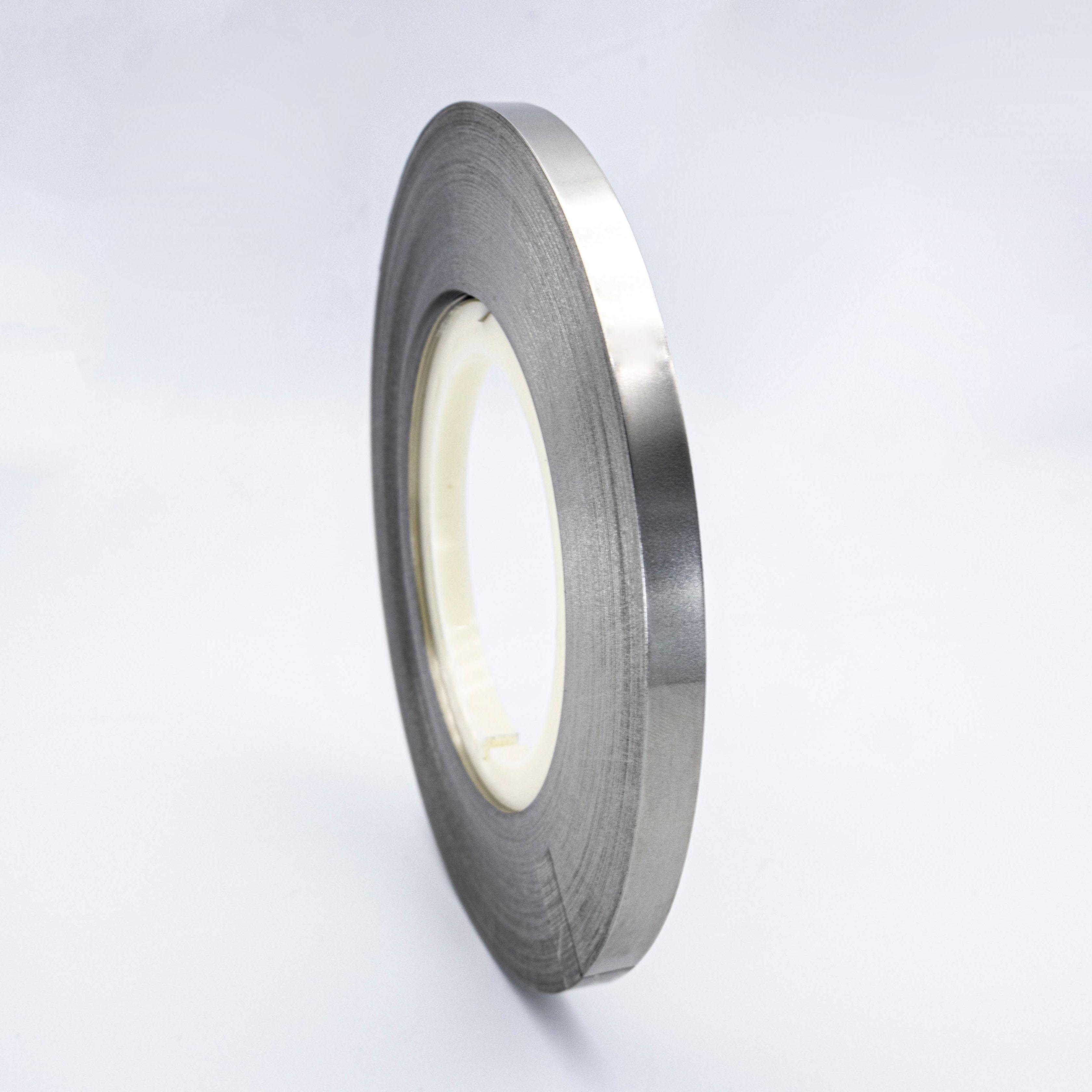

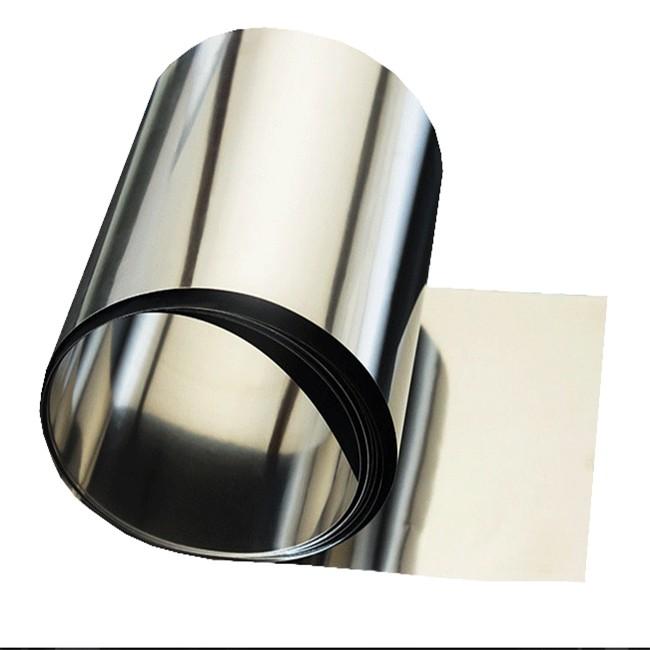

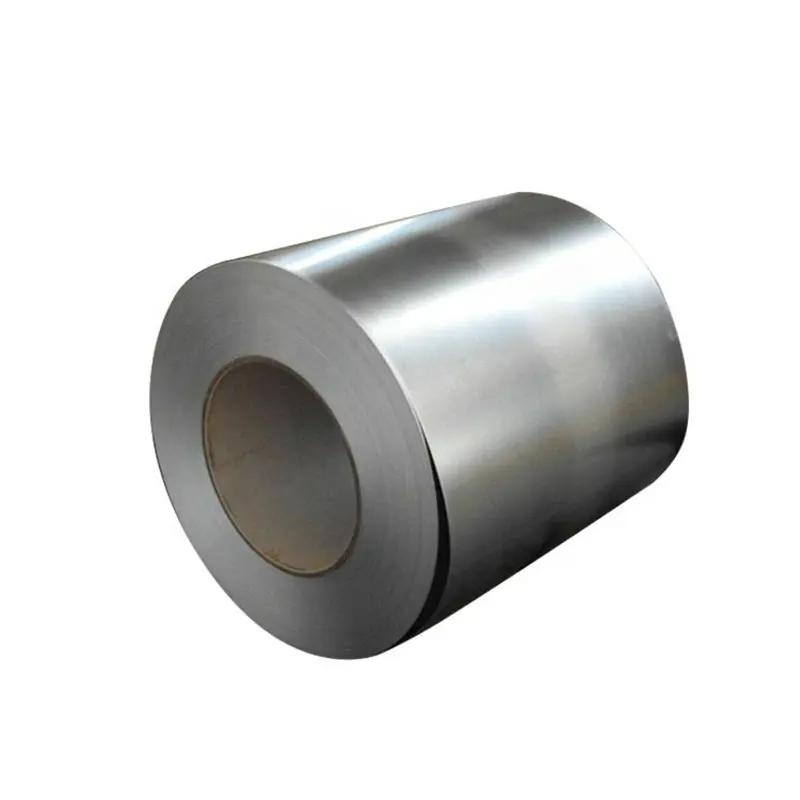

Our AMS 4911 titanium alloy foil, crafted from the high-performance Ti-6Al-4V alloy, is a top-tier material designed for aircraft structural components. Starting at just 0.01 mm thick, this foil is lightweight, incredibly strong, and corrosion-resistant, making it ideal for critical aerospace applications like airframe panels, wing structures, and fasteners. Compliant with AMS 4911 and ASTM B265 standards, it’s built to meet the rigorous demands of aircraft manufacturing. Our foil delivers the strength and reliability needed to keep planes flying safely.

For more details, pls directly contact us.

