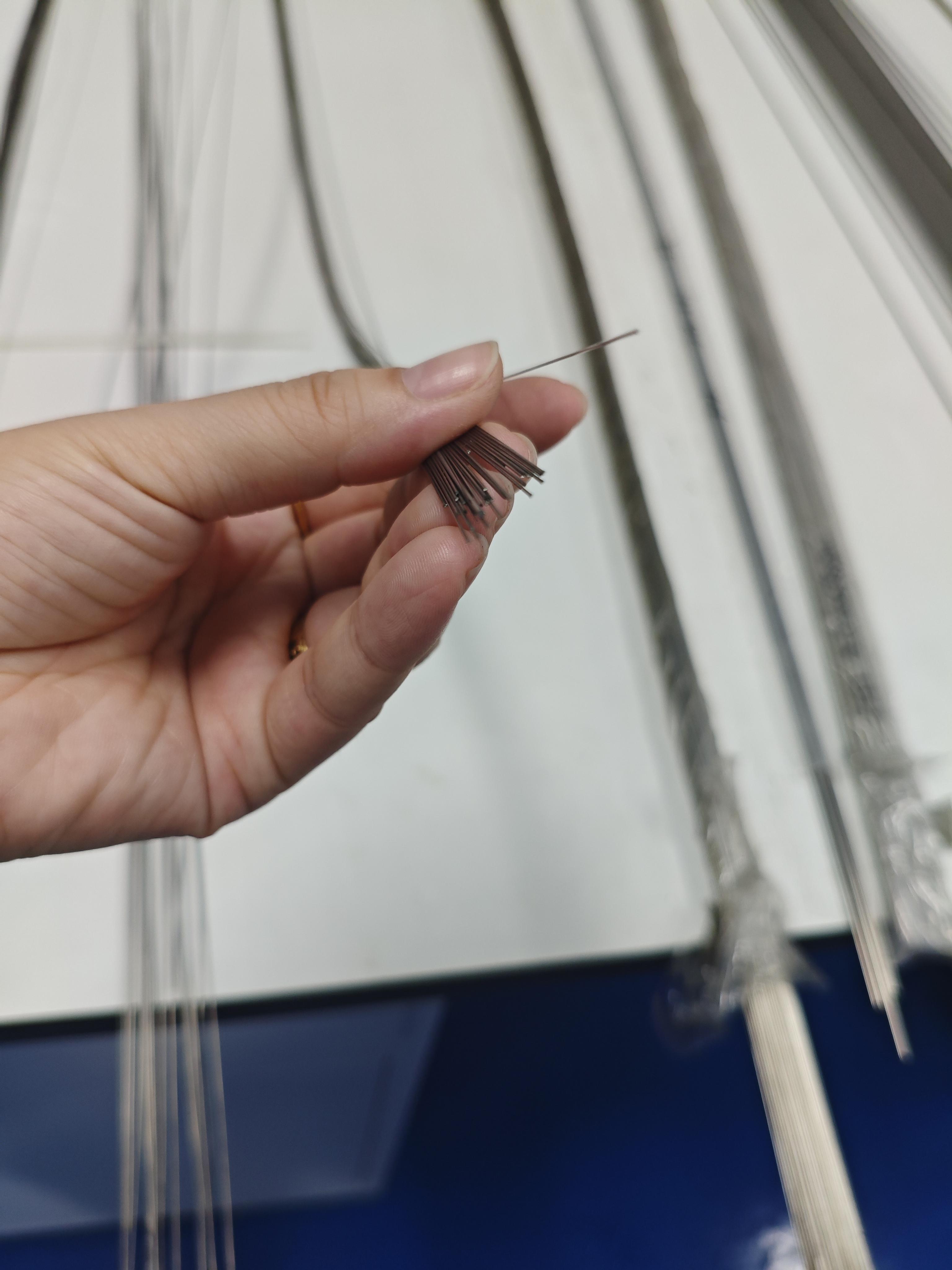

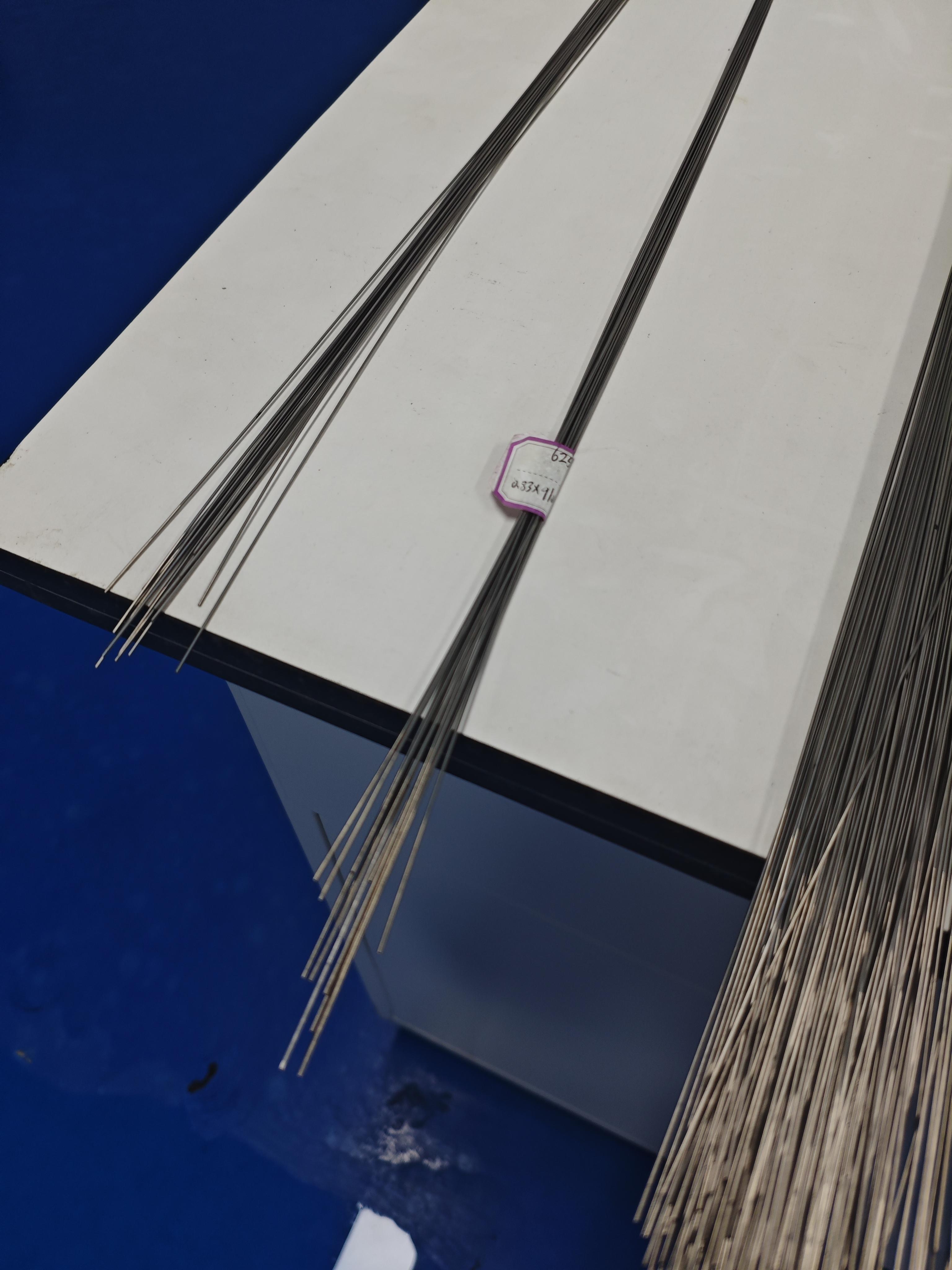

Let’s get into what makes our 17-4PH stainless steel tube for guidewire production a cut above. This precipitation-hardening alloy is a powerhouse, with 15-17.5% chromium for solid corrosion resistance, 3-5% nickel for toughness, 3-5% copper, and 0.15-0.45% niobium for boosted strength. With carbon below 0.07%, it meets ASTM A564 standards, perfect for medical-grade applications. We produce these tubes in diameters from 0.2mm to 3mm, with walls as thin as 0.05mm, ideal for guidewires that need to snake through tiny vessels. Our heat-treatment process dials in tensile strengths up to 1380 MPa, ensuring guidewires can flex and twist without breaking.

