Pure nickel wire is a rockstar in welding and chemical processing, and we’ve been crafting it to perfection for years. With a purity of 99% or higher, this wire brings unbeatable corrosion resistance, strength, and versatility to the table. Whether you’re welding tough joints in a chemical plant or building durable components for harsh processing environments, our pure nickel wire delivers. It’s not just about getting the job done—it’s about doing it better, longer, and smarter. From its material makeup to its applications, industry trends, and why we’re the top choice, let’s dive into what makes pure nickel wire a game-changer.

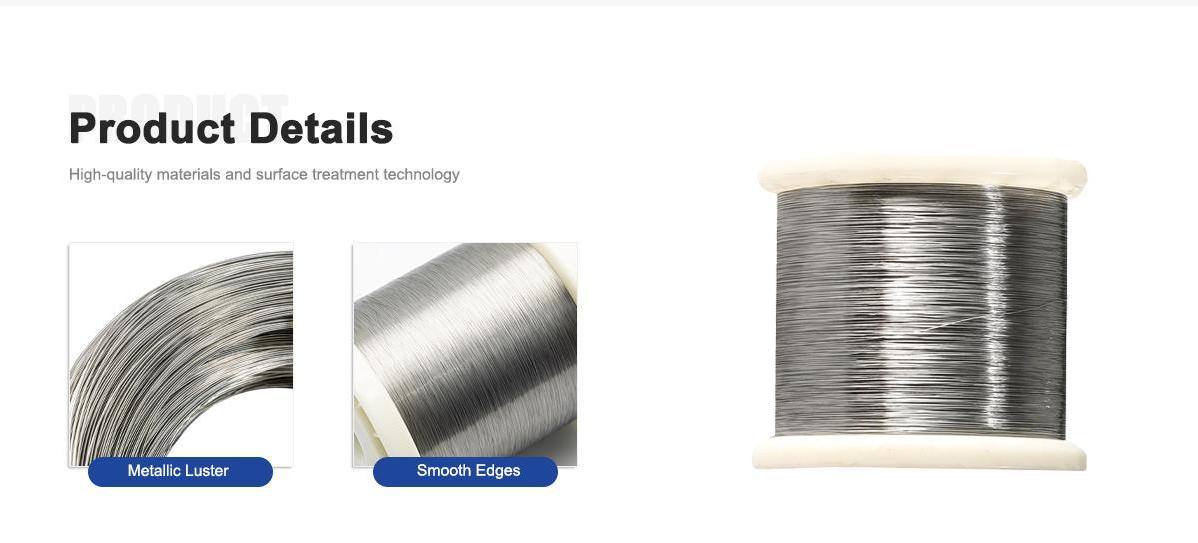

The materials behind our pure nickel wire are all about quality. We start with high-purity nickel, typically 99.6% for Nickel 200 or 99.0% with low carbon (less than 0.02%) for Nickel 201 . Small amounts of iron (up to 0.4%) and manganese (0.35%) are added to boost mechanical properties without compromising the wire’s core strengths—corrosion resistance and thermal stability. We source from ethical, reliable suppliers to keep impurities like sulfur low, which can cause brittleness. Our production process uses precision melting and drawing to create uniform, defect-free wire. This ensures it performs reliably, whether it’s being welded into a reactor or shaped into a chemical filter.

For more details, pls directly contact us.

We offer pure nickel wire in grades tailored for welding and chemical processing. Nickel 200, with 99.6% purity, is our go-to for general welding and corrosion-resistant applications, boasting a tensile strength of about 450 MPa when annealed. Nickel 201, with its low carbon content, shines in high-temperature environments above 315°C, avoiding intergranular corrosion that can plague other materials. Need something tougher? Our hard-drawn Nickel 200 hits 650–800 MPa, perfect for high-strength welds. The melting point for both grades, 1435–1446°C, ensures they hold up in hot welding processes or chemical reactors. We provide custom diameters, from 0.05mm for precision welding to 10mm for heavy-duty components, all rigorously tested to ASTM standards.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Corrosion resistance is where pure nickel wire really stands out, and it’s a big deal for both welding and chemical processing. The wire forms a natural oxide layer that protects against alkalis, acids, and saltwater. In chemical processing, where equipment faces caustic solutions or acidic gases, our wire keeps components like mesh filters and electrodes intact for years. In welding, it creates joints that resist corrosion in harsh environments, like marine or petrochemical setups. We’ve supplied wire for tanks handling sulfuric acid, and the feedback is clear: minimal degradation, even after prolonged exposure. Compared to steel or copper, pure nickel wire lasts longer, cutting maintenance costs and downtime.

In welding, pure nickel wire is a top choice for filler material. It creates strong, corrosion-resistant welds when joining nickel alloys or stainless steel, especially in chemical plants where equipment faces constant corrosion. Its ductility, with up to 47% elongation in annealed form, makes it easy to work with, while its high melting point ensures stable welds under intense heat. In chemical processing, the wire’s applications are vast—think wire mesh for filtration, electrodes for electrochemical processes, or linings for tanks. We’ve seen it used in flue gas desulfurization systems, where it withstands acidic slurries, and in pharmaceutical processing, where its purity prevents contamination. Our wire also shines in marine applications, resisting saltwater corrosion, and in food processing, where hygiene is critical.

