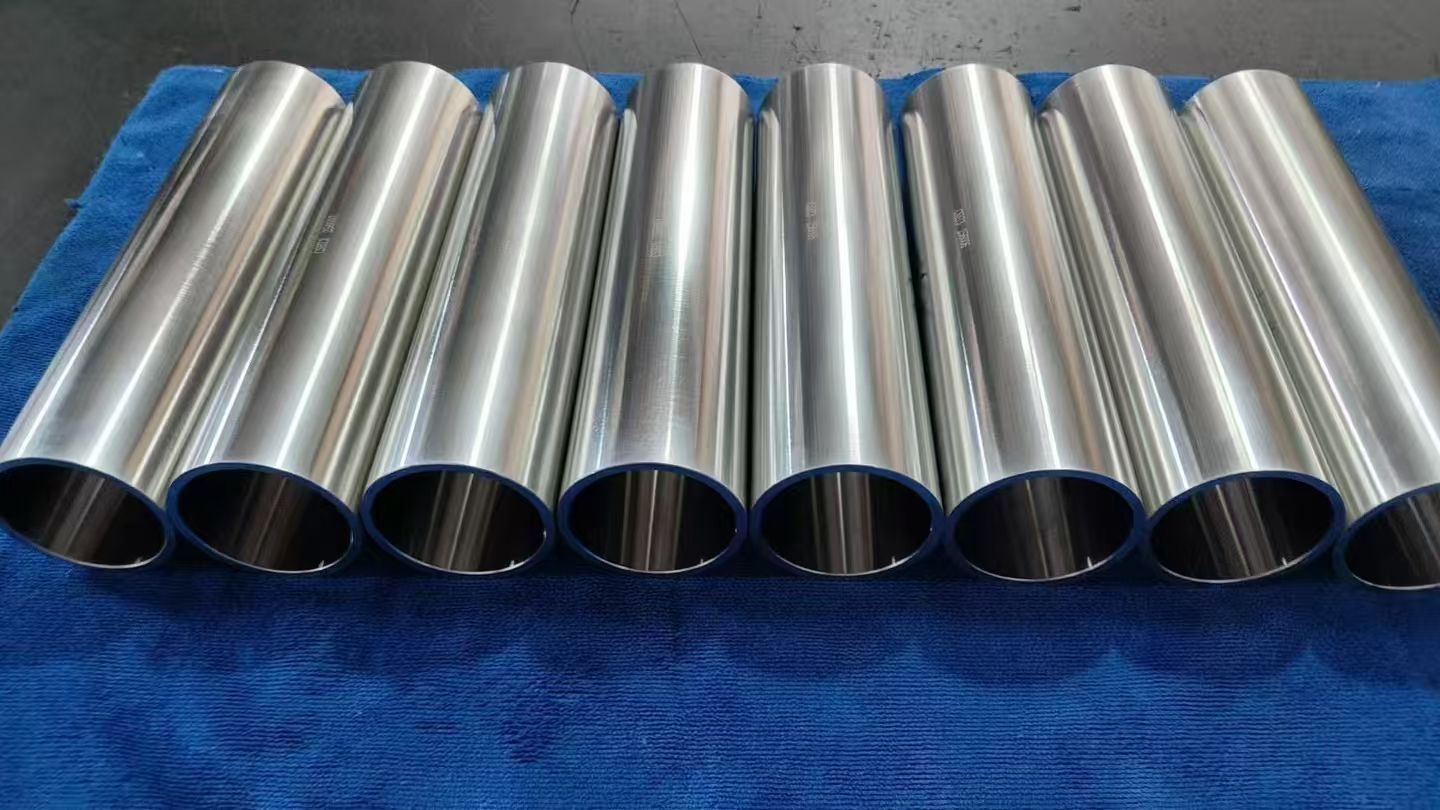

Our high-quality titanium seamless tubing is built to conquer the brutal conditions of offshore drilling. Meeting ASTM B338 and ASME SB338 standards, these tubes—often crafted from Grade 2 or Ti-6Al-4V alloys—deliver unmatched corrosion resistance, strength, and reliability. From deep-sea risers to subsea flowlines, our seamless tubing ensures leak-free performance under extreme pressures and corrosive environments. As offshore drilling pushes into deeper waters and harsher conditions, our titanium tubing is the backbone of reliable, long-lasting systems.

For more details, pls directly contact us.

Titanium seamless tubing is a game-changer for offshore drilling. With a density of about 4500 kg/m³, it’s way lighter than stainless steel (8000 kg/m³) or duplex steel (7800 kg/m³), making it easier to transport and install on offshore platforms. Its tensile strength, ranging from 900 to 1000 MPa for Grade 5, lets it handle insane pressures—up to 100 MPa—without buckling or leaking. That’s critical for deep-sea applications where failure isn’t an option.

