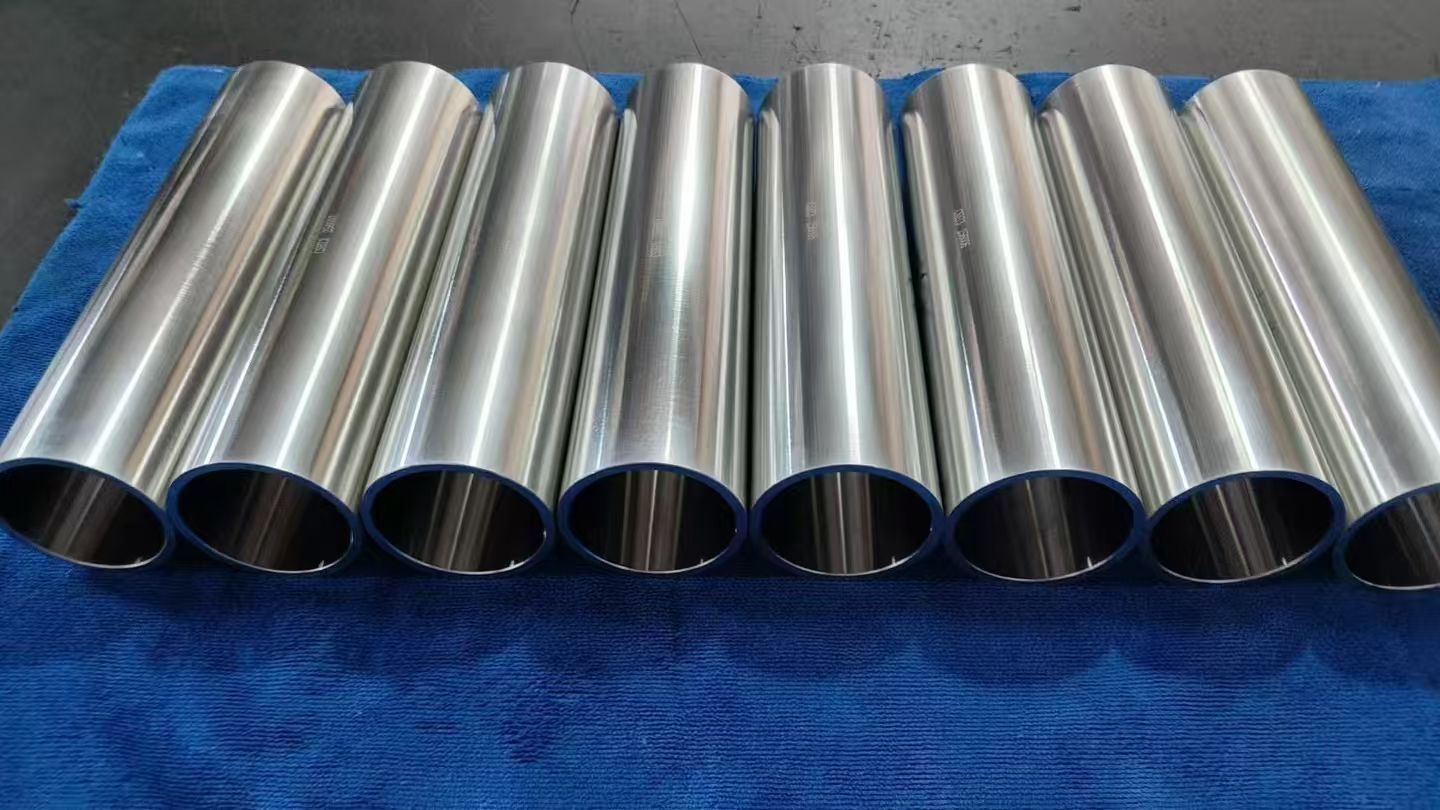

Our custom Titanium Grade 12 tubes are built to dominate in high-temperature environments where most materials would buckle. Alloyed with 0.8% nickel and 0.3% molybdenum, these tubes meet ASTM B338 standards and deliver a killer combo of corrosion resistance, strength, and heat tolerance. Whether it’s a chemical plant, power generation facility, or aerospace system, our Grade 12 Titanium Tube s keep things running smoothly under intense heat and corrosive conditions. As industries push for efficiency and durability, our custom tubes are the go-to solution for high-temperature challenges.

