Our medical-grade titanium tubing is designed to meet the rigorous demands of surgical instruments and implants. Built to ASTM F136 and ISO 5832-3 standards, these tubes offer unmatched biocompatibility, corrosion resistance, and strength. Whether it’s a precision surgical tool or a long-lasting implant, our titanium tubing delivers the reliability and safety that medical professionals and patients depend on. As the medical industry pushes for advanced, patient-friendly solutions, our tubing is the backbone of cutting-edge medical devices.

For more details, pls directly contact us.

Titanium is a rockstar in the medical world, and our tubing shows why. With a density of about 4500 kg/m³, it’s way lighter than stainless steel (8000 kg/m³) or cobalt-chromium (8300 kg/m³), making it ideal for implants that need to feel natural in the body. Its tensile strength, ranging from 900 to 1000 MPa, ensures it can handle the stresses of surgical tools or load-bearing implants like hip or knee replacements.

The real magic is its biocompatibility. Titanium is non-toxic, doesn’t trigger allergic reactions, and integrates seamlessly with bone tissue—a process called osseointegration. This makes it perfect for implants that need to bond with the body. It also resists corrosion from body fluids, saline, and sterilization processes, ensuring instruments and implants stay pristine over time. Fatigue resistance is another win, allowing our tubing to withstand the cyclic loads of surgical procedures or years of use in the body without cracking.

