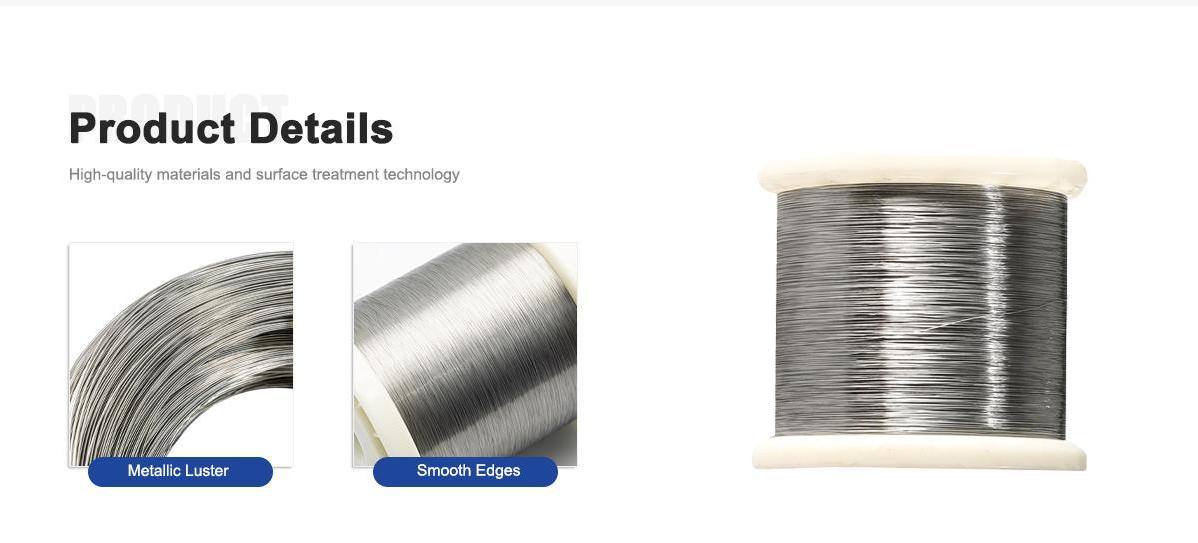

Nickel wire with 99.98% purity and a diameter of 0.025 mm is one of the most precise and reliable conductive materials used across high-tech industries today. At DLX Alloy, we have been manufacturing and supplying ultra-fine nickel wires for over a decade, serving customers in electronic, medical, energy, and research fields. Our production process involves vacuum melting, precision wire drawing, and multi-stage annealing to ensure consistent microstructure, superior tensile strength, and stable resistance performance.

For more details, pls directly contact us.

This 0.025 mm nickel wire, with a nearly pure Ni composition (99.98%), offers high corrosion resistance, excellent oxidation resistance, and stable electrical conductivity even in high-temperature or reactive environments. Its combination of purity and thinness allows it to perform reliably in delicate electronic devices and sensors where even micro-level fluctuations in conductivity can cause performance drift.

DLX Alloy produces this wire with strict dimensional tolerances (±0.001 mm) and uniform mechanical properties across the entire spool. Every batch undergoes X-ray fluorescence spectroscopy for purity validation and micro-tensile testing to ensure compliance with international standards.

| Grade | Nickel (Ni)+ Cobalt (Co) | Copper (Cu) | Silicon (Si) | Manganese (Mn) | Carbon (C) | Magnesium (Mg) | Sulfur (S) | Phosphorus (P) | Iron (Fe) |

| 99.9% | ≤0.015 | ≤0.03 | ≤0.002 | ≤0.01 | ≤0.01 | ≤0.001 | ≤0.001 | ≤0.04 | |

| 99.6% | 0.1 | 0.1 | 0.05 | 0.1 | 0.1 | 0.005 | 0.002 | 0.1 |

Physical & Mechanical Properties

| Grades | N4/Ni201 | N6/Ni200 |

| Density | 8.9g/cm³ | 8.9g/cm³ |

| Melting Point | 1455°C | 1445-1470℃ |

| Coefficient of Thermal Expansion | 13.0µm/m·°C | 13.3×10⁻⁶/℃ |

| Thermal Conductivity | 10.1W/m·K | 90.7 W/m·K |

| Electrical Resistivity | 0.103×10⁻⁶Ω·/m (at 20℃) | |

| Electrical Conductivity | 14.6% IACS | |

| Tensile Strength | ≥450MPa | ≥450 MPa |

| Yield Strength | ≥200MPa | ≥150 MPa |

| Elongation at Break | ≥40% | ≥40% |

| Hardness | ≤150 |

For more details, pls directly contact us.

