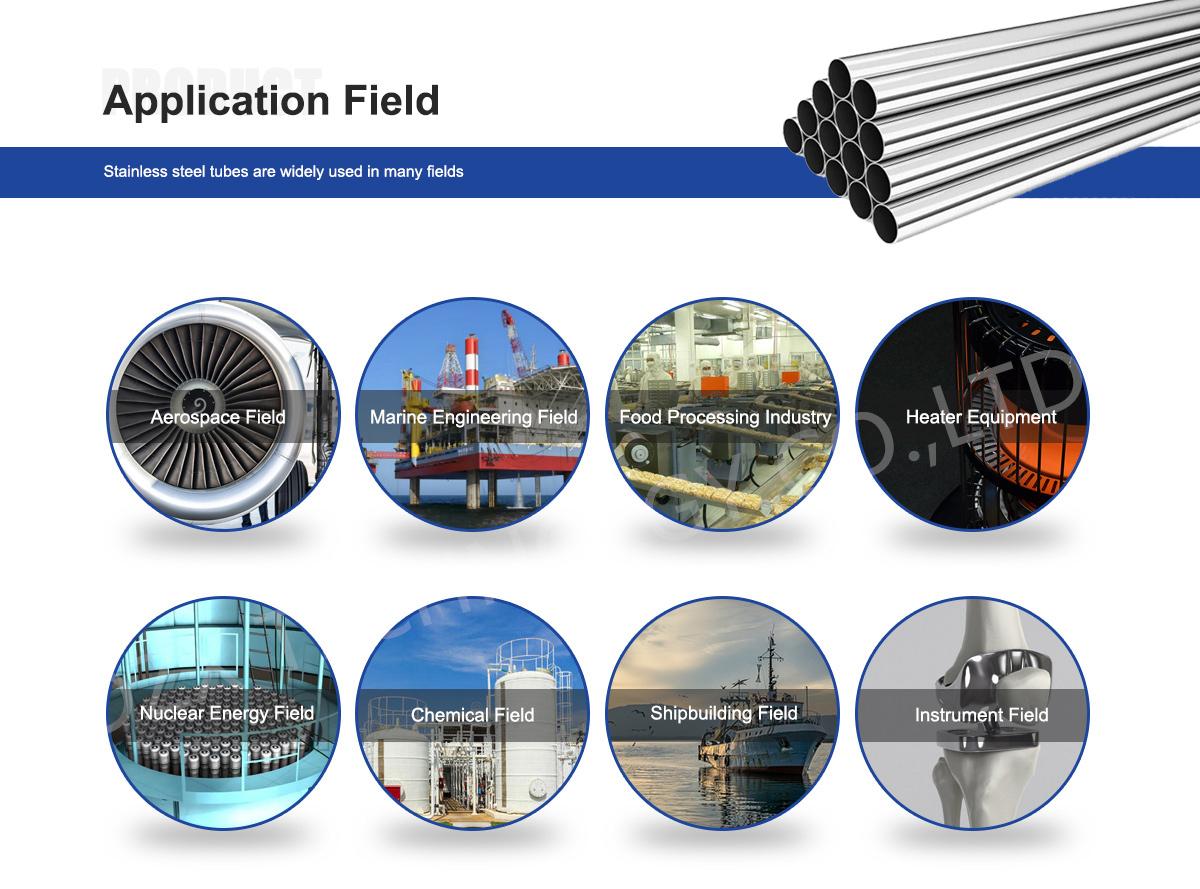

At our company, we’re all about crafting passivated 420 stainless steel tube for surgical tool fabrication that empowers surgeons to perform with precision and confidence. These tubes aren’t just metal—they’re the backbone of tools like scalpels, forceps, and endoscopes that make life-saving procedures possible. With a focus on hardness, durability, and affordability, we’re delivering solutions that keep operating rooms running smoothly and patients healing faster.

