We’re thrilled to be leading the charge in supplying cobalt-chromium alloys for medical applications. These alloys are the heavyweights of the healthcare world—strong, durable, and built to last inside the human body. Whether it’s a hip replacement that needs to withstand years of movement or a dental prosthetic that’s got to stay tough, cobalt-chromium alloys are our go-to for delivering top-tier performance. Let’s break down what makes these alloys special, how they’re used, and where the industry is headed.

Cobalt-chromium alloys are all about strength and staying power. These materials are incredibly tough, with tensile strengths ranging from 655 MPa for CoCrMo (ASTM F75) to over 1200 MPa for CoCrNi (ASTM F562). That kind of muscle makes them perfect for load-bearing implants that need to handle serious stress. They’re also super resistant to wear, which is critical for joints like hips and knees that are constantly in motion.

Corrosion resistance is another big win. The human body’s a tough place—salty, wet, and full of chemicals—but cobalt-chromium alloys hold up without rusting or breaking down. Add in their excellent biocompatibility, and you’ve got a material that plays nice with human tissue, reducing the risk of rejection. CoCrMo, for instance, is a star in orthopedic implants because it checks all these boxes, while CoCrNi shines in flexible applications like stents due to its higher elongation.

Applications in Healthcare

Our cobalt-chromium alloys are making waves across the medical field, powering some of the most critical devices out there. Here’s where they’re shining:

Orthopedic Implants: Hip and knee replacements rely heavily on CoCrMo for its unbeatable strength and wear resistance. These implants need to last decades, and our alloys deliver.

Dental Prosthetics: Crowns, bridges, and dental frameworks use CoCrMo or CoCrWNi because they’re tough enough to handle chewing forces and resist corrosion in the mouth’s harsh environment.

Cardiovascular Devices: CoCrNi (ASTM F562) is a favorite for stents and guidewires, offering the flexibility and strength needed to navigate blood vessels while staying corrosion-free.

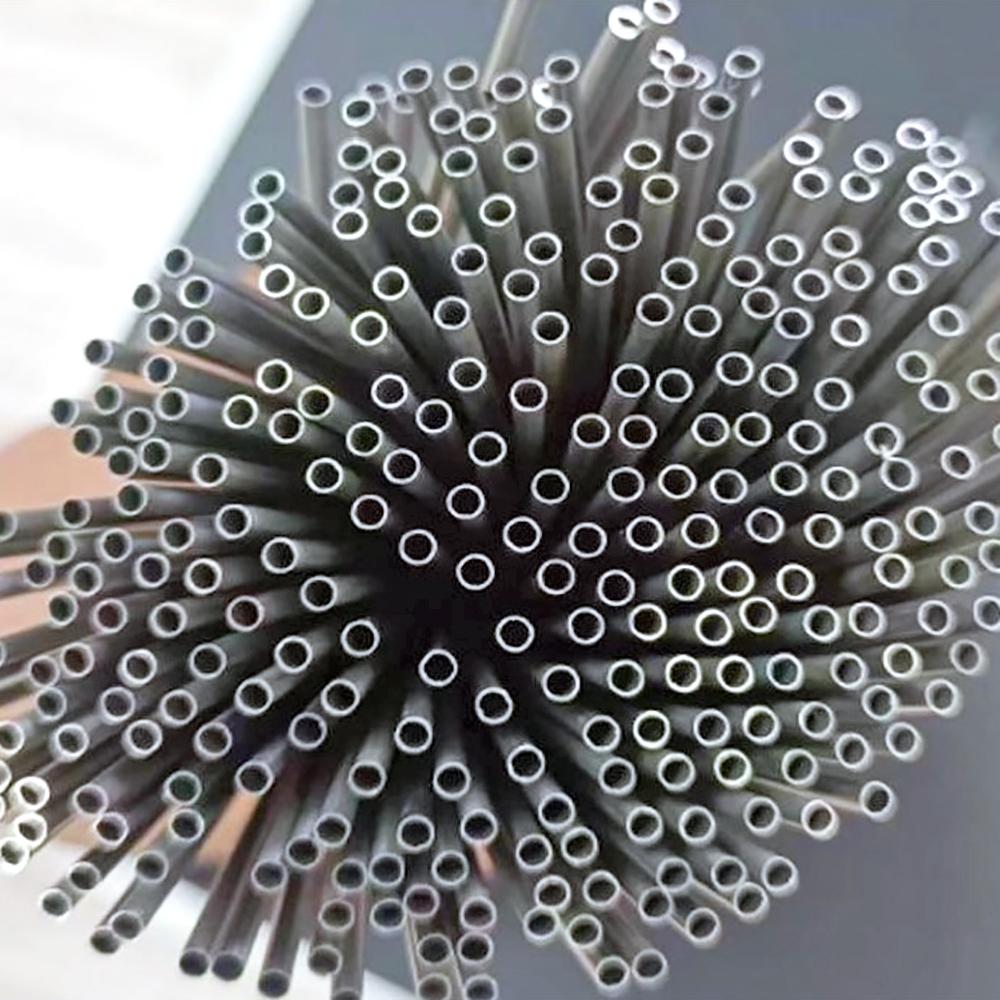

Surgical Tools: Cobalt-chromium alloys are used in high-precision tools like bone drills and saws, where durability and resistance to wear are non-negotiable.

