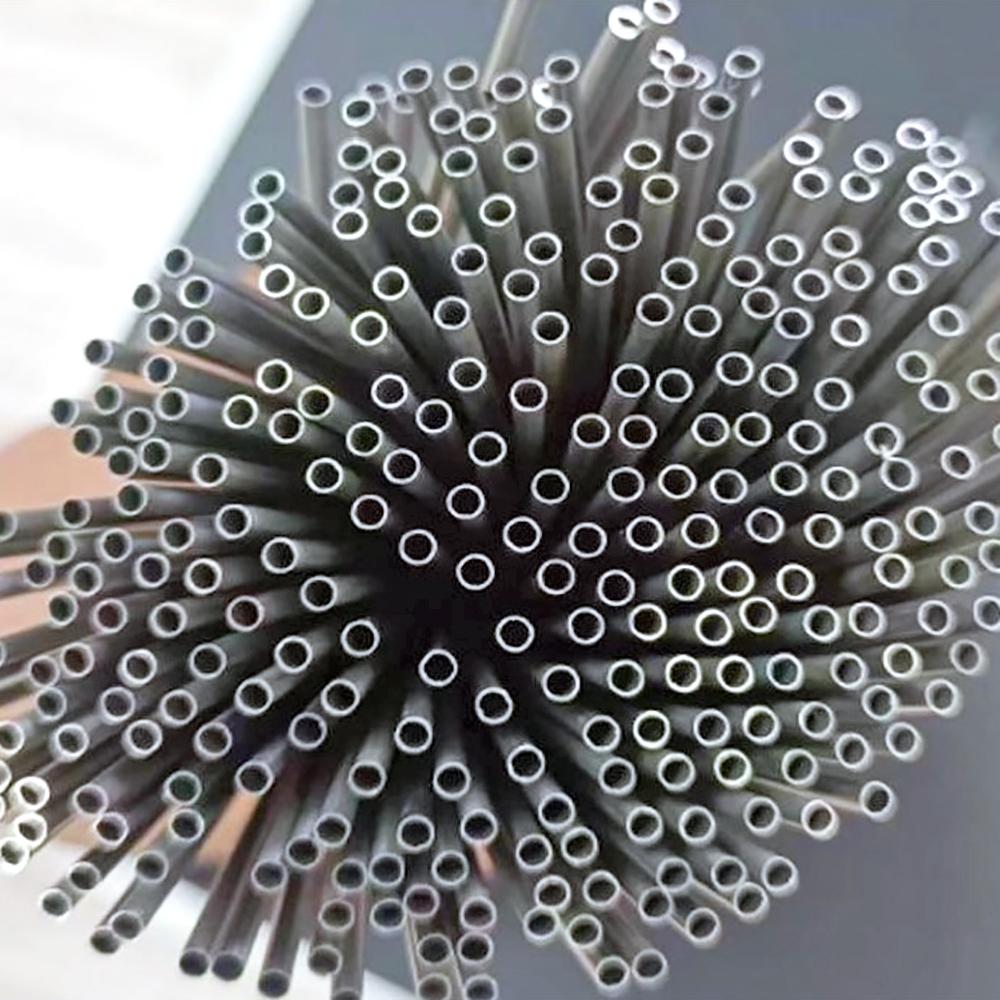

We’re proud to be at the forefront of supplying stainless steel for medical devices, a material that’s been a cornerstone of healthcare for decades. Stainless steel is tough, reliable, and easy to sterilize, making it a go-to choice for everything from surgical tools to implants. Its versatility and affordability keep it in high demand, and we’re excited to share how our stainless steel grades are making a difference in healthcare, along with what’s next for this trusty material.

Stainless steel’s magic lies in its balance of strength, corrosion resistance, and affordability. It’s a chromium-based alloy, which gives it that rust-proof edge even in the harsh, sterile environments of hospitals. For example, 316L stainless steel, with its low carbon content, offers top-notch corrosion resistance and biocompatibility, making it perfect for implants like bone pins or heart valve components. Meanwhile, 304 stainless steel is a budget-friendly option for non-implantable equipment like surgical trays and sterilizers. For applications needing extra strength, 17-4 PH stainless steel delivers high tensile strength—up to 1310 MPa—ideal for load-bearing components like bone screws.

What makes stainless steel a winner is its ability to be sterilized without degrading. Whether it’s autoclaving or chemical cleaning, our alloys hold up, ensuring patient safety and device longevity. Plus, stainless steel is easy to machine and shape, letting us create precise, reliable medical tools that doctors and patients can count on.

