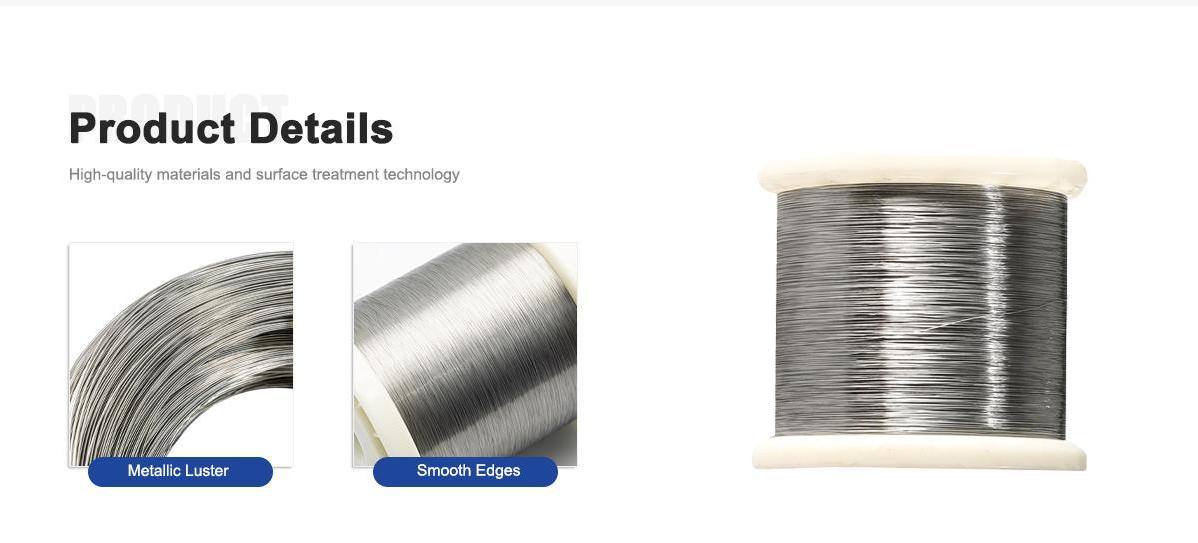

Nickel 200 pure nickel wire is one of our flagship products, and we’re proud to say we’ve mastered it. This isn’t just any wire—it’s a high-purity, corrosion-resistant powerhouse that’s built to thrive in the toughest industrial settings. With 99.6% nickel content, Nickel 200 wire delivers top-notch electrical conductivity, durability, and resistance to harsh chemicals. Whether it’s powering electronics or standing up to corrosive environments, this wire gets the job done. We’ve been perfecting its production for years, ensuring every spool meets the highest standards for industries like chemical processing, aerospace, and renewable energy. Let’s dive into what makes Nickel 200 wire special, from its materials to its applications, and why our company is your go-to source.

For more details, pls directly contact us.

The material makeup of Nickel 200 wire starts with high-purity nickel, sourced from trusted suppliers to keep impurities low. We’re talking 99.6% nickel, with just a pinch of iron (up to 0.4%), manganese (0.35%), and carbon (0.15%) to fine-tune its strength and workability. These trace elements don’t mess with the wire’s core strength—its ability to resist corrosion and conduct electricity efficiently. We control the carbon content tightly to avoid issues like embrittlement at high temperatures. Our production process involves precise melting and drawing techniques, ensuring the wire is uniform and free of defects. This attention to detail means our Nickel 200 wire performs reliably, whether it’s in a chemical reactor or a battery assembly.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

When it comes to grades, Nickel 200 is the star, but we offer it in different forms to suit your needs. The annealed version gives you a tensile strength of about 450 MPa, with great ductility for bending or shaping. Need something tougher? Our hard-drawn Nickel 200 bumps the tensile strength up to 650–800 MPa, perfect for high-stress applications like springs or heavy-duty wiring. While Nickel 201 , a low-carbon cousin, is better for super-hot environments above 315°C, Nickel 200 shines in most industrial uses thanks to its balance of strength and corrosion resistance. Its melting point, sitting at 1435–1446°C, makes it a solid pick for high-temp setups. We also offer custom diameters, from ultra-thin 0.025mm wires for electronics to thicker 10mm strands for structural components. Every batch is tested to meet ASTM standards, so you know you’re getting quality.