These applications aren’t just about function—they’re about giving patients better mobility, comfort, and quality of life. We’re proud to be part of that mission.

Parameter | CoCrMo (ASTM F75) | CoCrWNi (ASTM F90) | CoCrNi (ASTM F562) |

|---|---|---|---|

Density (g/cm³) | 8.3 | 8.5 | 8.4 |

Tensile Strength (MPa) | 655-900 | 860-1100 | 800-1200 |

Elongation (%) | 8-20 | 10-20 | 10-30 |

Corrosion Resistance | Excellent | Very Good | Excellent |

Biocompatibility | Excellent | Good | Excellent |

Main Applications | Hip/knee implants | Bone plates, screws | Stents, wires |

Machinability | Challenging | Moderate | Moderate |

Cost | High | Moderate | High |

The medical device industry is moving fast, and cobalt-chromium alloys are keeping up with some exciting developments. First up, additive manufacturing—think 3D printing—is changing the game. We’re using it to create custom implants with CoCrMo that fit a patient’s unique anatomy, improving outcomes and cutting surgery times.

Next, there’s a big focus on improving biocompatibility. While our alloys like CoCrMo and CoCrNi are already highly biocompatible, we’re tweaking compositions to make them even safer for long-term use, especially for sensitive applications like vascular implants.

Sustainability is also a hot topic. Healthcare is under pressure to go greener, and we’re stepping up by optimizing our production to reduce waste and energy use. Cobalt-chromium alloys are recyclable, which is a great start, but we’re also exploring cleaner manufacturing processes to shrink our environmental footprint.

The global demand for medical implants is skyrocketing, driven by an aging population and rising joint replacement surgeries. Industry forecasts predict the orthopedic implant market will grow at 6.1% annually through 2030, and cobalt-chromium alloys will stay a top choice due to their durability and cost-effectiveness compared to some pricier alternatives. We’re investing heavily in R&D to develop new alloy grades that push the limits of strength and wear resistance while keeping costs in check.

As a top supplier of cobalt-chromium alloys, we know the stakes are high. Lives depend on our materials, so we don’t cut corners. Every batch meets strict standards like ISO 10993 for biocompatibility and ASTM F75/F90/F562 for material quality. Our production facilities use advanced tech to ensure precision, from alloy formulation to final machining. Whether it’s a hip implant or a dental crown, our alloys are built to perform.

Looking ahead, we’re diving into some cool innovations. We’re exploring alloy additives to boost antimicrobial properties, which could reduce infection risks for implants. We’re also investigating cobalt-chromium’s potential in next-gen applications, like spinal implants or even wearable medical devices. Our goal is to keep pushing what’s possible in healthcare.

Wrapping It Up

Cobalt-chromium alloys are the unsung heroes of medical applications, delivering the strength and durability needed for life-changing devices. From hip replacements to stents, our alloys like CoCrMo, CoCrWNi, and CoCrNi are helping patients move better, live longer, and smile brighter. As the industry evolves, we’re committed to staying ahead with cutting-edge manufacturing, sustainable practices, and innovative alloy designs. The future of cobalt-chromium in healthcare is full of potential, and we’re excited to lead the way, ensuring doctors and patients have the materials they need to thrive.

What are cobalt-chromium alloys in medical applications?

Cobalt-chromium alloys are high-strength, corrosion-resistant materials designed for medical use, known for their durability and biocompatibility in implants and devices.What are the main grades of cobalt-chromium alloys used in healthcare?

Common grades include CoCrMo (ASTM F75), CoCrWNi (ASTM F90), and CoCrNi (ASTM F562), each tailored for specific strength and corrosion resistance needs.What are the primary applications of cobalt-chromium alloys in healthcare?

They are used in orthopedic implants (e.g., hip and knee replacements), dental prosthetics, and cardiovascular stents due to their strength and wear resistance.What advantages do cobalt-chromium alloys offer in medical devices?

They provide exceptional strength, wear resistance, corrosion resistance, and biocompatibility, making them ideal for load-bearing implants and long-term use.What are the industry trends for cobalt-chromium alloys in healthcare?

Trends include improved alloy compositions for better biocompatibility, additive manufacturing for custom implants, and sustainable production methods.