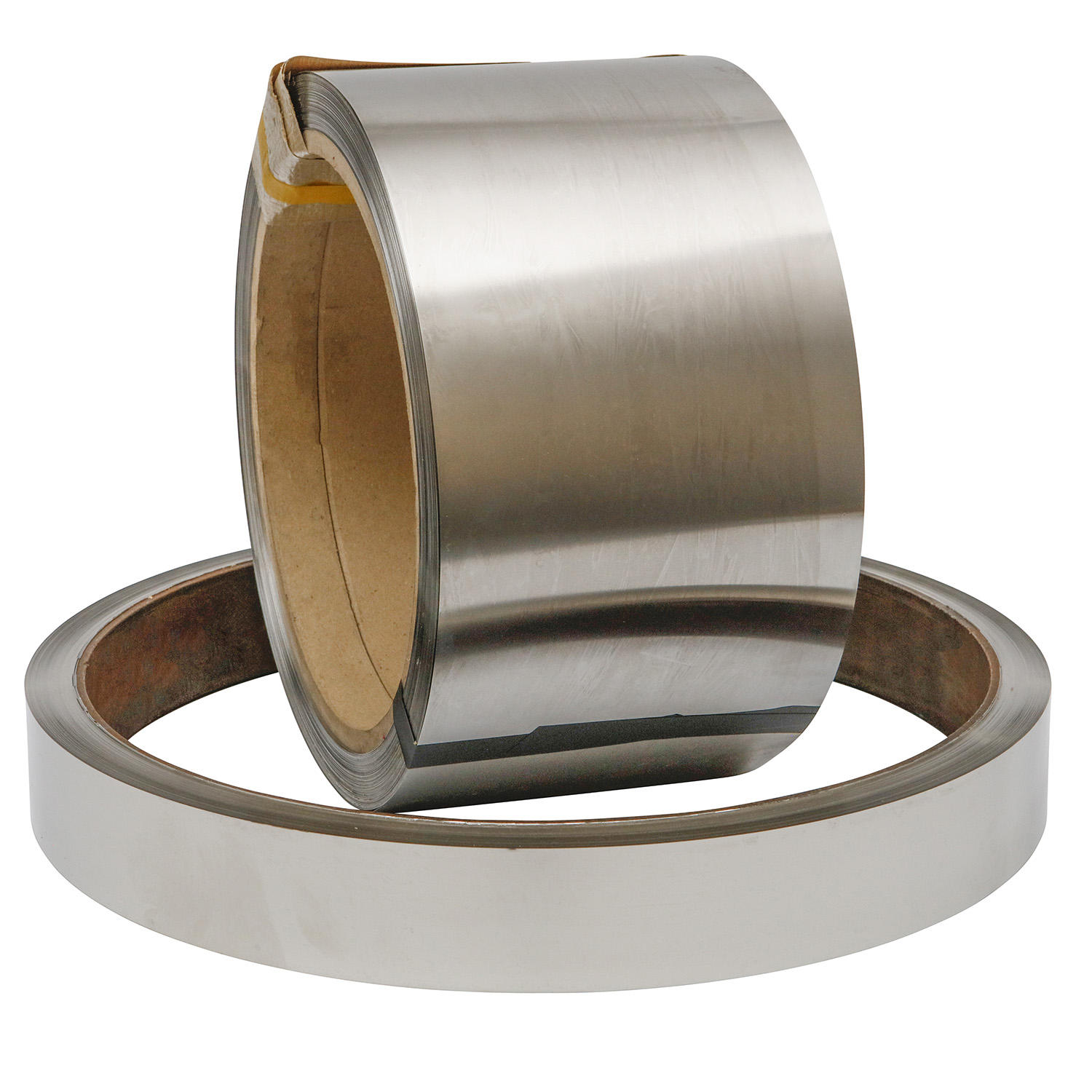

Nickel 201 strip occupies a unique position in modern industrial materials. While many alloys compete for attention in high-performance environments, high-purity nickel continues to prove its value wherever reliability, stability, and corrosion resistance are essential. In demanding sectors such as chemical processing and heat treatment, material selection is rarely about novelty. It is about consistency, predictability, and long-term durability. That is precisely where Nickel 201 strip stands out.

Nickel 201 is fundamentally a commercially pure wrought nickel with a deliberately reduced carbon content. This small adjustment in chemistry leads to a significant improvement in high-temperature behavior. At elevated temperatures, carbon can contribute to carbide formation and intergranular issues, which may compromise mechanical integrity. By minimizing carbon, Nickel 201 provides enhanced resistance to embrittlement and maintains ductility under thermal stress. For equipment exposed to repeated heating cycles or prolonged high-temperature service, this characteristic is not merely beneficial – it is critical.

For more details, pls directly contact us.