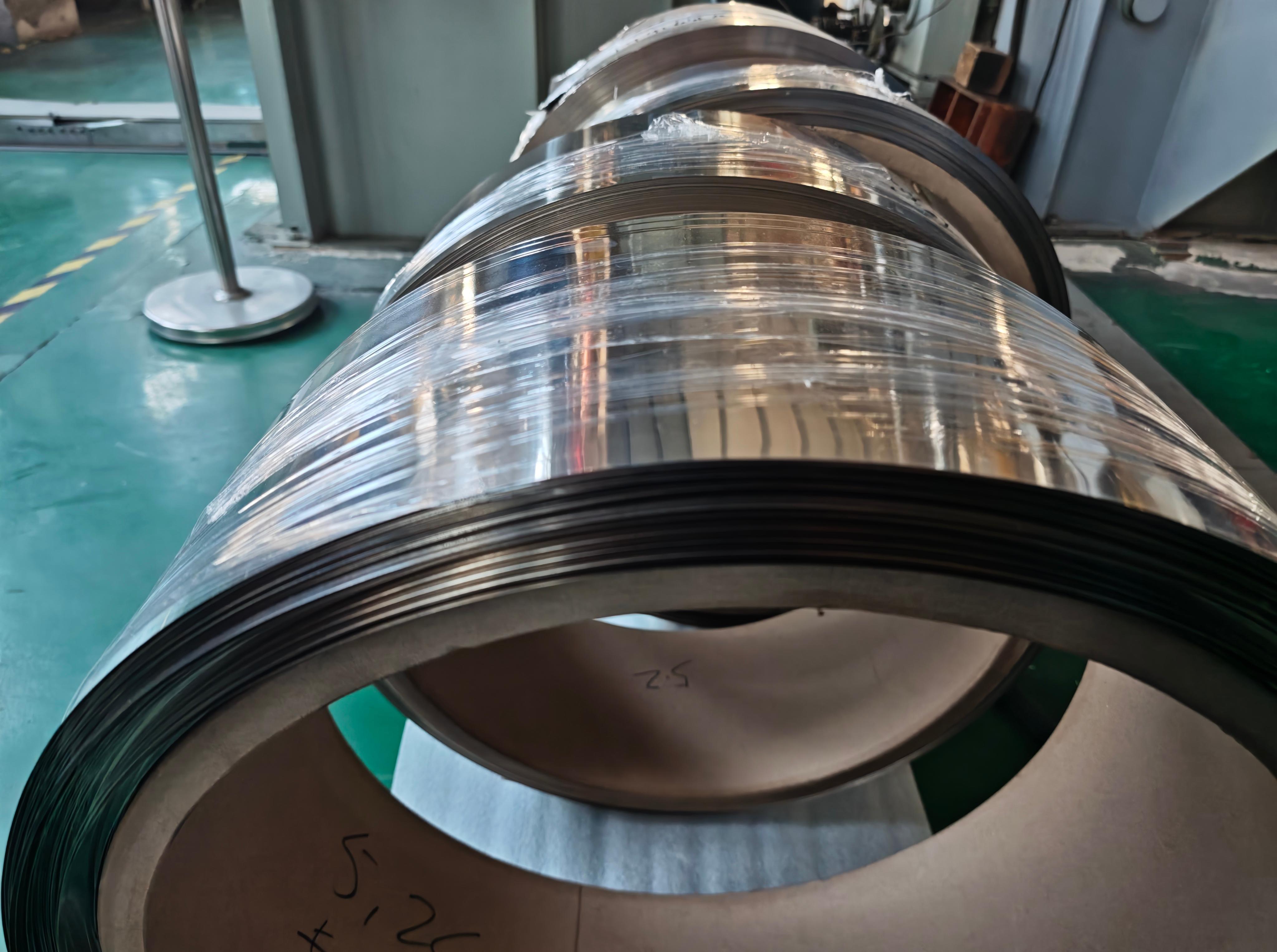

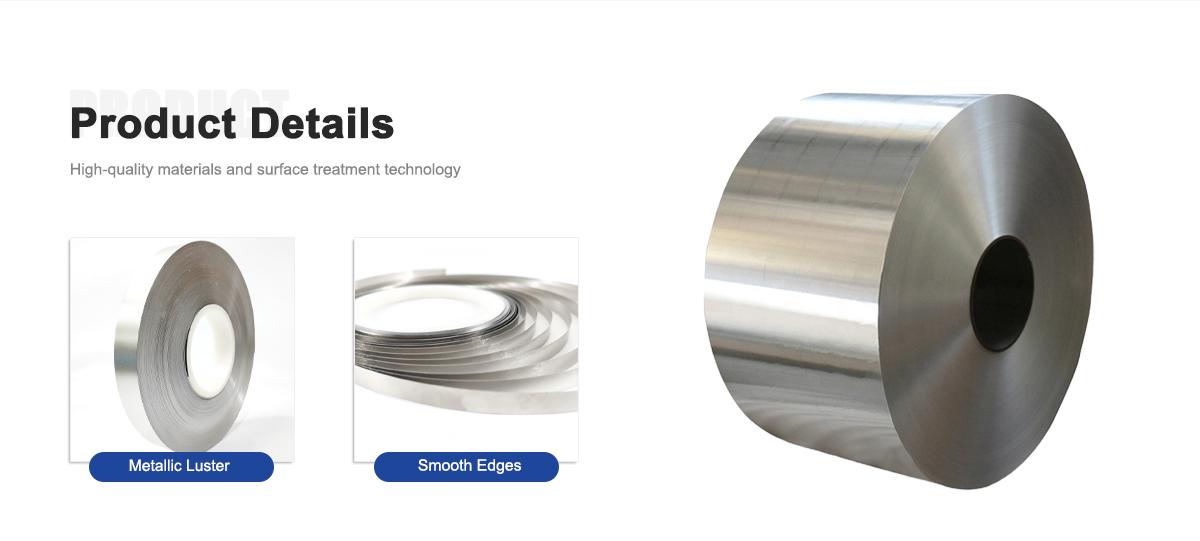

We produce this foil using advanced cold-rolling techniques, ensuring a smooth, uniform surface and precise tolerances for seamless integration into complex aerospace designs. With a density of 4.43 g/cm³—about 40% lighter than steel—and a tensile strength of ~900 MPa, it offers an exceptional strength-to-weight ratio. Its corrosion resistance handles high-altitude moisture, jet fuel, and harsh environments, while its thermal stability up to 600°C supports high-stress applications. Our stringent quality control ensures every batch performs consistently, giving manufacturers confidence in their aircraft components.

Our AMS 4911 Titanium Foil is a Ti-6Al-4V alloy, combining 6% aluminum and 4% vanadium with titanium for superior strength and heat resistance. Its low density of 4.43 g/cm³ makes it perfect for weight-sensitive aerospace applications. The tensile strength of ~900 MPa provides outstanding durability, while its moderate formability allows shaping into intricate structural components. The foil’s natural oxide layer offers excellent corrosion resistance against moisture, acids, and jet fuel, ensuring longevity in demanding conditions. Thermally stable up to 600°C and weldable, it’s a versatile choice for aircraft structural applications.

Applications

Our AMS 4911 titanium alloy foil is tailored for aircraft structural components but excels in a range of uses:

Airframe Panels: Lightweight and strong for fuselage and wing structures.

Wing Components: Durable for high-stress wing skins and supports.

Fasteners: Corrosion-resistant and strong for secure aircraft assemblies.

Structural Brackets: Formable for custom, high-strength aerospace parts.

Heat Shields: Resists high temperatures in engine-adjacent structures.

While aircraft structures are its primary focus, the foil also finds use in high-performance automotive parts for its strength and in medical implants for its biocompatibility, showcasing its versatility across industries.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The aerospace industry is soaring, with a projected CAGR of 6.9% for advanced materials through 2032, driven by demand for lightweight, high-strength components in commercial aircraft, military jets, and space exploration. Materials like our Ti-6Al-4V foil are critical as manufacturers aim to improve fuel efficiency, reduce emissions, and enhance structural integrity. The rise of electric aircraft and private space missions is pushing demand for materials that balance strength, weight, and durability, and our foil delivers on all fronts.

