Pure nickel strip produced under ASTM B162 UNS N02200 (commonly known as Nickel 200 ) is a high-purity metallic material designed for applications requiring excellent electrical conductivity, strong corrosion resistance, and stable mechanical behavior. With a minimum nickel content of 99.6%, Nickel 200 is widely recognized across global industrial sectors for its reliability and versatility.

Nickel 200 belongs to the family of commercially pure nickel grades. Its combination of properties makes it particularly valuable for electrical systems, precision components, chemical environments, and general industrial manufacturing. Unlike complex alloys, pure nickel provides predictable performance characteristics without the variability introduced by multi-element compositions.

Core material characteristics include:

High electrical conductivity

Low and stable electrical resistivity

Excellent ductility and formability

Strong resistance to alkaline corrosion

Good thermal conductivity

Stable mechanical performance after annealing

Because of these properties, ASTM B162 Nickel 200 strip is extensively used in electrical connectors, battery interconnections, resistance welding components, chemical processing equipment, and a wide range of OEM manufacturing processes.

For more details, pls directly contact us.

Main Applications

Electrical Conductivity Components

Nickel 200 strip is widely used in connectors, terminals, busbars, and conductive pathways requiring stable resistivity.Battery Interconnections

Used for lithium battery tabs, battery pack welding strips, and energy storage systems.Resistance and Spot Welding

Pure nickel ensures consistent weld performance with low contact resistance.Chemical Processing Equipment

Exhibits strong resistance to caustic alkalis and certain corrosive media.Heat Treatment Fixtures

Stable mechanical behavior under controlled temperature conditions.Precision Electronic Parts

Suitable for stamping, forming, and fine fabrication.EMI Shielding and Special Electrical Uses

Used where conductive and non-magnetic properties are beneficial.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Demand for pure nickel strip continues to rise alongside developments in electrification, renewable energy, and industrial automation. Several key market shifts are influencing procurement behavior:

Rapid growth in battery manufacturing

Expansion of electronic and electrical industries

Increased adoption of resistance welding technologies

Higher quality expectations for conductive materials

Greater emphasis on long-term supply reliability

Manufacturers today operate with tighter tolerances and higher production speeds. Materials that perform inconsistently can disrupt automated systems, increase defect rates, and generate hidden operational costs. As a result, buyers are prioritizing consistency, dimensional accuracy, and stable electrical performance.

Pure nickel strip is increasingly viewed as a performance-critical material rather than a basic commodity.

Typical Technical Parameters

| Property | Nickel 200 Strip (UNS N02200) |

|---|---|

| Nickel Content | ≥ 99.6% |

| Carbon | ≤ 0.15% |

| Density | 8.89 g/cm³ |

| Melting Point | 1435–1446°C |

| Tensile Strength (Annealed) | 380–550 MPa |

| Elongation | ≥ 30% |

| Electrical Resistivity | ~0.096 μΩ·m |

| Thermal Conductivity | ~90 W/m·K |

| Modulus of Elasticity | ~200 GPa |

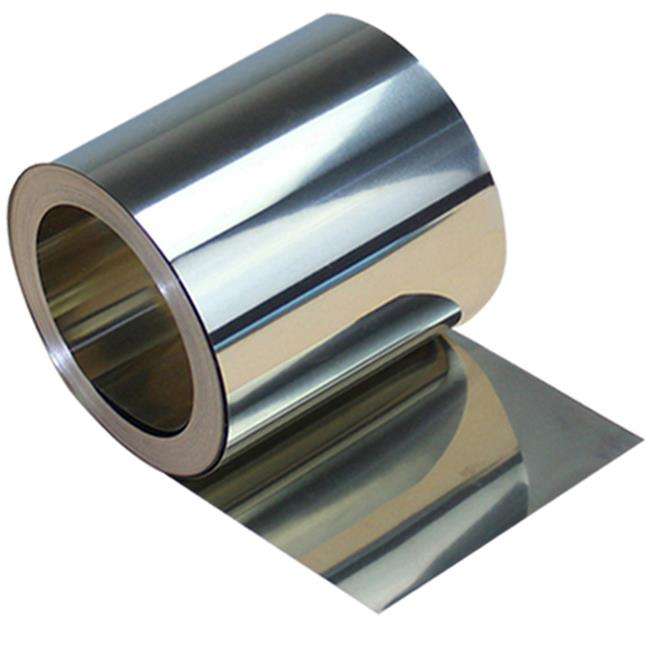

| Typical Thickness Range | 0.02 – 3.0 mm |

Available supply conditions:

Soft annealed

Cold rolled

Bright surface finish

Precision slit strip

Customized widths and coil sizes

In-Depth Article

Pure nickel strip manufactured to ASTM B162 UNS N02200 standards is far more than a basic industrial material. In many modern industries, it functions as a critical performance component that directly affects product reliability, electrical efficiency, and manufacturing stability.