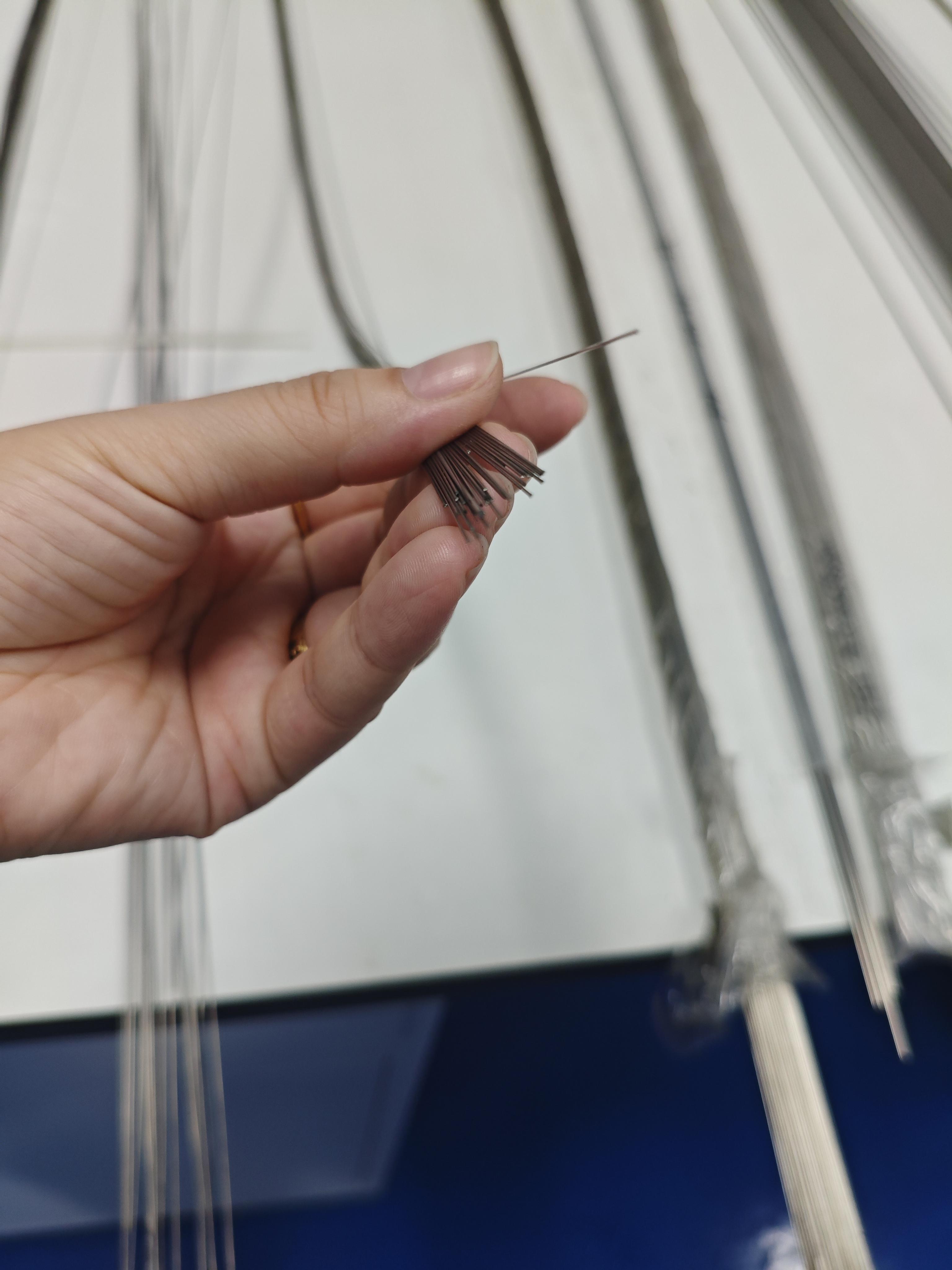

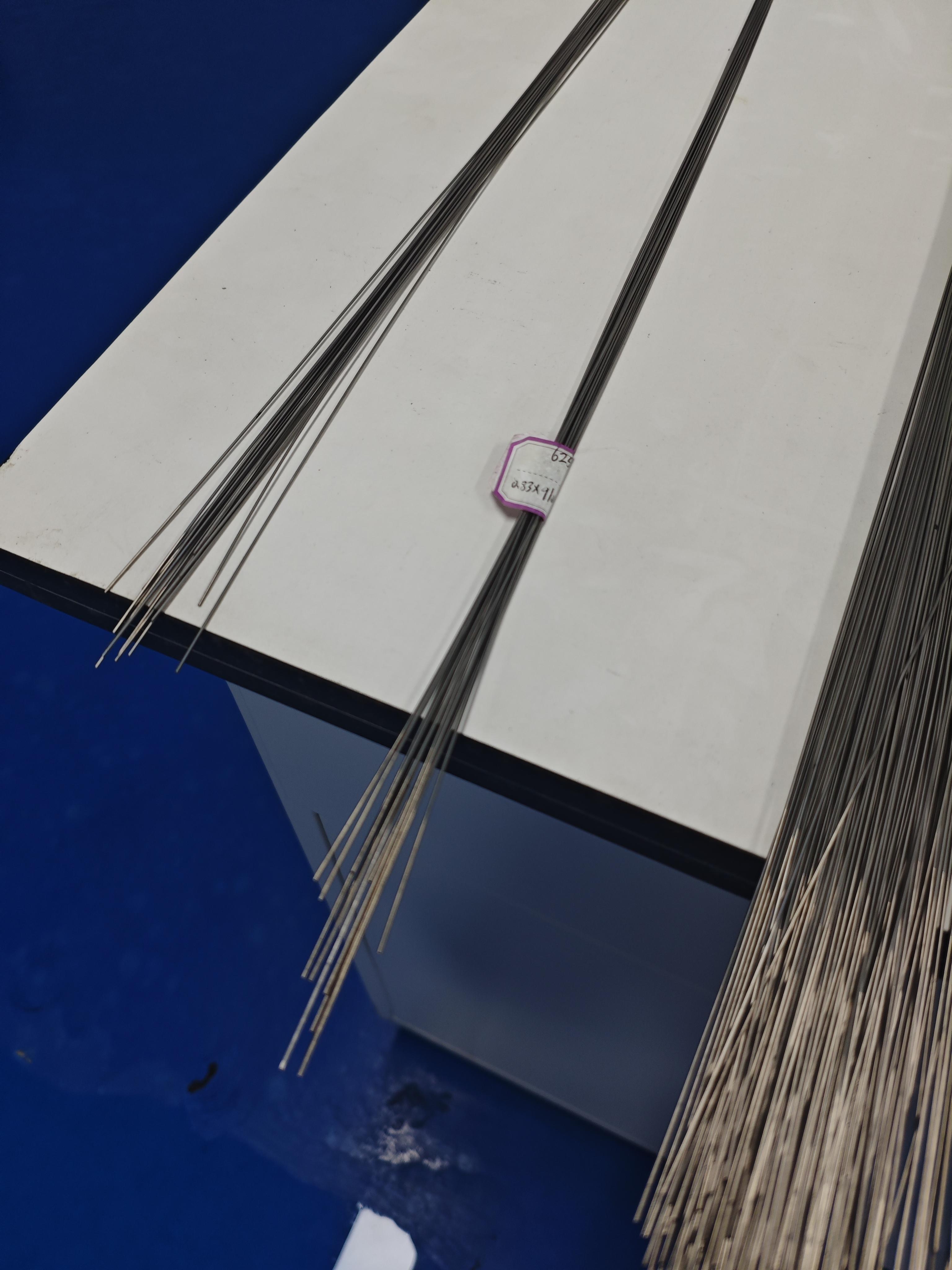

Let’s dive into what makes our 420 stainless steel tube for surgical tool fabrication a standout. This martensitic alloy is a tough contender, packing 12-14% chromium for solid corrosion resistance and 0.15-0.40% carbon for high hardness after heat treatment. Compliant with ASTM A276, it’s perfect for medical-grade applications. We produce these tubes in diameters from 1mm to 10mm, with wall thicknesses as low as 0.1mm, ideal for slender endoscopic shafts or robust scalpel handles. Our passivation process enhances corrosion resistance, creating a protective oxide layer that stands up to harsh sterilization cycles, while heat treatment achieves hardness up to 50 HRC for razor-sharp edges.

For more details, pls directly contact us.