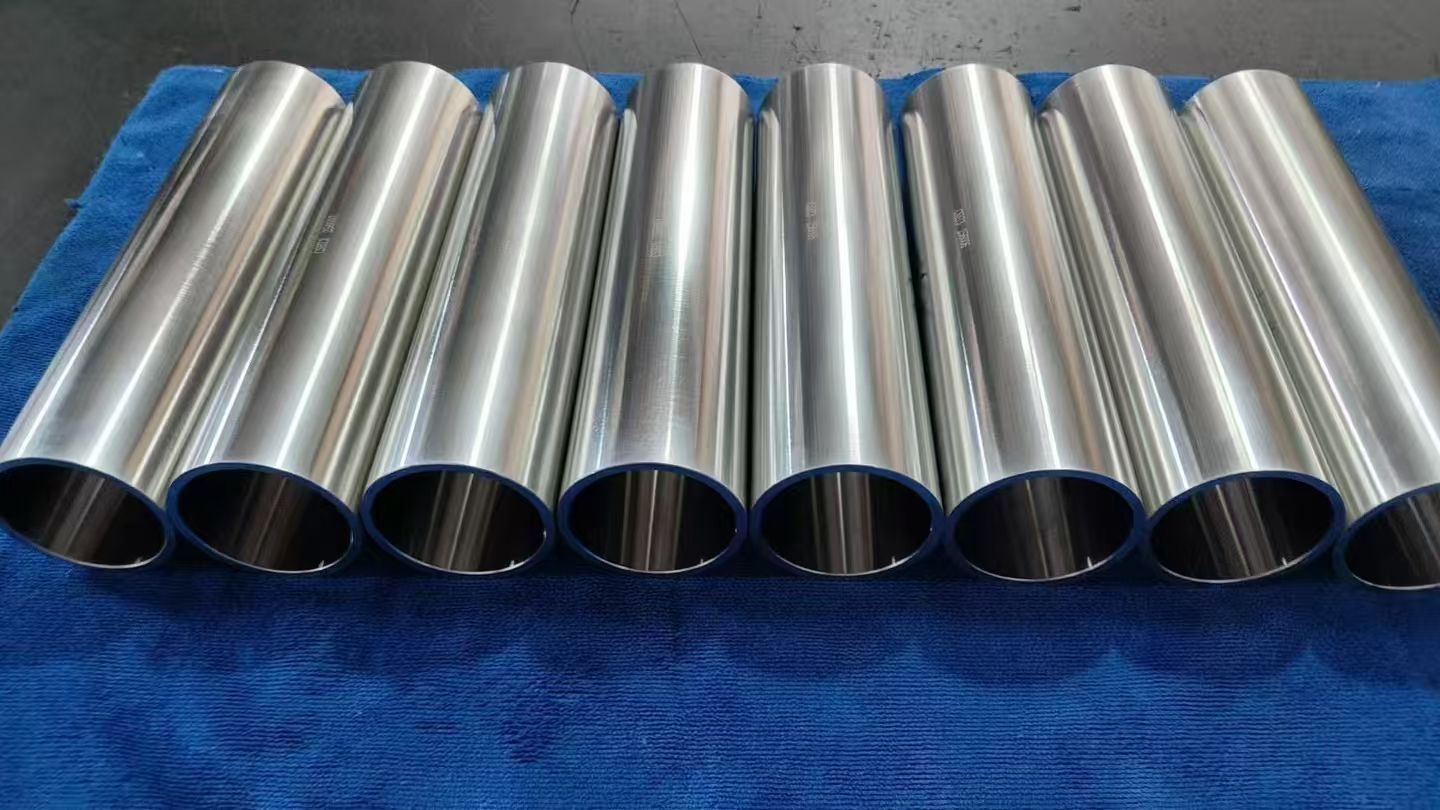

Our precision manufacturing takes it up a notch. With tight tolerances and smooth surfaces, our tubing ensures flawless performance in delicate applications, from minimally invasive tools to complex implants. Whether it’s Grade 5 (Ti-6Al-4V ELI) or Grade 2 titanium, we deliver the quality the medical industry demands.

Applications in Surgical Instruments and Implants

Our medical-grade titanium tubing is a game-changer for surgical instruments and implants. For instruments, it’s used in endoscopes, laparoscopic tools, and cutting devices, where precision and durability are critical. The lightweight nature makes tools easier to handle during long surgeries, while the corrosion resistance ensures they withstand repeated sterilization without degrading.

For implants, our tubing is used in spinal rods, dental implants, and orthopedic devices like bone screws or intramedullary nails. Its ability to integrate with bone makes it a top choice for long-term implants, while its strength supports load-bearing applications. In cardiovascular devices, like stents or pacemaker components, our tubing’s biocompatibility and corrosion resistance ensure safety and reliability.

Beyond medical, our titanium tubing finds use in aerospace and chemical processing, but healthcare is where it truly shines. From minimally invasive surgeries to life-changing implants, our tubing delivers the performance that saves lives.

Industry Trends Driving Titanium Adoption

The medical device industry is booming, and our titanium tubing is right at the heart of it. The global medical titanium market is expected to grow from $1.7 billion in 2023 to $2.9 billion by 2030, with a CAGR of 7.8%. This growth is fueled by rising demand for minimally invasive surgeries, advanced implants, and an aging population needing orthopedic solutions.

Additive manufacturing is transforming medical device production, allowing us to create complex, custom tubing designs with less waste. This is a big deal for personalized implants tailored to individual patients. The push for biocompatibility is also huge—hospitals and regulators want materials that are safe and long-lasting, and titanium checks every box. Sustainability is another driver; titanium’s recyclability aligns with the industry’s move toward eco-friendly practices.

Emerging fields like robotic surgery and 3D-printed implants are increasing demand for precision materials. Our tubing fits perfectly, offering the strength and accuracy needed for next-gen devices. As healthcare systems expand in regions like Asia-Pacific, the need for high-quality, biocompatible materials is only growing.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

Our medical-grade titanium tubing is a cut above, and it’s all about precision and quality. We manufacture to ASTM F136 and ISO 5832-3 standards, using advanced techniques like seamless drawing and laser cutting to achieve ultra-tight tolerances. Every tube undergoes rigorous testing—ultrasonic, chemical analysis, and biocompatibility checks—to ensure it meets medical-grade requirements. Our titanium is sourced from high-purity sponge, guaranteeing consistency and safety.

Customization is where we excel. Whether you need micro-tubing for catheters or larger diameters for spinal implants, we tailor every detail—size, thickness, surface finish—to your specs. Our heat treatment processes, like annealing or vacuum processing, optimize the tubing’s microstructure for strength and biocompatibility. Our supply chain is rock-solid, with global sourcing and strict quality control to deliver on time, every time.

Compared to a typical competitor, our tubing offers better surface finish and tighter tolerances, ensuring seamless integration into precision instruments or implants. We also deliver faster lead times and more flexible customization, so you’re not stuck waiting or compromising on your design. Our technical team works with you from concept to production, ensuring your medical device performs flawlessly, whether it’s for a prototype or a large-scale order.