In chemical equipment, corrosion is the constant adversary. Many processing environments involve caustic solutions, reactive substances, and aggressive cleaning agents. Nickel 201 strip demonstrates excellent resistance to alkaline media, particularly caustic alkalis. This makes it highly suitable for components such as shields, linings, connectors, and flexible elements within chemical systems. Its performance is not defined by a single property but by a balanced combination of corrosion resistance, formability, and mechanical stability.

Heat treatment applications impose a different but equally severe set of challenges. Thermal cycling, oxidation, and dimensional stability are everyday concerns. Materials must withstand expansion, contraction, and elevated temperatures without cracking or degrading. Nickel 201 strip performs well in these environments due to its stable microstructure and resistance to intergranular degradation. Whether used in fixtures, carriers, or specialized thermal components, it delivers dependable performance across repeated cycles.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

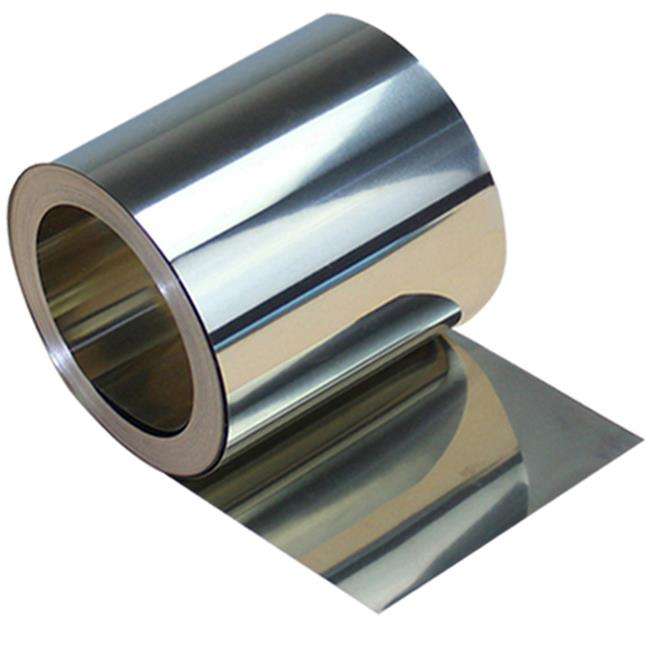

Beyond its thermal and chemical advantages, Nickel 201 strip also offers practical manufacturing benefits. It is highly workable and can be rolled, stamped, bent, and formed with relative ease. This versatility simplifies fabrication and reduces production complexity. In automated manufacturing, where uniformity is vital, predictable forming behavior directly translates into higher yields and lower defect rates.

Electrical performance is another important aspect. Nickel 201 retains high electrical conductivity while offering strong resistance to oxidation and environmental attack. This dual advantage supports its widespread use in electrical connectors, battery tabs, and precision components. In energy storage systems, for instance, strip materials must combine conductivity with weldability and mechanical reliability. Nickel 201 meets these demands without the need for complex alloying strategies.

From an industry perspective, demand patterns for high-purity nickel materials continue to evolve. Growth in renewable energy, battery technologies, hydrogen systems, and advanced manufacturing has reinforced the importance of stable, corrosion-resistant conductive materials. Nickel 201 strip aligns naturally with these trends. It is not tied to a single niche but supports multiple high-growth sectors simultaneously.

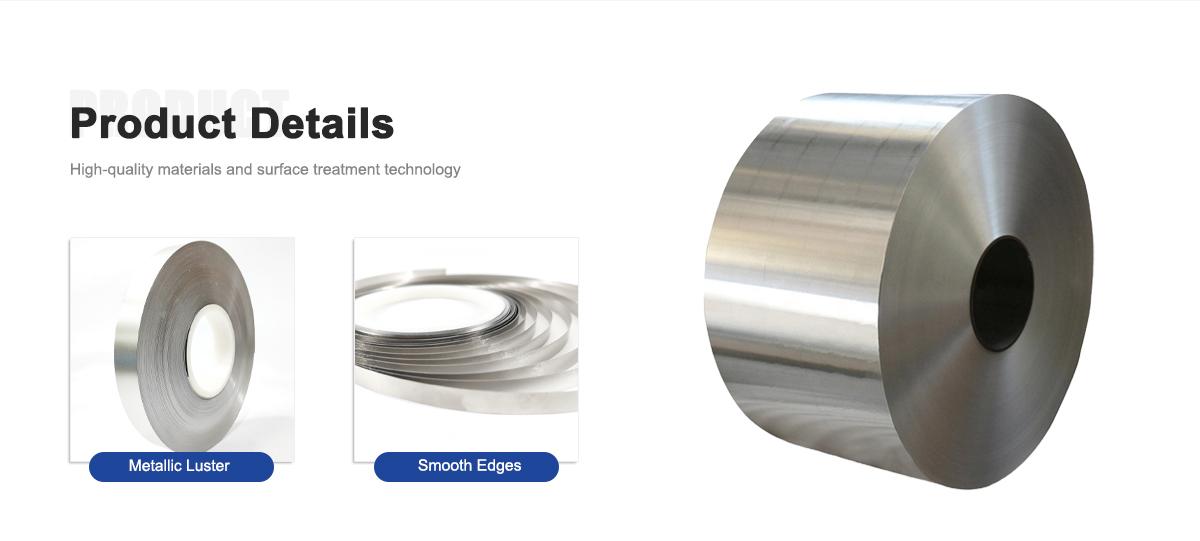

Within this competitive landscape, supplier capability becomes as important as material specification. Consistency of composition, precision of rolling, and control of surface quality directly affect downstream manufacturing. Variations in strip thickness or surface defects can lead to welding failures, assembly problems, and costly production interruptions. Industrial buyers increasingly prioritize suppliers that demonstrate not only technical competence but also process stability and quality discipline.

