Soft annealed pure nickel strip is a high-performance conductive material produced from commercially pure nickel with a minimum nickel content of 99.6%. The most commonly used grades include Nickel 200 (UNS N02200 / DIN 2.4060) and Nickel 201 (UNS N02201 / DIN 2.4066). These materials are widely used in battery pack manufacturing, resistance welding, and energy storage applications where conductivity, ductility, and welding stability are critical.

The soft annealing process is a key differentiator. Through precisely controlled heat treatment, internal stresses generated during rolling are relieved, resulting in:

-

Lower hardness

-

Improved ductility

-

Enhanced flexibility

-

Better weldability

-

Stable mechanical behavior

-

Consistent electrical performance

Compared to cold-worked material, soft annealed nickel strip exhibits superior forming and welding characteristics. This makes it especially suitable for automated battery pack assembly lines and high-speed spot welding operations.

Nickel 200 provides excellent overall performance for standard battery welding environments, while Nickel 201, with its lower carbon content, offers improved stability when thermal exposure or welding heat cycles are more demanding.

For more details, pls directly contact us.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

|

|

99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 |

|

|

99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

-

Battery Pack Welding

Soft annealed nickel strip ensures stable weld formation and consistent electrical connection between cells. -

Energy Storage Systems

Used in stationary energy storage modules and battery assemblies requiring reliable conductive pathways. -

Spot Welding and Resistance Welding

Low hardness improves contact behavior and weld nugget consistency. -

Lithium Battery Interconnections

Suitable for cylindrical, pouch, and prismatic cell designs. -

Automated Battery Production Lines

Excellent flexibility and feeding stability support high-speed manufacturing. -

Electrical Connectors and Busbars

Provides low contact resistance and dependable conductivity.

| Property | Nickel 200 Strip | Nickel 201 Strip |

|---|---|---|

| Nickel Content | ≥ 99.6% | ≥ 99.6% |

| Carbon | ≤ 0.15% | ≤ 0.02% |

| Density | 8.89 g/cm³ | 8.89 g/cm³ |

| Tensile Strength (Soft Annealed) | 380–550 MPa | 380–550 MPa |

| Elongation | ≥ 30% | ≥ 30% |

| Electrical Resistivity | ~0.096 μΩ·m | ~0.096 μΩ·m |

| Thermal Conductivity | ~90 W/m·K | ~90 W/m·K |

| Hardness (Annealed) | Low / Controlled | Low / Controlled |

| Thickness Range | 0.02 – 3.0 mm | 0.02 – 3.0 mm |

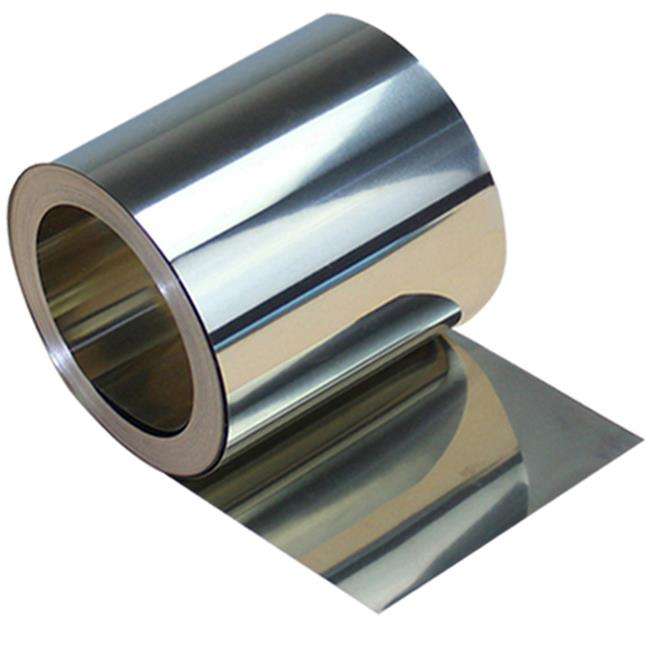

Available supply options:

-

Soft annealed condition

-

Precision slit strip

-

Bright surface finish

-

Customized widths and coil sizes

-

Tight thickness tolerances

Global battery production continues to accelerate due to electric vehicles, renewable energy integration, and portable electronics. As production volumes increase, manufacturers are placing greater emphasis on material reliability and process compatibility.

Key trends influencing soft annealed nickel strip demand include:

-

Expansion of battery pack automation

-

Higher welding speed requirements

-

Increased focus on weld consistency

-

Tighter thickness tolerances

-

Demand for stable mechanical properties

-

Long-term supplier qualification strategies

Battery manufacturers today operate in environments where even small material deviations can cause significant production disruptions. Stable softness, consistent surface condition, and uniform electrical performance are no longer optional — they are essential.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQ – Frequently Asked Questions

-

Why is soft annealed nickel strip preferred for battery welding?

Soft annealed material provides better ductility and more stable weld behavior, reducing welding defects. -

Does hardness affect spot welding performance?

Yes. Excessive hardness can lead to unstable weld formation and inconsistent joint quality. -

What is the advantage of Nickel 201 over Nickel 200?