Corrosion resistance is where our tubing really flexes. Offshore environments throw everything at you—seawater, sour gas (H2S), carbon dioxide (CO2), and chlorides. Our titanium tubes form a protective oxide layer that shrugs off these corrosive agents, ensuring decades of reliable performance. The seamless design eliminates weld imperfections, providing consistent strength and leak-free operation under the intense stresses of drilling. They also hold up at temperatures up to 400°C, perfect for hot reservoir fluids or high-temperature processing.

Fatigue resistance is another big win. Offshore systems face constant vibrations and cyclic loads from waves, currents, and equipment. Our tubing takes it all in stride, resisting cracks and maintaining integrity. Plus, their smooth surfaces reduce biofouling, keeping pipelines clear of marine growth and boosting operational efficiency.

Applications in Offshore Drilling

Our titanium seamless tubing is a staple in offshore drilling. It’s used in risers, flowlines, and production tubing, where it handles corrosive fluids and extreme pressures in deep-sea environments. In subsea control systems, our tubing ensures reliable hydraulic lines that withstand saltwater exposure. It’s also found in heat exchangers and cooling systems on offshore platforms, where corrosion resistance and durability are non-negotiable.

Beyond drilling, our tubing shines in other high-stakes applications. In chemical processing, it handles aggressive fluids. In geothermal energy, it tackles hot, corrosive brines. Even in aerospace, its strength-to-weight ratio makes it a go-to for hydraulic systems. But for us, offshore drilling is where our tubing makes the biggest splash, delivering performance where conditions are toughest.

| Titanium (Ti) | Aluminum (Al) | Vanadium (V) | Tin (Sn) | |

| Ti-6Al-4V | Rest | 5.5%-6.8% | 3.5%-4.5% | |

| Ti-5Al-2.5Sn | Rest | 4.5%-5.5% | 2.0%-3.0% |

Physical Properties

| Density | 4.4-4.5g/cm³ |

| Melting Point | 1660°C |

| Coefficient of Thermal Expansion | 8-10×10⁻⁶/K (20°C-500°C) |

| Thermal Conductivity | 6-22 W/(m·K) (depending on alloy grade) |

| Electrical Resistivity | 0.14-0.17 μΩ·m |

| Tensile Strength | 600-1200 MPa (depending on alloy grade) |

| Yield Strength | 480-1100 MPa |

| Elongation at Break | 10%-25% |

| Hardness | 200-400 HB |

For more details, pls directly contact us.

The offshore drilling industry is evolving, and our titanium seamless tubing is riding the wave. The global offshore drilling market is expected to grow from $92 billion in 2023 to $145 billion by 2030, with a CAGR of 6.7%. This growth is fueled by deep-sea exploration, unconventional reservoirs, and the push for sustainable energy solutions like carbon capture and storage (CCS). Titanium’s corrosion resistance and strength make it a top choice for these challenging applications.

Sustainability is a big driver. Offshore platforms need materials that last longer and require less maintenance to cut costs and environmental impact. Our tubing delivers, with lifespans stretching decades in corrosive conditions. The rise of green energy projects, like offshore wind and CCS, is also increasing demand for materials that can handle harsh fluids and environments. Titanium’s recyclability aligns with the industry’s eco-friendly goals, making it a smart choice.

Additive manufacturing is transforming production, letting us create complex tube designs with less waste, which keeps costs down and enables custom solutions. As drilling moves into deeper waters and harsher regions like the Arctic, our lightweight, durable tubing is becoming a must-have for reliable operations.

How We Stand Out

Our titanium seamless tubing is a cut above, and it’s all about precision and quality. We manufacture to ASTM B338 and ASME SB338 standards, using advanced techniques like rotary piercing and cold drawing to achieve flawless, seamless construction. Every tube is rigorously tested—ultrasonic, hydrostatic, and dimensional checks—to ensure zero defects. Our titanium is sourced from high-purity sponge, guaranteeing consistent performance across every batch.

Customization is our strength. Need a specific diameter, wall thickness, or alloy grade like Grade 2 or Ti-6Al-4V? We tailor every detail to fit your drilling project, whether it’s a single riser or an entire subsea system. Our heat treatment processes, like annealing or stress relieving, optimize the tubing’s strength and corrosion resistance. Our supply chain is rock-solid, with global sourcing and strict quality control to deliver on time, every time.

Compared to a typical competitor, our tubing offers better corrosion resistance in H2S and CO2 environments, thanks to our proprietary manufacturing methods. We also deliver tighter tolerances and smoother surfaces, reducing biofouling and improving flow efficiency. Our faster lead times and flexible customization mean you’re not stuck waiting or compromising on your design. Our technical team works with you from concept to installation, ensuring your offshore system performs at its peak.