We’re obsessive about precision. Our tubes are cold-drawn to tolerances of ±0.01mm, ensuring they fit perfectly into complex surgical tools like biopsy forceps. The passivated Ra <0.4µm finish resists corrosion from blood and saline, making cleaning and sterilization a breeze. We test for wear resistance, simulating thousands of cutting cycles to confirm tools stay sharp and durable. Magnetic properties are no issue for most surgical applications, but we optimize surface treatments to minimize interference in imaging-heavy procedures. We also offer custom laser-cutting and sharpening, tailoring tubes to specific tool designs for optimal performance.

Comparison of Medical Stainless Steel Grades, Materials, and Applications

Grade | Composition | Key Properties | Corrosion Resistance | Biocompatibility | Applications | Advantages | Limitations |

|---|---|---|---|---|---|---|---|

316L | Fe (60-70%), Cr (16-18%), Ni (10-14%), Mo (2-3%), C (<0.03%) | Tensile: 485-620 MPa, Yield: 170-290 MPa, Elongation: 40-50%, Hardness: 95 HRB | Excellent (passive oxide layer, resists pitting) | High, minimal ion release, rare Ni sensitivity | Bone plates, screws, stents, hip stems, dental implants | Cost-effective, machinable, fatigue-resistant | Possible Ni sensitivity, heavier than Ti |

304L | Fe (65-74%), Cr (18-20%), Ni (8-10.5%), C (<0.03%) | Tensile: 485-550 MPa, Yield: 170-240 MPa, Elongation: 40-55%, Hardness: 92 HRB | Good, less resistant to pitting than 316L | Moderate, higher Ni release risk | Temporary implants, surgical tools, guidewires | Affordable, easy to form, widely available | Limited for long-term implants due to corrosion |

17-4 PH | Fe (70-78%), Cr (15-17.5%), Ni (3-5%), Cu (3-5%), C (<0.07%) | Tensile: 930-1100 MPa, Yield: 725-860 MPa, Hardness: 30-44 HRC | Very good, but less than 316L in saline | Good, but less biocompatible than 316L | Load-bearing implants, surgical instruments | High strength, heat-treatable, durable | Complex processing, less corrosion-resistant |

420 | Fe (80-90%), Cr (12-14%), C (0.15-0.4%) | Tensile: 700-950 MPa, Yield: 340-450 MPa, Hardness: 45-50 HRC | Moderate, prone to pitting in body fluids | Moderate, not ideal for long-term implants | Cutting tools, temporary pins, dental drills | High hardness, wear-resistant, sharpenable | Poor corrosion resistance for permanent use |

440C | Fe (78-85%), Cr (16-18%), C (0.95-1.2%) | Tensile: 760-1000 MPa, Yield: 450-600 MPa, Hardness: 56-60 HRC | Moderate, better than 420 but less than 316L | Limited, high carbon affects biocompatibility | Surgical blades, high-wear tools | Extremely hard, excellent edge retention | Not suitable for long-term implants |

F138 (316LVM) | Fe (60-70%), Cr (17-19%), Ni (13-15%), Mo (2.25-3.5%), C (<0.03%) | Tensile: 490-690 MPa, Yield: 190-300 MPa, Elongation: 40-50%, Hardness: 95 HRB | Superior, optimized for medical use | Excellent, lowest ion release, vacuum-melted | Orthopedic implants, cardiovascular stents | Enhanced purity, top biocompatibility | Higher cost than standard 316L |

303 | Fe (65-75%), Cr (17-19%), Ni (8-10%), S (0.15-0.35%) | Tensile: 500-620 MPa, Yield: 240-290 MPa, Elongation: 35-50%, Hardness: 90 HRB | Moderate, sulfur reduces corrosion resistance | Moderate, not ideal for permanent implants | Machined components, non-implant devices | Excellent machinability, cost-effective | Not suitable for long-term implants |

Nitronic 60 | Fe (60-70%), Cr (16-18%), Ni (8-9%), Mn (7-9%), N (0.08-0.18%) | Tensile: 620-793 MPa, Yield: 345-414 MPa, Hardness: 95-100 HRB | Very good, resists galling and wear | Good, but less studied for implants | Wear-resistant implants, joint components | High wear resistance, galling resistance | Limited medical use, higher cost |

For more details, pls directly contact us

The surgical instruments market is thriving, valued at USD 14.9 billion in 2025 and projected to hit USD 22.7 billion by 2032 at a 6.1% CAGR. Rising global surgeries—over 300 million procedures annually—are driven by aging populations, chronic diseases, and trauma cases. Minimally invasive surgeries, like laparoscopy, now account for 40% of procedures, demanding tools with high strength and precision. Our passivated 420 stainless steel tube for surgical tool fabrication is built for this, offering the hardness for cutting and the flexibility for intricate endoscopic designs, all at a cost that keeps budgets in check.