The pure nickel wire market is thriving, valued at $1.8 billion in 2024 and projected to reach $3.4 billion by 2032, with a 7.3% CAGR. What’s driving this? The chemical processing industry is expanding, especially in Asia-Pacific, needing corrosion-resistant materials. Electric vehicles (EVs), growing at 15% annually, rely on pure nickel wire for battery welding. Renewable energy, like solar and hydrogen production, demands durable components. Sustainability is a hot trend—we’re seeing more recycled nickel, and we’re ahead with eco-friendly sourcing. High-purity wires are in demand for advanced chemical processes, and stricter regulations push for better corrosion resistance. Nickel price volatility can be tricky, but our long-term contracts keep costs stable.

Our company’s edge comes from our obsession with quality and customization. We test every batch with spectrometry to ensure purity, a step not all suppliers take. In-house production cuts delivery times by up to two weeks compared to industry averages. Need a specific diameter or temper for welding? We tailor it to your needs, no extra costs for unnecessary features. Our tech support team is on standby, helping with everything from alloy selection to weld optimization. In a recent chemical plant project, our Nickel 201 wire extended equipment life by 30% in a corrosive environment. Compared to standard offerings, our wire has fewer defects, meaning less rework and better performance.

Let’s get into the nitty-gritty of materials. Pure nickel’s face-centered cubic structure gives it excellent malleability, letting us draw it into fine wires for precision welding without cracking. We keep sulfur content low to avoid brittleness, and our annealing process delivers wires with high elongation for flexible applications. Compared to alloyed nickels, our pure nickel wire offers better corrosion resistance in reducing environments, making it ideal for chemical processing. We also provide coatings like insulation for specific uses, adding versatility.

On corrosion, the oxide film on pure nickel wire is a lifesaver. It resists uniform corrosion in alkalis and reducing media, with ASTM tests showing minimal weight loss in harsh acids. In welding, this ensures joints stay strong in corrosive settings. Chemical processing applications, like scrubbers or reactors, benefit from its durability. The EV sector relies on it for battery welds, and we’re innovating with thinner wires for compact systems.

Comparison Parameters Table

| Parameter | Nickel 200 (Annealed) | Nickel 201 (Annealed) | Nickel 200 (Hard-Drawn) |

|---|---|---|---|

| Purity (%) | 99.6 | 99.0 (carbon <0.02) | 99.6 |

| Melting Point (°C) | 1435-1446 | 1435-1446 | 1435-1446 |

| Tensile Strength (MPa) | 450 | 400-450 | 650-800 |

| Density (g/cm³) | 8.89 | 8.89 | 8.89 |

| Electrical Resistivity (µΩ·cm) | 9.6 | 8.5 | 9.6 |

| Corrosion Resistance | Excellent in reducing environments, alkalis, and salts | Superior at high temps (>315°C), resists embrittlement | Similar to annealed, less ductile |

| Thermal Conductivity (W/m·K) | 90.9 | 79.3 | 90.9 |

| Typical Applications | Welding filler, chemical tanks | High-temp welding, chemical filters | High-strength welding, structural components |

Applications are expanding. In welding, pure nickel wire handles high-temperature processes like TIG or MIG, creating joints that last in petrochemical plants. In chemical processing, it’s used for mesh screens, pump components, and tank linings. Marine applications leverage its saltwater resistance, while food processing benefits from its hygiene. Trends show pure nickel wire in additive manufacturing for custom parts, and our scalable production, backed by ISO 9001, meets demand from small batches to bulk orders.

Industry analysis highlights supply chain shifts, with localized sourcing gaining traction. Nickel price swings are a challenge, but our hedging ensures predictable costs. Green tech, like hydrogen production, favors pure nickel wire’s durability, and we’re leading with recycled options to reduce emissions.

In a company comparison, while typical suppliers might cut corners on testing, we use advanced spectrometry for every spool. Our lead times are shorter, and we offer custom tempers or coatings. Clients report 25% better performance in corrosive environments with our wire. It’s not just about supplying wire—it’s about delivering solutions that keep your operations running smoothly.

Pure nickel wire is a cornerstone for welding and chemical processing, and we’re committed to making it the best. From materials and applications to industry trends, our wire offers unmatched reliability. Whether you need it for corrosion-resistant welds or durable chemical components, we’ve got the quality and expertise to make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is pure nickel wire used for in welding and chemical processing?Pure nickel wire is used as a filler material in welding for corrosion-resistant joints and in chemical processing for components like mesh filters and electrodes.

What materials make up pure nickel wire?It’s primarily 99%+ nickel with trace amounts of iron (up to 0.4%), manganese (0.35%), and carbon (0.15% or less) to enhance strength and workability.

What are the common grades of pure nickel wire?Key grades include Nickel 200 (99.6% purity) for general use and Nickel 201 (low carbon, <0.02%) for high-temperature chemical and welding applications.

How does pure nickel wire benefit welding?It provides strong, corrosion-resistant welds, ideal for joining stainless steel or nickel alloys in harsh environments like chemical plants.

Why is pure nickel wire suitable for chemical processing?Its oxide layer resists alkalis, acids, and high temperatures, ensuring durability in reactors, tanks, and filtration systems.

What are the industry trends for pure nickel wire?The market is growing at a 7.3% CAGR, driven by chemical processing, green energy, and welding for EVs, with a push for sustainable nickel sourcing.

What is the melting point of pure nickel wire?It ranges from 1435–1446°C, making it reliable for high-temperature welding and chemical processing applications.

What is the tensile strength of pure nickel wire?Annealed pure nickel wire typically has a tensile strength of 400–450 MPa, balancing strength and ductility for welding and processing.