Overcoming Challenges

Titanium’s higher cost and machinability challenges can be hurdles, but we’ve got it covered. Our advanced manufacturing—like automated extrusion and 3D printing—helps keep costs down while maintaining quality. We use specialized tooling to handle titanium’s low thermal conductivity, ensuring smooth production and consistent results. For budget-conscious projects, we optimize tube designs to use less material, like thinner walls or shorter lengths, without sacrificing strength or performance.

Comparison Table: Titanium Seamless Tubing vs. Stainless Steel vs. Duplex Steel for Offshore Drilling Applications

Parameter | Titanium Seamless Tubing | Stainless Steel | Duplex Steel |

|---|---|---|---|

Density (kg/m³) | ~4500 (Low) | ~8000 (High) | ~7800 (High) |

Tensile Strength (MPa) | ~900–1000 (High) | ~520–690 (Moderate) | ~620–850 (High) |

Corrosion Resistance | Excellent (Resists seawater, H2S, CO2) | Good (Prone to pitting in chlorides) | Very Good (Strong but less in H2S) |

Thermal Conductivity (W/m·K) | ~15–22 (Low, retains heat) | ~15–25 (Moderate) | ~15–20 (Moderate) |

Max Service Temperature (°C) | ~400 (High) | ~800 (Very High) | ~300 (Moderate) |

Fatigue Resistance | Excellent (Handles cyclic loads well) | Good (Moderate under stress) | Very Good (Strong but heavier) |

Weight Reduction | High (Improves installation efficiency) | Low (Heavier, harder to handle) | Low (Heavier, less efficient) |

Cost | Higher (Premium material) | Moderate (Widely available) | High (Specialized alloy) |

The future is bright for our titanium seamless tubing in offshore drilling. As exploration pushes into deeper waters and tougher reservoirs, demand for corrosion-resistant, high-strength materials will keep growing. Our tubing is ready to meet that demand, especially in emerging fields like CCS, hydrogen transport, and deep-sea geothermal. These applications need materials that can handle extreme conditions, and our titanium tubing delivers.

Additive manufacturing will keep driving innovation, letting us create lightweight, complex components that were once too costly. Sustainability will also shape the industry, and our eco-friendly production processes—combined with titanium’s recyclability—put us ahead of the curve. As offshore drilling expands globally, our tubing will be there to keep systems running strong.

Why Choose Our Titanium Seamless Tubing?

Our high-quality titanium seamless tubing is built to dominate offshore drilling challenges. It’s corrosion-resistant, strong, and engineered for the high-pressure, harsh environments of deep-sea operations. With our cutting-edge manufacturing, flexible customization, and rock-solid quality control, we’re not just selling tubing—we’re delivering solutions that keep your drilling systems reliable and efficient.

Ready to power your next offshore project? Our team is here to provide the perfect titanium tubing solution, tailored to your needs and built to last. Let’s make your drilling operation a success with the strength of titanium.

For more details, pls directly contact us.

About Us:

Our 12,000㎡ factory is equipped with complete capabilities for research, production, testing, and packaging. We strictly adhere to ISO 9001 standards in our production processes, with an annual output of 1,200 tons. This ensures that we meet both quantity and quality demands. Furthermore, all products undergo rigorous simulated environment testing including high temperature, high pressure, and corrosion tests before being dispatched, ensuring they meet customer specifications.

For all our clients, we offer timely and multilingual after-sales support and technical consulting, helping you resolve any issues swiftly and efficiently.

Client Visits

Building Stronger Partnerships

We support all kinds of testing:

FAQs:

Why use titanium seamless tubing for offshore drilling?

Its exceptional corrosion resistance and high strength make it ideal for harsh seawater and high-pressure environments.How does titanium tubing perform in corrosive offshore conditions?

It resists corrosion from seawater, H2S, and CO2, ensuring long-term reliability in subsea systems.What makes seamless titanium tubing better than welded for drilling?

Seamless construction eliminates weak points, providing superior strength and leak-free performance under extreme pressures.Can titanium seamless tubing be customized for offshore projects?

Yes, we offer tailored sizes, wall thicknesses, and alloy grades to meet specific drilling requirements.How long does titanium tubing last in offshore environments?

It can last decades with minimal maintenance, even in aggressive saltwater conditions.Is titanium tubing suitable for high-pressure drilling applications?

Absolutely, it handles pressures up to 100 MPa, perfect for deep-sea drilling operations.How does titanium tubing improve offshore drilling efficiency?

Its lightweight design reduces equipment weight, while its durability minimizes downtime and maintenance costs.What industry trends support titanium tubing in offshore drilling?

Growing demand for deep-sea exploration and sustainable energy solutions drives adoption of durable, corrosion-resistant materials.