Regulatory standards are tightening, with the FDA and EU MDR demanding strict material safety and traceability. Our 420 tubes meet ISO 10993 standards for short-term contact, ensuring low tissue reactivity for tools like retractors that touch skin and tissue. Sustainability is a growing focus—hospitals want recyclable materials, and 420 stainless steel’s near-100% recyclability makes it a green choice. The medical tubing market is set to grow from USD 812.59 million in 2025 to USD 1,547.53 million by 2034 at a 6.7% CAGR, with cost-effective, hardenable alloys like 420 leading for surgical tool applications.

Emerging trends are shaping the future. Minimally invasive surgery is booming, with robotic-assisted procedures expected to hit USD 14.4 billion by 2026, demanding durable tubing for articulated tools. Reusable tools are gaining traction in hospitals for cost savings, and 420’s ability to withstand repeated sterilization cycles makes it ideal. Antimicrobial coatings are trending to reduce infection risks, and our tubes can integrate these for added safety. The rise of outpatient surgical centers—growing at 6.5% CAGR—calls for affordable, high-performance components, where our 420 tubes shine. Developing regions like Asia-Pacific are seeing increased surgical demand, boosting the need for cost-effective materials.

Applications for our passivated 420 stainless steel tube for surgical tool fabrication are vast. In general surgery, they’re used in scalpel handles and scissors, providing the hardness for clean, precise cuts. For minimally invasive procedures, our tubes form endoscopic shafts and graspers, enabling access through tiny incisions. In orthopedics, they’re key in bone drills and reamers, handling high-torque stresses without dulling. They’re also used in biopsy forceps for tissue sampling, where sharpness and corrosion resistance ensure clean results.

Dental and ENT surgeries benefit too—our tubes support rigid endoscopes and curettes, balancing strength with lightweight design. In neurosurgery, they’re used in delicate tools like micro-scissors, where precision is critical. For reusable tools, 420’s durability withstands thousands of sterilization cycles, making it a hospital favorite. The minimally invasive surgical instruments market, valued at USD 28.6 billion in 2025, is growing at 9.8% CAGR, highlighting the need for reliable, cost-effective tubing.

When it comes to standing out, our company’s approach to passivated 420 stainless steel tube for surgical tool fabrication is unmatched. While standard suppliers might offer generic tubing, we customize with tailored heat treatments to optimize hardness for specific tools, like high-precision scalpels. Our in-house testing is rigorous—corrosion trials in simulated surgical environments and wear tests mimic years of use, ensuring zero failures. This durability means longer-lasting tools, reducing replacement costs for hospitals.

We’re lean on production, using automated cold-drawing to achieve tolerances of ±0.01mm, perfect for intricate tool designs. Cost-wise, we keep it budget-friendly by optimizing material use, delivering medical-grade quality at prices that support mass production. Surgeons love our tubes’ consistency, ensuring predictable performance in high-stakes procedures like laparoscopic cholecystectomies. Unlike others who might skip passivation, we treat every tube to enhance corrosion resistance, extending tool life by up to 30% in harsh sterilization conditions.

Sustainability is core to our ethos—we recycle 95% of scrap metal, aligning with healthcare’s green push. Our supply chain is rock-solid, with just-in-time delivery to keep operating rooms stocked, even during peak surgical seasons. We also offer design support, collaborating with manufacturers to tweak tube specs for innovative tools, a service most suppliers can’t match. Clients praise our fast prototyping—often under two weeks—speeding up the launch of next-gen surgical instruments.