Parameter | 316L Stainless Steel | 304 Stainless Steel | 17-4 PH Stainless Steel |

|---|---|---|---|

Density (g/cm³) | 8.0 | 8.0 | 7.8 |

Tensile Strength (MPa) | 485-620 | 515-690 | 930-1310 |

Elongation (%) | 40-60 | 40-60 | 10-16 |

Corrosion Resistance | Superior | Good | Moderate |

Biocompatibility | Excellent | Good | Moderate |

Main Applications | Implants, surgical tools | Trays, medical equipment | Bone screws, structural components |

Machinability | Moderate | Good | Moderate |

Cost | Moderate | Low | Higher |

Our stainless steel grades are hard at work across the medical field, supporting a range of critical applications:

Surgical Instruments: Scalpels, forceps, and retractors often use 316L or 304 stainless steel for their durability and ease of sterilization. These tools need to stay sharp and corrosion-free through countless procedures.

Orthopedic Implants: Bone pins, plates, and screws rely on 316L or 17-4 PH for their strength and ability to integrate with the body without causing irritation.

Dental Tools: Dental drills and probes use 304 or 316L for their precision and resistance to the moist, acidic environment of the mouth.

Medical Equipment: From hospital bed frames to sterilization trays, 304 stainless steel is a cost-effective choice for non-implantable devices that need to withstand frequent cleaning.

These applications show why stainless steel is a healthcare staple—it’s tough, safe, and versatile, helping improve patient outcomes every day.

Industry Trends and Future Outlook

The medical device industry is evolving, and stainless steel is keeping pace with some exciting trends. First, precision manufacturing is a big deal. Advanced CNC machining and laser cutting let us produce intricate stainless steel components with tighter tolerances, which is crucial for complex devices like minimally invasive surgical tools.

Second, there’s a push for enhanced biocompatibility. While 316L is already a star in this area, we’re exploring new alloy formulations with even better tissue compatibility to reduce the risk of rejection in implants. This could open doors for stainless steel in more advanced applications, like next-generation stents or neural implants.

Third, sustainability is gaining traction. The healthcare industry is under pressure to reduce its environmental footprint, and we’re responding by optimizing our production processes to cut waste and energy use. Recyclable stainless steel is already eco-friendly, and we’re working to make our supply chain even greener.

Finally, the global medical device market is booming, driven by an aging population and rising demand for surgeries. Industry data suggests the market will grow at 5.4% annually through 2030, with stainless steel remaining a key material due to its affordability and reliability. We’re investing in R&D to develop stronger, lighter alloys that can compete with pricier materials like titanium while keeping costs down for healthcare providers.

Our Commitment to Quality

As a leading supplier of medical-grade stainless steel, we take our responsibility seriously. Every batch we produce meets stringent standards like ISO 10993 for biocompatibility and ASTM A240 for material quality. Our production facilities use cutting-edge technology to ensure consistency, from melting to finishing. Whether it’s a scalpel blade or a bone plate, our stainless steel is built to perform under pressure.

Looking ahead, we’re excited about the possibilities. We’re researching alloys with added antimicrobial properties to reduce infection risks—a game-changer for implants and surgical tools. We’re also exploring stainless steel’s potential in wearable medical devices, where durability and corrosion resistance are key. Our goal is to keep pushing the boundaries of what stainless steel can do in healthcare.

Wrapping It Up

Stainless steel is the unsung hero of medical devices, delivering strength, safety, and affordability across countless applications. From the operating room to the dental chair, our grades like 316L, 304, and 17-4 PH are helping doctors save lives and improve patient care. As the industry evolves, we’re committed to staying ahead with innovative alloys, sustainable practices, and precision manufacturing. The future of stainless steel in healthcare is bright, and we’re thrilled to be leading the charge, making sure patients and providers have the materials they need to thrive.

Word count: 1,208

FAQ: Stainless Steel in Medical Devices

What is medical-grade stainless steel?

Medical-grade stainless steel is a corrosion-resistant, durable alloy designed for medical applications, meeting strict biocompatibility and hygiene standards for devices and implants.

What are the main grades of stainless steel used in medical devices?

Common grades include 316L, 304, and 17-4 PH, each offering different levels of corrosion resistance, strength, and machinability for specific medical uses.

What are the primary applications of stainless steel in healthcare?

It’s used in surgical instruments, orthopedic implants, dental tools, and medical equipment like trays and sterilizers due to its strength, durability, and ease of sterilization.

What advantages does stainless steel have in medical applications?

Stainless steel offers excellent corrosion resistance, high strength, cost-effectiveness, and ease of fabrication, making it ideal for reusable and long-term medical devices.

What are the industry trends for stainless steel in medical devices?

Trends include advanced alloy formulations for enhanced biocompatibility, precision manufacturing with CNC machining, and eco-friendly production to reduce environmental impact.