For more details, pls directly contact us.

Precision is our thing. We cold-draw tubes to tolerances of ±0.005mm, ensuring they fit perfectly into guidewire assemblies. Electropolishing creates a Ra <0.2µm finish, reducing friction and enhancing biocompatibility for smooth vessel navigation. We test for fatigue resistance, simulating thousands of bends to mimic real-world catheter insertions, ensuring durability. While slightly magnetic, our tubes are optimized for minimal interference in imaging, keeping procedures safe. We also offer custom coatings, like hydrophilic layers, to improve lubricity, making guidewires glide through vessels with ease.

The guidewires market is booming, valued at USD 2.5 billion in 2025 and projected to hit USD 4.1 billion by 2032 at a 5.6% CAGR. Cardiovascular diseases are driving this growth—over 900 million people globally face heart issues, fueled by diabetes, obesity, and aging populations. Minimally invasive procedures, like percutaneous coronary interventions (PCI), are now standard, with over 3 million guidewires used annually. Our high-quality 17-4PH stainless steel tube for guidewire production is built for this, offering the strength for torque control and the flexibility to navigate tortuous vessels.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

Regulatory standards are tightening, with the FDA and EU MDR demanding rigorous biocompatibility and traceability. Our 17-4PH tubes meet ISO 10993 standards for short-term contact, with low ion release to minimize tissue reactions in vascular use. Sustainability is a big deal—hospitals want recyclable materials, and stainless steel’s near-100% recyclability makes it a green choice. The medical tubing market is set to grow from USD 812.59 million in 2025 to USD 1,547.53 million by 2034 at a 6.7% CAGR, with high-strength alloys like 17-4PH leading for their durability in guidewire applications.

Emerging trends are shaping the future. Hydrophilic and lubricious coatings are gaining traction to reduce friction, improving guidewire performance in complex vessels. Robotic-assisted surgeries, expected to hit USD 14.4 billion by 2026, demand ultra-precise tubing for articulated systems, where 17-4PH excels. The rise of neurovascular procedures, like aneurysm coiling, is pushing demand for micro-tubes, and our 17-4PH delivers the finesse needed. Smart guidewires with sensors for real-time navigation are emerging, and our tubes can serve as robust cores for these innovations. The coronary guidewires market, valued at USD 1.2 billion in 2025, is growing at a 5.8% CAGR, highlighting the need for reliable tubing.