For more details, pls directly contact us.

Grade 12 titanium is a beast for high-temperature applications. Its density of around 4500 kg/m³ makes it way lighter than stainless steel (8000 kg/m³) or Inconel (8400 kg/m³), which means easier handling and less structural strain. With a tensile strength of 480–620 MPa, it’s strong enough to handle high-pressure systems while staying flexible for complex designs. But what really sets it apart is its ability to shrug off corrosion in harsh environments—think acids, chlorides, or oxidizing agents—at temperatures up to 600°C.

The nickel and molybdenum in Grade 12 give it an edge over other titanium grades, boosting its resistance to crevice corrosion and reducing acids. This makes it a rockstar for applications where stainless steel might pit or Inconel might be overkill. Its oxidation resistance keeps it stable at high temperatures, preventing scaling or degradation. Plus, its fatigue resistance ensures it can handle the vibrations and cyclic loads common in high-temperature systems without cracking.

Applications in High-Temperature Environments

Our Grade 12 titanium tubes are a perfect fit for industries dealing with extreme heat. In chemical processing, they’re used in heat exchangers, reactors, and piping systems handling hot, corrosive fluids like sulfuric acid or chlorides. In power generation, they shine in boiler tubes and condensers, where high temperatures and steam are constant. Aerospace? You bet—they’re used in engine components and hydraulic lines that need to withstand heat and pressure while keeping weight low.

They also have a place in oil and gas, particularly in geothermal plants or high-temperature reservoirs, where they handle hot, corrosive brines. Marine applications benefit too, with their corrosion resistance tackling seawater in high-temperature cooling systems. But for us, the sweet spot is any system where heat and corrosion team up to test material limits—our Grade 12 tubes are built to win that fight.

Industry Trends Driving Grade 12 Titanium Adoption

The push for high-temperature, high-efficiency systems is reshaping industries, and our Grade 12 titanium tubes are right in the mix. The global titanium market is expected to grow from $8.1 billion in 2023 to $13.5 billion by 2030, with a CAGR of 7.6%. Industries like chemical processing, power generation, and aerospace are driving this growth, chasing materials that can handle extreme conditions while cutting weight and maintenance costs.

Green energy is a big factor. As power plants shift to supercritical CO2 cycles or geothermal systems, they need materials that can take the heat and corrosive fluids. Our Grade 12 tubes are perfect for these applications, offering durability and efficiency. The aerospace sector is also leaning harder into lightweight materials to improve fuel efficiency, and our tubes deliver the strength-to-weight ratio they need.

Additive manufacturing is shaking things up, too. It lets us create complex, custom tube designs with less waste, making Grade 12 titanium more cost-effective for specialized projects. Sustainability is another driver—titanium’s recyclability and long lifespan align with industry goals to reduce environmental impact. As regulations tighten on emissions and waste, our tubes help industries stay compliant while boosting performance.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our Grade 12 titanium tubes aren’t just another product—they’re a testament to our commitment to quality and innovation. We manufacture to ASTM B338 standards, using advanced techniques like seamless extrusion and precision cold drawing to ensure flawless performance. Every tube goes through rigorous testing—ultrasonic, hydrostatic, and more—to guarantee zero defects. Our titanium is sourced from high-purity sponge, ensuring consistent quality across every batch.

Customization is where we really flex. Need a specific diameter, wall thickness, or surface finish? We tailor every detail to fit your project, whether it’s a one-off prototype or a large-scale production run. Our heat treatment processes, like annealing or solution treating, optimize the tubes’ microstructure for maximum strength and corrosion resistance. And our supply chain is bulletproof, with global sourcing and strict quality control to deliver on time, every time.

Compared to a typical competitor, our tubes offer better corrosion resistance in reducing acids and tighter tolerances, thanks to our proprietary alloying and manufacturing methods. We also deliver faster lead times and more flexible customization, so you’re not stuck waiting or compromising on your design. Our technical team is with you from concept to installation, ensuring your high-temperature system performs at its peak.