Comparison Parameters Table

| Parameter | 420 Stainless Steel (Passivated) | 304 Stainless Steel | 316L Stainless Steel | 17-4PH Stainless Steel |

|---|---|---|---|---|

| Carbon Content (%) | 0.15-0.40 | ≤0.08 | ≤0.03 | ≤0.07 |

| Corrosion Resistance | Good (Cr, enhanced by passivation) | Good (Cr, suitable for short-term use) | Excellent (Mo, resists body fluids) | Excellent (Cr, Cu, resists acids) |

| Tensile Strength (MPa) | 700-950 | 515-690 | 485-620 | 1030-1380 |

| Yield Strength (MPa) | 400-700 | 205-310 | 170-310 | 760-1170 |

| Biocompatibility | Good (short-term contact, passivated) | Good (short-term use) | High (implant-grade) | Good (short-term contact) |

| Density (g/cm³) | 7.7 | 8.0 | 8.0 | 7.8 |

| Magnetic Properties | Magnetic | Non-magnetic | Non-magnetic | Slightly magnetic |

| Cost Effectiveness | Highly affordable | Most affordable | Moderate | Moderate, high strength |

| Common Medical Use | Surgical tools, scalpels | Needles, surgical instruments | Implants, catheters | Guidewires, surgical tools |

Looking ahead, we’re diving into smart surgical tools, exploring 420 tubes as supports for sensors that monitor cutting pressure or tool wear, tapping into IoT trends. With minimally invasive and robotic-assisted surgeries growing, our flexible production is ready to deliver custom solutions. The rise of AI-driven surgical planning means our tubes must support precision systems, and we’re optimizing for that now. As global surgical demand increases, our 420 tubes are poised to meet the needs of emerging markets with cost-effective, reliable solutions.

In essence, choosing our passivated 420 stainless steel tube for surgical tool fabrication means partnering with a team obsessed with quality and affordability. We’re not just making tubes; we’re enabling precise, life-saving surgeries. From hardenable materials to tailored designs, we’re built to lead in a market craving durability and value. As surgical tech evolves with demographics and innovation, our 420 tubes remain a trusted cornerstone, ready for tomorrow’s operating rooms.

To sum it up, our strengths shine: cost-effective hardness, customizable precision, and a green approach that sets us apart. Whether it’s a routine appendectomy or a complex endoscopic procedure, our passivated 420 stainless steel tube for surgical tool fabrication delivers the performance surgeons need to save lives.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is 420 stainless steel suitable for surgical tool fabrication?

Passivated 420 stainless steel offers high hardness, good corrosion resistance, and sharpenability, making it ideal for surgical tools like scalpels, forceps, and scissors that require precision and durability.What is the material composition of 420 stainless steel for surgical tools?

It contains 12-14% chromium and 0.15-0.40% carbon, providing hardness and corrosion resistance after passivation, compliant with ASTM A276 for medical-grade applications.What are the primary applications of 420 stainless steel tubes in surgical tools?

These tubes are used in scalpel handles, endoscopic shafts, biopsy forceps, and bone drills, offering structural support and sharpness for precise cutting and minimally invasive procedures.How do industry trends influence the use of 420 stainless steel in surgical tools?

The surgical instruments market, valued at USD 14.9 billion in 2025, is projected to grow at a 6.1% CAGR to USD 22.7 billion by 2032, driven by rising surgeries and demand for durable, cost-effective tools.What mechanical properties make 420 stainless steel effective for surgical tubing?

It provides tensile strength of 700-950 MPa, yield strength of 400-700 MPa, hardness up to 50 HRC after heat treatment, and good wear resistance, ensuring tools maintain sharpness and withstand stress.Is passivated 420 stainless steel biocompatible for surgical tool applications?

Yes, it meets ISO 10993 standards for short-term contact, with passivation enhancing corrosion resistance and reducing tissue reactivity, suitable for external surgical tools.What emerging trends support 420 stainless steel in surgical tool fabrication?

Trends include minimally invasive surgery, reusable tool adoption, and a medical tubing market expected to reach USD 1,547.53 million by 2034 at a 6.7% CAGR, favoring hardenable, cost-effective alloys.How does passivated 420 stainless steel handle sterilization for surgical tools?

It withstands autoclaving, chemical sterilization, and gamma irradiation without pitting, maintaining a smooth, passivated surface for repeated use in sterile surgical environments.