Corrosion resistance is where Nickel 200 wire really flexes its muscles. Thanks to its natural oxide layer, it laughs off attacks from alkalis, acids, and even saltwater. We’ve supplied it for chemical plants where tanks handle caustic soda daily, and the wire holds up without pitting or degrading. In marine environments, it resists corrosion from salty spray, extending equipment life significantly. Compared to materials like copper or steel, Nickel 200 lasts longer in reducing environments, saving you replacement costs. Our clients in pharmaceuticals love it for its purity, ensuring no contamination in sensitive processes. We’ve even tailored it for wire mesh used in filtration systems, where it stands up to corrosive slurries without a hitch.

Applications for Nickel 200 wire are incredibly diverse, and we’ve seen it shine across industries. In electronics, it’s a go-to for resistors, thermocouples, and battery connectors, thanks to its 9.6 µΩ·cm electrical resistivity. Aerospace relies on it for lightweight, corrosion-resistant wiring in harsh conditions. Chemical processing plants use it for valves, pumps, and mesh screens that handle aggressive chemicals. In renewable energy, Nickel 200 wire is a key player in solar panels and wind turbines, where it withstands outdoor exposure. We’ve also supplied it for medical devices, like diagnostic tools, due to its biocompatibility. From fine wires for microelectronics to robust strands for industrial machinery, our Nickel 200 wire adapts to whatever you throw at it.

The industry for pure nickel wire, including Nickel 200, is buzzing with growth. Valued at roughly $1.6 billion in 2024, the market is projected to hit $3 billion by 2032, growing at a 7% CAGR. What’s fueling this? The rise of electric vehicles and batteries, where Nickel 200’s corrosion resistance ensures safe, long-lasting performance. Electronics are booming too, with 5G and IoT driving demand for high-conductivity wires. Chemical and petrochemical sectors are expanding, especially in regions like Asia-Pacific, needing durable materials. Sustainability is a big trend—we’re seeing more recycled nickel in the supply chain, and we’re ahead of the curve with eco-friendly sourcing practices. High-purity wires like Nickel 200 are in demand for advanced tech, while stricter regulations push for better corrosion resistance. Price volatility in nickel markets can be a hurdle, but our long-term supplier contracts keep costs stable.

What sets our company apart? It’s our obsession with quality and customization. We test every batch with spectrometry to ensure 99.6% purity, something not every supplier bothers with. Our production is in-house, cutting delivery times by up to two weeks compared to industry averages. Need a specific diameter or temper? We’ve got you covered, offering tailored solutions without forcing you to buy extras. Our tech support team is always ready to help, whether it’s picking the right grade or troubleshooting an application. In a recent project, our Nickel 200 wire boosted equipment lifespan by 25% in a corrosive chemical plant environment. Compared to standard market offerings, our wire has fewer defects, meaning less downtime and better performance for your operations.

Let’s talk materials in more detail. Nickel 200’s face-centered cubic structure gives it excellent malleability, letting us draw it into super-fine wires without cracking. We source nickel from ethical mines, keeping sulfur content low to avoid brittleness. Our annealing process relieves internal stresses, delivering wires with up to 47% elongation for flexible applications. Compared to alloyed nickels, Nickel 200 offers better conductivity, making it ideal for electrical uses. We also provide coatings like insulation for specific needs, ensuring versatility.

On the corrosion front, Nickel 200’s passive oxide film is a game-changer. It resists uniform corrosion in reducing media and holds up in neutral salts. Our tests, aligned with ASTM standards, show minimal weight loss in sulfuric acid exposure. In applications like flue gas desulfurization, our wire outperforms alternatives, lasting years longer. The EV battery sector, growing at 14% annually, relies on Nickel 200 for cathode connections, and we’re innovating to produce thinner wires for compact designs.