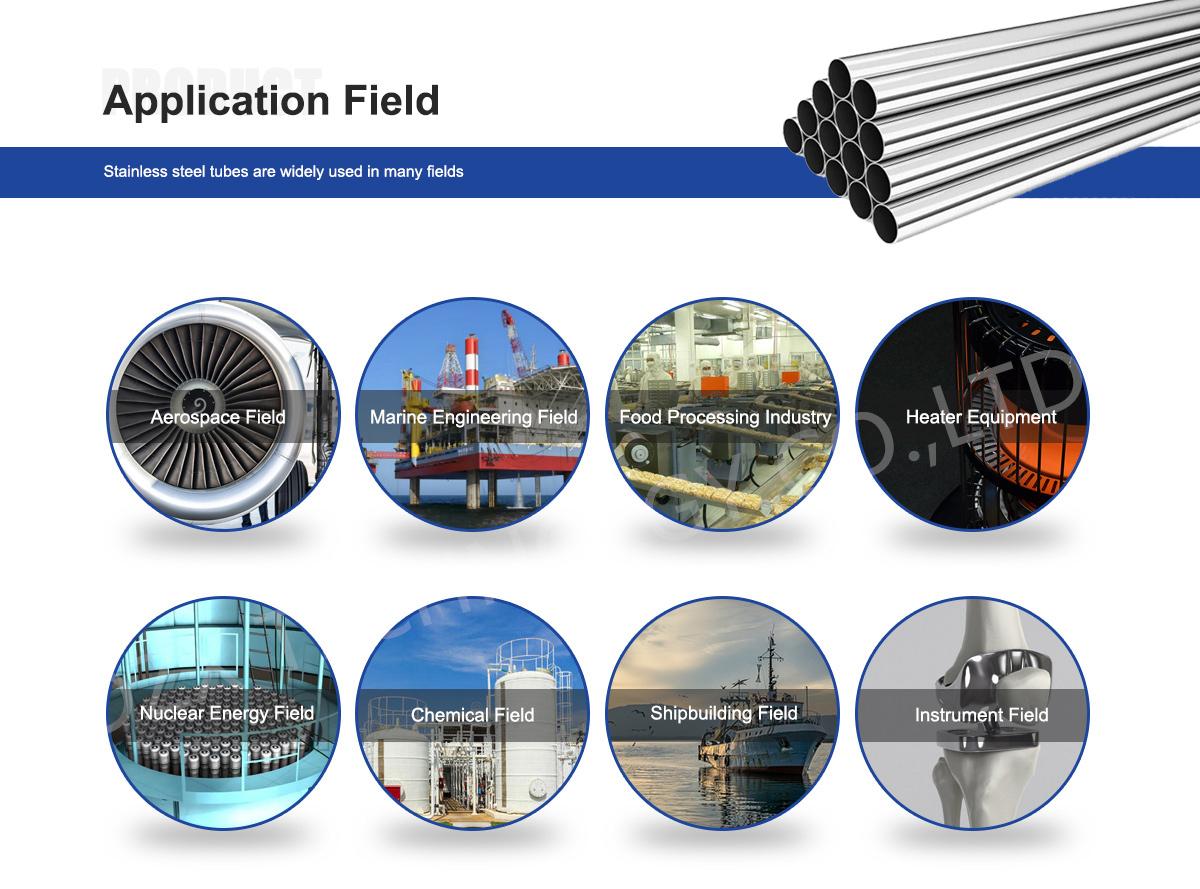

Applications for our high-quality 17-4PH stainless steel tube for guidewire production are diverse. In coronary interventions, they form the core of guidewires used in angioplasty, guiding stents to blocked arteries to restore blood flow. For peripheral vascular procedures, like those in legs or arms, our tubes provide the strength to handle high-torque navigation. In neurovascular applications, they support guidewires for stroke treatments, navigating delicate brain vessels with precision. They’re also used in urological and gastrointestinal procedures, guiding catheters for biopsies or stone removal.

Our tubes excel in hybrid guidewires, combining metal cores with polymer tips for enhanced flexibility. In acute cases, like myocardial infarctions, 17-4PH’s strength ensures reliable performance under time pressure. For diagnostic angiographies, our tubes enable smooth catheter delivery, reducing vessel trauma. The interventional cardiology devices market, valued at USD 12.8 billion in 2025, is growing at a 6.3% CAGR, underscoring the critical role of high-performance guidewires.

When it comes to standing out, our company’s approach to high-quality 17-4PH stainless steel tube for guidewire production is unmatched. While standard suppliers might offer generic tubing, we customize with tailored heat treatments to optimize flexibility for specific vascular paths, like tortuous coronary arteries. Our in-house testing is rigorous—corrosion trials in simulated blood environments and mechanical stress tests mimic real-world navigation, ensuring zero failures. This reliability means fewer procedural complications, saving time and improving patient outcomes.

We’re lean on production, using automated cold-drawing to achieve tolerances of ±0.005mm, perfect for micro-guidewires. Cost-wise, we keep it competitive by streamlining material use, delivering high-strength 17-4PH at prices that work for manufacturers. Interventionalists praise our tubes’ consistency, which translates to predictable torque response in high-stakes procedures. Unlike others who might skip advanced surface treatments, we electropolish and coat every tube to reduce friction, enhancing navigability and biocompatibility.

Sustainability is core to our ethos—we recycle 95% of scrap metal, aligning with healthcare’s green push. Our supply chain is rock-solid, with just-in-time delivery to keep production lines running, even during global disruptions. We also offer design collaboration, working with manufacturers to tweak tube specs for next-gen guidewires, a service most suppliers can’t match. Clients highlight our fast prototyping—often under two weeks—as a game-changer for innovative designs.