Overcoming Challenges

Titanium’s higher cost and machinability challenges can be hurdles, but we’ve got it handled. Our advanced manufacturing—like automated drawing and 3D printing—keeps costs down while maintaining quality. We use specialized tooling to tackle titanium’s low thermal conductivity, ensuring smooth production and consistent results. For budget-conscious projects, we optimize designs to use less material, like thinner walls or shorter lengths, without sacrificing performance or safety.

Comparison Table: Medical-Grade Titanium vs. Stainless Steel vs. Cobalt-Chromium for Surgical Instruments and Implants

|

Parameter |

Medical-Grade Titanium |

Stainless Steel |

Cobalt-Chromium |

|---|---|---|---|

|

Density (kg/m³) |

~4500 (Low) |

~8000 (High) |

~8300 (High) |

|

Tensile Strength (MPa) |

~900–1000 (High) |

~520–690 (Moderate) |

~800–1200 (High) |

|

Corrosion Resistance |

Excellent (Resists body fluids, sterilization) |

Good (Prone to pitting in saline) |

Very Good (Strong but less biocompatible) |

|

Biocompatibility |

Excellent (Non-toxic, bone integration) |

Good (Possible allergic reactions) |

Moderate (Less bone integration) |

|

Thermal Conductivity (W/m·K) |

~15–22 (Low) |

~15–25 (Moderate) |

~10–15 (Low) |

|

Fatigue Resistance |

Excellent (Handles cyclic loads well) |

Good (Moderate under stress) |

Very Good (Strong but heavier) |

|

Weight Reduction |

High (Lightweight for implants) |

Low (Heavier, less ideal for implants) |

Low (Heavier, less comfortable) |

|

Cost |

Higher (Premium material) |

Moderate (Widely available) |

High (Specialized alloy) |

The future is bright for medical-grade titanium tubing. As minimally invasive surgeries and personalized medicine grow, demand for biocompatible, precision materials will skyrocket. Our tubing is ready to meet that demand, especially in fields like robotic surgery, 3D-printed implants, and regenerative medicine. These applications need materials that are safe, durable, and adaptable, and our titanium tubing delivers.

Additive manufacturing will keep pushing the boundaries, letting us create complex, patient-specific designs that were once impossible. Sustainability will also shape the industry, and our eco-friendly production processes—combined with titanium’s recyclability—put us at the forefront. As healthcare advances globally, our tubing will be there to support life-saving innovations.

Why Choose Our Medical-Grade Titanium Tubing?

Our medical-grade titanium tubing is built to power the future of healthcare. It’s biocompatible, corrosion-resistant, and engineered for the precision demands of surgical instruments and implants. With our cutting-edge manufacturing, flexible customization, and unwavering commitment to quality, we’re not just selling tubing—we’re delivering solutions that improve lives.

Ready to elevate your medical device project? Our team is here to provide the perfect titanium tubing solution, tailored to your needs and built to last. Let’s make your next project a success with the strength of titanium.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

-

Why is medical-grade titanium tubing used for surgical instruments?

Its biocompatibility, corrosion resistance, and high strength make it ideal for precision instruments that need durability and safety. -

How does titanium tubing benefit medical implants?

It’s non-toxic, resists body fluids, and integrates well with bone, ensuring long-lasting implants. -

What makes titanium tubing better than stainless steel for medical applications?

It’s lighter, more corrosion-resistant, and less likely to cause allergic reactions in patients. -

Can medical-grade titanium tubing be customized for specific medical devices?

Yes, we offer tailored sizes, wall thicknesses, and finishes to meet precise medical specifications. -

How long do titanium implants last in the human body?

They can last decades without degrading, thanks to their corrosion resistance and biocompatibility. -

Is medical-grade titanium tubing suitable for high-precision surgical tools?

Absolutely, its strength and precision manufacturing ensure reliable performance in delicate procedures. -

How does titanium tubing handle sterilization processes?

It withstands repeated autoclaving and chemical sterilization without corroding or weakening. -

What industry trends support titanium tubing in medical applications?

Growing demand for minimally invasive surgeries and advanced implants drives adoption of biocompatible materials.