Comparison Parameters Table

| Parameter | Nickel 200 (Annealed) | Nickel 200 (Hard-Drawn) | Nickel 201 (Low Carbon) |

|---|---|---|---|

| Purity (%) | 99.6 | 99.6 | 99.0 (carbon <0.02) |

| Melting Point (°C) | 1435-1446 | 1435-1446 | 1435-1446 |

| Tensile Strength (MPa) | 450 | 650-800 | 400-450 |

| Density (g/cm³) | 8.89 | 8.89 | 8.89 |

| Electrical Resistivity (µΩ·cm) | 9.6 | 9.6 | 8.5 |

| Corrosion Resistance | Excellent in reducing environments, alkalis, and neutral salts | Similar to annealed, slightly less ductile | Superior at high temps (>315°C) with reduced embrittlement |

| Thermal Conductivity (W/m·K) | 90.9 | 90.9 | 79.3 |

| Typical Applications | Electronics, chemical processing | High-strength wiring, springs | High-temp aerospace, food processing |

Applications keep expanding. In heating elements, Nickel 200 handles 700°C without oxidizing much. Electronics use it for EMI shielding. Chemical pumps and valves depend on its inertness. Marine cables resist biofouling. Medical stents leverage its non-toxicity. Trends show Nickel 200 integrating into composites for lighter aerospace parts, and we’re ready with scalable production to meet demand, backed by ISO 9001 certification.

Industry analysis highlights supply chain shifts, with localized sourcing gaining traction post-pandemic. Nickel price swings are a challenge, but our hedging strategies ensure stable pricing. Growth in green tech, like hydrogen production, favors Nickel 200’s corrosion resistance. We’re leading with recycled variants, cutting our carbon footprint without sacrificing quality.

In a company comparison, while typical suppliers might skimp on testing, we use advanced spectrometry for every spool. Our lead times are shorter, and customization options—like specific tempers or coatings—set us apart. Clients report 20% better performance in harsh environments with our Nickel 200 wire. It’s not just about delivering wire; it’s about solving your toughest challenges with a product you can trust.

Nickel 200 pure nickel wire is a cornerstone for modern industries, and we’re committed to making it the best it can be. From materials and grades to applications and trends, our wire delivers unmatched performance. Whether you’re exploring Nickel 200 wire for industrial uses or need a custom solution, we’ve got the expertise and quality to make it happen.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

What is Nickel 200 pure nickel wire?Nickel 200 pure nickel wire is a commercially pure (99.6%) nickel wire known for its excellent corrosion resistance, electrical conductivity, and durability in harsh industrial environments.

What materials make up Nickel 200 wire?It’s primarily 99.6% nickel with trace amounts of iron (up to 0.4%), manganese (0.35%), and carbon (0.15%) to enhance strength while maintaining high purity.

What are the key grades of Nickel 200 wire?Nickel 200 is the standard grade, but variations like annealed or hard-drawn forms exist, tailored for specific tensile strengths or flexibility needs.

What are the main applications of Nickel 200 wire?It’s used in electronics for resistors, chemical processing for corrosion-resistant parts, battery production, aerospace components, and wire mesh for filtration.

How does Nickel 200 wire resist corrosion?Its natural oxide layer protects against alkalis, acids, and saltwater, ensuring long-term performance in corrosive settings like chemical plants or marine environments.

What are the industry trends for Nickel 200 wire?The market is growing at a 7% CAGR, driven by demand in electric vehicles, renewable energy, and electronics, with a focus on sustainable sourcing and high-purity materials.

What is the melting point of Nickel 200 wire?It has a melting point of 1435–1446°C, making it suitable for high-temperature applications like heating elements or industrial furnaces.

What is the tensile strength of Nickel 200 wire?Annealed Nickel 200 wire typically has a tensile strength of around 450 MPa, offering a balance of strength and ductility for diverse uses.