At DLX Company, we view Nickel 200 strip through a practical engineering lens. Our customers are not simply purchasing metal — they are selecting a material that must perform predictably in demanding production environments.

Electrical conductivity is one of the defining advantages of pure nickel. In connectors, terminals, battery interconnections, and conductive assemblies, stable resistivity is essential. Variations in material composition or microstructure can influence current flow, heat generation, and long-term durability. Pure nickel, with its controlled chemistry and uniform structure, provides dependable performance.

But conductivity alone does not explain its widespread adoption.

Manufacturing behavior is equally important. Nickel 200 strip offers excellent ductility, making it suitable for stamping, forming, bending, and welding operations. Soft annealed material can withstand complex deformation without cracking, which is essential in precision electronic and battery manufacturing.

In resistance welding applications, nickel strip demonstrates another key advantage. Consistent hardness and clean surfaces promote stable weld formation. Unstable material properties often lead to inconsistent weld nuggets, spatter, or excessive heat concentration. These issues reduce production yield and increase rejection rates.

That is why dimensional and mechanical consistency matter so much.

Across global industries, procurement strategies are evolving. Buyers are no longer focused only on material availability or nominal specifications. They are evaluating suppliers based on stability, repeatability, and long-term reliability. A small inconsistency between batches can require machine adjustments, interrupt automated workflows, and increase operational risk.

DLX Company’s manufacturing philosophy is built around eliminating those uncertainties.

Our production process begins with high-quality raw nickel to ensure purity. Melting and refining operations are strictly controlled to minimize impurities that could affect electrical or mechanical behavior. Rolling processes maintain precise thickness tolerances, while annealing cycles are calibrated to achieve uniform mechanical properties.

Consistency across shipments is a central objective.

Many industrial users experience challenges when sourcing nickel strip from general market suppliers. Common issues include hardness fluctuation, dimensional variation, and inconsistent surface conditions. These problems may not always be visible during incoming inspection but can emerge during high-speed production.

At DLX, process stability is prioritized at every stage.

Surface quality is another major consideration. Bright and clean nickel strip surfaces improve electrical contact performance and welding efficiency. Oxide layers or contamination can increase resistance and compromise weld stability. Our surface treatment and handling procedures are designed to maintain clean, production-ready conditions.

Industry demand patterns further reinforce the importance of quality stability.

Electrification, renewable energy systems, battery production, and electronic device manufacturing are all expanding globally. As these industries scale, tolerance for material variability decreases. Automated production lines require materials that behave identically from batch to batch.

That is where a specialized manufacturer offers distinct advantages.

Compared to standard trading suppliers, DLX operates as an integrated producer with strong control over metallurgy, rolling parameters, and heat treatment processes. This allows us to deliver predictable mechanical behavior, precise dimensional accuracy, and consistent electrical performance.

Customization also plays a critical role.

Different applications require different strip characteristics. Battery tabs may demand specific thickness and softness combinations. Electrical connectors may require precise slit widths. OEM manufacturers often need tailored coil sizes for automated feeding systems. Our production flexibility supports these diverse requirements without compromising quality consistency.

From a cost perspective, material stability contributes directly to manufacturing efficiency. Lower defect rates, improved welding yield, and reduced machine downtime generate long-term savings that far exceed small price differences. Experienced procurement teams understand this relationship clearly.

Pure nickel strip, therefore, becomes a strategic material choice rather than a simple purchase decision.

DLX Company positions itself as a long-term manufacturing partner for industries requiring high reliability conductive materials. We focus on technical precision, repeatable production quality, and responsive cooperation with customers.

Looking ahead, industrial expectations will continue to rise. As manufacturing tolerances tighten and automation increases, materials must meet higher performance standards. Suppliers must deliver not only compliant products but also stable and predictable production behavior.

Pure nickel strip under ASTM B162 UNS N02200 standards remains one of the most reliable solutions for electrical conductivity and industrial supply applications.

At DLX, we make sure it stays that way.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ – Frequently Asked Questions

What does ASTM B162 specify for nickel strip?

ASTM B162 defines chemical composition, mechanical properties, and quality requirements for nickel plate, sheet, and strip.Why is Nickel 200 preferred for electrical applications?

Its high purity and low resistivity ensure stable conductivity and minimal energy loss.Is Nickel 200 suitable for welding applications?

Yes. It offers excellent resistance welding and spot welding performance.How does nickel strip perform in corrosive environments?

Pure nickel provides strong resistance to alkaline corrosion and many industrial chemicals.Can thickness and width be customized?

Yes. Nickel strip is commonly supplied in precision dimensions based on application needs.What mechanical condition is best for forming operations?

Soft annealed strip is preferred for bending, stamping, and deep forming.Does surface finish affect performance?

Yes. Clean, bright surfaces improve welding behavior and electrical contact stability.What quality documentation is typically provided?

Mill test certificates, composition analysis, and mechanical test reports are available.