The global demand for high-purity nickel alloys is increasing, driven by aerospace expansion and the surge in electric vehicles (EVs). In aerospace, engines are operating at higher temperatures and stress levels, requiring alloys that resist creep, oxidation, and deformation. In the battery sector, nickel-rich cathodes are essential for maximizing energy density and longevity, leading to an increased demand for high-purity nickel materials.

Sustainability and energy efficiency trends are pushing manufacturers to select premium alloys produced with low-energy, high-precision processes. Vacuum melting and controlled alloying ensure reliable performance and minimal environmental impact.

DLX Alloy has adopted advanced production and quality control systems, delivering alloys with consistent composition, excellent surface quality, and performance reliability under extreme operating conditions.

| Property | Standard Nickel Alloy | High-Purity Nickel Alloy |

|---|---|---|

| Nickel Content | 99.0–99.5% | 99.9–99.99% |

| Maximum Operating Temp (°C) | 1000 | 1200 |

| Oxidation Resistance | Good | Excellent |

| Corrosion Resistance | Good | Superior in acids/alkalis |

| Mechanical Strength | Medium | High |

| Electrical Resistivity (μΩ·m) | 6.9 | 6.8–7.0 |

| Typical Applications | Industrial furnace parts, chemical vessels | Aerospace components, battery cathodes, high-end chemical processing |

High-purity nickel alloy clearly outperforms standard variants in oxidation resistance, mechanical strength, and reliability, making it indispensable for critical industrial applications.

DLX Alloy – Supplier Advantages

DLX Alloy provides a competitive edge as a trusted supplier and manufacturer:

Vacuum induction melting produces clean, high-purity alloy with minimal impurities.

Precision rolling and heat treatment deliver uniform microstructure and tight tolerances.

Quality assurance includes mechanical testing, chemical analysis, and oxidation testing.

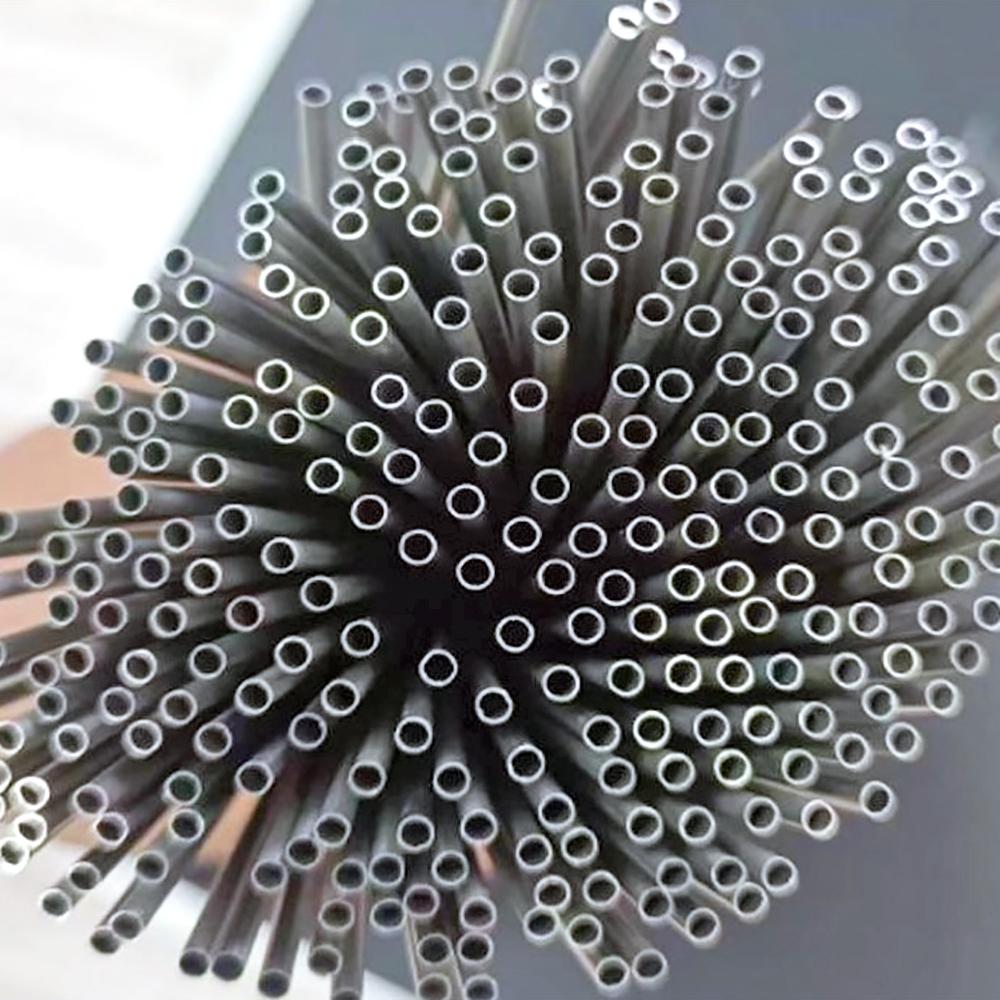

Custom solutions: rods, wires, plates, and tubes can be tailored to client specifications.

Global supply capabilities ensure timely delivery and technical support for B2B industrial clients.

Our alloys are engineered to withstand long-term thermal cycling, maintaining both electrical performance and structural integrity. This makes DLX Alloy a reliable partner for aerospace engineers, battery manufacturers, and industrial system designers.

Market Insights

Global nickel demand is increasingly influenced by renewable energy and electric mobility trends. Nickel-rich cathodes are critical for high-energy batteries, while aerospace applications require materials capable of withstanding extreme temperatures and stress cycles.

DLX Alloy’s high-purity nickel rods, wires, and plates address these needs, providing:

Long-lasting performance in extreme conditions

High corrosion resistance for chemical processing and battery applications

Superior thermal and mechanical properties for aerospace components

With the rise of EV adoption, expansion of battery storage systems, and aerospace industry growth, high-purity nickel alloy demand is expected to increase steadily, positioning DLX Alloy as a leading B2B supplier.

FAQs about High-Purity Nickel Alloy

1. Why choose high-purity nickel over standard nickel?

Higher nickel content reduces impurities, improving corrosion resistance, thermal stability, and mechanical strength.

2. Which industries benefit most?

Aerospace, battery manufacturing, chemical processing, electronics, and high-temperature industrial operations.

3. Can DLX Alloy supply customized shapes and sizes?

Yes, including rods, plates, wires, and tubes tailored to industrial specifications.

4. What is the maximum operating temperature?

High-purity nickel alloys are reliable up to 1200°C, depending on application conditions.

5. How does it resist corrosion?

It withstands strong acids, alkalis, and oxidizing environments, ideal for battery and chemical applications.

6. What quality checks are performed?

Chemical composition verification, mechanical testing, and high-temperature oxidation assessments ensure reliability.

7. Is it suitable for aerospace components?

Yes, it maintains strength, dimensional stability, and oxidation resistance under extreme thermal and mechanical loads.

8. How does DLX Alloy ensure supply reliability?

Through optimized production processes, stringent quality control, and a global logistics network.

Conclusion

DLX Alloy’s high-purity nickel alloy provides outstanding corrosion resistance, thermal stability, and mechanical strength, making it ideal for aerospace components, battery systems, and high-performance industrial applications. Customizable forms, stringent quality standards, and global supply capabilities make DLX Alloy a trusted manufacturer and supplier for B2B clients seeking reliable, high-performance materials.