Overcoming Challenges

Grade 12 titanium comes with a higher price tag than stainless steel, and its low thermal conductivity can make machining tricky. But we’ve got it handled. Our advanced manufacturing—like automated welding and 3D printing—keeps costs down while maintaining quality. We use specialized tooling to tackle titanium’s quirks, ensuring smooth production and consistent results. For budget-conscious projects, we optimize designs to use less material, like thinner walls or shorter lengths, without sacrificing performance.

The Future of Grade 12 Titanium Tubes

The future is looking hot for Grade 12 titanium tubes. As industries push for higher efficiency and sustainability, demand for materials that can handle extreme heat and corrosion will keep growing. Our tubes are ready to meet that demand, especially in emerging fields like green hydrogen production, supercritical CO2 power cycles, and next-gen aerospace systems. These applications need materials that can take a beating, and Grade 12 titanium delivers.

Additive manufacturing will keep driving innovation, letting us create lightweight, complex components that were once too expensive. Sustainability will also shape the industry, and our eco-friendly production processes—combined with titanium’s recyclability—put us at the forefront. As high-temperature applications expand globally, our tubes will be there to keep systems running strong.

Comparison Table: Grade 12 Titanium vs. Stainless Steel vs. Inconel for High-Temperature Applications

|

Parameter |

Grade 12 Titanium |

Stainless Steel |

Inconel |

|---|---|---|---|

|

Density (kg/m³) |

~4500 (Low) |

~8000 (High) |

~8400 (High) |

|

Tensile Strength (MPa) |

~480–620 (Moderate) |

~520–690 (Moderate) |

~690–1100 (High) |

|

Corrosion Resistance |

Excellent (Resists acids, chlorides) |

Good (Prone to pitting at high temps) |

Very Good (Strong but less in acids) |

|

Thermal Conductivity (W/m·K) |

~15–22 (Low, retains heat) |

~15–25 (Moderate) |

~10–15 (Low) |

|

Max Service Temperature (°C) |

~600 (Very High) |

~800 (Very High) |

~1000 (Extremely High) |

|

Oxidation Resistance |

Excellent (Stable at high temps) |

Moderate (Prone to scaling) |

Very Good (Strong but costly) |

|

Fatigue Resistance |

Good (Handles cyclic loads well) |

Good (Moderate under stress) |

Very Good (Strong but heavier) |

|

Cost |

Higher (Premium material) |

Moderate (Widely available) |

High (Expensive for specialized alloys) |

Our custom Grade 12 titanium tubes are built to conquer high-temperature challenges. They’re corrosion-resistant, strong, and tailored to your exact needs, making them the perfect choice for heat exchangers, reactors, and more. With our cutting-edge manufacturing, flexible customization, and rock-solid quality control, we’re not just selling tubes—we’re delivering solutions that keep your systems running at peak performance.

Ready to power up your high-temperature project? Our team is here to provide the perfect Grade 12 titanium tube solution, designed to fit your needs and built to last. Let’s make your next project a success with the strength of titanium.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

What makes Grade 12 titanium tubes ideal for high-temperature applications?

Their excellent corrosion resistance and strength at temperatures up to 600°C ensure reliable performance in extreme conditions. -

How do Grade 12 titanium tubes perform in corrosive environments?

They resist corrosion from acids, chlorides, and oxidizing agents, making them perfect for harsh high-temperature settings. -

What industries use Grade 12 titanium tubes?

They’re used in chemical processing, power generation, aerospace, and oil and gas for high-temperature systems. -

Can Grade 12 titanium tubes be customized for specific projects?

Yes, we offer tailored sizes, wall thicknesses, and finishes to meet unique application needs. -

How long do Grade 12 titanium tubes last in high-temperature environments?

With proper design, they can last decades, even under constant heat and corrosion exposure. -

Why choose Grade 12 over other titanium grades for high temperatures?

Its molybdenum and nickel content boosts corrosion resistance and strength at elevated temperatures compared to other grades. -

Are Grade 12 titanium tubes suitable for high-pressure systems?

Absolutely, their high strength-to-weight ratio handles pressures in demanding applications like heat exchangers. -

What industry trends support Grade 12 titanium tube adoption?

Rising demand for durable, lightweight materials in green energy and high-efficiency systems drives their use.