Purity: 99.98% Ni (verified by third-party laboratory certification)

Diameter: 0.025 mm ± 0.001 mm

Electrical Resistivity: 0.097–0.102 μΩ·m

Melting Point: 1453°C

Tensile Strength: 400–450 MPa

Elongation: ≥ 20%

Operating Temperature: Up to 600°C continuous use

| Parameter | DLX 0.025mm Ni Wire | General Market Standard |

|---|---|---|

| Nickel Purity | 99.98% (third-party certified) | 99.9% |

| Diameter Tolerance | ±0.001 mm | ±0.005 mm |

| Surface Finish | Vacuum annealed, mirror finish | Cold drawn, unannealed |

| Resistivity Stability | <2% variation | Up to 5% variation |

| Tensile Strength | 400–450 MPa | 350–380 MPa |

| Spool Weight Options | 50 g–2 kg | Limited |

| Third-Party Certification | SGS, RoHS | Optional |

Industry Analysis

The demand for ultra-pure fine nickel wire is steadily increasing due to its critical role in microelectronics, sensors, battery technology, and medical equipment. With the global trend toward miniaturization and high precision, 0.025 mm wires have become a key component in new-generation devices, from flexible electrodes in lithium batteries to sensor coils in MRI systems.

In particular, the semiconductor and medical imaging sectors are rapidly expanding their need for stable and high-purity nickel conductors. According to third-party reports (e.g., MarketsandMarkets, 2024), the global high-purity nickel wire market is projected to grow at a CAGR of over 8.2% from 2025 to 2030, driven by advancements in clean energy and precision electronics.

DLX Alloy has been actively partnering with research institutes and industrial customers to develop customized nickel wire solutions, improving consistency in resistance and surface oxidation control—two of the most common challenges faced by users of ultra-thin metallic wires.

Electronic Components: Precision resistors, conductive leads, and micro-coils.

Battery Technology: Current collectors in small-format cells and flexible electrodes.

Medical Equipment: Heating elements for endoscopic tools, micro-sensors, and implantable device leads.

Aerospace Systems: Signal transmission lines and thermocouple extensions.

Research Laboratories: Thin film deposition, electron microscopy targets, and vacuum equipment.

At DLX Alloy, we supply both standard 0.025 mm nickel wire and custom sizes upon request. Our factory is equipped with laser diameter control systems and fully automated annealing lines, ensuring uniform softness and coiling stability—key for users involved in automated winding or micro-welding applications.

True Material Traceability: Every coil is tracked from melting batch to final inspection with complete test data.

Third-Party Verification: Purity and performance verified by SGS and RoHS reports for international shipments.

Tailored Annealing Process: Temperature and tension precisely controlled for the wire’s final use scenario (e.g., soft condition for sensor leads, harder temper for micro-spring coils).

Experience-Based Support: Our team has worked with hundreds of global buyers developing custom nickel solutions, offering recommendations based on real industrial data.

Fast Delivery: In-stock standard sizes available for immediate dispatch, with custom drawing and spooling options within 10–14 days.

Environmental Compliance: Nickel sourced from certified refineries under ISO 14001 environmental management systems.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

1. What is the tolerance of DLX’s 0.025 mm nickel wire?

±0.001 mm, achieved using laser micrometer inspection during drawing.

2. Can DLX provide custom spool sizes or core materials?

Yes, available in plastic, metal, or wooden spools, depending on shipment and machine compatibility.

3. What purity certification do you provide?

Each batch includes a material test certificate and third-party SGS report confirming ≥99.98% Ni content.

4. Is the wire suitable for welding or soldering applications?

Yes, due to its high ductility and oxidation resistance, it performs well under controlled soldering conditions.

5. How do you ensure consistent resistance across long wire lengths?

Our vacuum annealing and tension-controlled drawing ensure resistance variation stays under 2%.

6. What is the maximum operating temperature?

Continuous use up to 600°C, with short-term exposure possible up to 800°C depending on application.

7. Do you support small-batch R&D orders?

Yes, we support minimum orders starting from 50 g for laboratory or prototyping use.

8. How does DLX packaging prevent surface oxidation?

Wires are vacuum-sealed with argon protection and shipped in anti-static moisture-proof containers.