Comparison Parameters Table

| Parameter | 17-4PH Stainless Steel | 316L Stainless Steel | 304 Stainless Steel | Nitinol (Ni-Ti Alloy) |

|---|---|---|---|---|

| Carbon Content (%) | ≤0.07 | ≤0.03 | ≤0.08 | N/A (No carbon) |

| Corrosion Resistance | Excellent (Cr, Cu, resists acids) | Excellent (Mo, resists body fluids) | Good (Cr, less in chlorides) | Outstanding (oxide layer, shape memory) |

| Tensile Strength (MPa) | 1030-1380 | 485-620 | 515-690 | 800-1500 |

| Yield Strength (MPa) | 760-1170 | 170-310 | 205-310 | 200-800 |

| Biocompatibility | Good (short-term contact) | High (implant-grade) | Good (short-term use) | Excellent (vascular implants) |

| Density (g/cm³) | 7.8 | 8.0 | 8.0 | 6.45 |

| Magnetic Properties | Slightly magnetic | Non-magnetic | Non-magnetic | Non-magnetic |

| Cost Effectiveness | Moderate, high strength | Affordable | Most affordable | High, for shape memory |

| Common Medical Use | Guidewires, surgical tools | Stents, implants | Surgical instruments | Guidewires, stents |

Looking ahead, we’re diving into smart guidewires, exploring 17-4PH tubes as conduits for sensors that monitor vessel conditions in real time, tapping into IoT trends. With personalized medicine growing—custom guidewires are expected to hit USD 500 million by 2030—our flexible production is ready to deliver patient-specific solutions. The rise of robotic-assisted PCI and AI-driven navigation means our tubes must support precision systems, and we’re optimizing for that now.

In essence, choosing our high-quality 17-4PH stainless steel tube for guidewire production means partnering with a team obsessed with quality and innovation. We’re not just making tubes; we’re enabling life-saving procedures. From high-strength materials to tailored designs, we’re built to lead in a market craving reliability and precision. As guidewire tech evolves with demographics and innovation, our 17-4PH tubes remain a trusted cornerstone, ready for tomorrow’s challenges.

To sum it up, our strengths shine: top-tier strength, customizable precision, and a green approach that sets us apart. Whether it’s a routine angioplasty or a complex neurovascular procedure, our high-quality 17-4PH stainless steel tube for guidewire production delivers the performance doctors need to save lives.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is 17-4PH stainless steel ideal for guidewire production?

High-quality 17-4PH stainless steel offers exceptional strength, corrosion resistance, and flexibility, making it perfect for guidewires used in minimally invasive vascular and interventional procedures.What is the material composition of 17-4PH stainless steel for guidewires?

It contains 15-17.5% chromium, 3-5% nickel, 3-5% copper, 0.15-0.45% niobium, and carbon below 0.07%, providing high strength and corrosion resistance, compliant with ASTM A564 for medical applications.What are the primary applications of 17-4PH stainless steel tubes in guidewires?

These tubes are used in coronary, neurovascular, and peripheral guidewires, enabling precise navigation through vessels for procedures like angioplasty, stenting, and catheter delivery.How do industry trends influence the use of 17-4PH in guidewire production?

The guidewires market, valued at USD 2.5 billion in 2025, is projected to grow at a 5.6% CAGR to USD 4.1 billion by 2032, driven by rising demand for minimally invasive surgeries and cardiovascular interventions.What mechanical properties make 17-4PH suitable for guidewire tubing?

It offers tensile strength of 1030-1380 MPa, yield strength of 760-1170 MPa, elongation up to 18%, and excellent fatigue resistance, ensuring guidewires withstand bending and torque in complex vascular paths.Is 17-4PH stainless steel biocompatible for guidewire applications?

Yes, it meets ISO 10993 standards for short-term contact, with low ion release and minimal tissue reactivity, suitable for temporary vascular devices like guidewires.What emerging trends support 17-4PH in guidewire manufacturing?

Trends include hydrophilic coatings for better navigation, growth in robotic-assisted procedures, and a medical tubing market expected to reach USD 1,547.53 million by 2034 at a 6.7% CAGR, favoring high-strength alloys.How does 17-4PH handle sterilization for guidewire production?

It withstands autoclaving, gamma irradiation, and chemical sterilization without corrosion, maintaining surface integrity and flexibility for sterile, single-use guidewire applications.