Comparison of Typical Parameters

| Property / Feature | Nickel 201 Strip | Nickel 200 Strip |

|---|---|---|

| UNS Designation | N02201 | N02200 |

| Carbon Content | Lower (improved high-temp stability) | Higher than 201 |

| Corrosion Resistance | Excellent, especially in caustic media | Excellent |

| High-Temperature Behavior | Superior resistance to embrittlement | Good, but less stable at high temperatures |

| Electrical Conductivity | High | High |

| Weldability | Very good | Very good |

| Typical Applications | Heat treatment, chemical equipment, battery | General industrial, electrical components |

| Mechanical Stability | Better for prolonged heat exposure | Suitable for moderate temperatures |

From the DLX company perspective, the emphasis is on delivering exactly that stability. Industrial customers rarely struggle with theoretical material knowledge; they struggle with variability, lead times, and inconsistent batches. By maintaining strict control over raw material selection, rolling processes, and inspection standards, DLX focuses on repeatable quality rather than marketing claims. The goal is straightforward: ensure that every coil of Nickel 201 strip behaves the same way in stamping, welding, and forming operations.

Another critical factor is customization. Industrial applications rarely conform to generic dimensions. Thickness tolerance, temper condition, and surface finish must often be adapted to specific equipment or production lines. DLX supports this requirement by offering flexible production configurations designed around real manufacturing constraints rather than rigid catalog limitations.

Reliability also extends beyond the material itself. Industrial procurement cycles depend on predictable delivery, responsive communication, and technical clarity. In sectors such as chemical processing and heat treatment, unexpected material delays can disrupt entire production schedules. A stable supply partner reduces operational risk just as effectively as a high-performance alloy.

Nickel 201 strip continues to demonstrate why high-purity materials remain indispensable in advanced industries. Its combination of corrosion resistance, high-temperature stability, workability, and conductivity makes it a practical solution for engineers and procurement specialists alike. In applications where failure is not an option and consistency is paramount, material simplicity often becomes an advantage rather than a limitation.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

What is Nickel 201 strip and how is it different from Nickel 200?

Nickel 201 is essentially a low-carbon version of Nickel 200. The reduced carbon content improves resistance to intergranular embrittlement at elevated temperatures, making Nickel 201 more suitable for heat treatment environments and high-temperature chemical processing. In strip form, it offers excellent workability, conductivity, and corrosion resistance.Why is Nickel 201 preferred for high-temperature applications?

The low carbon content minimizes the risk of carbide precipitation during prolonged exposure to temperatures above roughly 315°C. This means better mechanical stability, less brittleness, and more predictable performance in thermal cycles, which are common in furnaces and heat treatment systems.Is Nickel 201 strip resistant to chemical corrosion?

Yes. Nickel 201 demonstrates outstanding resistance to a wide range of corrosive media, particularly caustic alkalis. It performs well in environments involving sodium hydroxide, potassium hydroxide, and similar aggressive substances, which is why it is widely used in chemical equipment.What industries commonly use Nickel 201 strip?

Typical industries include chemical processing, heat treatment, electronics, battery manufacturing, power generation, aerospace support systems, and general industrial manufacturing. Any application requiring high purity nickel, stable conductivity, and corrosion resistance can benefit from Nickel 201 strip.Can Nickel 201 strip be welded or spot welded easily?

Nickel 201 has very good weldability. It can be resistance welded, TIG welded, and spot welded using conventional methods. Its consistent composition and ductility allow reliable joint quality, which is important in battery tabs and electrical assemblies.How does Nickel 201 strip perform in electrical applications?

Nickel 201 maintains high electrical conductivity combined with excellent oxidation resistance. This makes it ideal for lead connectors, terminals, and components where both electrical performance and environmental stability matter.What thicknesses and dimensions are typically available?

Nickel 201 strip is commonly produced in a wide range of thicknesses, often from ultra-thin precision foil to heavier industrial gauges. Width, temper, and surface finish can be customized depending on forming, welding, or stamping requirements.What should buyers focus on when sourcing Nickel 201 strip?

Key factors include chemical composition accuracy, dimensional tolerance, surface quality, mechanical consistency, and supplier reliability. Stable quality and repeatability are critical for industrial production, especially for automated welding and forming processes.