Nickel 201 has lower carbon content, improving performance under elevated temperature conditions. -

Is soft annealed nickel strip suitable for automated equipment?

Absolutely. Its flexibility and controlled mechanical properties support smooth feeding and repeatable welding. -

Can dimensions be customized for battery designs?

Yes. Thickness, width, and coil configuration can be tailored to production requirements. -

How does surface quality influence welding?

Clean, bright surfaces reduce contact resistance and improve weld consistency. -

Does nickel strip degrade over time in battery applications?

Pure nickel maintains conductivity and structural stability under normal operating conditions. -

What quality controls are important for battery materials?

Thickness accuracy, mechanical consistency, chemical purity, and surface cleanliness are critical factors.

In-Depth Article

Soft annealed pure nickel strip has become a cornerstone material in battery pack welding and energy storage systems. Its importance goes far beyond basic conductivity. In high-speed automated manufacturing environments, material behavior directly influences production efficiency, weld reliability, and long-term device performance.

At DLX Company, we understand that battery manufacturers are not simply purchasing metal strips. They are selecting materials that must perform flawlessly across millions of welds, thousands of production hours, and complex mechanical operations.

The primary reason soft annealed nickel strip is so widely adopted lies in its mechanical characteristics. Soft annealing reduces hardness and increases ductility, allowing the strip to deform and respond predictably under welding pressure and electrical current. This stability is essential for resistance welding processes where contact behavior determines heat generation and fusion quality.

In practical terms, a strip that is too hard may resist proper weld formation. A strip that lacks uniform softness may produce inconsistent weld nuggets. Variability in mechanical properties can force machine adjustments, disrupt automated lines, and increase rejection rates.

That is why controlled annealing is critical.

Pure nickel itself offers inherent advantages. With high purity levels (≥99.6% Ni), it provides excellent electrical conductivity and strong resistance to alkaline environments. In battery systems, low and stable resistivity ensures efficient current flow, minimizing unwanted heat buildup and energy loss.

However, conductivity alone does not guarantee manufacturing success.

Battery pack production relies heavily on automated spot welding machines. These systems operate at high speeds, leaving little tolerance for material inconsistency. Thickness deviation, hardness fluctuation, or unstable surface conditions can significantly impact welding results. Even minor variations can propagate into large-scale production problems.

DLX Company’s manufacturing approach is designed specifically to address these challenges.

We begin with carefully selected high-purity raw materials to maintain chemical stability. Melting and refining processes are tightly controlled to minimize impurities that could affect electrical or mechanical performance. Rolling operations are calibrated for precision thickness control, ensuring dimensional consistency across coils.

Annealing processes are managed with strict temperature and time control to achieve uniform softness. This ensures that each batch exhibits predictable tensile strength and elongation — two parameters that directly influence welding stability and forming behavior.

Consistency between shipments is one of the most important factors for industrial buyers.

In large battery factories, procurement teams depend on repeatable material performance. A change in strip behavior between batches can require welding parameter adjustments, slow production speed, or introduce quality risks. Our focus on process stability helps eliminate these uncertainties.

Surface quality is another key performance variable.

Spot welding efficiency depends heavily on contact resistance. Clean, bright strip surfaces promote stable electrical contact and predictable heat distribution. Oxide layers or contamination can interfere with weld formation, resulting in weak joints or excessive spatter.

DLX nickel strips are produced with controlled surface conditions optimized for welding applications.

Industry demand patterns further reinforce the value of high-quality nickel strip. Global battery production is expanding rapidly across electric vehicles, renewable energy storage, and consumer electronics. At the same time, manufacturing processes are becoming more automated and tolerance-sensitive.

As production technologies evolve, material requirements become more stringent.

Buyers increasingly evaluate suppliers based on quality stability, production capacity, technical understanding, and long-term cooperation reliability. Price remains important, but it is no longer the sole decision factor. The cost of welding defects, downtime, and production instability often exceeds small differences in material pricing.

This is where a specialized manufacturer offers significant advantages.

Compared to general trading suppliers, DLX operates as an integrated producer with deep control over metallurgy, rolling parameters, and annealing cycles. This allows us to deliver predictable mechanical behavior and consistent dimensional accuracy — qualities that directly support automated battery production.

Customization capability is equally important.

Different battery designs require different strip thicknesses, widths, and mechanical characteristics. Some applications demand extremely thin, highly flexible strips. Others require balanced strength and ductility. Our production flexibility enables tailored solutions without sacrificing consistency.

Soft annealed pure nickel strip plays a strategic role in improving welding yield and reducing operational risk. Stable material behavior reduces machine adjustments, minimizes defect rates, and enhances overall manufacturing efficiency.

From a procurement perspective, reliability creates long-term value.

At DLX Company, we position ourselves not simply as a strip supplier, but as a long-term industrial partner supporting battery manufacturers and energy storage system producers. Precision, stability, and consistency define our production philosophy.

Soft annealed nickel strip may look simple, but its impact on welding performance and energy system reliability is profound.

We make sure that impact is always positive.