Challenges include high raw material costs and complex supply chains, but we’ve optimized our production for cost-effectiveness and reliable supply. The growing use of additive manufacturing and advanced composites in aerospace aligns with our foil’s precision and compatibility with 3D printing. Sustainability is a key focus, with the industry seeking recyclable materials to meet environmental regulations, and our foil is fully recyclable, supporting these green goals.

Industry Trends

Lightweighting: Reducing aircraft weight boosts fuel efficiency, and our foil excels.

High-Strength Materials: Aerospace demands durable materials, and our foil delivers.

Sustainability: Recyclable materials are a must, and our foil is 100% recyclable.

Additive Manufacturing: 3D printing in aerospace pairs well with our foil’s precision.

Space Exploration: Private space missions need high-strength, lightweight materials.

Electric Aircraft: Lightweight materials support efficiency in next-gen planes.

Advanced Composites: High-strength foils enhance composite structures.

Automation: Automated production lines require consistent, reliable materials.

Comparison Table

Parameter | Our AMS 4911 Titanium Foil | Other Titanium Foils |

|---|---|---|

Thickness Range | 0.01 mm - 0.25 mm | 0.05 mm - 0.3 mm |

Tensile Strength | ~900 MPa | ~240-900 MPa |

Corrosion Resistance | Excellent (acids, fuel) | Good to Excellent |

Thermal Stability | Up to 600°C | Up to 350-600°C |

Surface Finish | Smooth, uniform | Varies, less consistent |

Standards Compliance | AMS 4911, ASTM B265 | ASTM B265 or lower |

Weldability | High | Moderate to High |

Recyclability | Fully recyclable | Varies |

Company Comparison

Our AMS 4911 titanium alloy foil stands out in the aerospace market for its superior quality and performance. While other foils are available, our advanced cold-rolling process delivers a smoother surface and tighter tolerances, ensuring flawless integration into aircraft structural designs. We prioritize sustainability with eco-friendly production and fully recyclable materials, aligning with the industry’s green goals. Our streamlined supply chain guarantees fast, reliable delivery, even during market disruptions. Every batch is rigorously tested to AMS 4911 and ASTM B265 standards, ensuring it meets the demanding requirements of aerospace applications.

Why Choose Our Titanium Foil?

High Strength: ~900 MPa tensile strength for robust aircraft components.

Top Quality: Meets AMS 4911 and ASTM B265 standards for reliability.

Eco-Friendly: Fully recyclable with sustainable production processes.

Fast Delivery: Optimized logistics ensure timely supply.

Versatile Design: Weldable and formable for complex aerospace parts.

Industry Outlook

The aerospace industry is moving toward lighter, stronger, and more sustainable materials to meet the demands of next-gen aircraft and spacecraft. As electric aviation, private space exploration, and fuel efficiency gain traction, our AMS 4911 titanium foil is well-positioned to deliver the high-strength, lightweight performance needed. Its compatibility with additive manufacturing and precision fabrication ensures it’s ready for advanced production methods, while its recyclability aligns with environmental goals. We’re continuously refining our processes to stay ahead, delivering materials that power the future of aerospace innovation.

Conclusion

Our AMS 4911 titanium alloy foil is a must-have for aircraft structural components. Its exceptional strength, lightweight design, and corrosion resistance make it ideal for airframes, wings, and fasteners. With top-tier quality, sustainable production, and reliable delivery, we’re here to support your aerospace projects. Choose our foil for materials that keep your aircraft designs soaring strong and efficient in the toughest conditions.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why is AMS 4911 titanium foil ideal for aircraft structures?

Its high strength, lightweight, and corrosion resistance make it perfect for airframes and fasteners.How thin is this foil?

It starts at 0.01 mm, ideal for precision aerospace components.Can it handle high temperatures?

Yes, it’s stable up to 600°C, suitable for high-stress aircraft parts.Is it corrosion-resistant?

It resists moisture, acids, and jet fuel with a natural oxide layer.Does it meet industry standards?

It complies with AMS 4911 and ASTM B265 for reliable quality.Is it suitable for welding?

Yes, its weldability supports complex aerospace designs.Can it be used in 3D printing?

Its uniform thickness makes it ideal for additive manufacturing.Is it recyclable?

100% recyclable, supporting sustainable aerospace manufacturing.